Patents

Literature

279results about "Sack sewing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

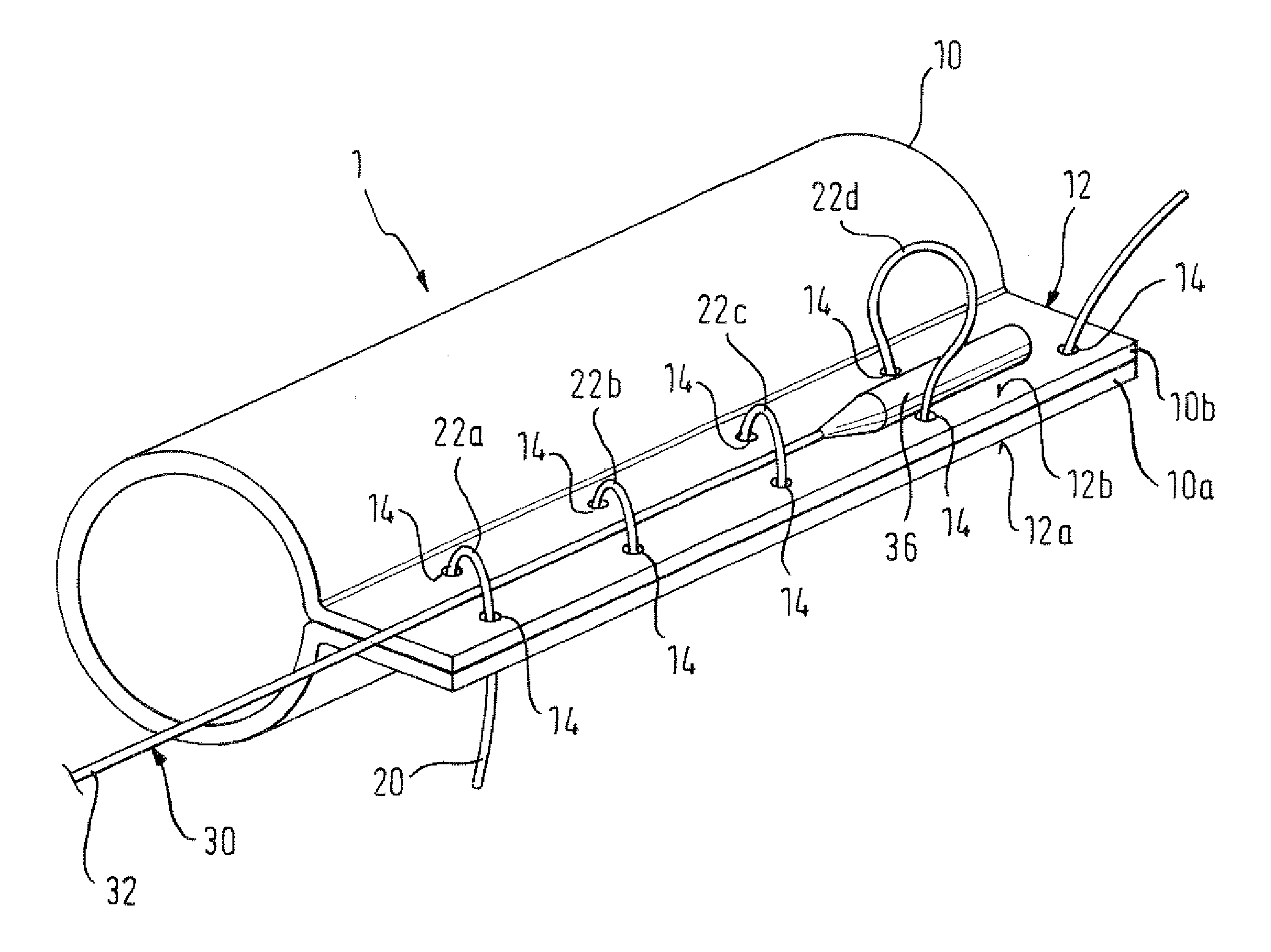

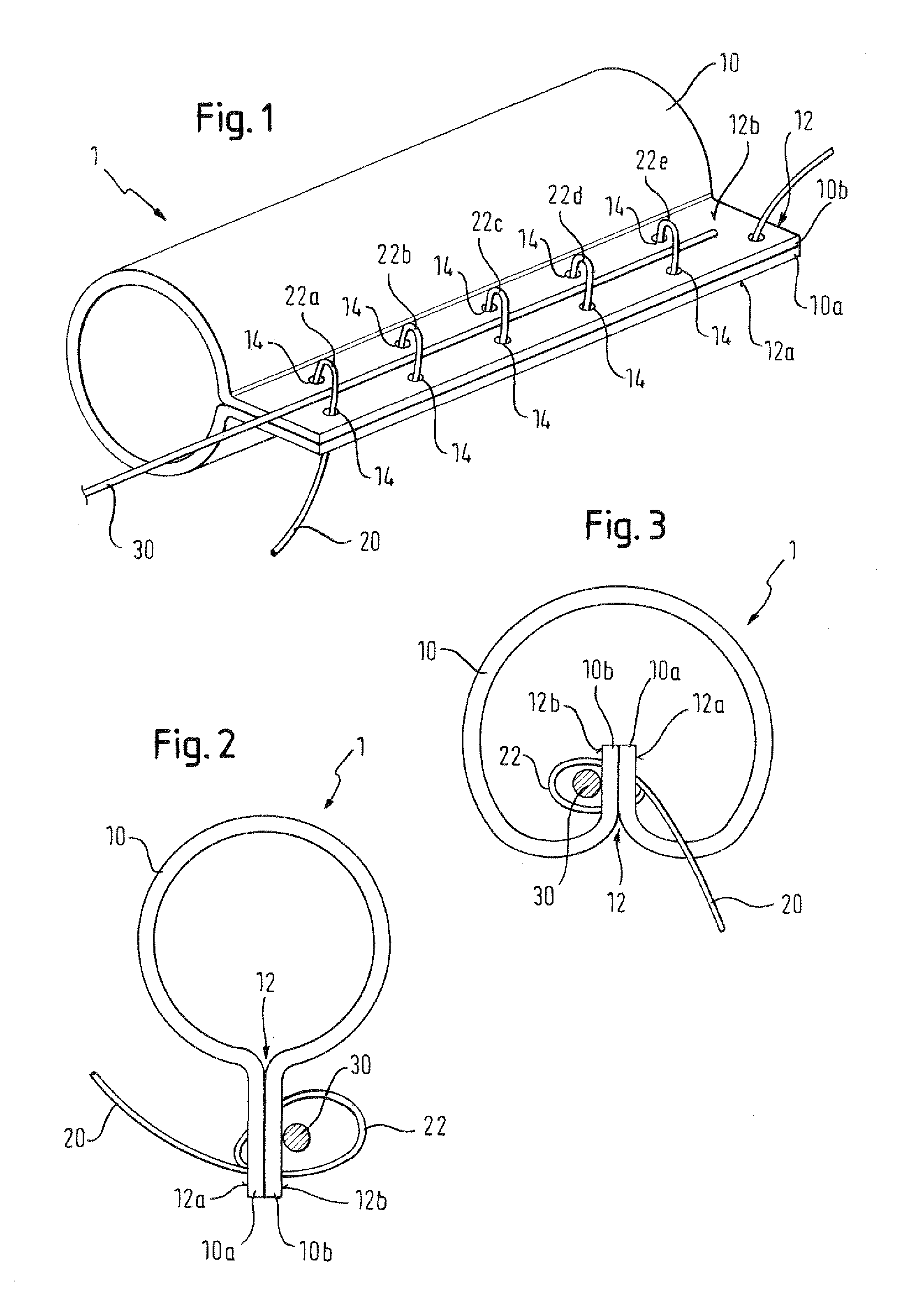

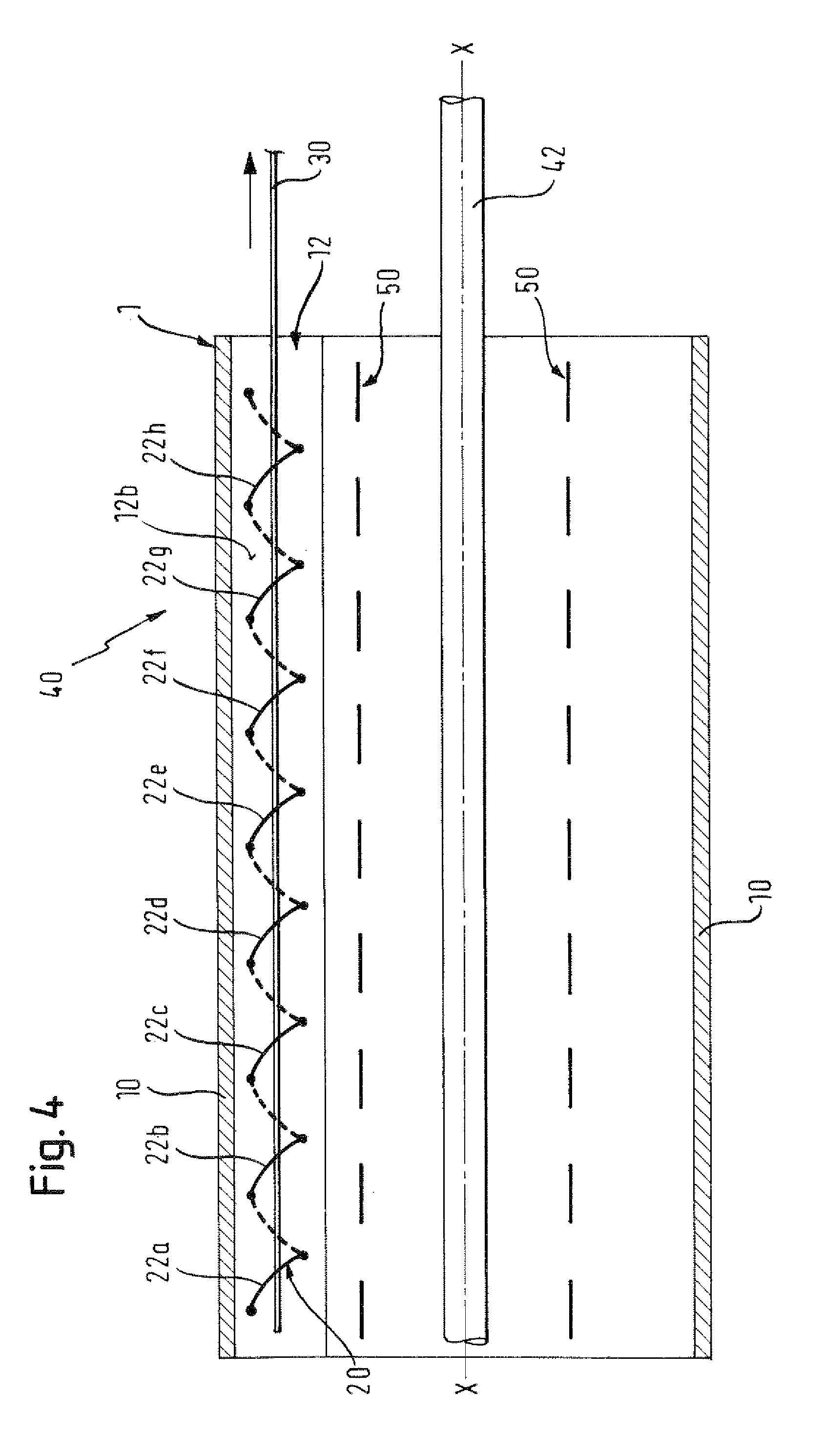

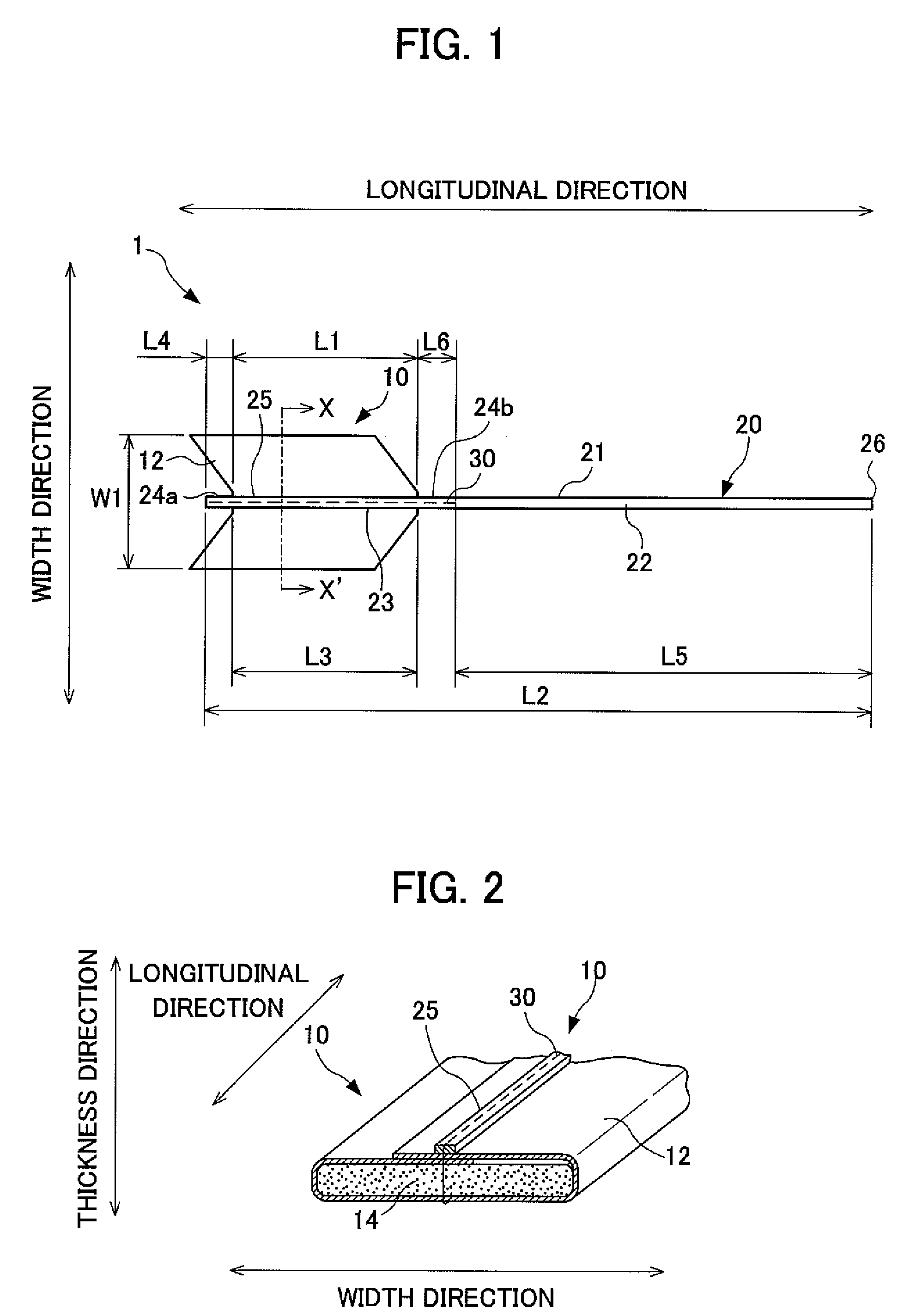

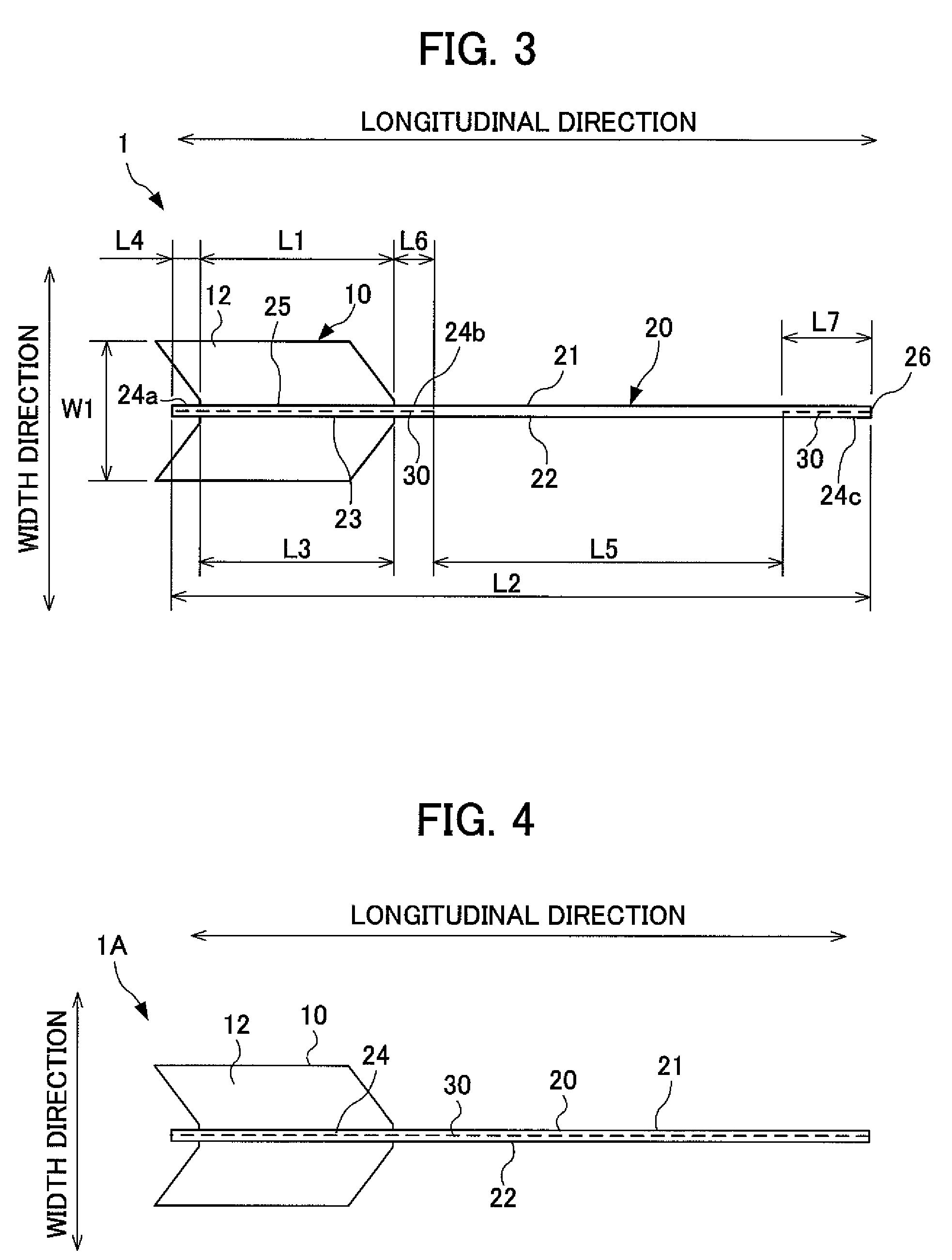

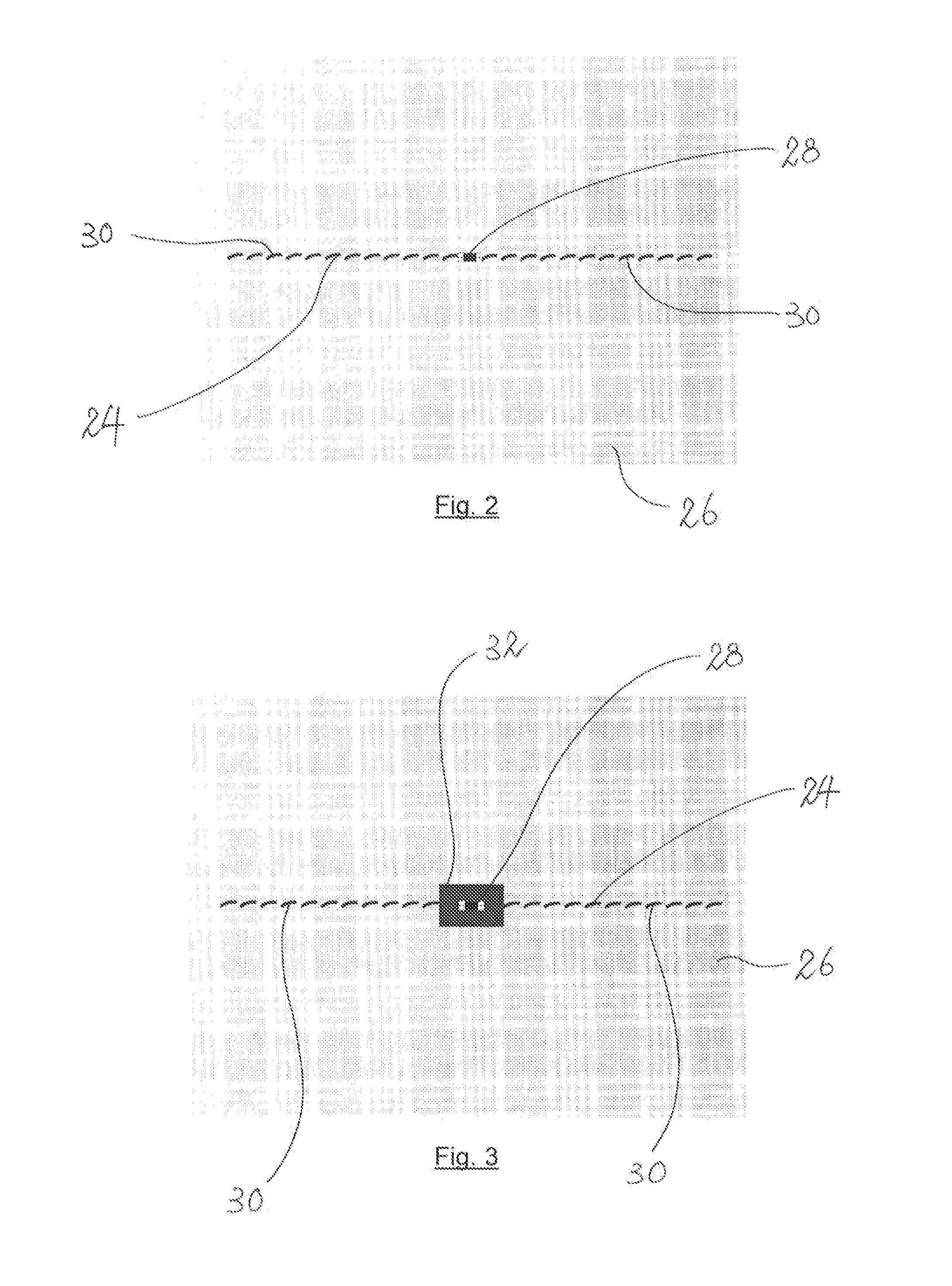

Catheter sheath for implant delivery

ActiveUS20120022630A1Increase deflectionLarge radiusStentsLeather sewingBiomedical engineeringCatheter sheath

