Twist needle light in inserting/pulling force

A light plugging force, twist needle technology, applied in the direction of contact parts, etc., can solve the problems of difficult plugging and plugging, large plugging force, etc., and achieve the effect of improving the effective contact area, improving reliability and flexibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

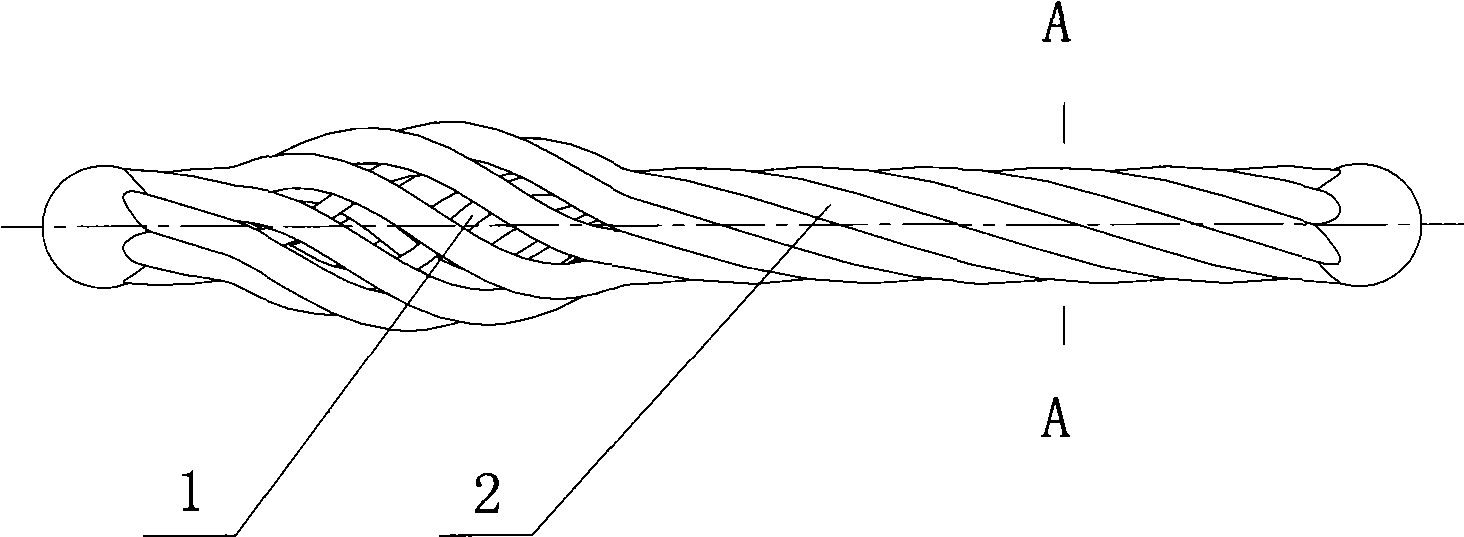

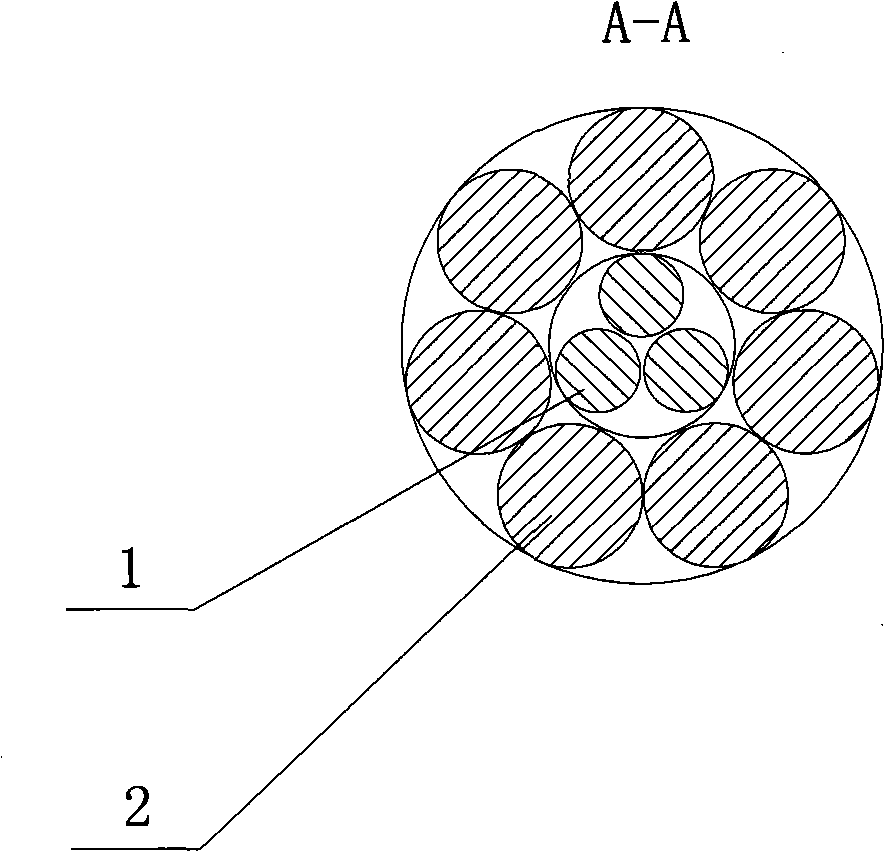

[0027] image 3 , Figure 4 It is a view of the twist needle with light insertion and withdrawal force according to Embodiment 1 of the present invention. As shown in the figure, the twist needle contact with light insertion and withdrawal force consists of three copper-based alloy wires as the first layer, and ten copper-based alloy wires as the second layer. After the second layer is reversely twisted with the first layer, it is Shaped after cutting, laser spot welding and fattening. After hinged, the metal alloy wire 2 of the second layer is enveloped into a circle, and the space formed inside is enough to accommodate the metal alloy wire 1 of the first layer. The metal alloy wires 1 of the first layer and the metal alloy wires 2 of the second layer have the same diameter.

