Multi-pole connector

A multi-pole connector and connector technology, applied in the direction of connection, two-part connection device, parts of the connection device, etc., can solve the problem that the terminal unit 102 cannot change the distance between the contacts 103, the power terminal is damaged, and the plug connector is inserted. Problems such as increased pulling force, to achieve the effect of implementing product management, easy core count expansion, and easy product management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0069] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

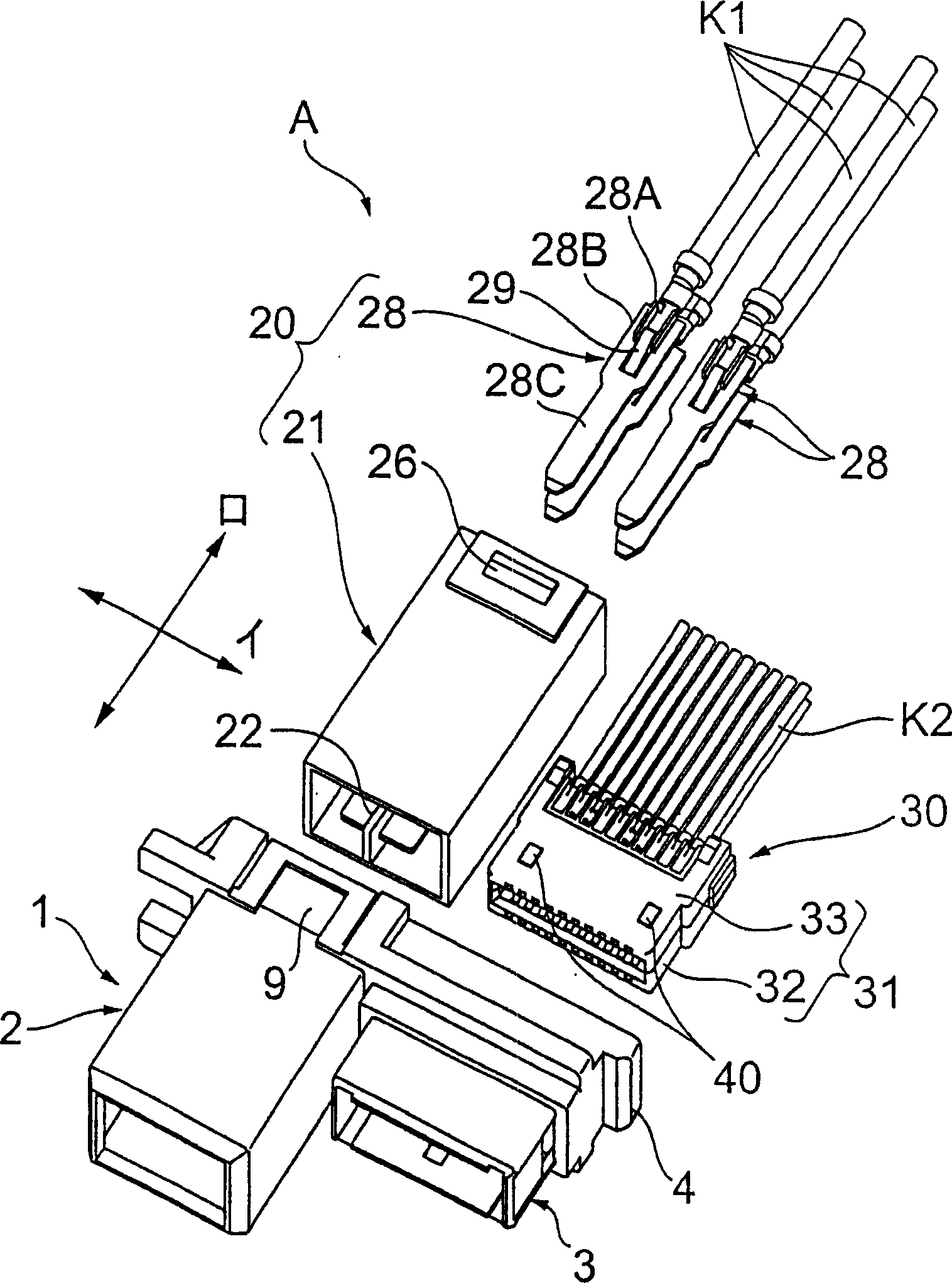

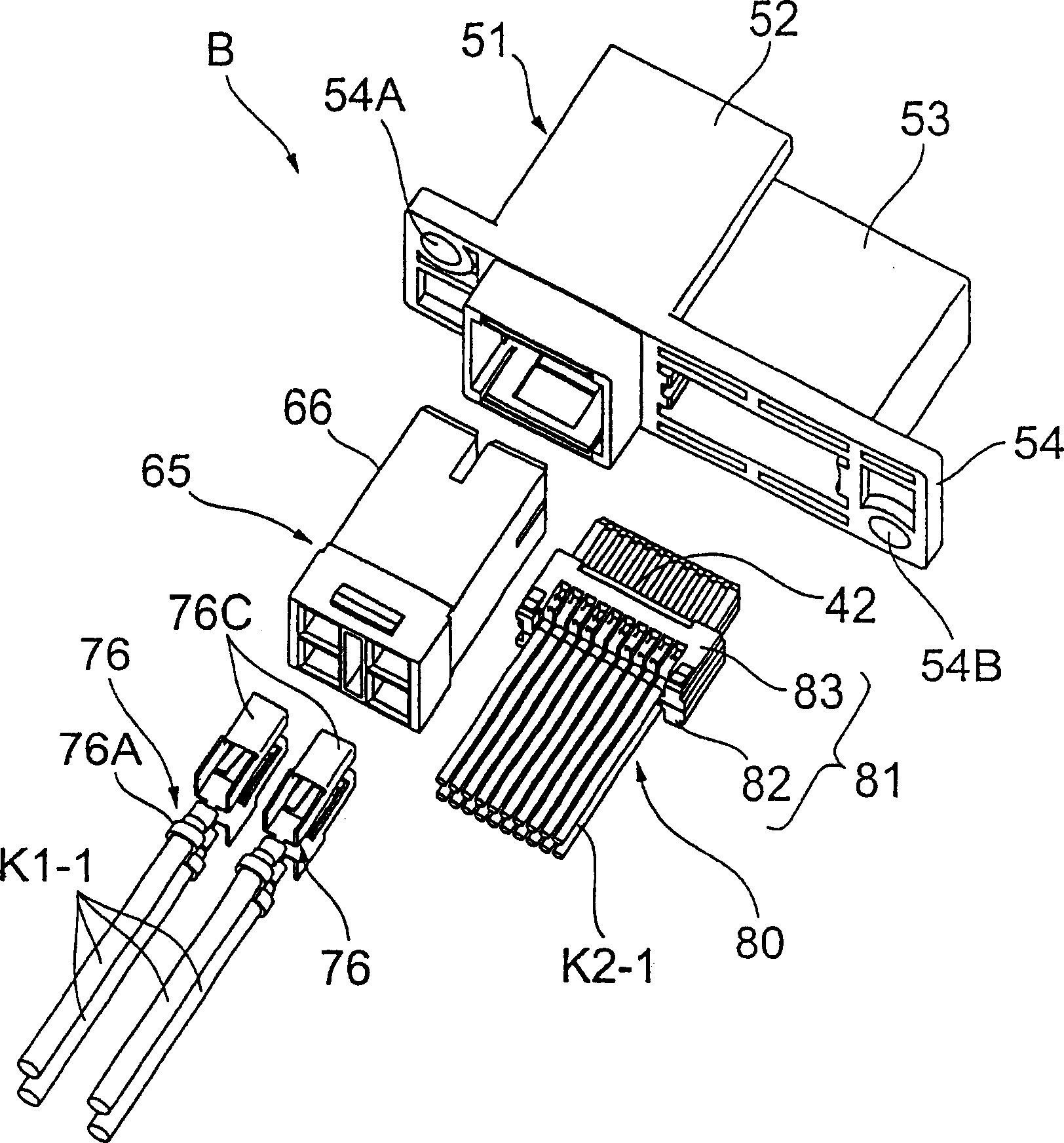

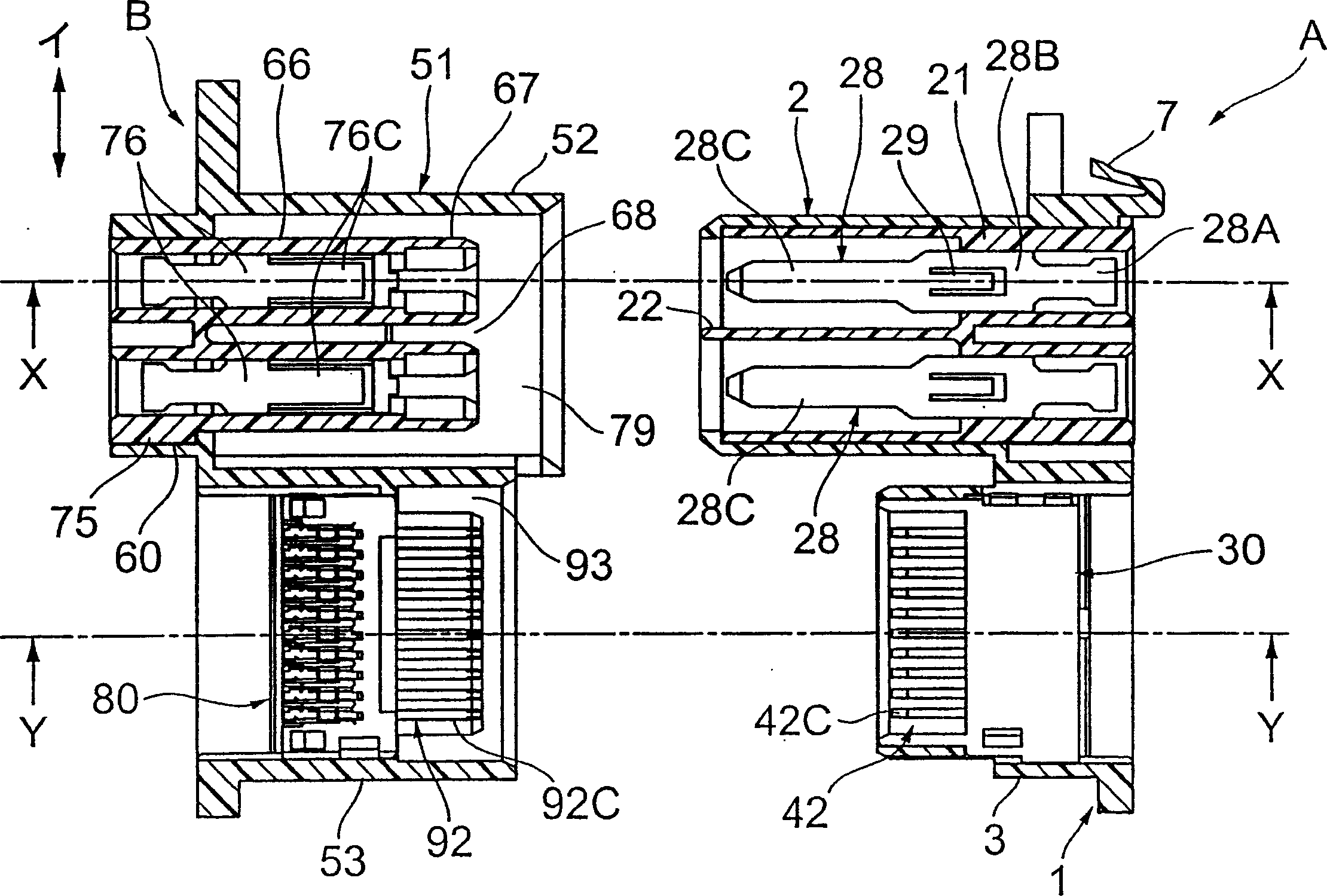

[0070] figure 1 It is a perspective view of the plug connector of the multi-pole connector of the embodiment of the present invention. figure 2 It is a perspective view of the receptacle connector of the multi-pole connector of the embodiment of the present invention. image 3 This is a cross-sectional view of the plug connector and receptacle connector before mating. Figure 4 yes image 3 The X-X section view. Figure 5 yes image 3 The X-X section view.

[0071] The multi-pole connector of the present invention has a plug connector A as a connector and a receptacle connector B that is a counterpart connector coupled to the connector A. As shown in FIG.

[0072] Plug connector A such as figure 1 As shown, there are a connector housing 1 , a power supply terminal unit (terminal unit) 20 , and a signal terminal unit (terminal unit) 30 .

[0073] like figure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com