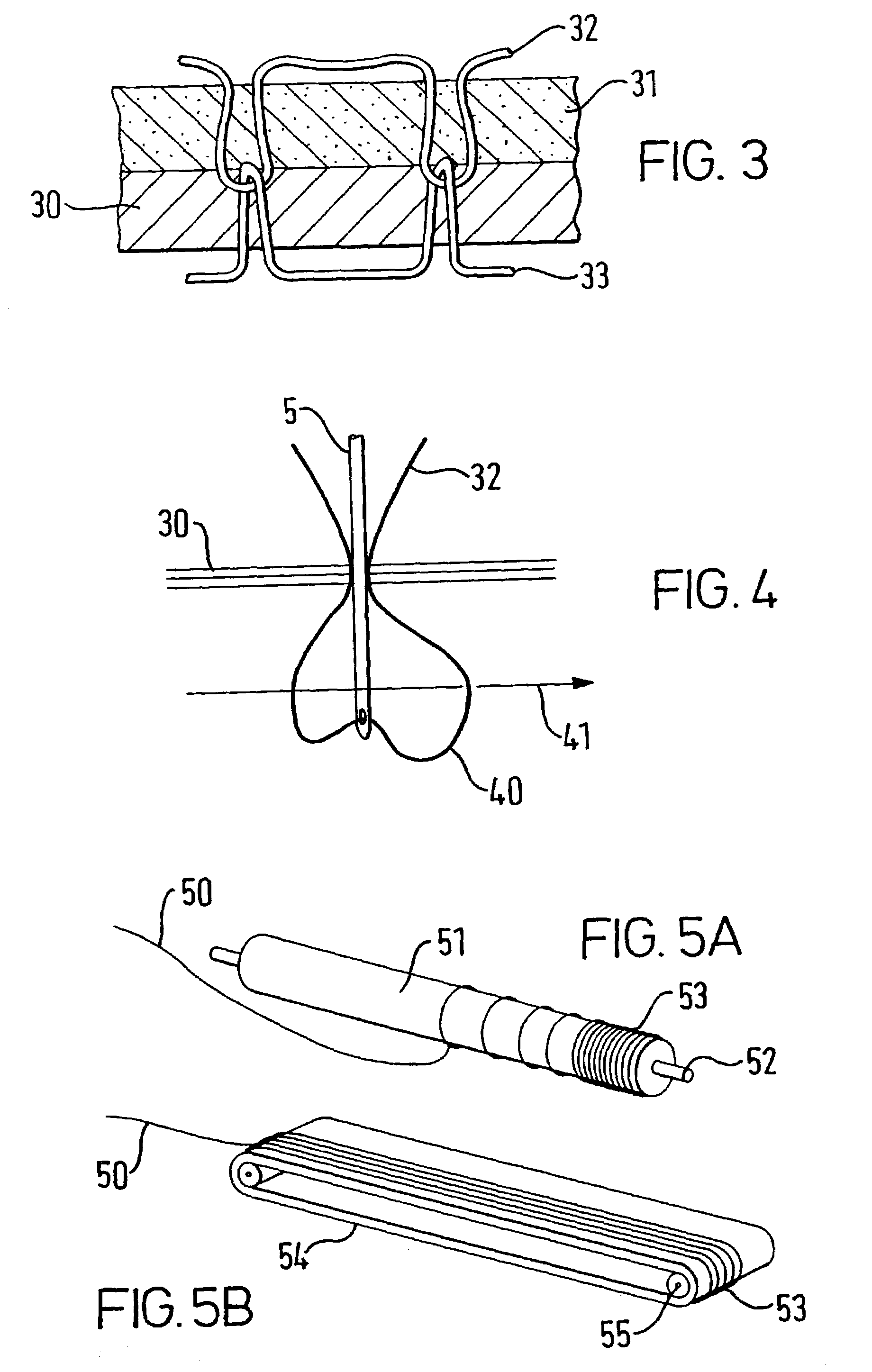

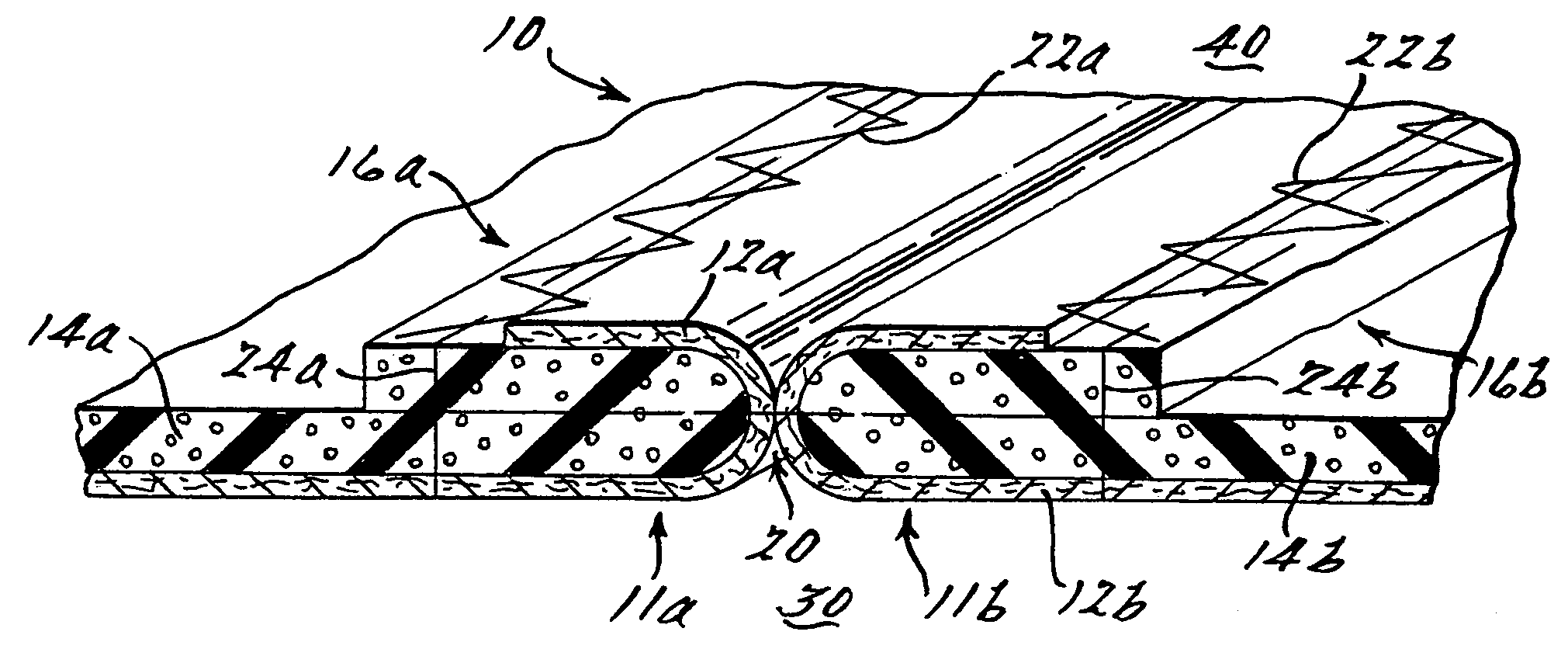

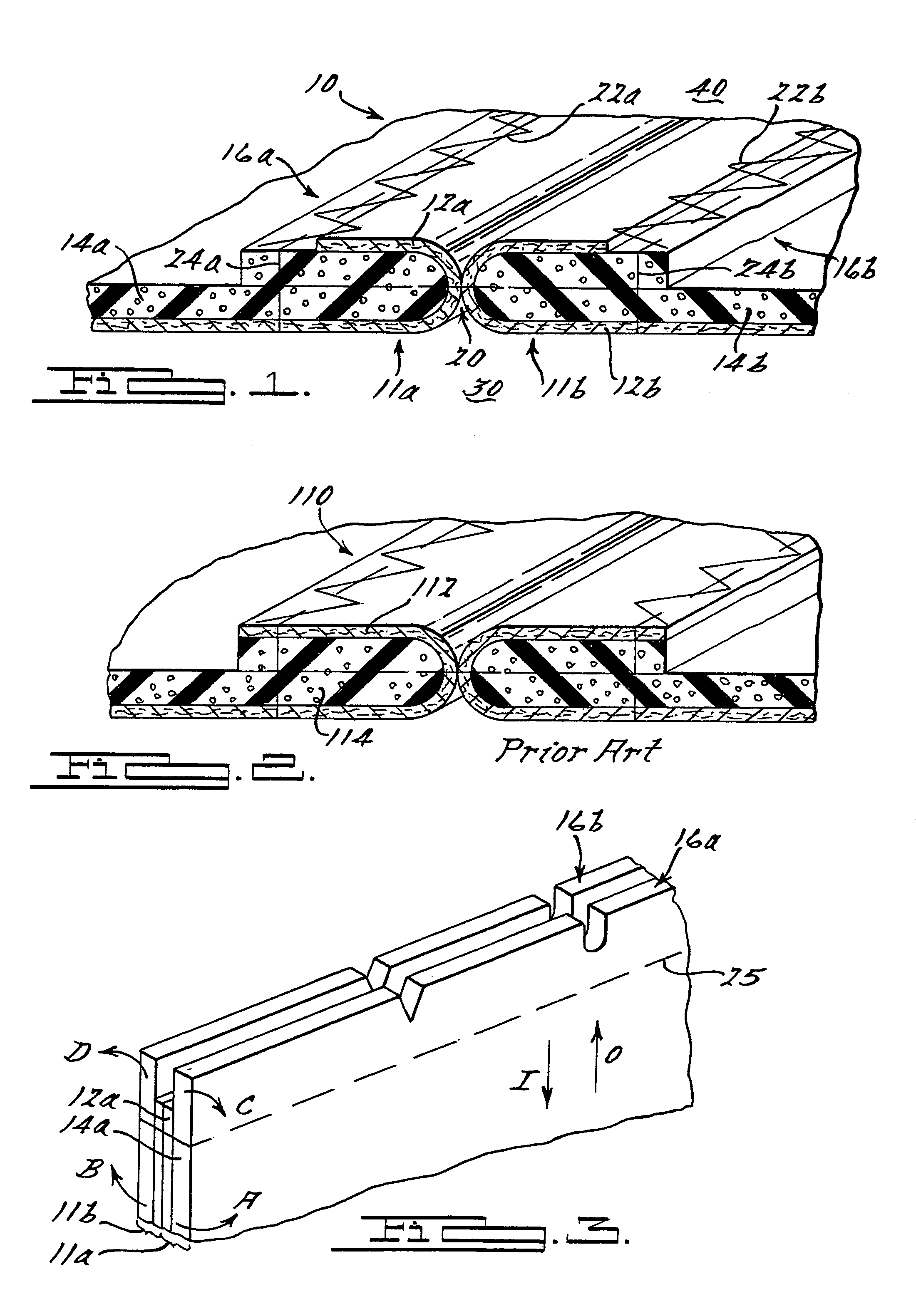

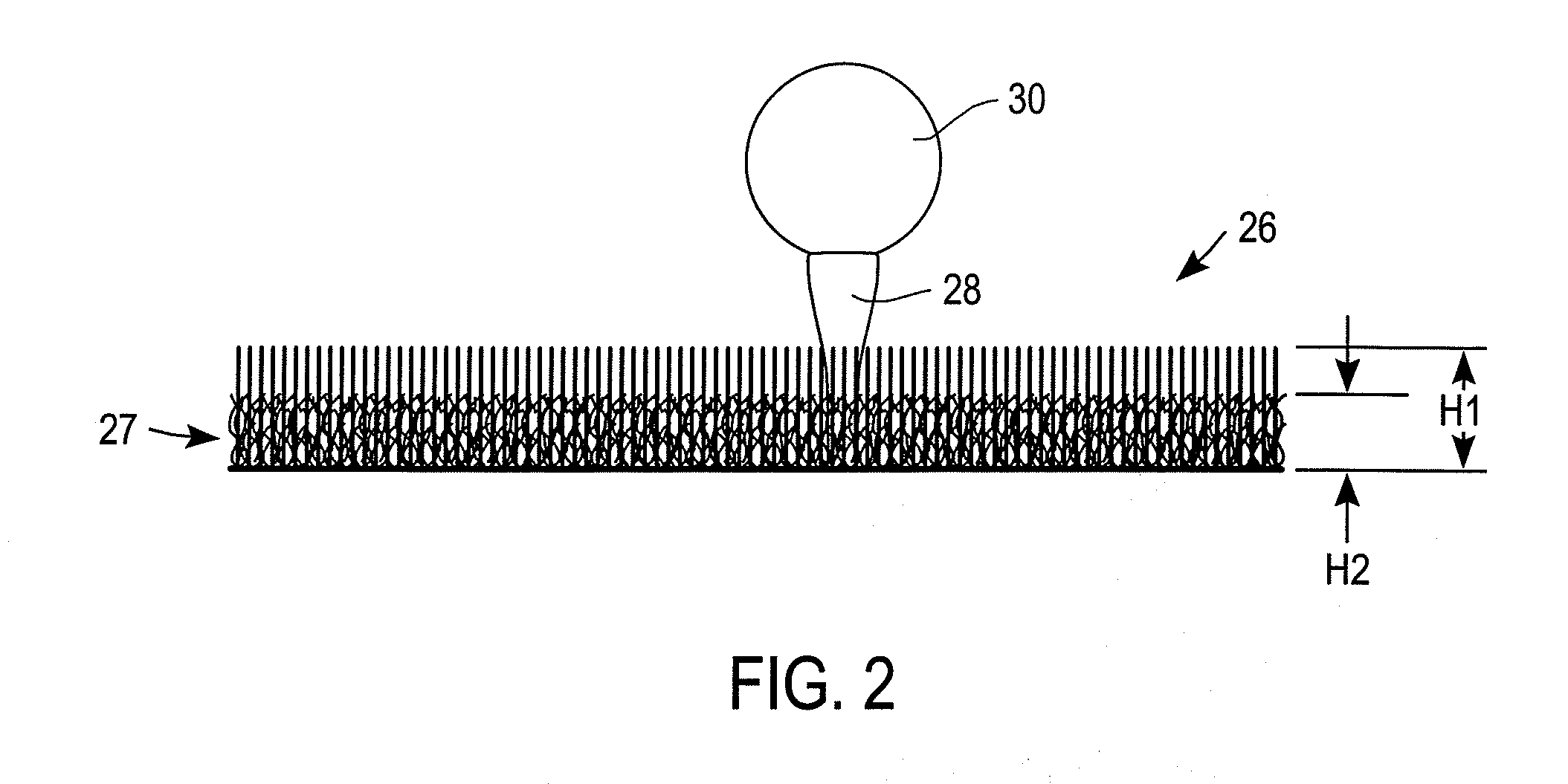

There is disclosed herein a tube of material (1) having a seam (12) extending between a proximal end and a distal end, two edges (10a, 10b) of the material meeting and at least partially overlapping along the seam (12) and being sewn together at the seam by stitches (21, 22, 24) of relatively flexible thread (20), the thread of one or more of the stitches (22, 24) passing from a first side (12a) of the overlapped edges (10a, 10b) of material, through both layers of overlapped material, crossing a relatively rigid member (30) which is disposed on a second, opposite side (12b) of the overlapped edges of material, and passing back to the first side (12a). There is further disclosed an implant delivery catheter (40) incorporating the tube of material (1), and associated methods for its manufacture.

Owner:CR BARD INC

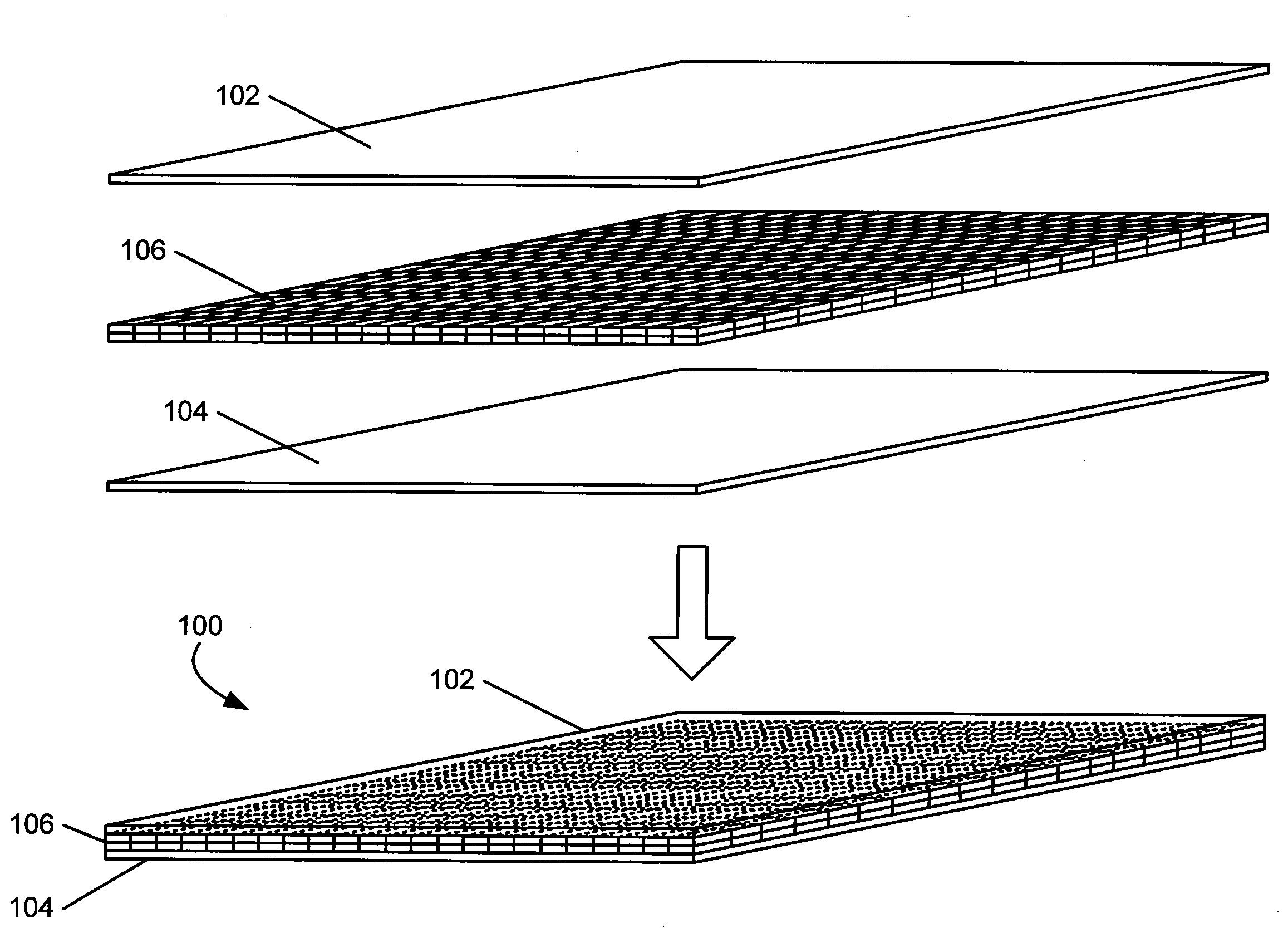

Footwear uppers and other textile components including reinforced and abutting edge joint seams

ActiveUS20100077634A1Strong and stable and durable constructionShoemaking devicesLeather sewingEngineeringMechanical engineering

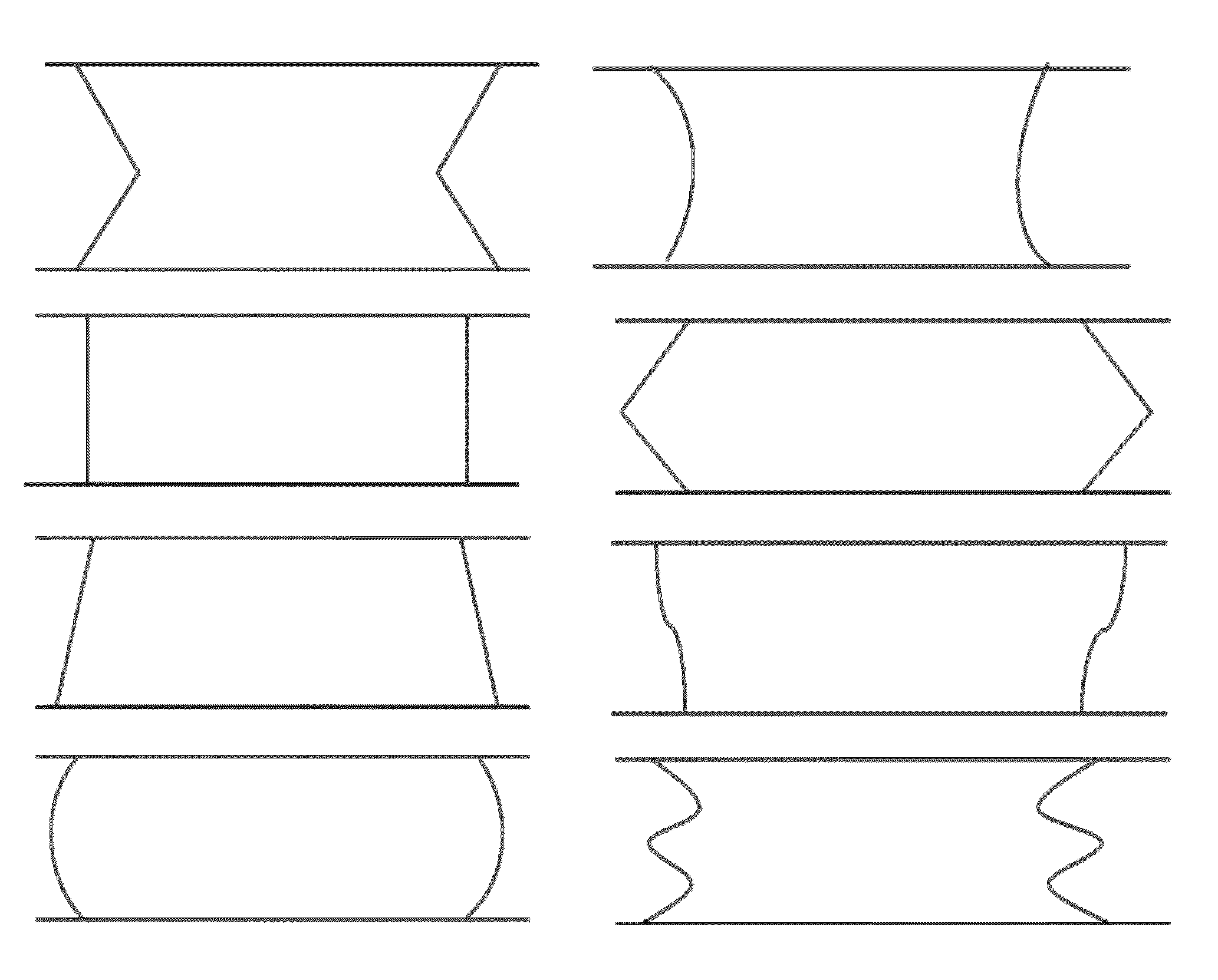

Textile Components, such as upper members for articles of footwear, include: (a) a first portion having a first edge, wherein the first edge includes a first portion of material engaged with a first seam support material via a first thermoplastic material; (b) a second portion having a second edge, wherein the second edge includes a second portion of material engaged with a second seam support material via a second thermoplastic material; and (c) structure to engage the first and second edges in an abutting edge joint (such as a zig-zag stitch). The resulting textile components may be lightweight and breathable (e.g., due to use of lightweight upper fabric), having a comfortable fit (e.g., due to the abutting edge joint), while still providing a strong, stable, and durable construction (e.g., due to the presence of the seam support member(s)).

