Small carton packing machine

A baler and carton technology, which is used in the packaging, packaging, transportation and packaging of paper products, can solve the problems of losing the protective effect of the bottom of the carton, and the corner protector is easy to be taken out, so as to increase the protection effect, increase the packaging efficiency, The effect of reducing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

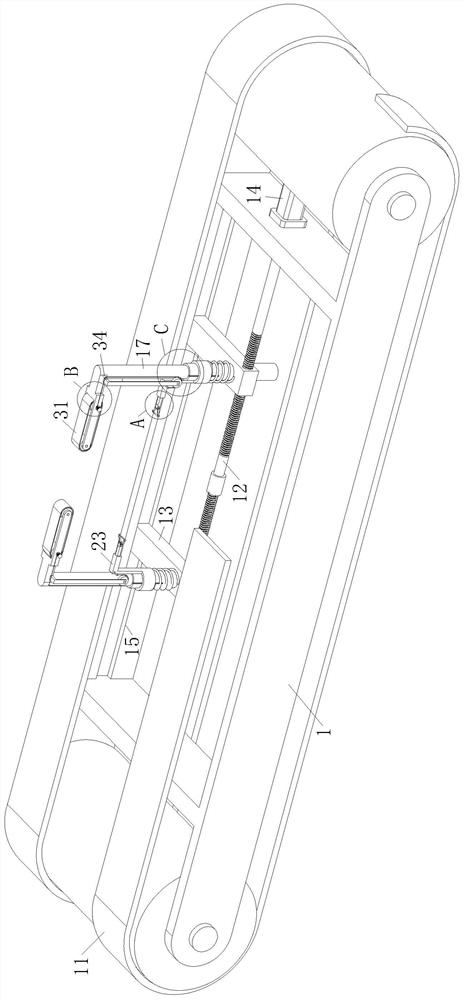

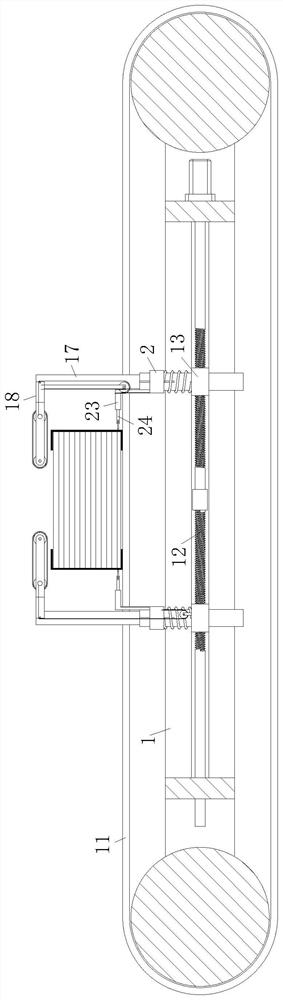

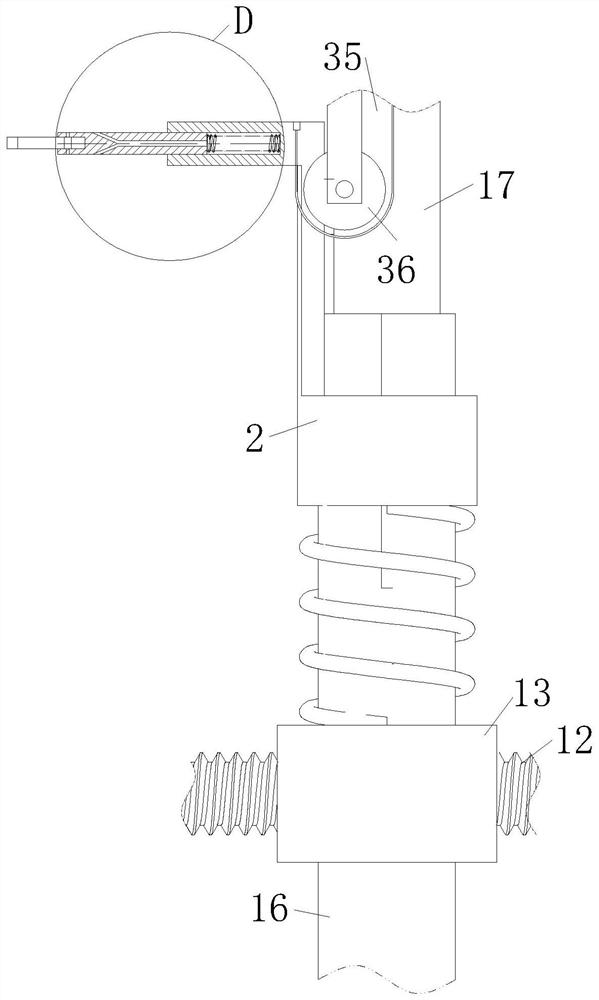

Image

Examples

Embodiment approach

[0026] As an embodiment of the present invention, the sliding rod 24 is in sliding and sealed connection with the sliding cylinder 23; the sliding rod 24 is provided with a nozzle hole 25 communicating with the bottom of the sliding cylinder 23, and the nozzle hole 25 is inclined in a direction away from the sliding cylinder 23 , the nozzle hole 25 is used to spray airflow to the carton to clean up paper scraps; because the sliding rod 24 is connected with the sliding cylinder 23 in a sliding and sealed manner, when the sliding rod 24 shrinks into the sliding cylinder 23, compressed air is generated in the sliding cylinder 23, and the compressed air passes through the sliding cylinder 23. Spray from the spray hole 25, and then clean the carton, reduce the paper dust falling on the slip ring 2 and the screw 12 and affect the normal activities of the compression rod 18, and then ensure that the compression rod 18 can be folded and compressed flexibly and quickly with the slider 13...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com