Connector jack with low insertion and extraction force

A plug-in force, connector technology, applied in the direction of contact parts, etc., can solve the problems of high plug-in force, unsupported live plug-in, low resistance to probe damage, etc., and achieve the effect of low plug-in force and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

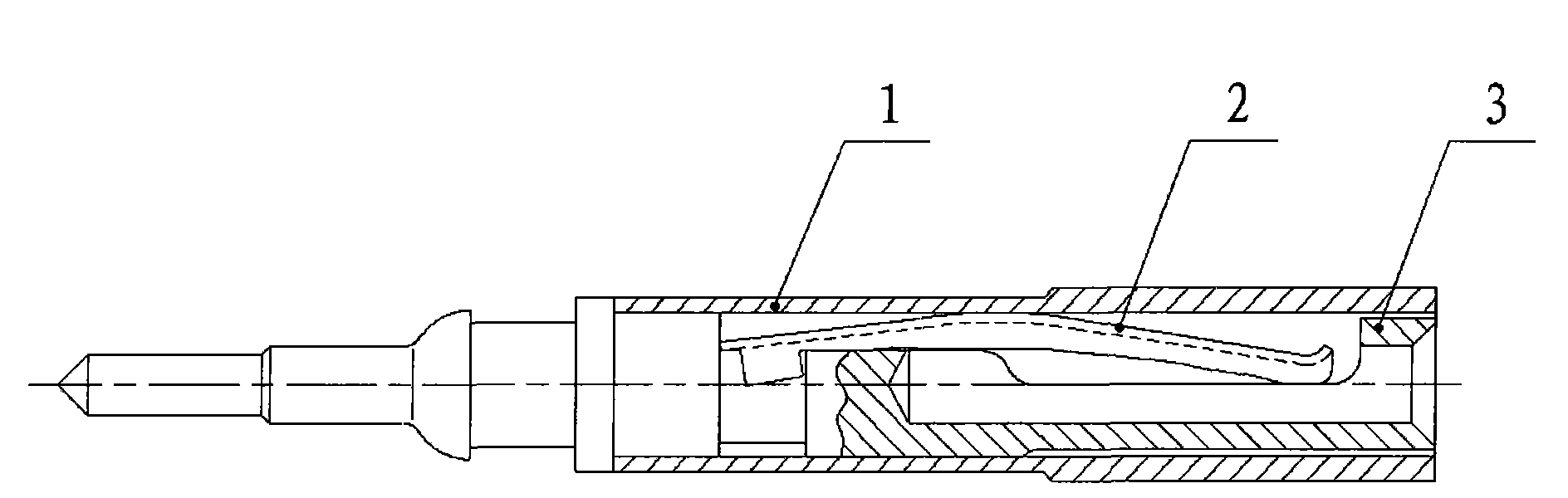

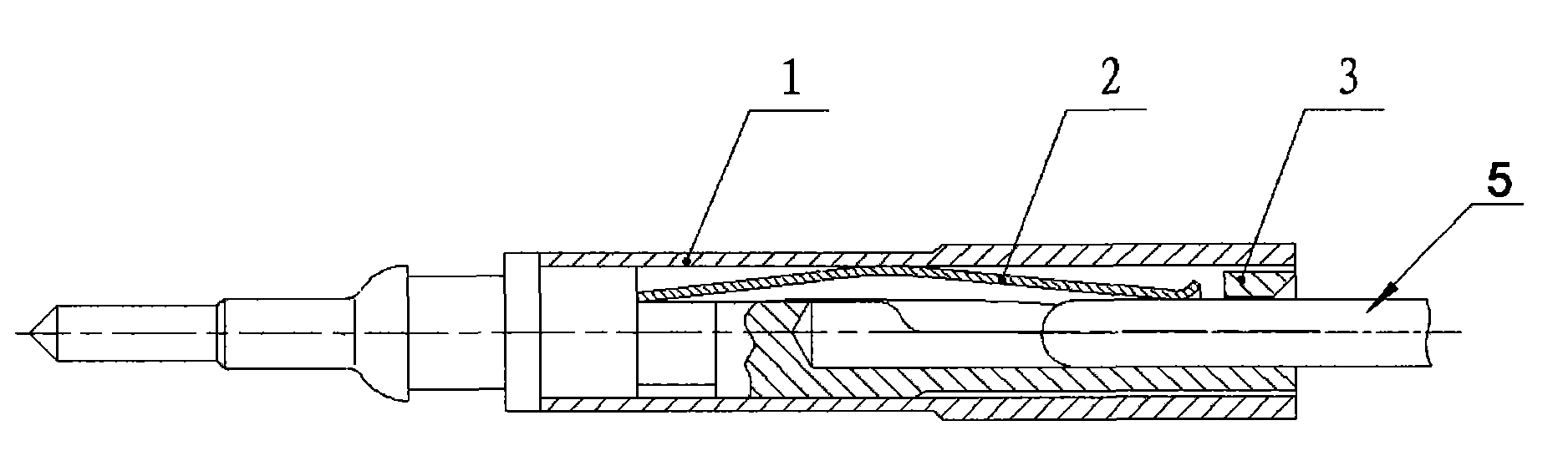

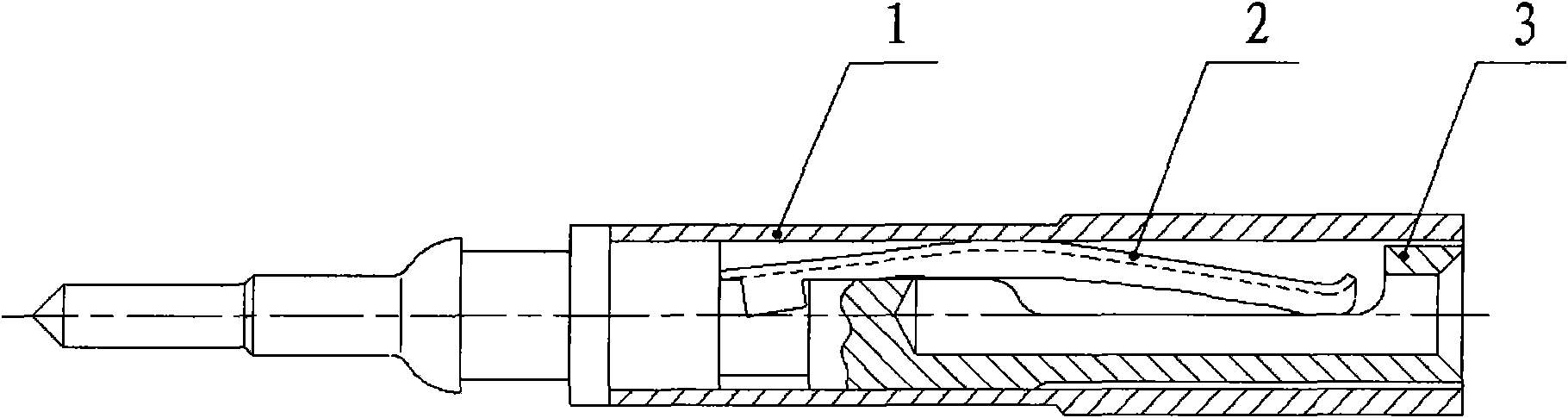

[0014] Example: such as figure 1 , figure 2 As shown, a connector socket with low insertion force is composed of a sheath 1, a reed 2 and a socket 3. The reed 2 is the core part of the low insertion force jack. It is formed by blanking and bending the beryllium copper strip. The left end of the reed 2 is designed with convex teeth, which are stuck in the slot of the jack 3 to realize the reed 2. Axial fixed to form a fixed fulcrum, the reed 2 is bent into an arch, the highest point of the arch is in contact with the sheath 1, this contact point is a sliding fulcrum, and the right end is a cantilever. Reed 2 just forms the mechanical model of outrigger beam. In order to make the reed 2 form an elastic contact with the pin 5, a part of the socket 3 is cut off, and less parts are cut off to provide a certain supporting surface for the reed 2, and half of the parts are cut off so that the reed 2 can Stretch into the jack 3 hole. Such as figure 2 As shown, when the pin 5 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com