Owner:NIKE INC

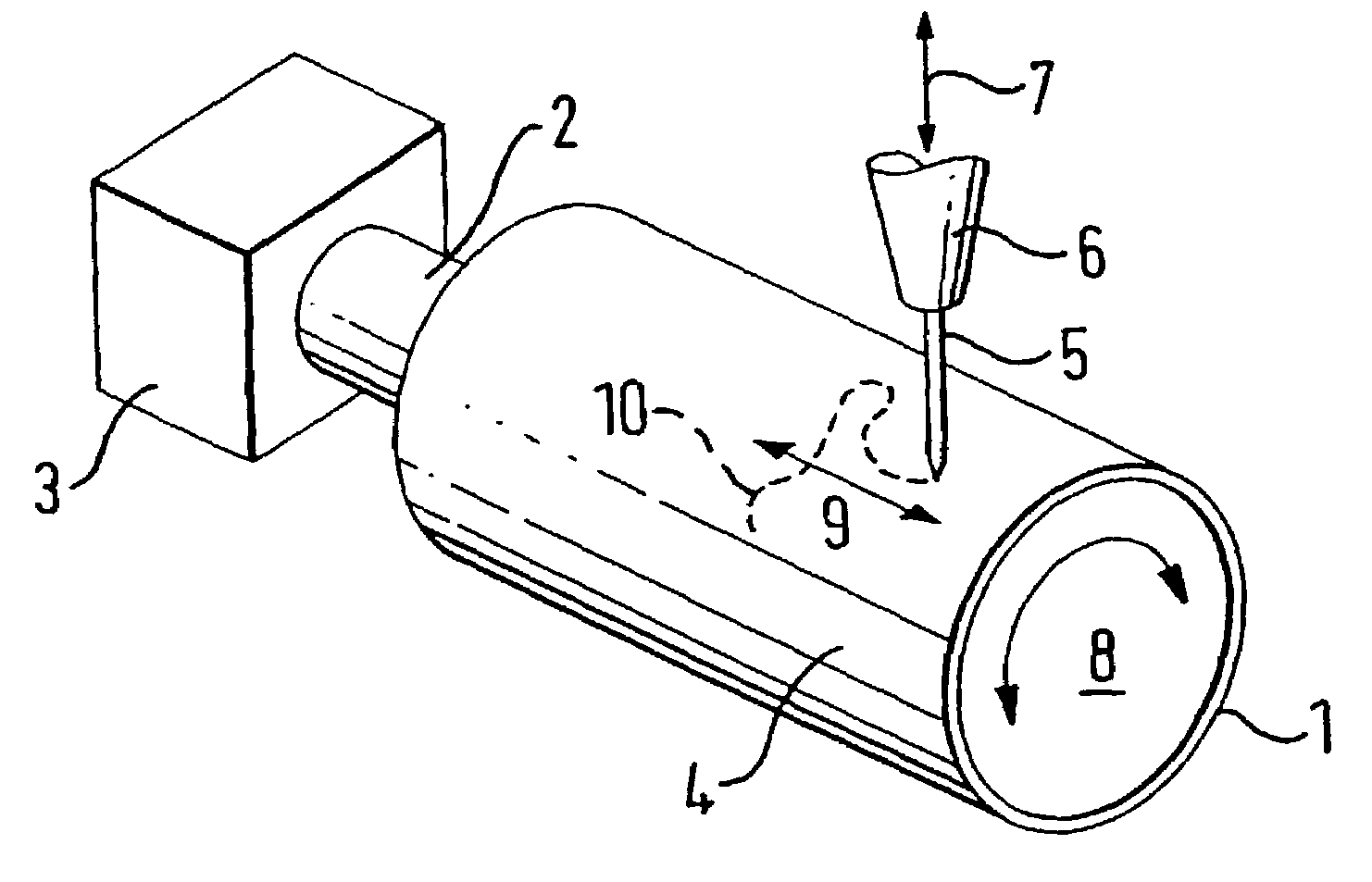

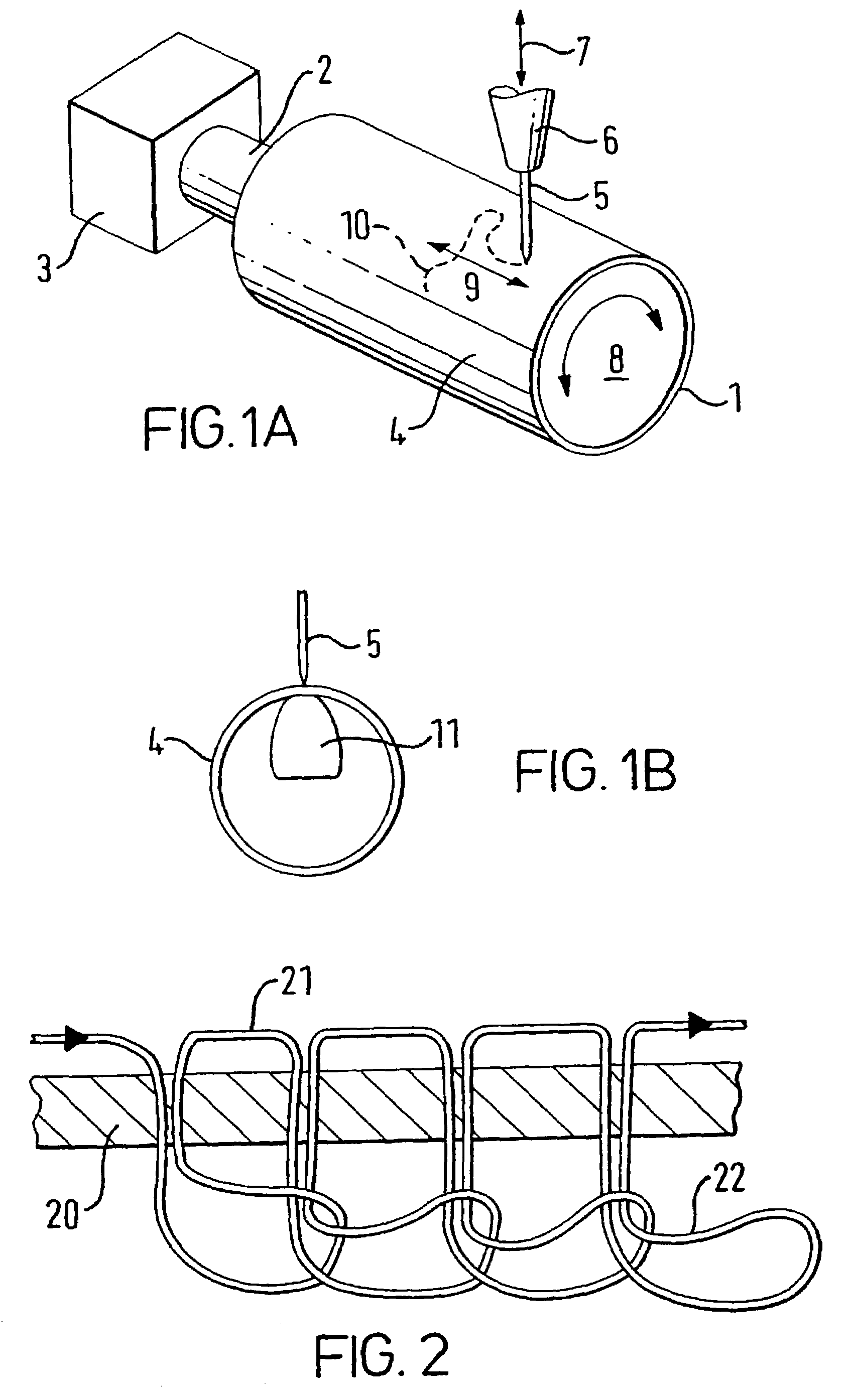

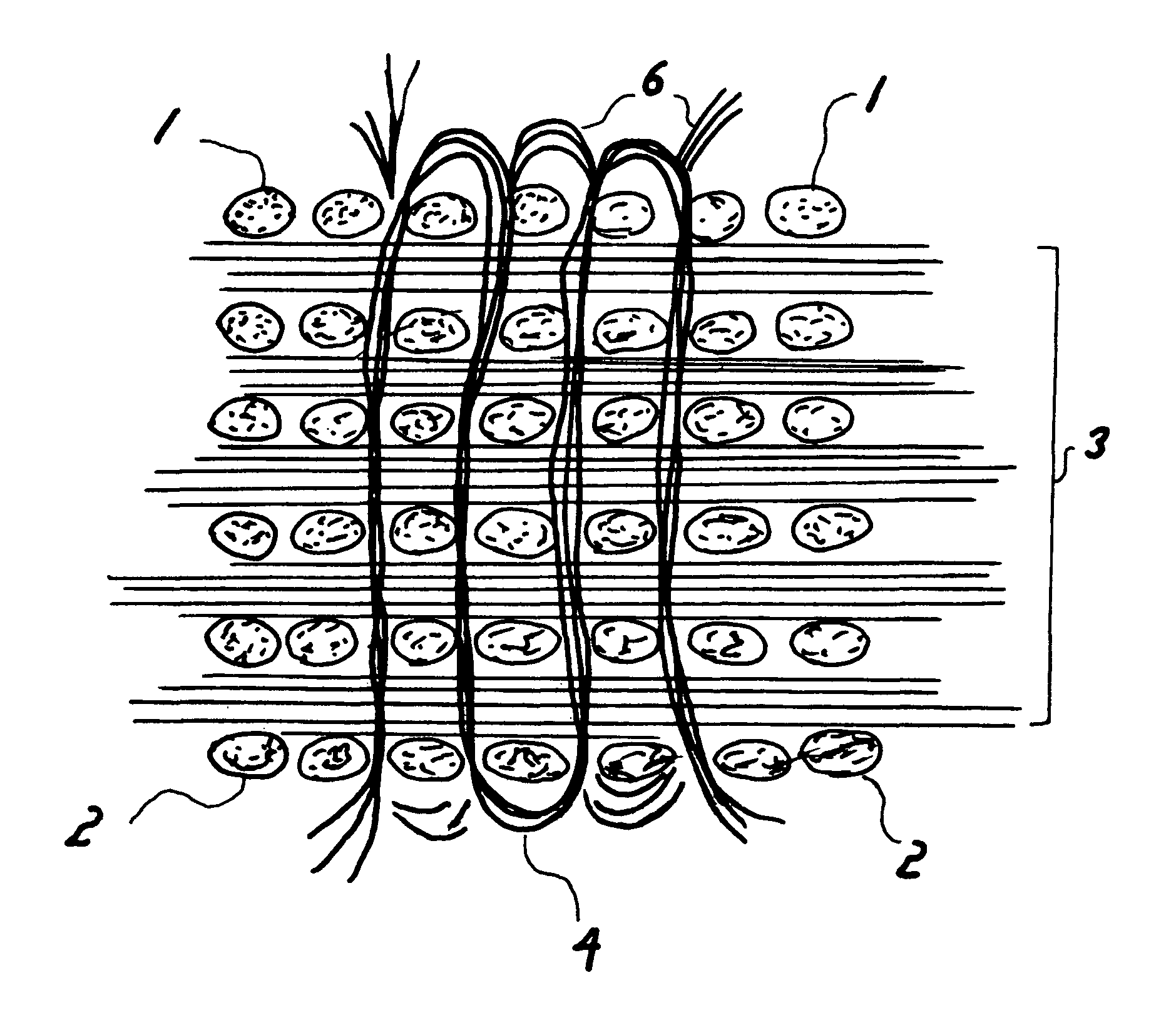

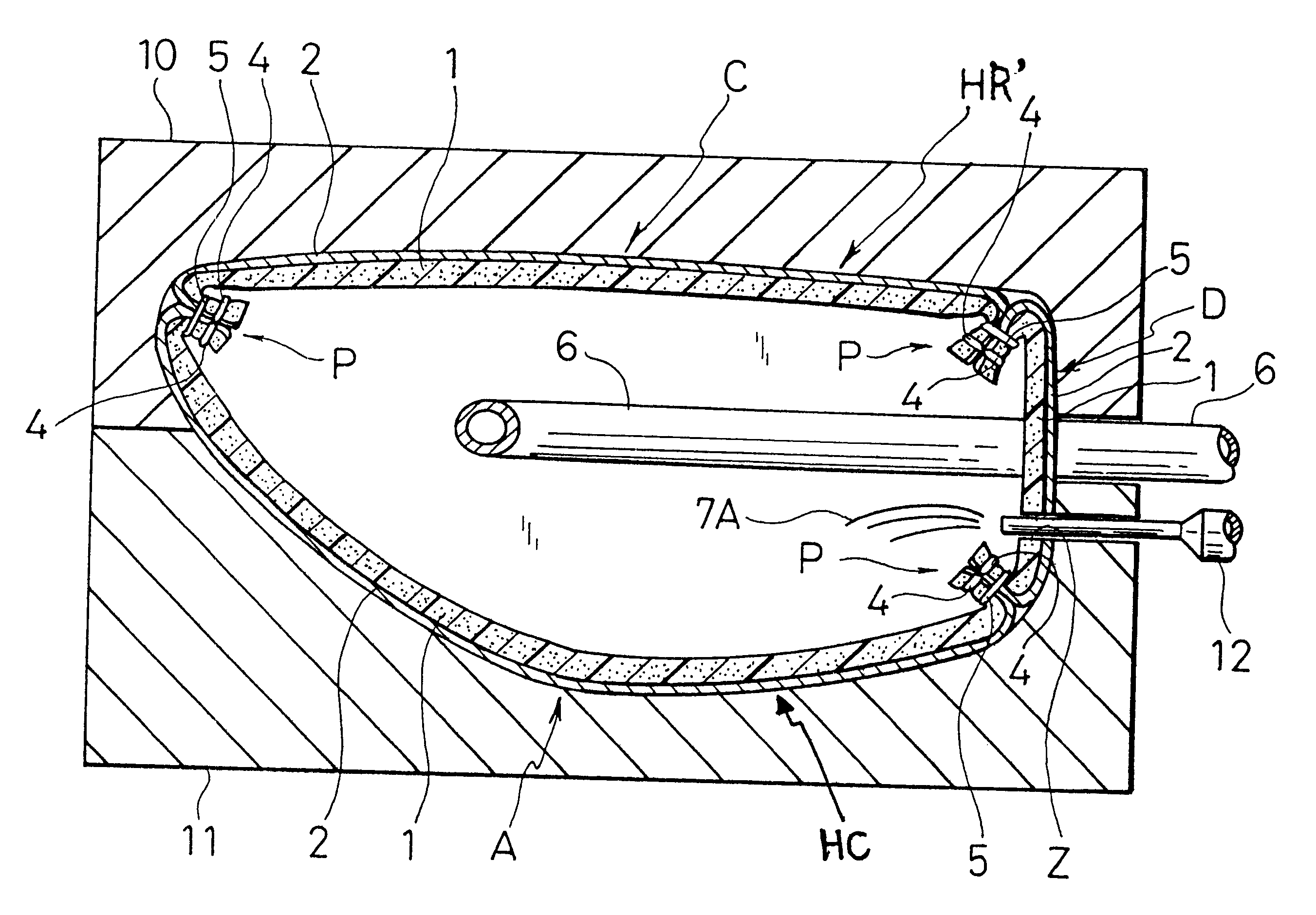

Method for manufacturing a medical implant

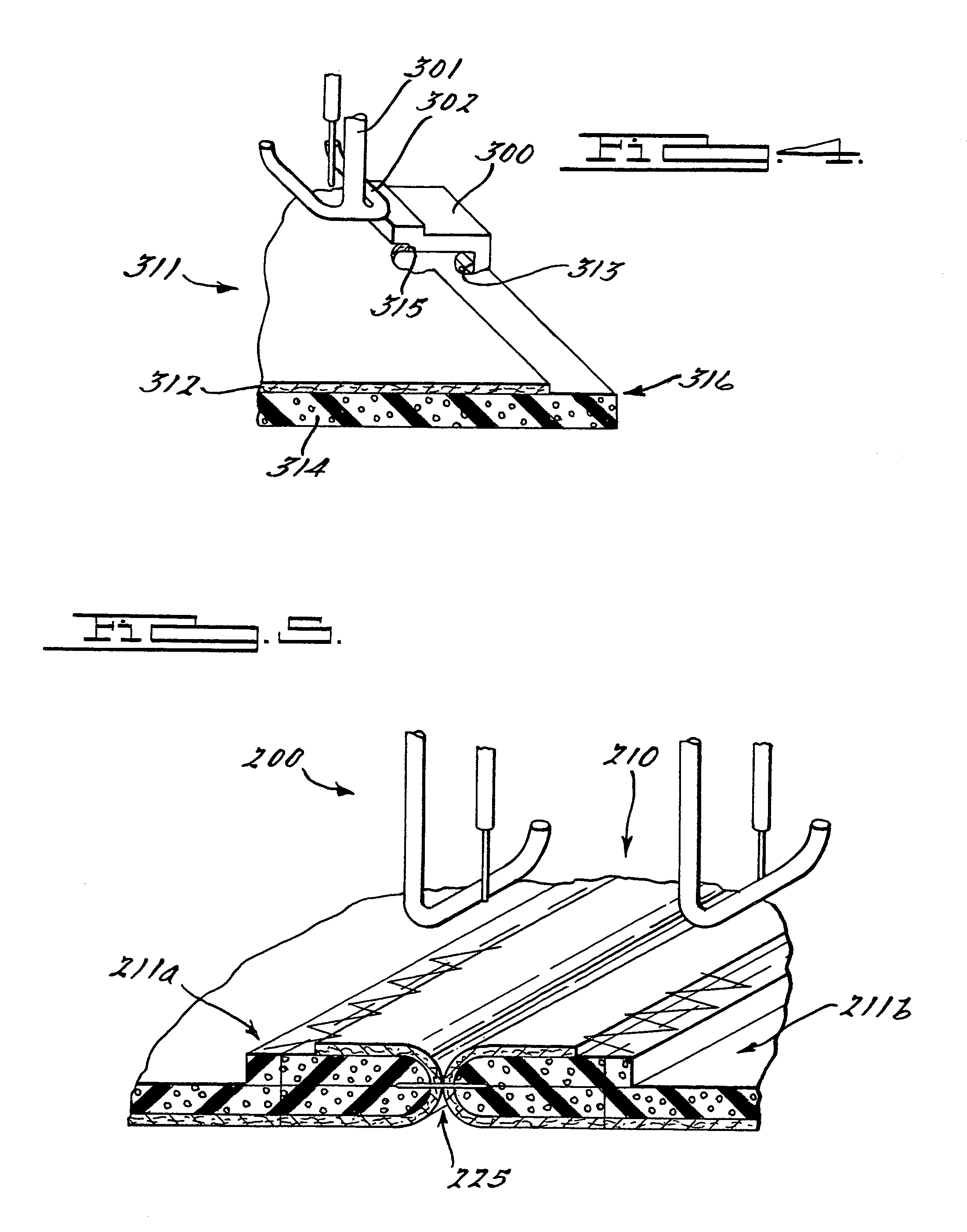

A method for stitching thread onto the wall of a tubular medical implant (preferably a graft) employs a sewing machine with an elongate bobbin or a needle on an elongate element, depending on whether it is desired to sew from the outside-in or the inside-out. A motor rotates and translates the implant, which is mounted on a hollow drum, relative to the needle.

