Jack of high-elasticity pawl spring type

A technology with high elasticity and spring claws, which is applied in the direction of contact parts, can solve the problems of limited use occasions, poor contact, etc., and achieve the effect of low insertion force, long contact length, and highly reliable electrical connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

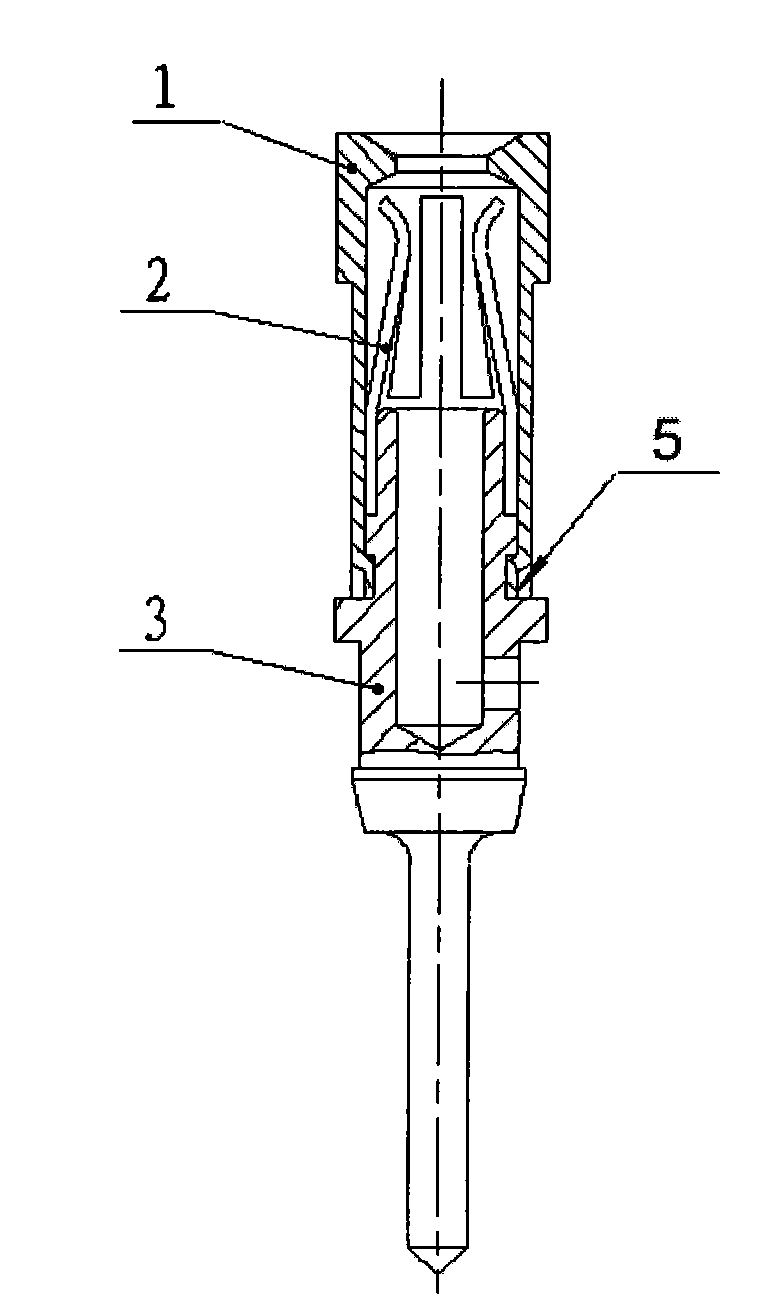

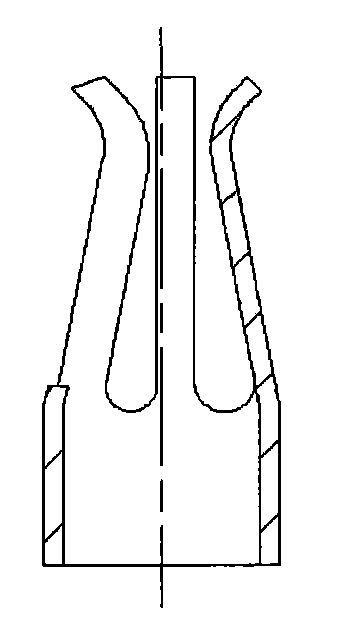

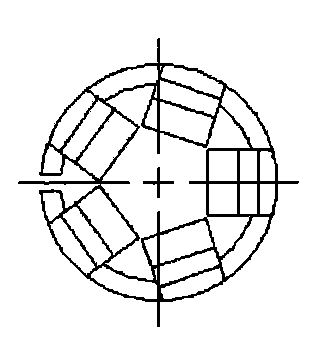

[0016] Example: such as figure 1 As shown, a high-elastic spring claw jack is composed of a sheath 1, a spring claw 2 and a socket 3. The spring claw 2 is the core part of the spring claw jack. It is made of beryllium bronze strip after blanking, bending, and rolling to form a rotary part with multiple elastic contact pieces (refer to figure 2 , image 3 ), the ends of multiple elastic contact pieces are closed to form an inscribed circle. When the pin is inserted into the spring claw socket, the pin will properly stretch the elastic contact piece at the inscribed circle to form an elastic connection. electrical connection. In order to guide, the end of each elastic contact piece is bent with a certain circular arc. The spring claw 2 is assembled on the outer circle of the socket 3, and the axial limit is realized by the step set by the socket 3. In order to reliably fix the spring claw 2 on the socket 3, a sheath 1 is configured, and the sheath 1 passes through Interfere...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com