Embodiment 2

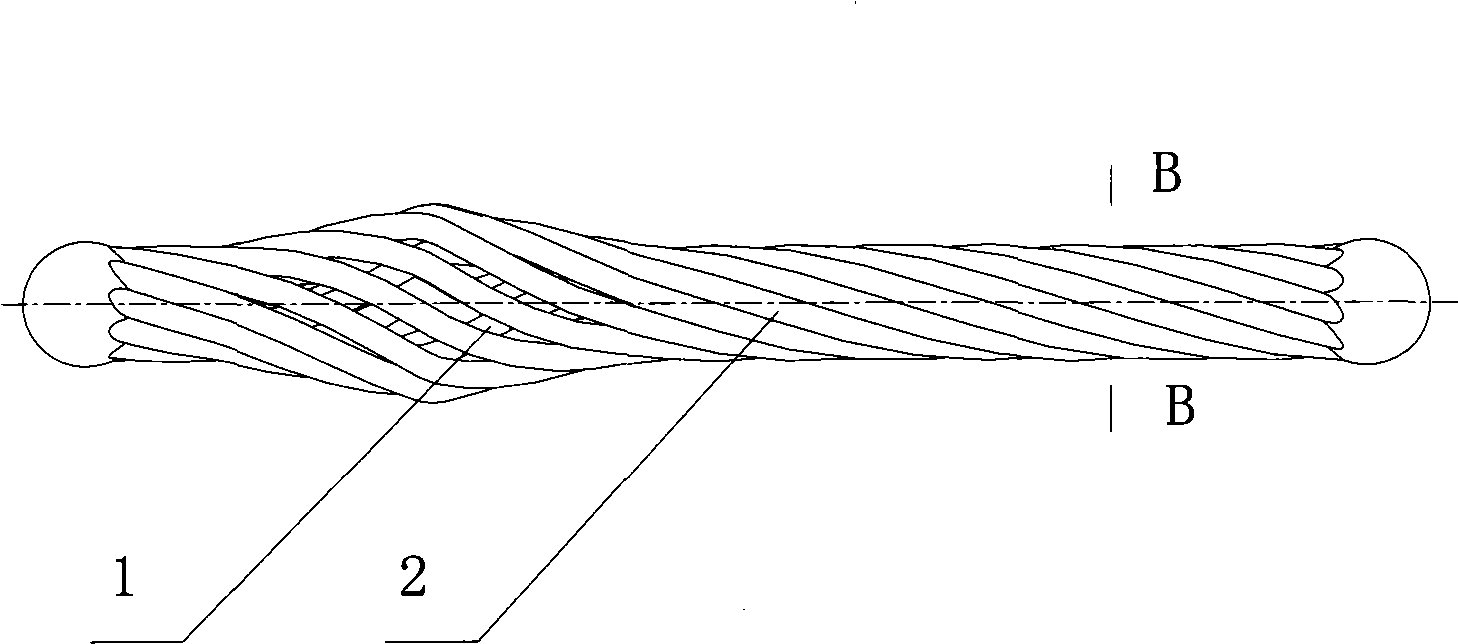

[0029] Figure 5 , Figure 6 It is the view of the twist needle with light insertion and withdrawal force in the second embodiment of the present invention. As shown in the figure, the twist needle contact with light insertion and withdrawal force consists of three copper-based alloy wires as the first layer, ten copper-based alloy wires as the second layer, sixteen copper-based alloy wires as the third layer, and the second layer The first layer and the first layer are twisted against each other, and the third layer is twisted against the second layer. After hinged, the alloy wires of each layer are enveloped into a circle, and the adjacent layers are closely bonded. After the stranding is completed, it is shaped after cutting, laser spot welding and fattening. The diameters of the first layer metal alloy wire 1 , the second layer metal alloy wire 2 and the third layer metal alloy wire 3 are equal.

[0030] The number of metal alloy wires in each layer is related to the di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com