Owner:ANSON MEDICAL LTD

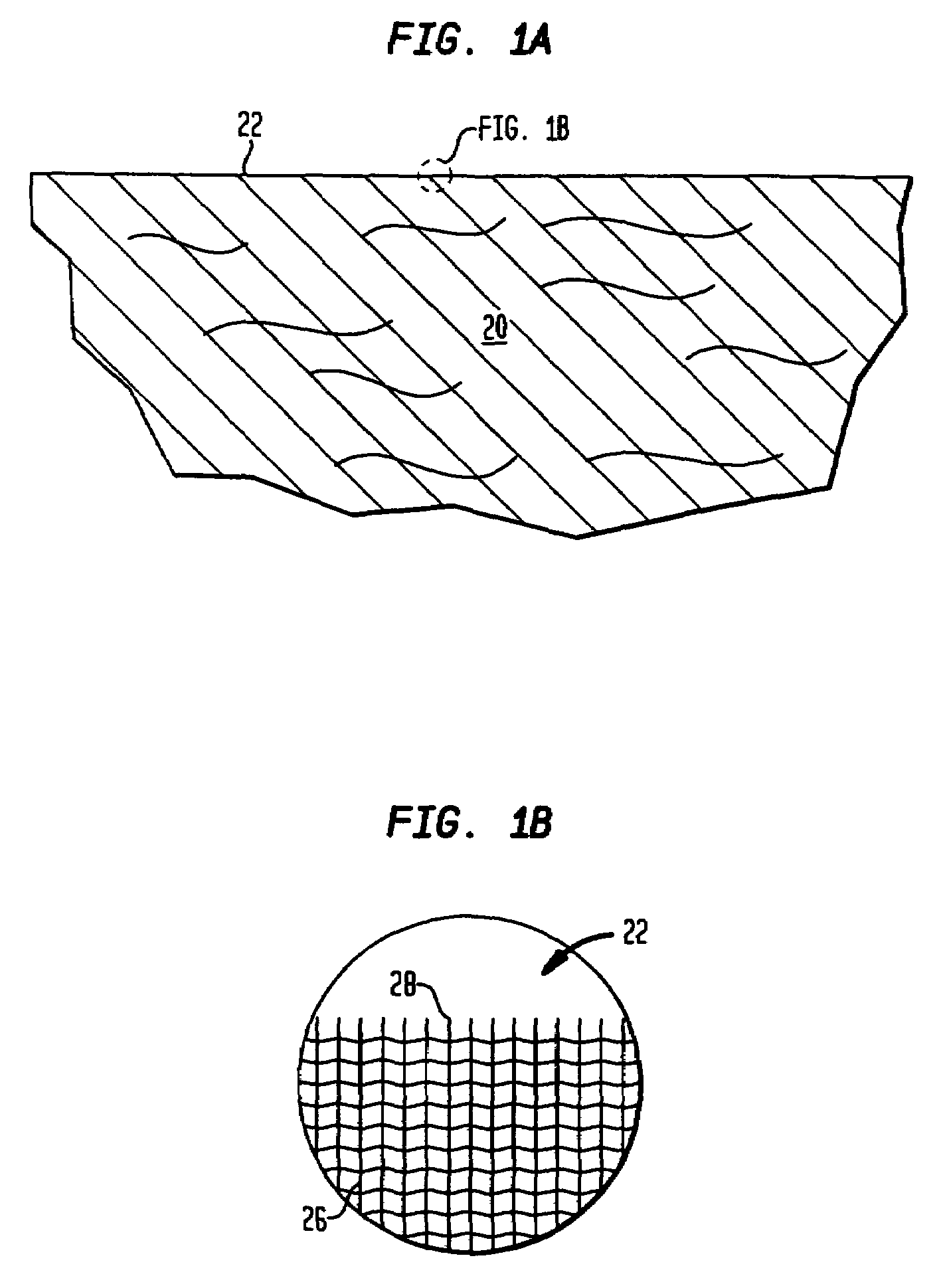

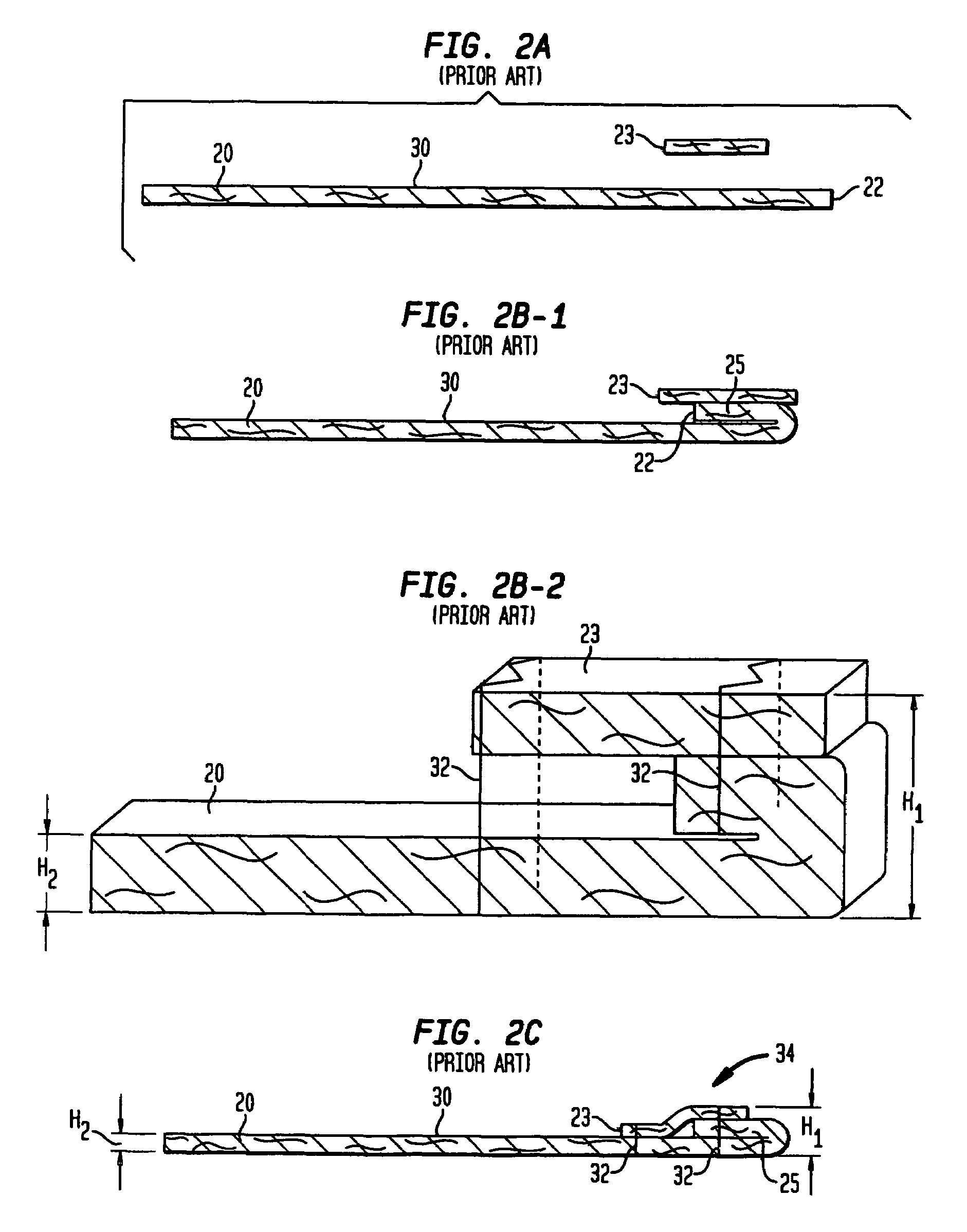

Method of Making an Endoluminal Vascular Prosthesis

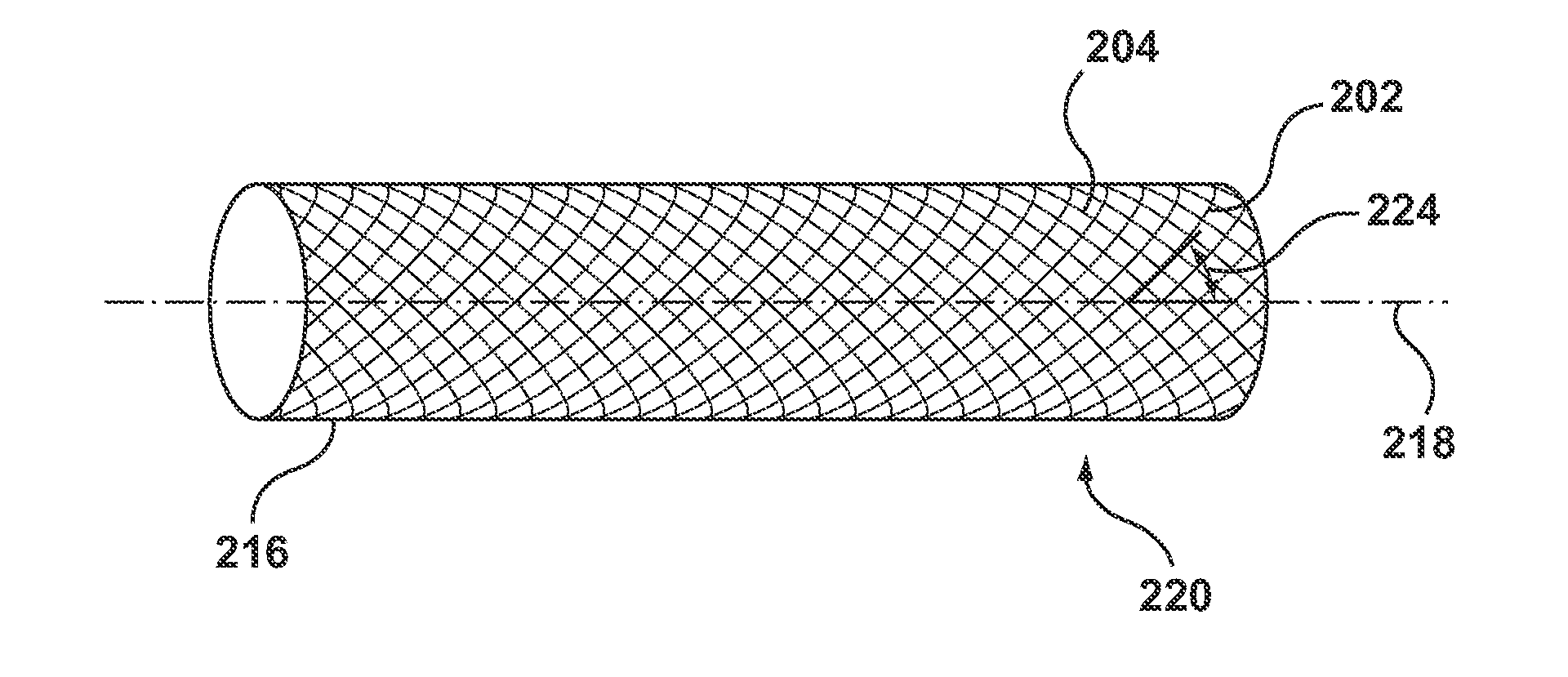

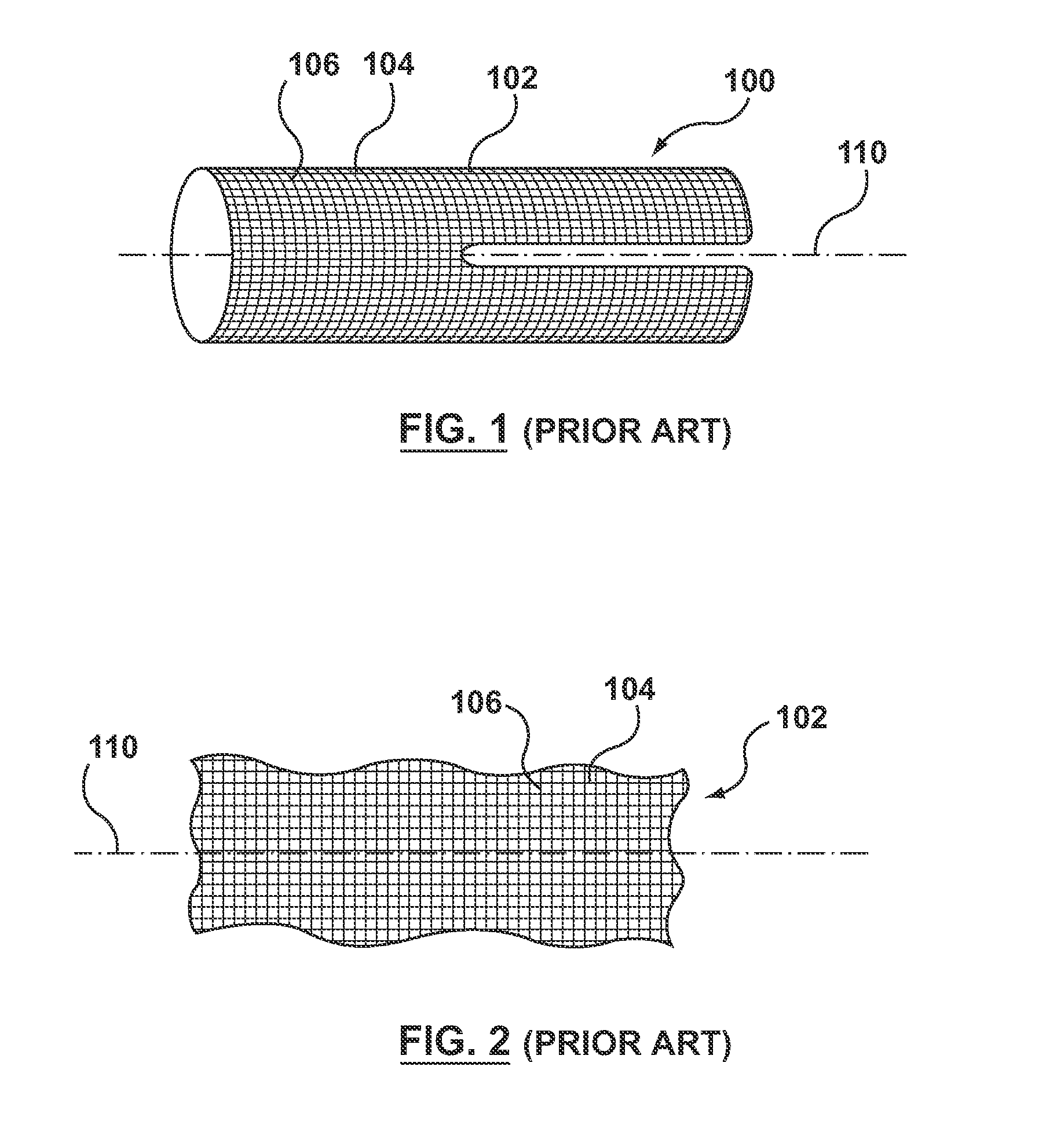

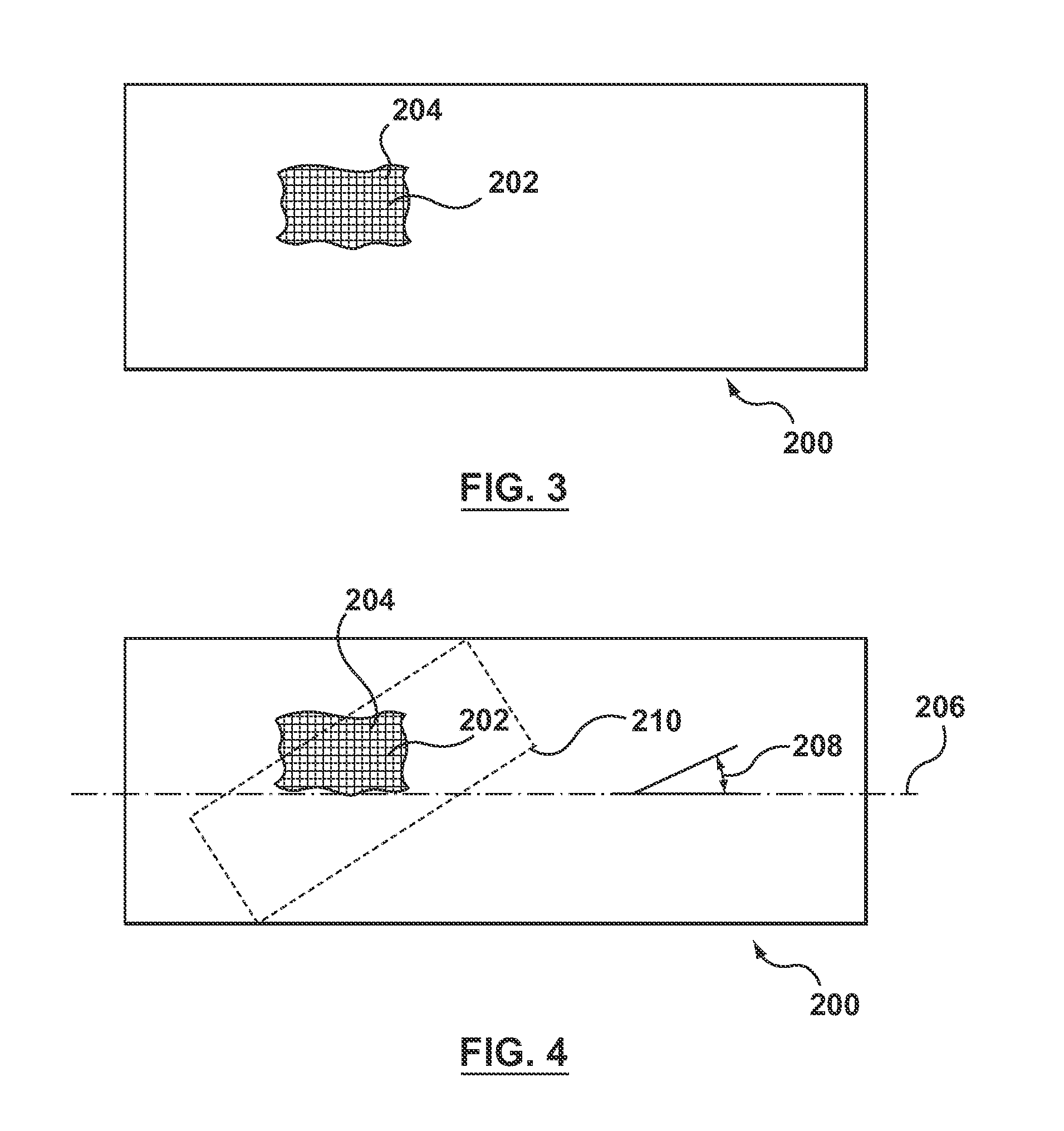

A flat sheet of woven material includes warp yarns and weft yarns interlaced at substantially right angles to each other. A graft material is cut from the flat sheet of woven material such that the graft material includes a graft material longitudinal axis and the warp yarns are disposed at an angle relative to the graft material longitudinal axis. The warp yarns and weft yarns are not parallel to or perpendicular to the graft material longitudinal axis. The graft material is formed into the shape of an endoluminal prosthesis, such as by rolling opposing edges towards each other and securing the opposing edges to each other. The endoluminal prosthesis thus includes warp yarns disposed at an angle relative to the prosthesis longitudinal axis.

Owner:MEDTRONIC VASCULAR INC

Undergarments having finished edges and methods therefor

ActiveUS7228809B2Improve material yieldDirect contact guaranteeLeather sewingWork-feeding meansFiberEngineering

A method of making a fabric having a finished edge includes providing a fabric having a plurality of fibers with free ends of the fibers at an edge of the fabric, disposing a curable polymer such as silicone over the edge of the fabric so that the curable polymer engages the free ends of the fibers at the edge of the fabric, and, after the disposing step, curing the polymer for finishing the edge of the fabric. The polymer binds the free ends of the fibers to prevent fraying of the fabric. The fabric is cut into a pattern piece for a garment before the step of disposing the curable polymer on the edge of the fabric.

Owner:CUPID FOUND

Method for stitching vehicle interior components and components formed from the method

A method of applying stitching to an interior component is provided herein. The method including the steps of: a) penetrating an outer skin layer, a substrate layer and an intermediary layer of the interior component with an awl to form a piercing therethrough; b) retracting the awl from the outer skin layer, the substrate layer and the intermediary layer; c) inserting a needle through the piercing through the substrate layer, the intermediary layer and the outer skin layer to grasp a thread positioned on the outer skin layer; d) pulling the thread through the outer skin layer, the intermediary layer and the substrate layer; e) looping the thread with a previous stitch passed through the outer skin layer, the intermediary layer and the substrate layer; f) advancing the interior component to another position; and g) repeating steps a-f until a predetermined amount of stitches are applied to the interior component.

Owner:INTEVA PRODUCTS LLC

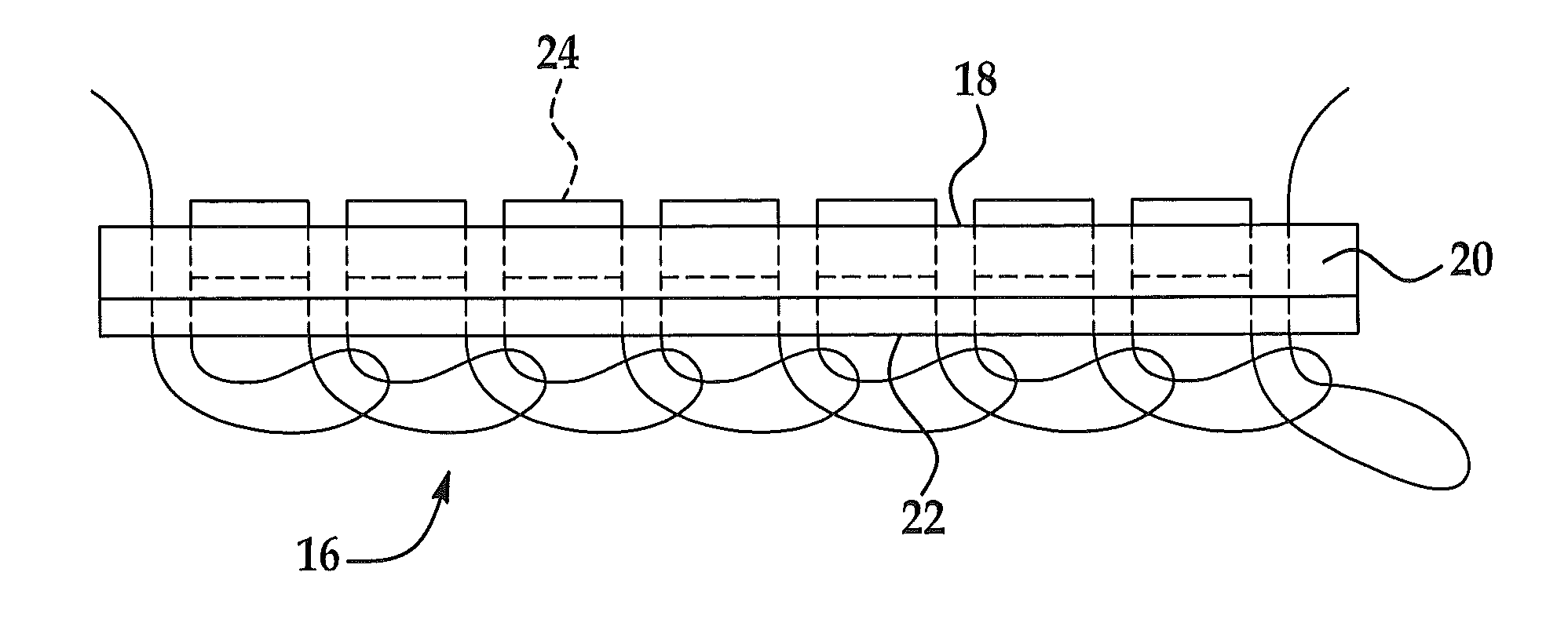

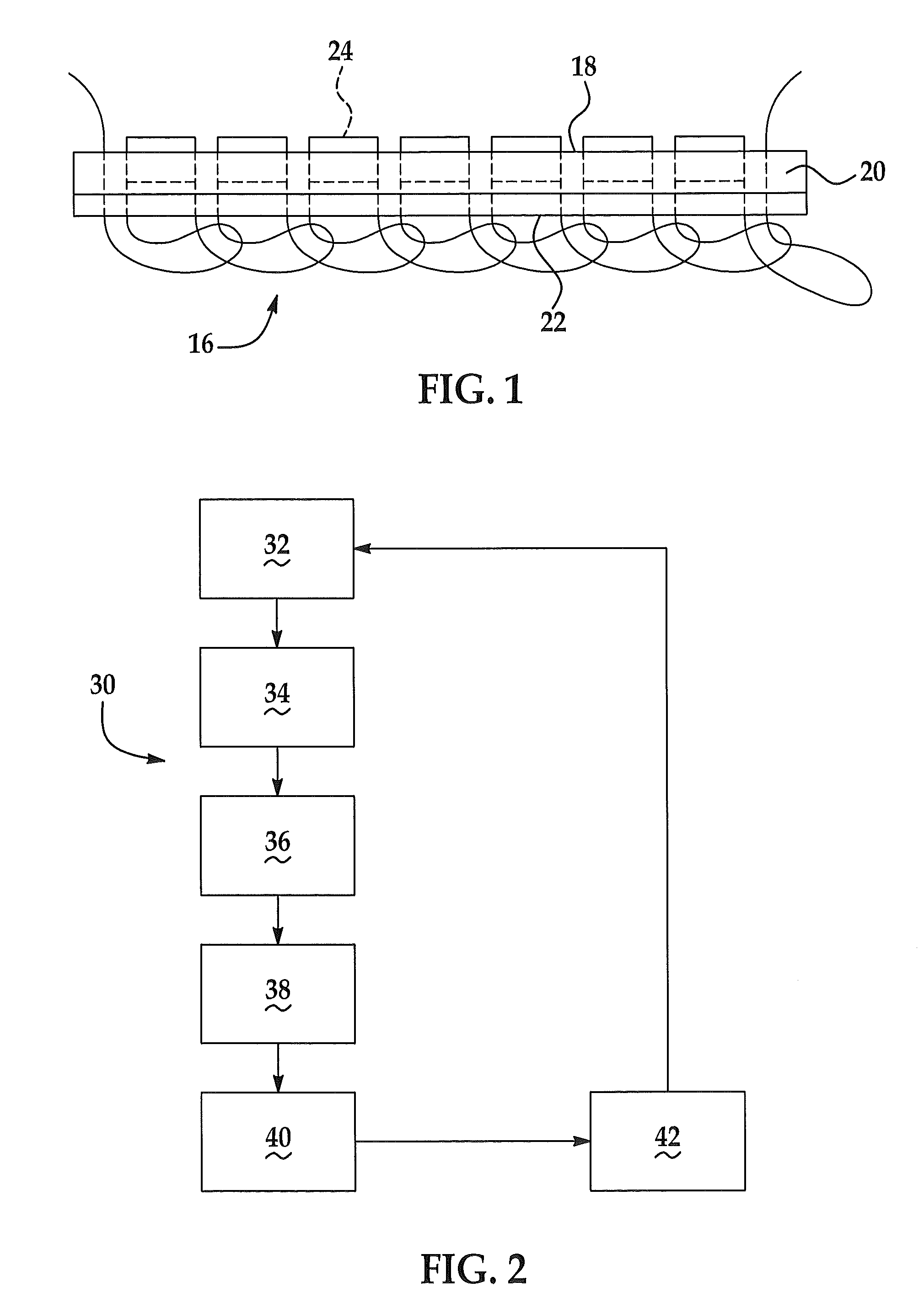

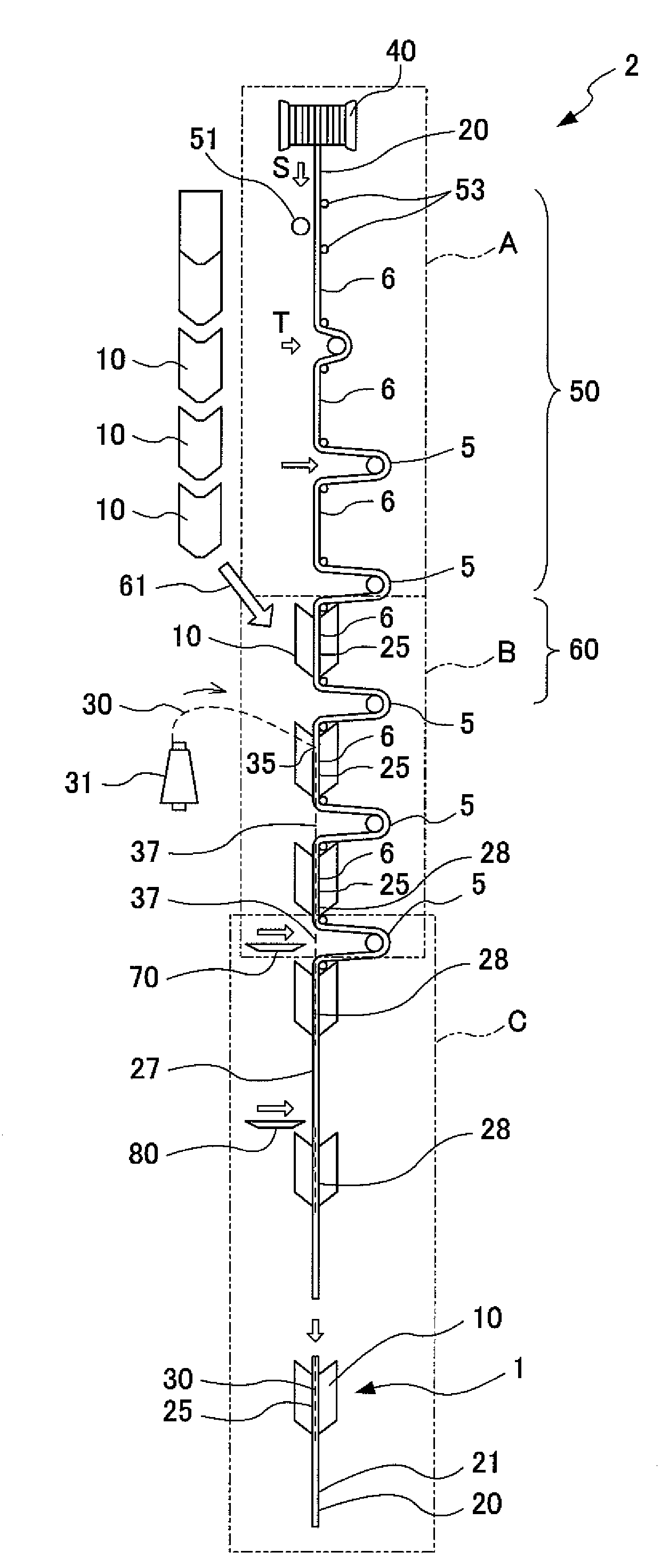

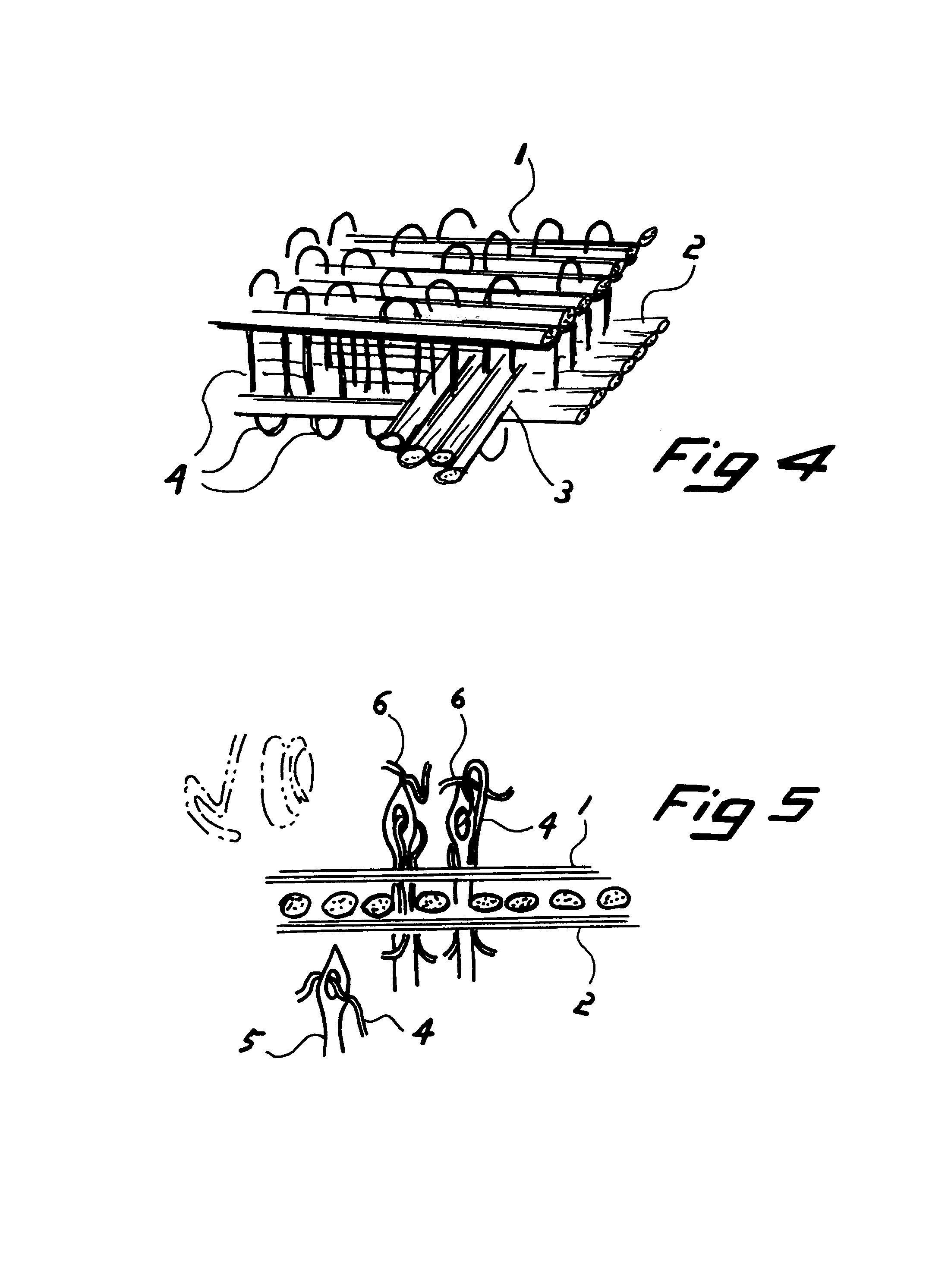

Manufacturing system and manufacturing method for sheet-like structure

An object of the present invention is to provide a manufacturing system and a method for manufacturing sheet-like structures. The manufacturing system of sheet-like structures contains a loosened portion forming apparatus by which plural loosened portions, which are substantially U-shaped, are formed on a cord member, and plural linear portions, which connect each of the plural loosened portions, are formed substantially linearly; and a sewing apparatus by which each of the plural absorbing members and each of the plural linear portions are sewn with a thread member.

Owner:UNI CHARM CORP

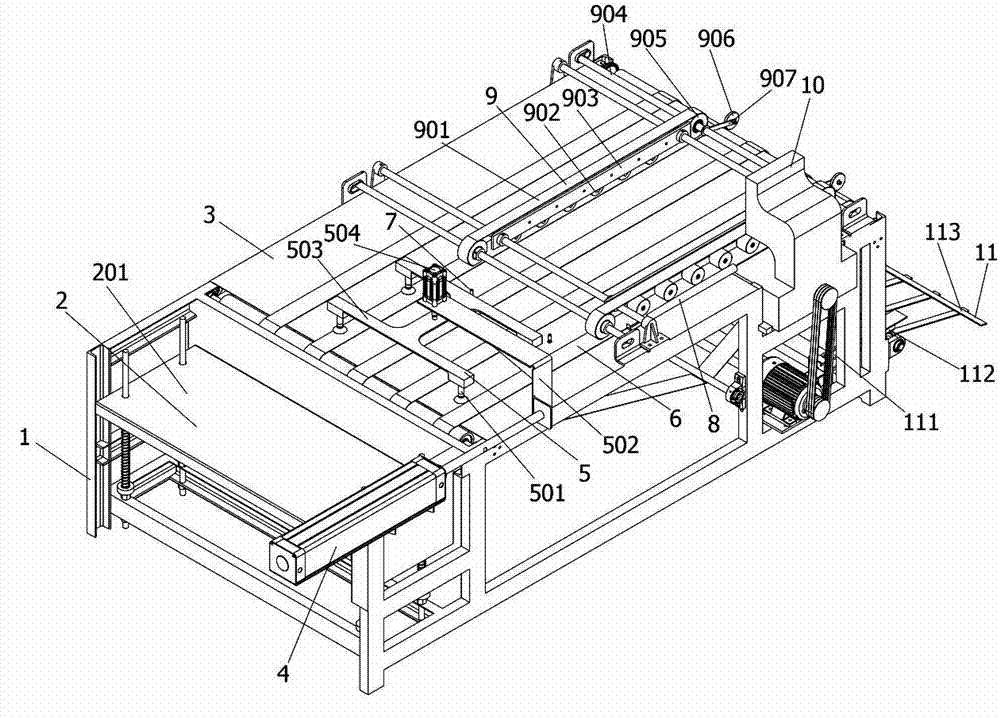

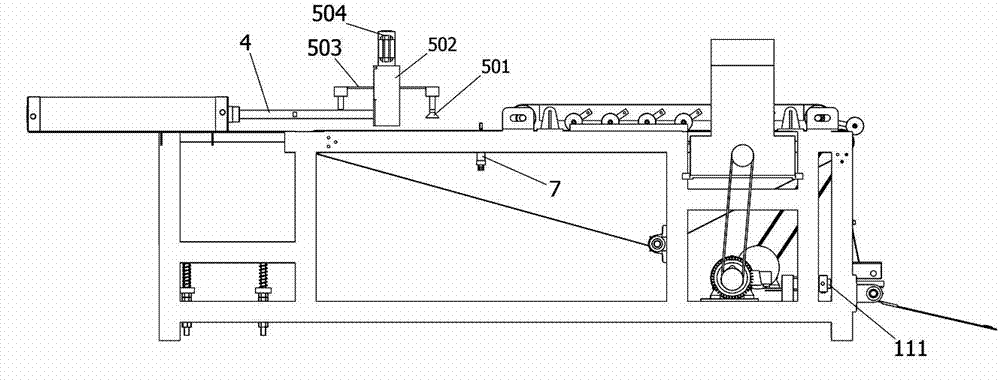

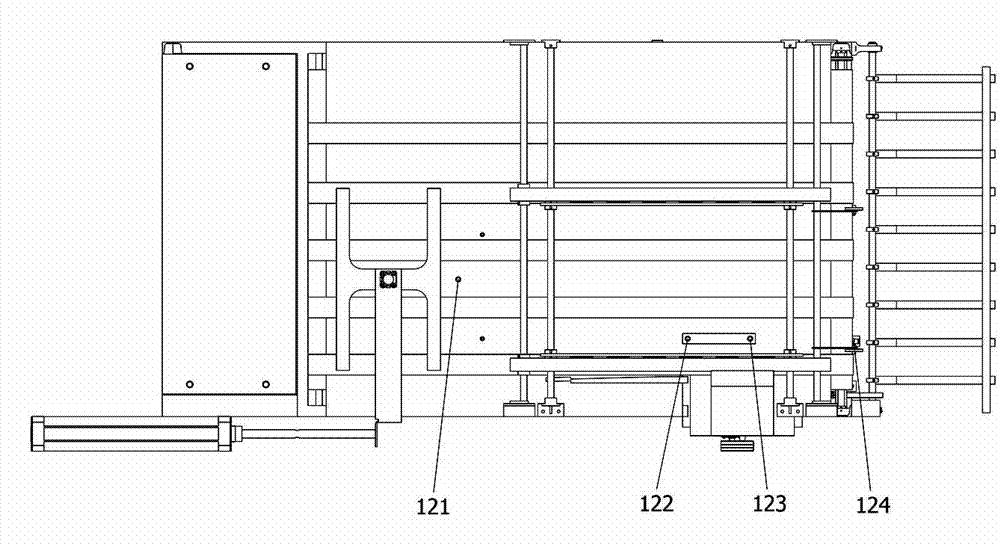

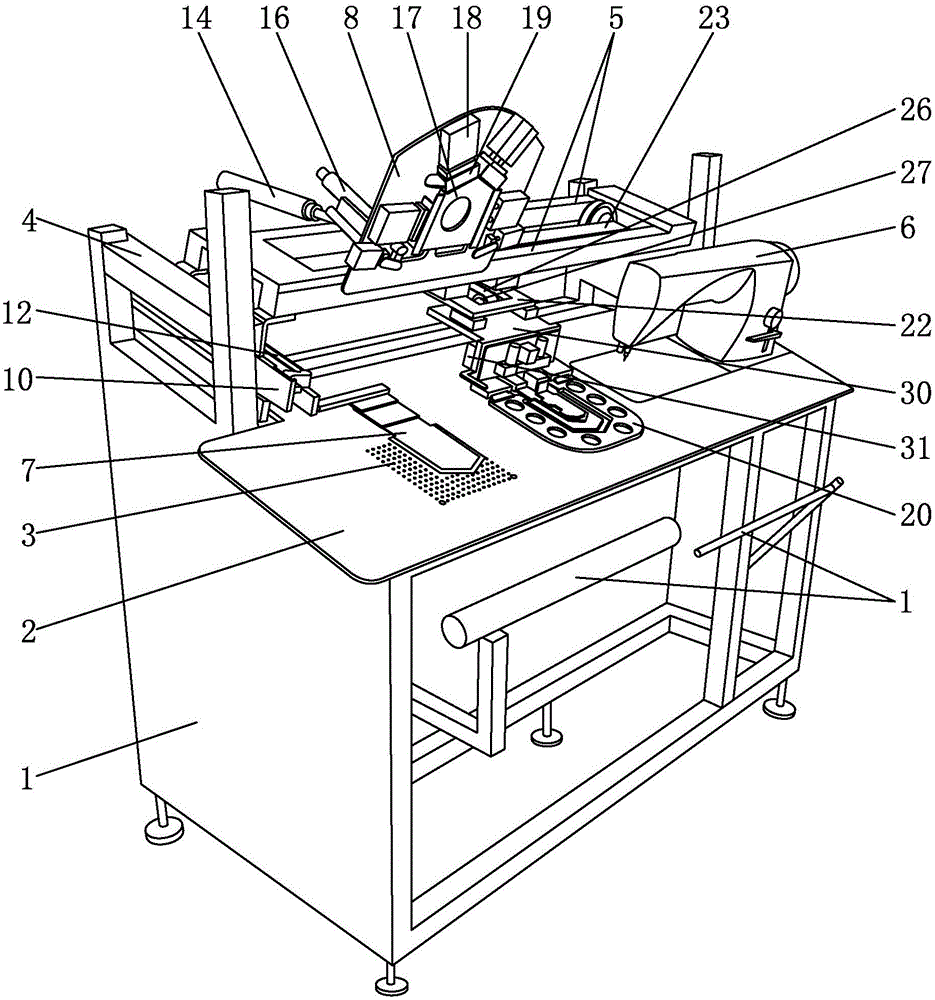

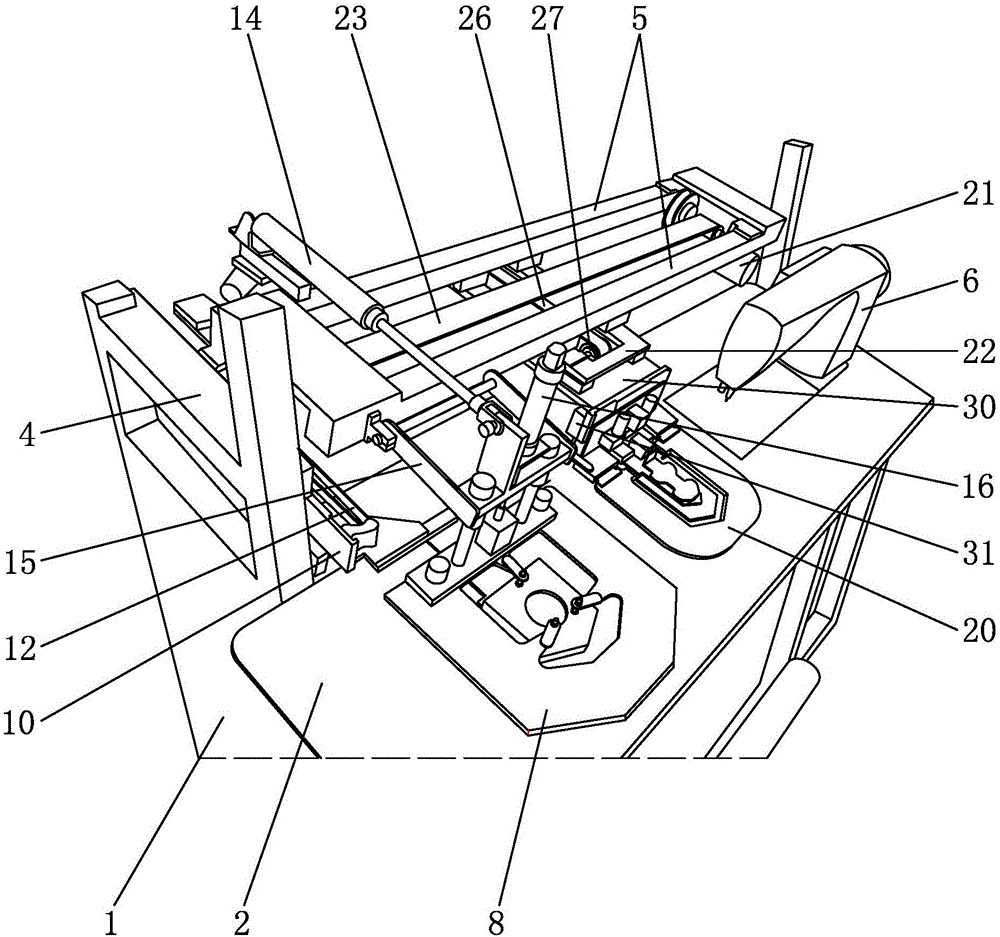

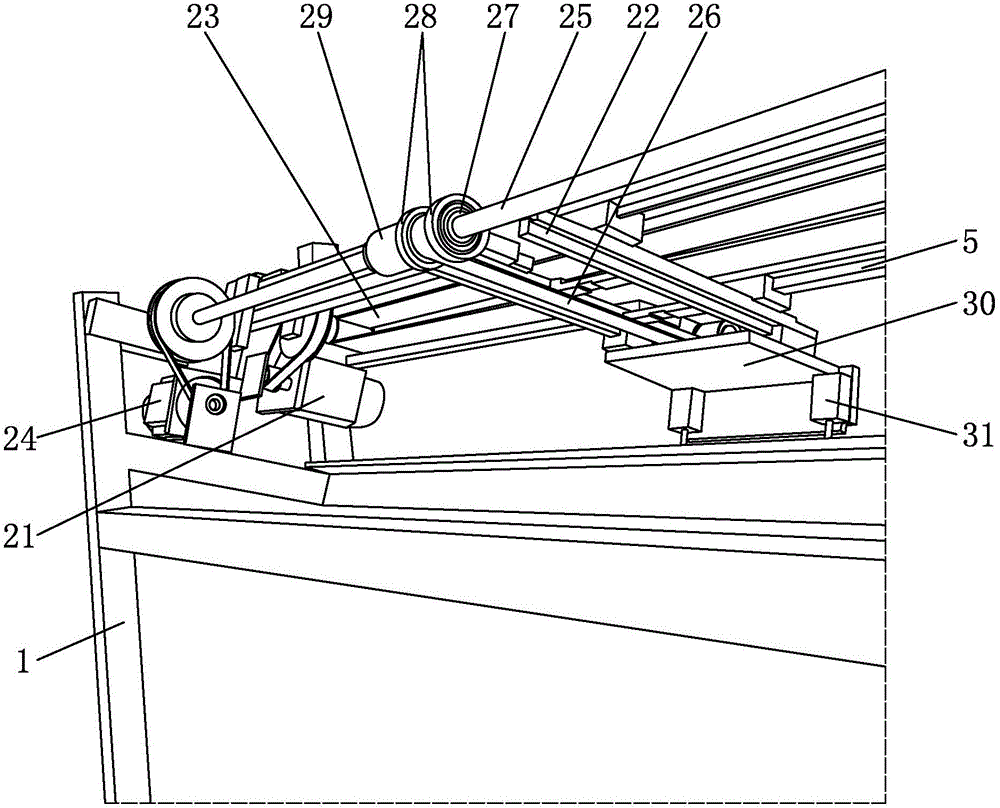

Automatic bag sewing machine

InactiveCN103882629AReduce labor costsShorten the lengthWork-feeding meansWork-collecting devicesReciprocating motionAutomation

The invention discloses an automatic bag sewing machine which comprises a rack assembly, a conveying assembly, a suction cup feeding assembly and a pressing wheel assembly. The rack assembly is located at the feeding end of the conveying assembly, and woven bags to be sewn are placed on the rack assembly. The suction cup feeding assembly is installed above the conveying assembly and the rack assembly and can reciprocate above the conveying assembly and the rack assembly so that the woven bags to be sewn can be moved from the rack assembly onto the conveying assembly. The pressing wheel assembly is installed on the conveying assembly so that the woven bags moving on the conveying assembly can be tightly attached to the conveying assembly to be flattened. A hemmer and a sewing machine body are installed on at least one side of the conveying assembly. The automatic bag sewing machine has the advantages of being simple and compact in structure, high in automation degree, good in consistency of sewn products, capable of reducing the labor cost and the like.

Owner:重庆市巨恒塑料有限公司

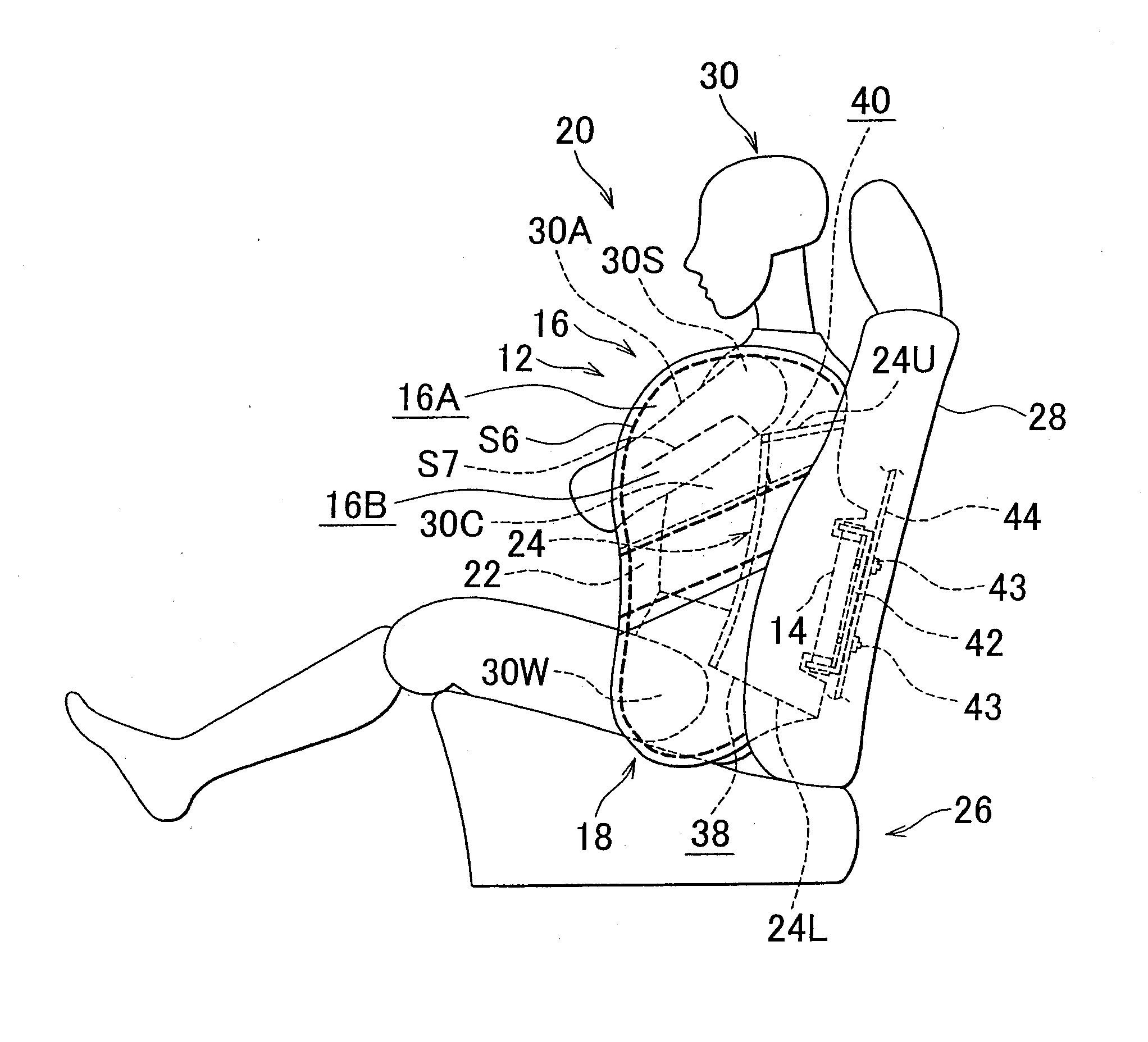

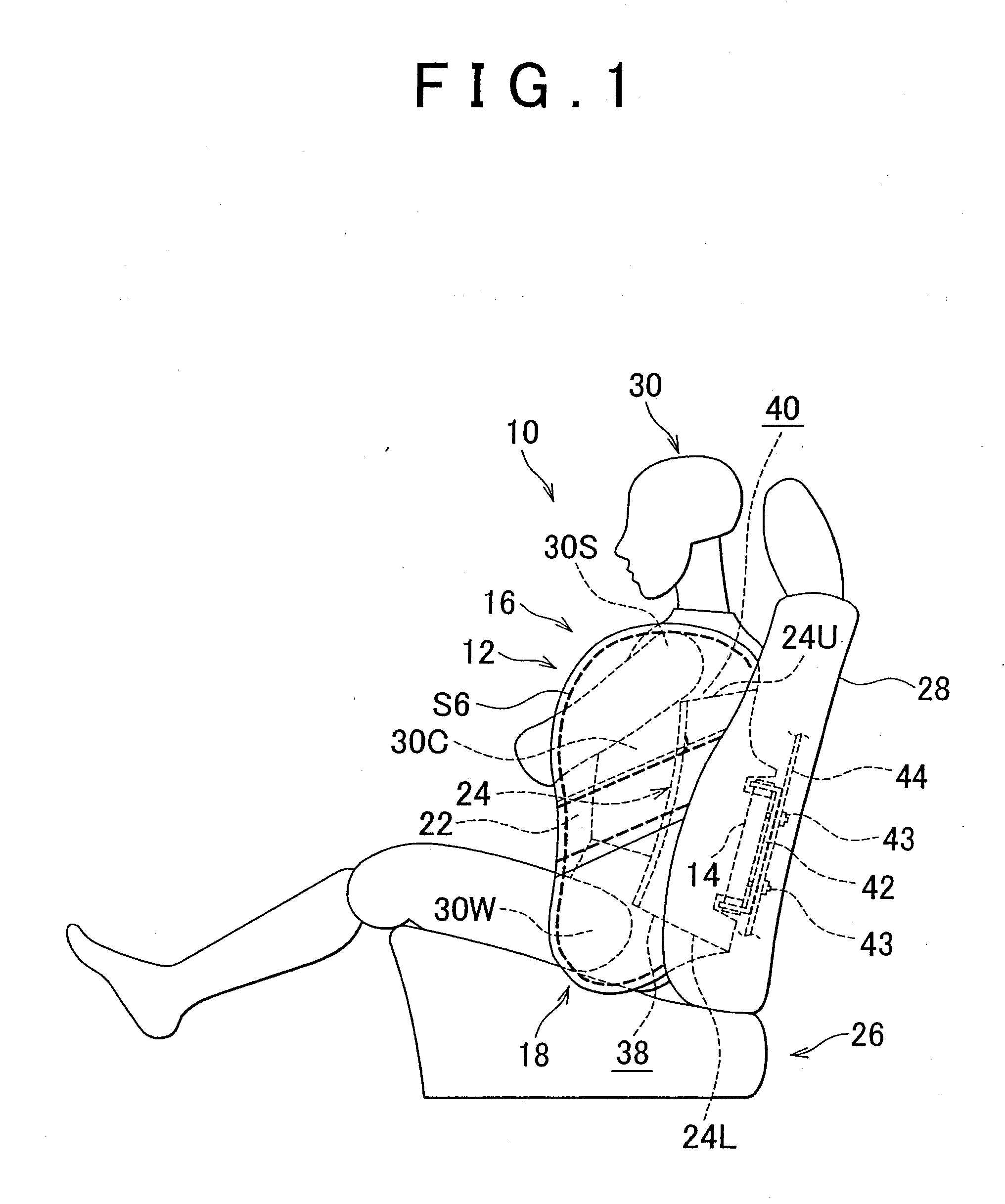

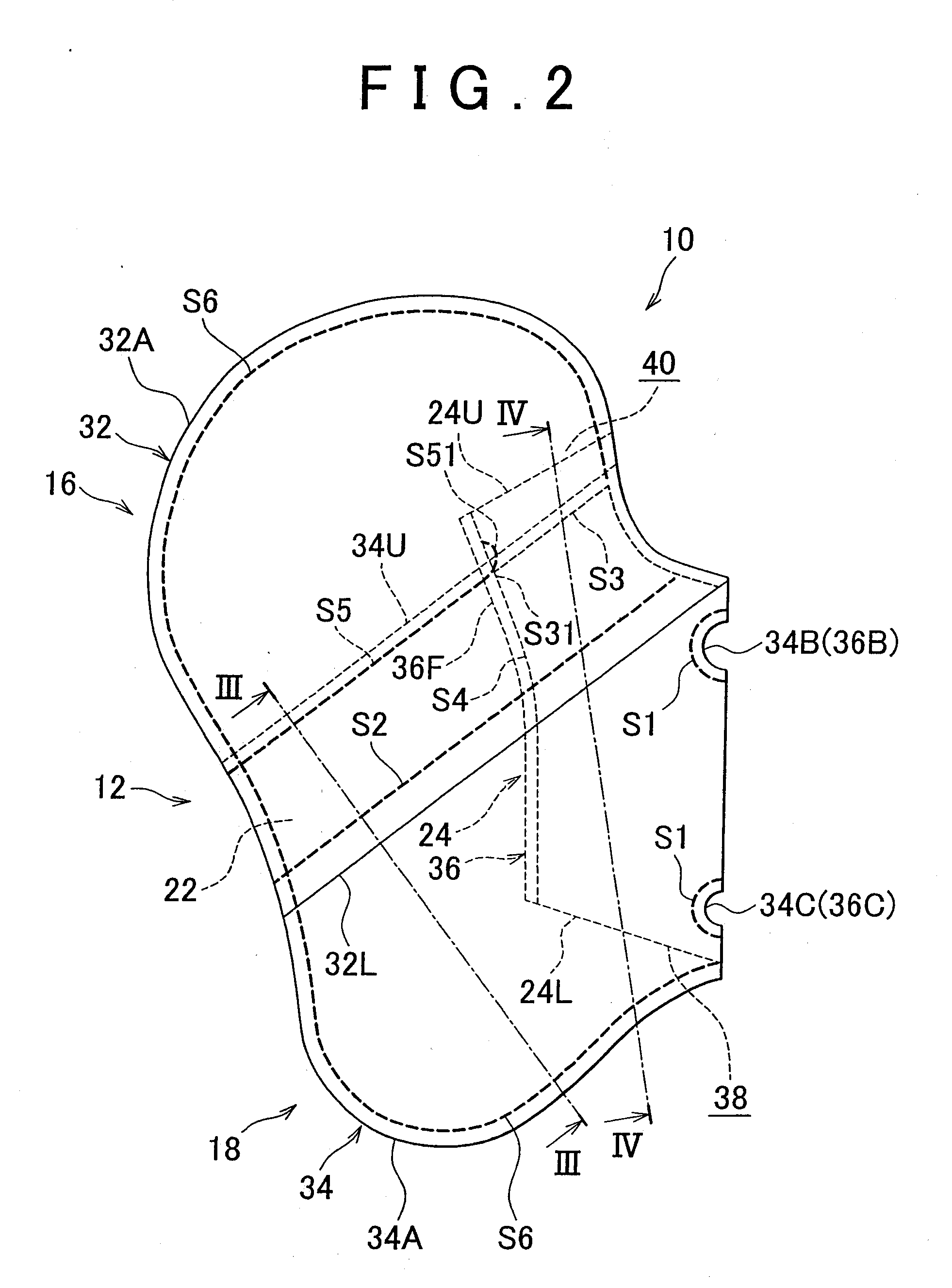

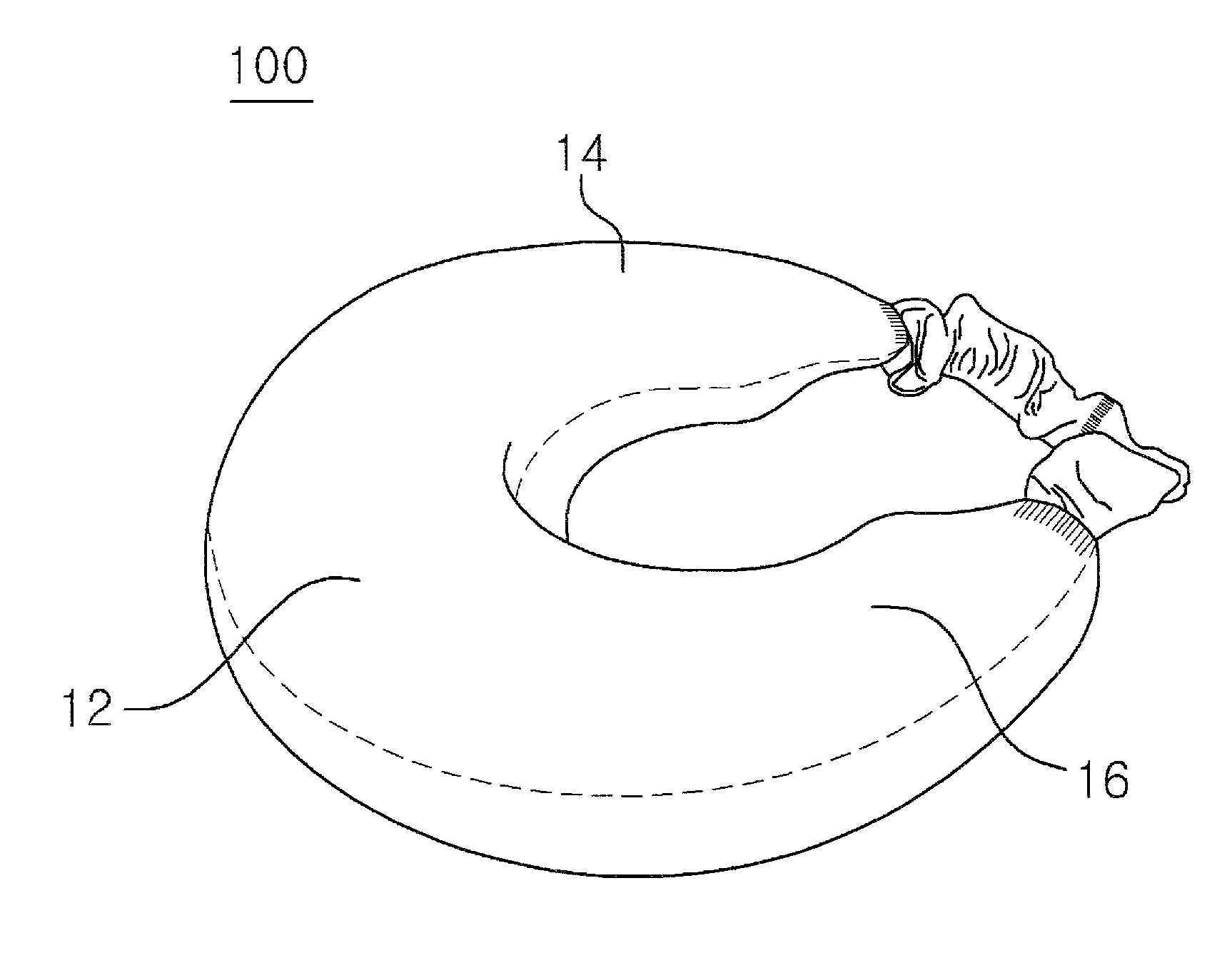

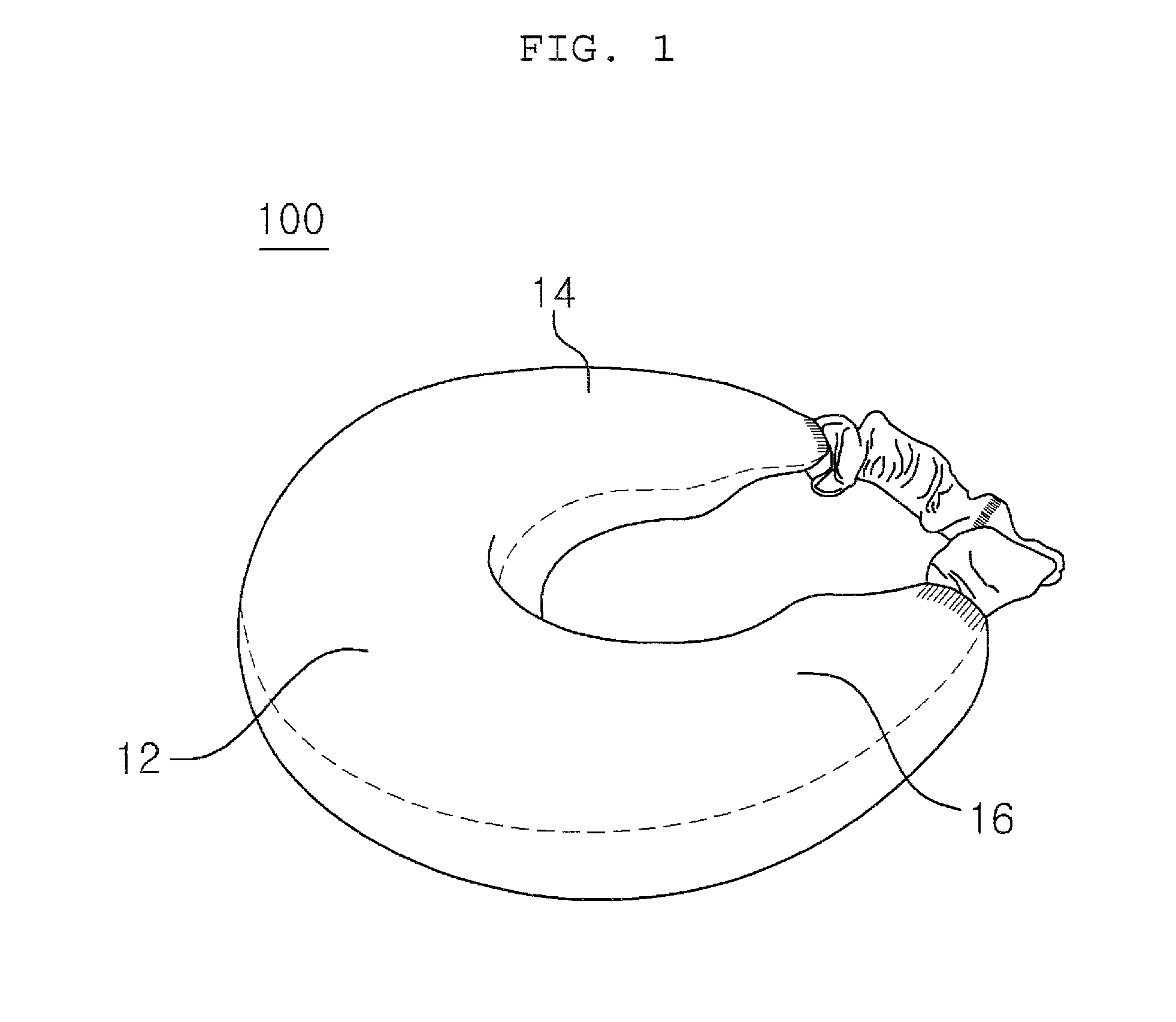

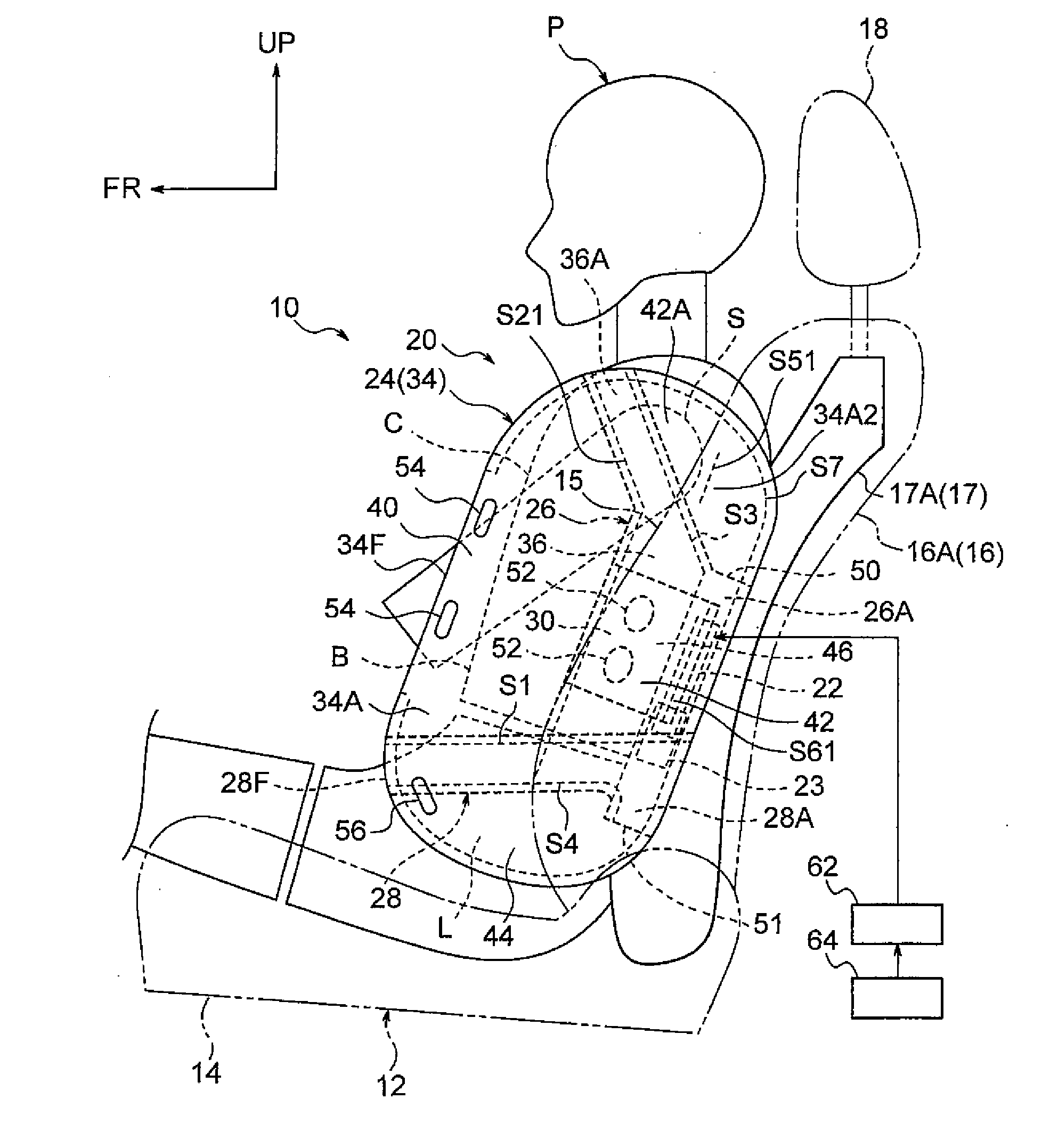

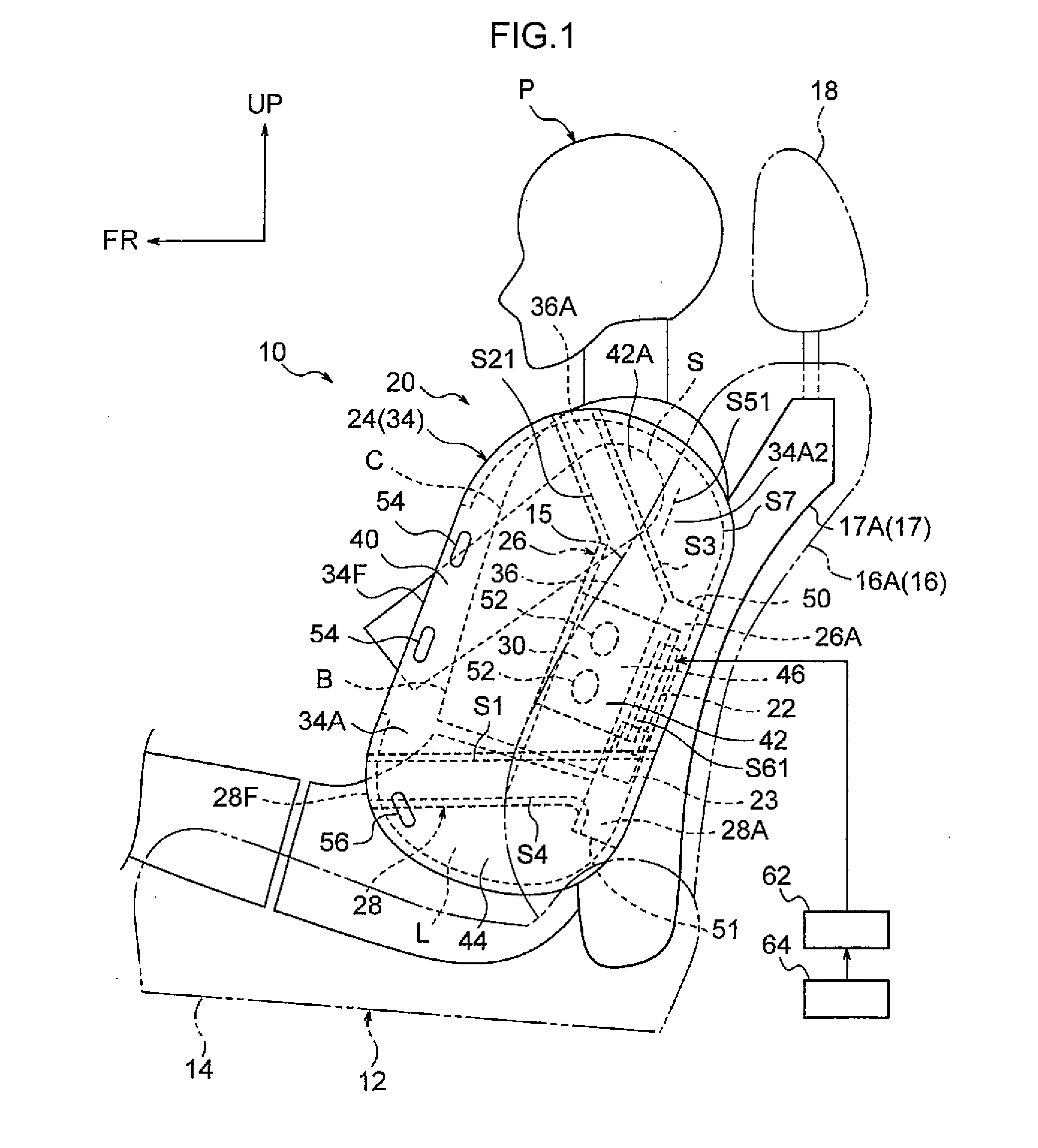

Side airbag system and method of manufacturing side airbag

In a side airbag system (10), a tether portion (22), which serves as a partition between an upper bag portion (16) and a lower bag portion (18), is formed of upper regions (34U) of a piece of lower base fabric (34), and is formed by sewing the upper regions (34U) of the lower base fabric (34), folded toward a vehicle front side along a fold axis, together. In addition, a tube (24) that distributes inflation gas between the upper bag portion (16) and the lower bag portion (18) extends through the tether portion (22) to the lower bag portion (18) and to the upper bag portion (16). The tube (24) is formed into a cylindrical shape in such a manner that a piece of tube base fabric (36) is sewed to the upper regions (34U) of the lower base fabric (34) and folded toward a vehicle front side along the fold axis and then front ends (36F) of the folded tube base fabric are sewed together in a tube longitudinal direction.

Owner:TOYOTA JIDOSHA KK

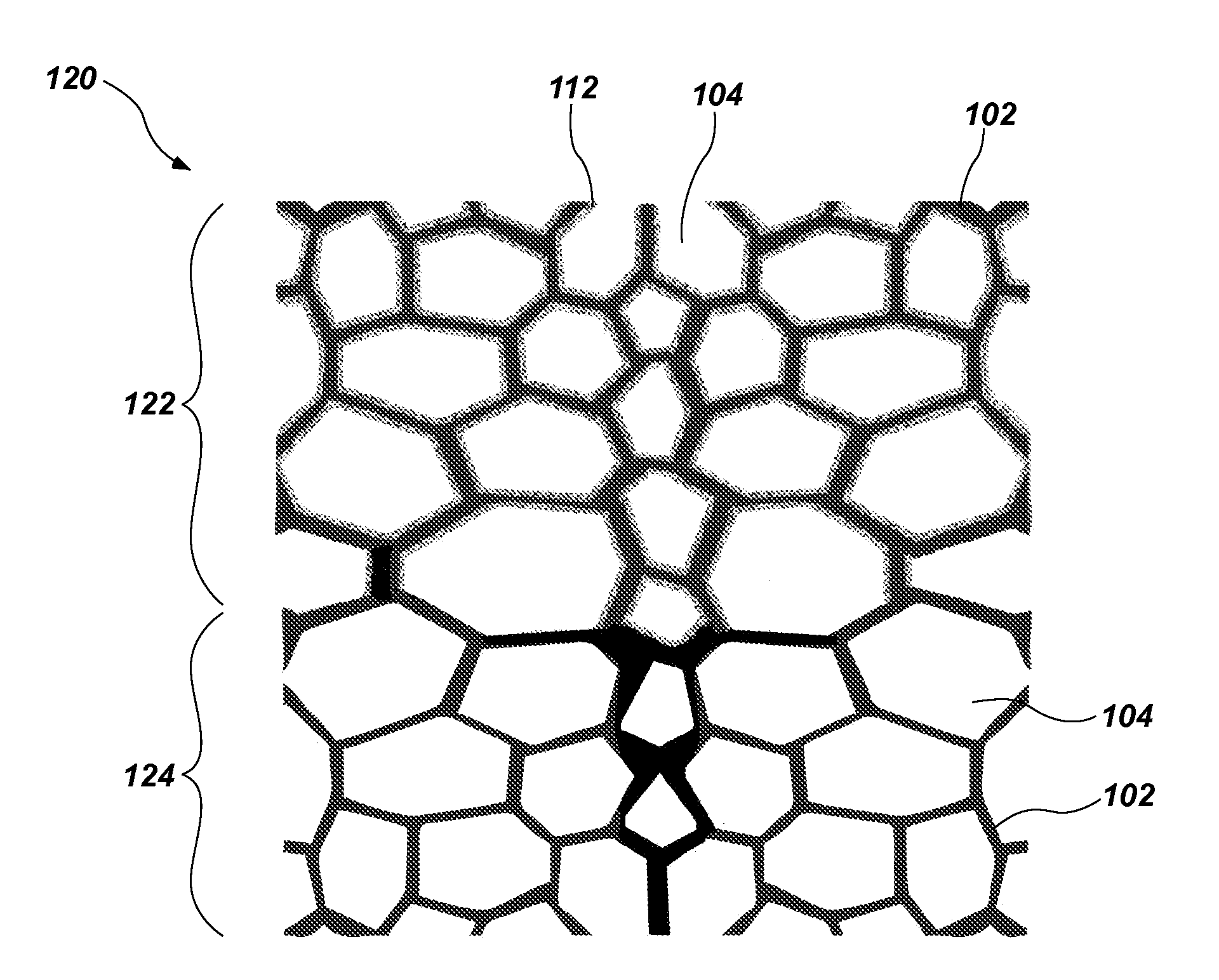

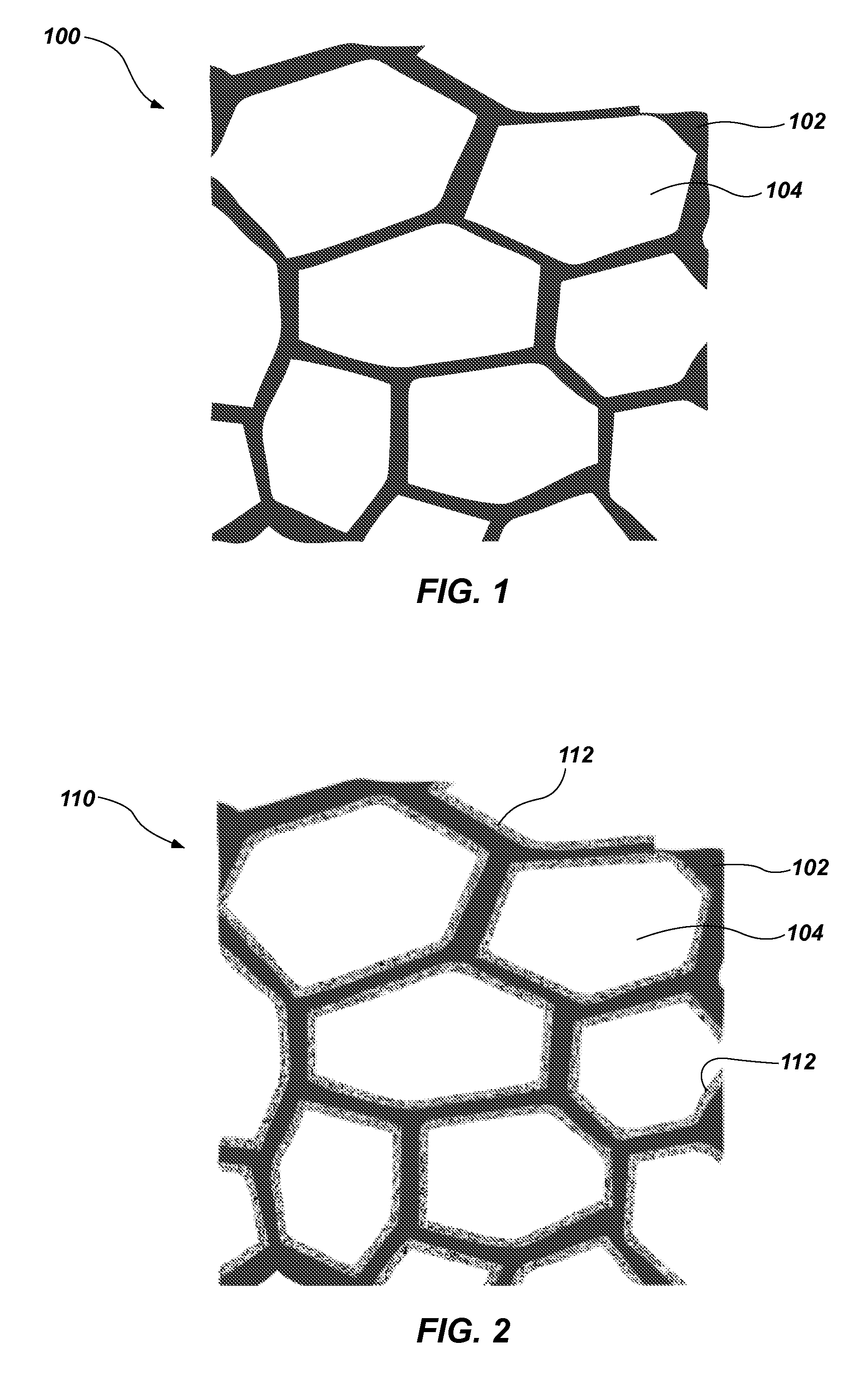

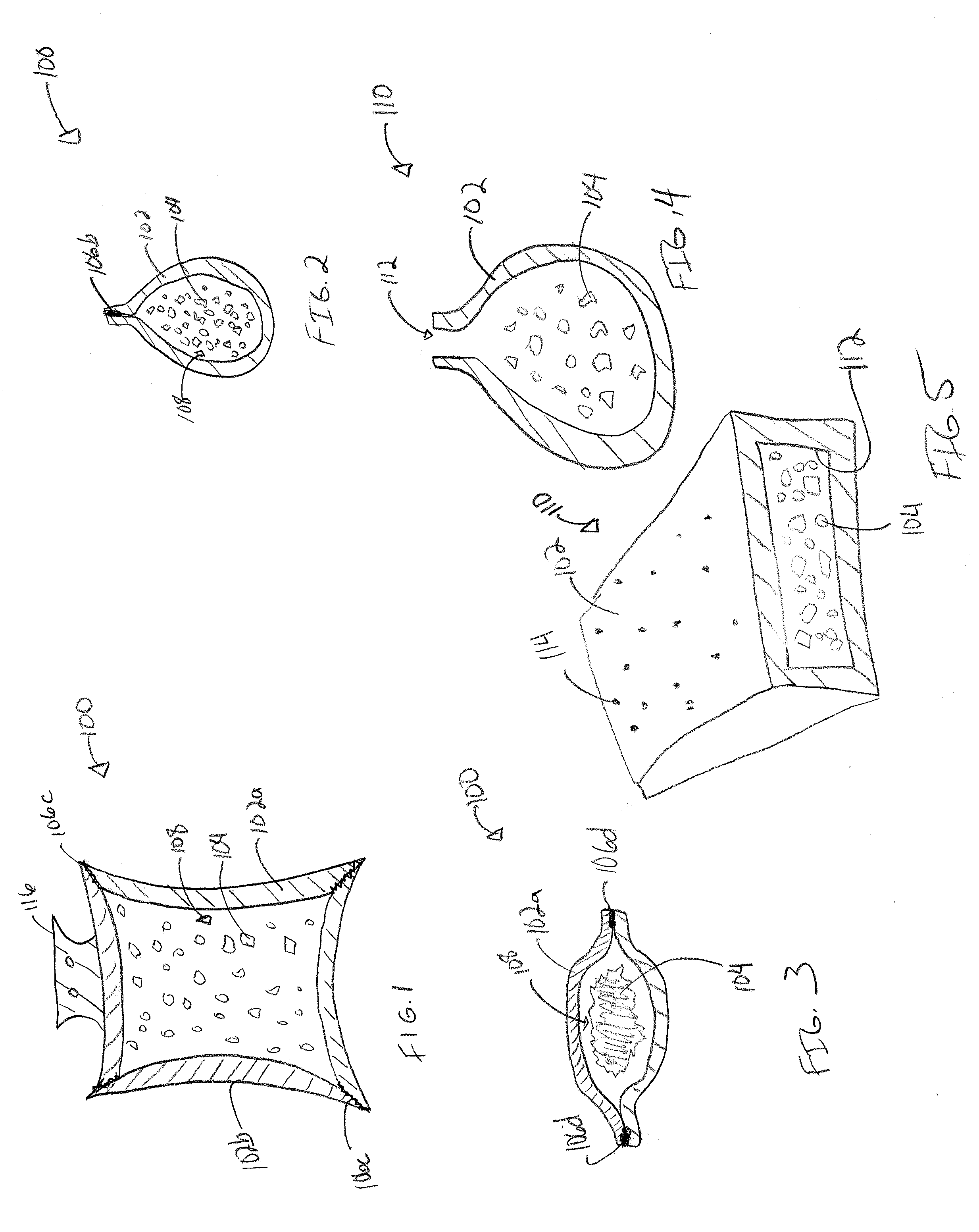

Cushioning elements comprising elastomeric material and methods of forming same

Cushioning elements include a porous foam comprising a series of interconnected cell walls and an elastomeric material formed over at least a portion of the interconnected cell walls. The porous foam is configured to allow gases to pass through at least a portion thereof. Methods of forming cushioning elements may include coating interconnected cell walls of a breathable porous foam with a liquid comprising an elastomeric material, solidifying at least a portion of the elastomeric material, and providing a gas path through the elastomeric material. Other methods include pressing sheets of foam together at a pinch point, disposing a liquid between the foam over the pinch point, coating the foam with the liquid, and separating the sheets beyond the pinch point. Some methods include consolidating a plurality of portions of porous foam into a continuous cushioning material.

Owner:PURPLE INNOVATION LLC

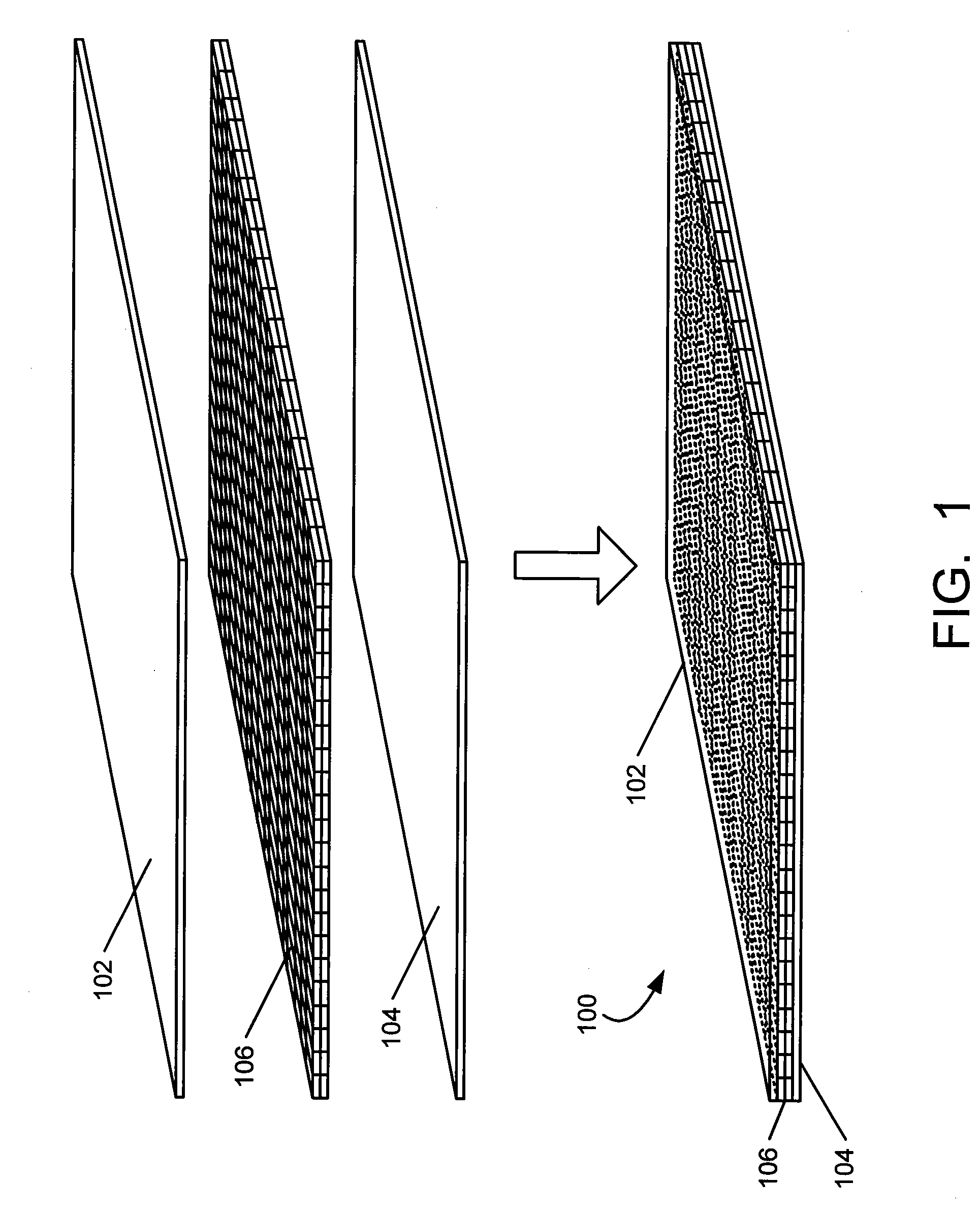

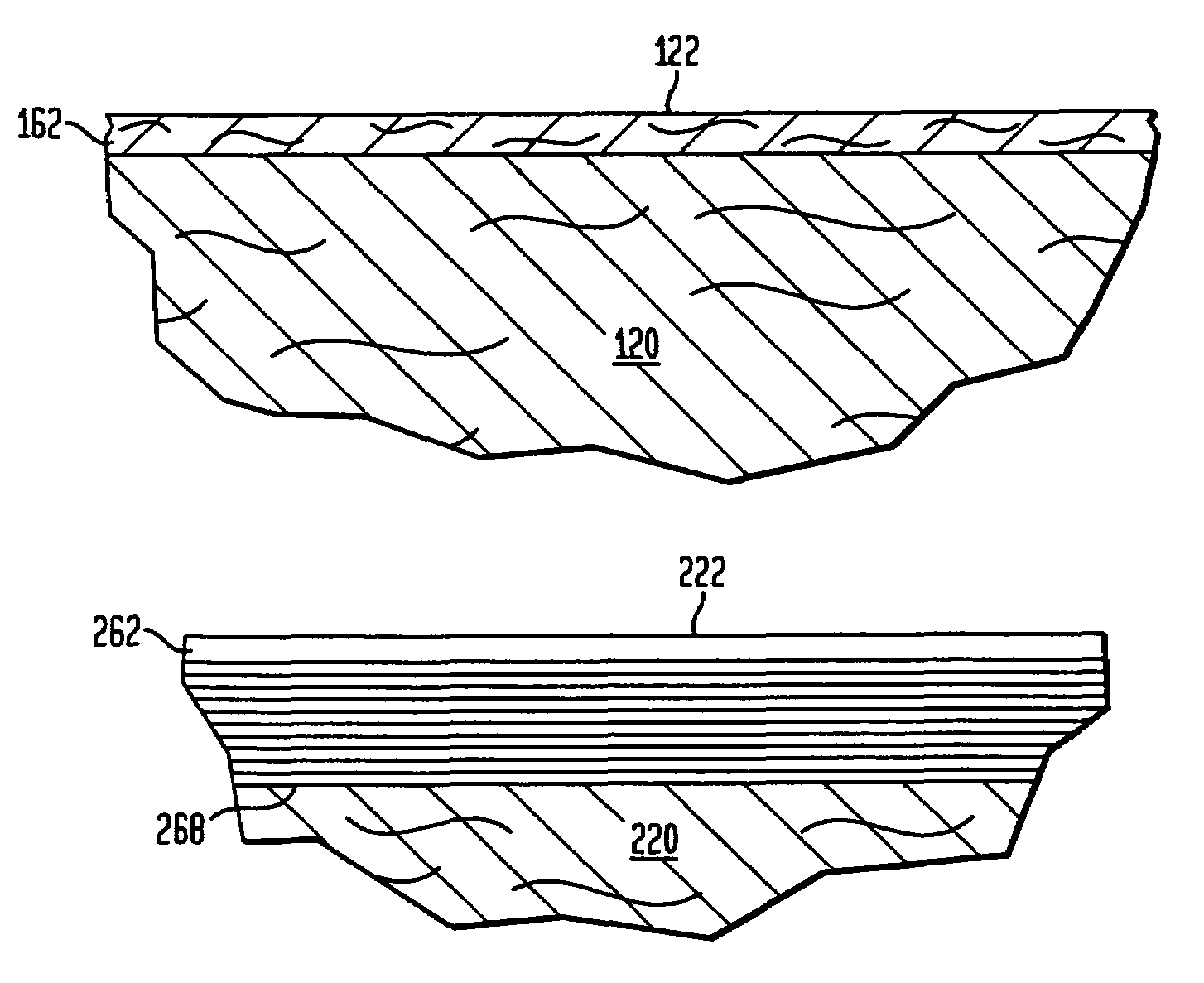

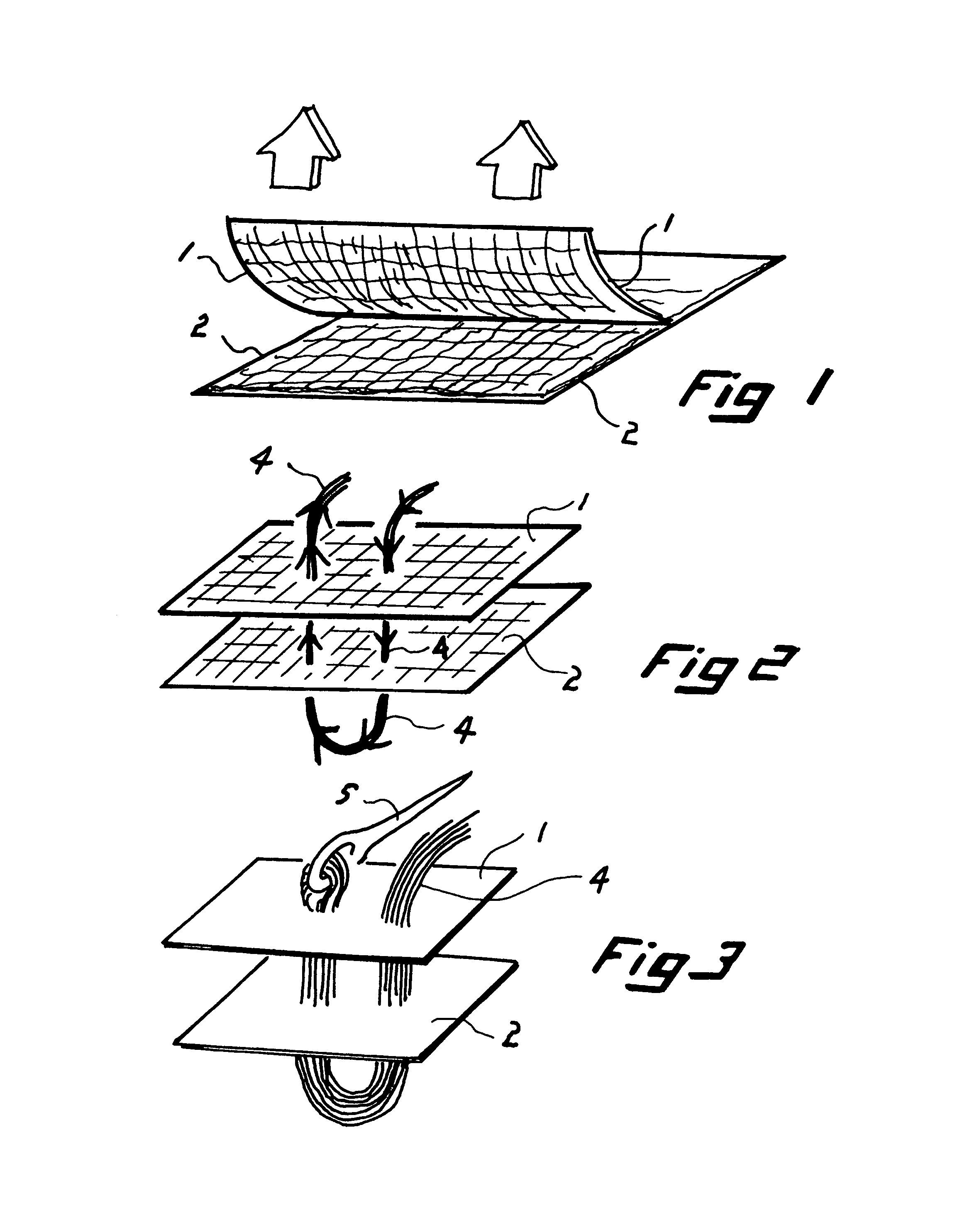

Inter/pre-cured layer/pre-cured embroidered composite laminate and method of producing same

InactiveUS8312827B1High strengthHigh peel strengthLeather sewingLayered productsMaterial typeFiber bundle

Methods of pre-cured (wet-out) composite lay up, are improved upon by embroidering, sewing, stitching, bundle-wrapping, tying, etc., substantially between layers and substantially normal, or in the “Z-direction” to the lay up with a wet or pre-cured fiber bundle or tow. The pre-cured tow is embroidered, etc. either in with a like, homogeneous wet to wet layering or a heterogeneous non-similar layering, between double or multiple layers. Heterogeneous examples include differing material types among layers, laying and embroidering in objects or voids, as well as wet-laminating / sewing in with an already-dry (set / cured) layer.

Owner:FREE JAMES J

Weighted blanket

A weighted blanket includes an inner liner that is filled with weighted filler material and closed to limit movement of the weighted material within the inner liner. In some embodiments, the inner liner is securely sewn within an outer liner to prevent movement of the inner liner within the outer liner, thereby preventing the inner liner from becoming detached from the outer liner.

Owner:PARKER EILEEN LINDA

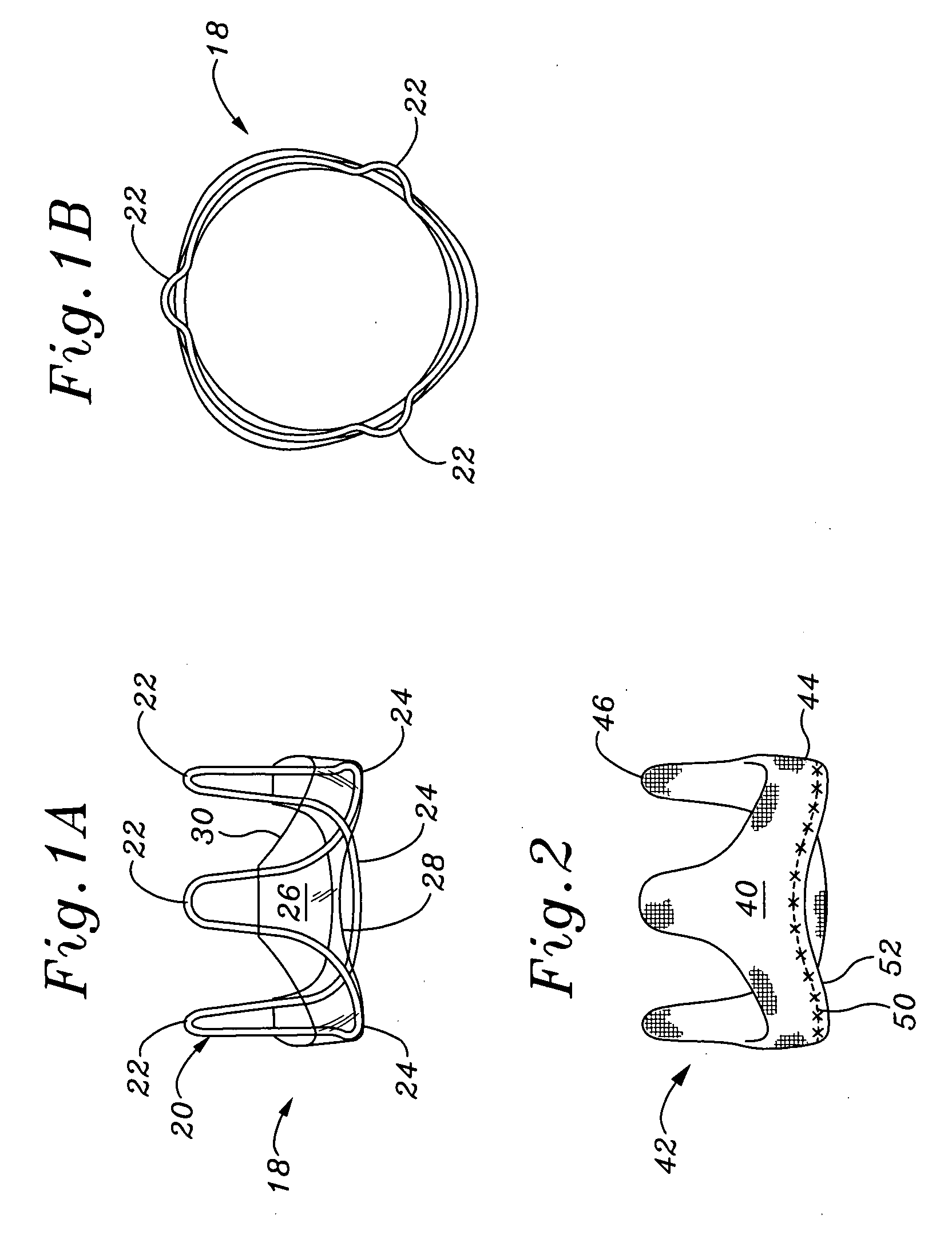

Systems and methods for assembling components of a fabric-covered prosthetic heart valve

Owner:EDWARDS LIFESCIENCES CORP

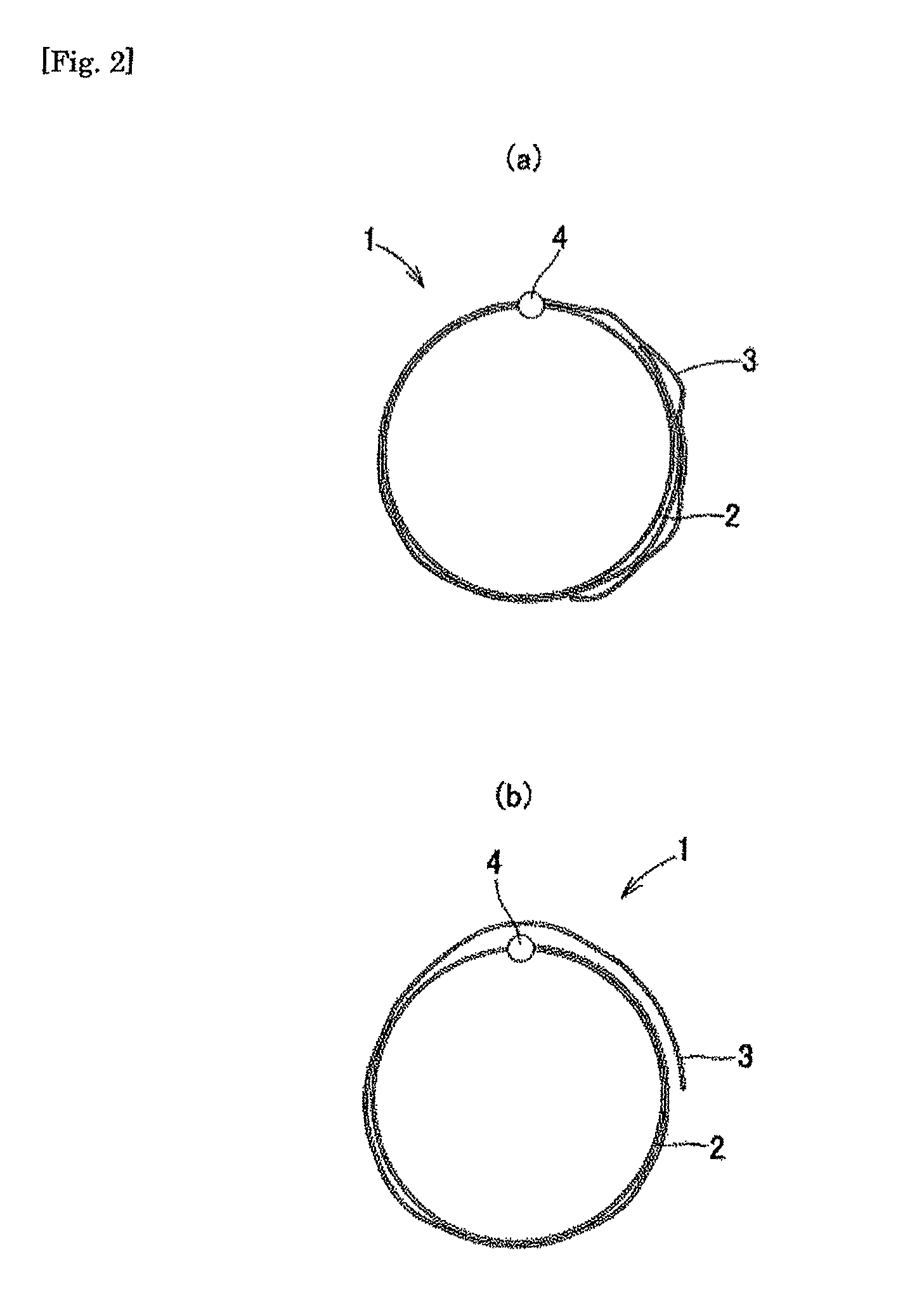

Medical device for body cavity and method of producing the same

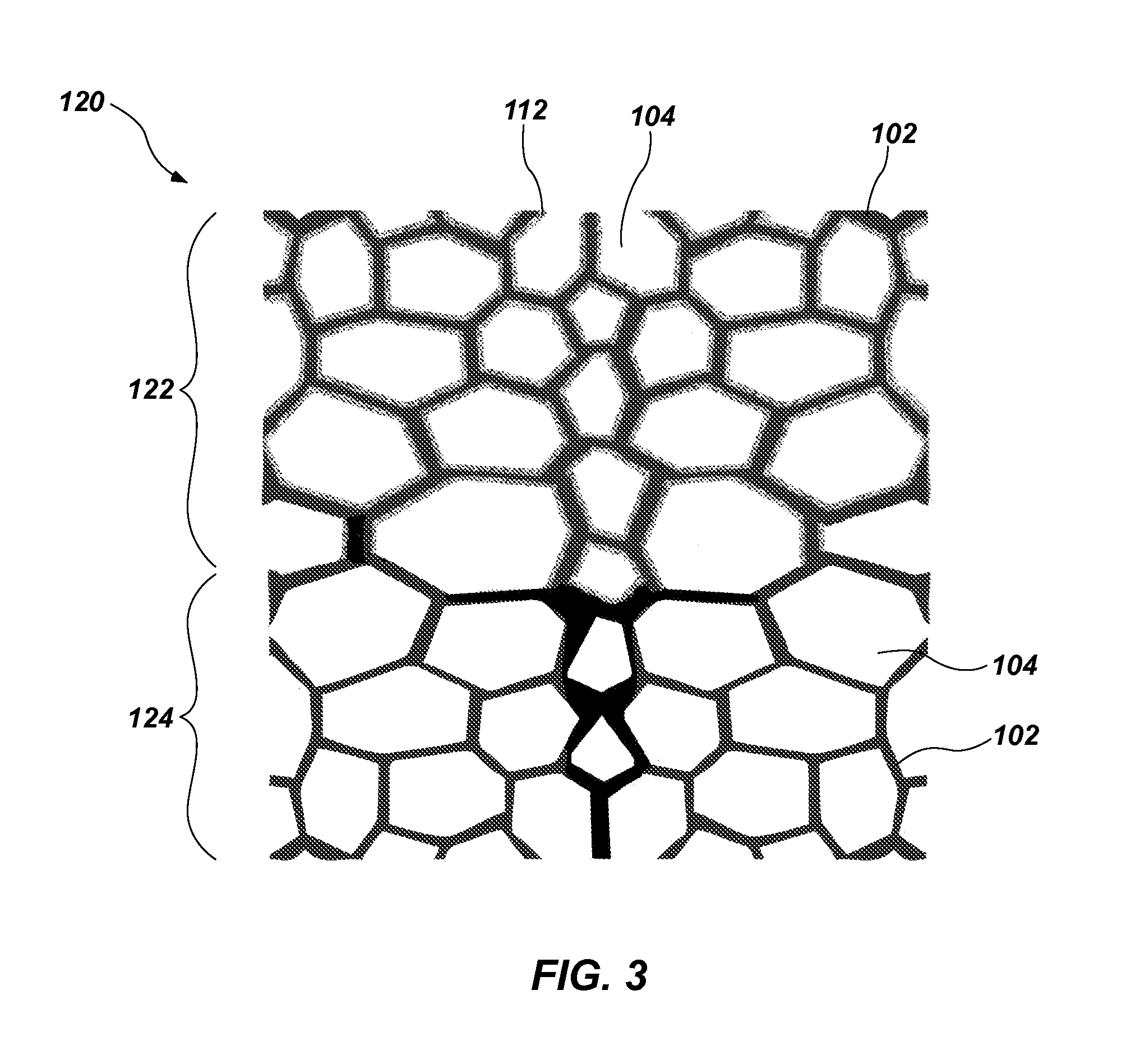

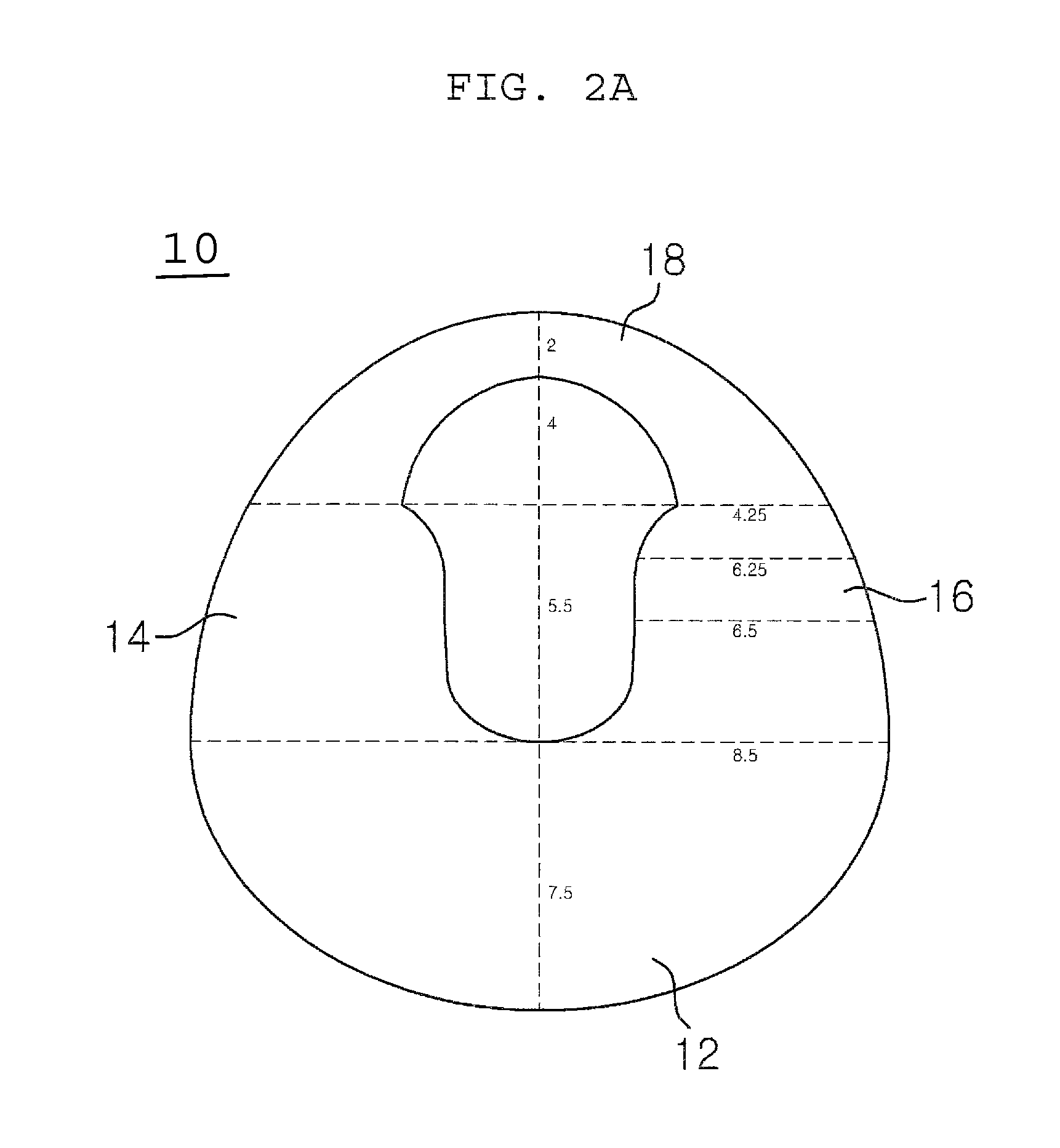

InactiveUS20090326640A1Decreased blood flowFlow assuranceStentsLeather sewingMedical deviceDelivery system

A medical device for body cavity which has a main stent body and a sheet-shaped member having an opening and covering at least a part of the main stent body as described above. It is desirable that, when the main stent body is dilated from the first diameter in the compressed state to the second diameter, the above-described sheet-shaped member spreads so as to cover at least a part of the main stent body without restricting the movement of the main stent body toward the circumferential direction while the shape of the opening of the above-described sheet-shaped member is retained even after the dilation of the main stent body. The above-described medical device for body cavity is applied to a delivery system which has a first catheter for transporting the medical device for body cavity into the body. In this delivery system, the above-described medical device for body cavity is located at the front end of the first catheter as described above so as to allow indwelling thereof.

Owner:GIFU UNIVERSITY +1

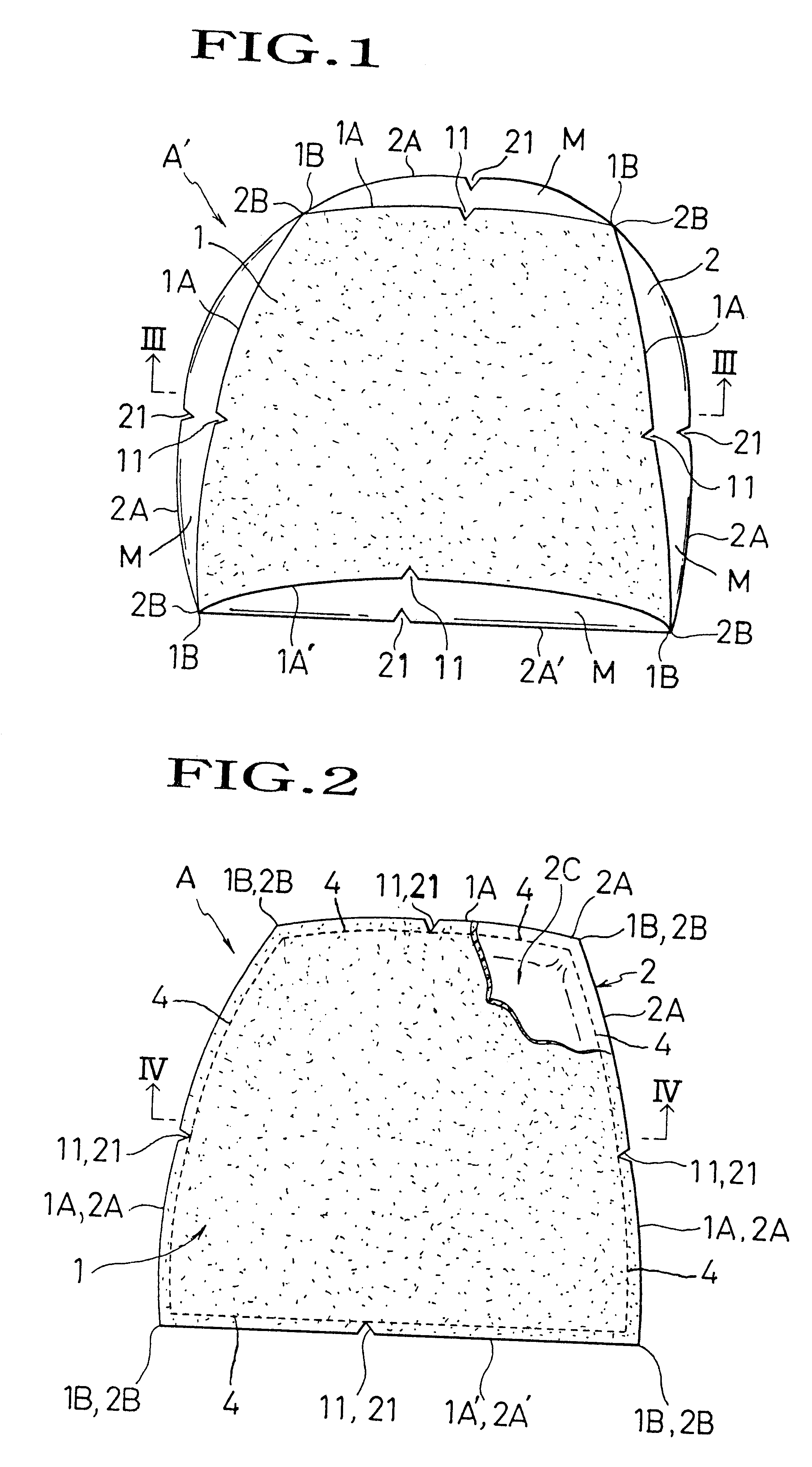

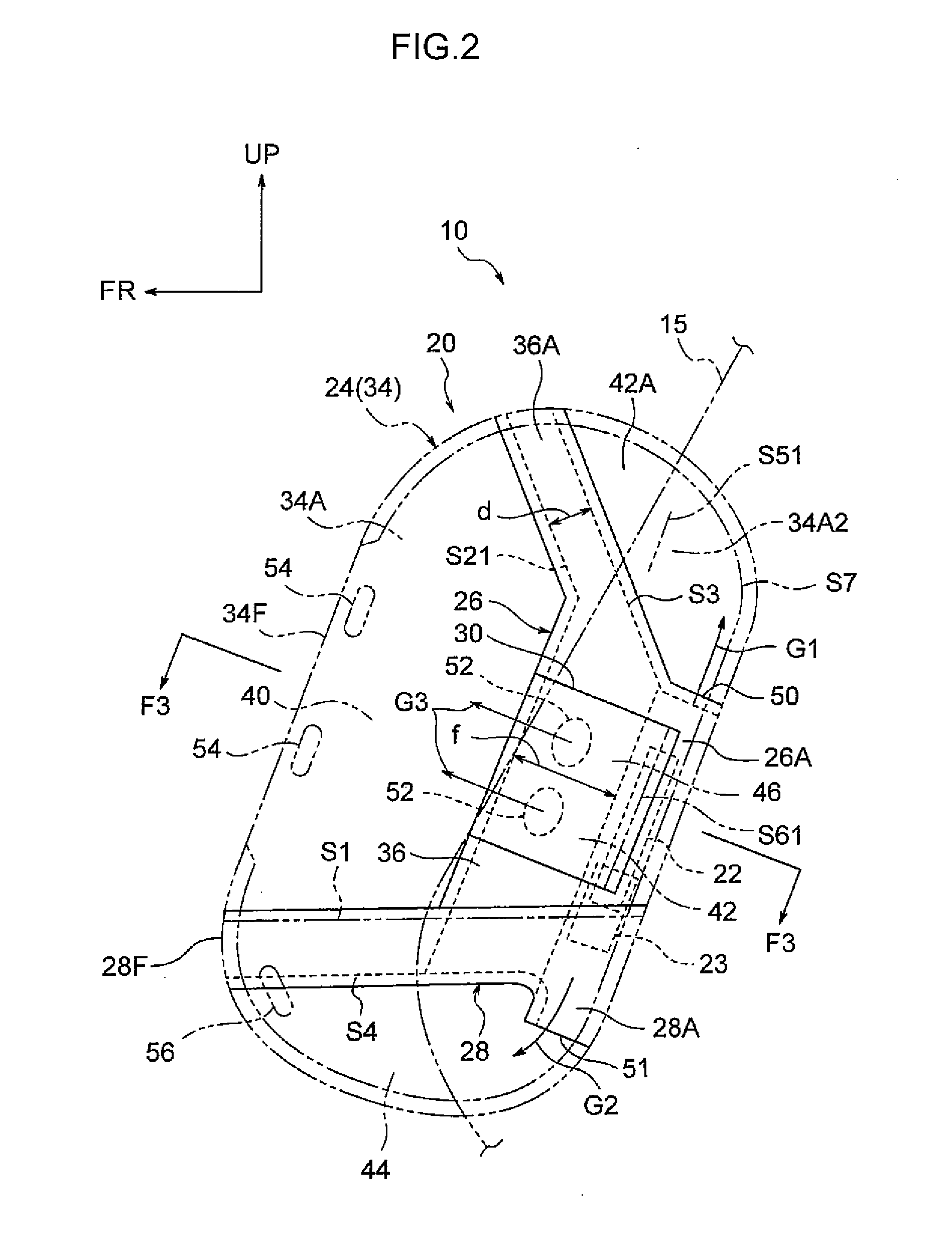

Method for forming a foamed product integral with trim cover assembly

InactiveUS6505570B1Effective stretchingAvoid creatingVehicle seatsLeather sewingEngineeringSurface cover

Method for forming a foamed product integral with trim cover assembly, in which a foam padding piece and a surface cover piece are formed such that the former is small in size relative to the latter. According to the method, the peripheral ends of the foam padding piece are aligned and sewn with the peripheral ends of the surface cover piece to form a cover section. A plurality of such cover sections are provided and are bent at their respective end portions, stretching each surface cover piece on and over each foam padding piece, after which, the thus-bend end portions of cover sections are sewn with one another to form a three-dimensional trim cover assembly. A liquid foaming material is injected and cured in that trim cover assembly to form a foamed product integral with the trim cover assembly.

Owner:TACHI S CO LTD

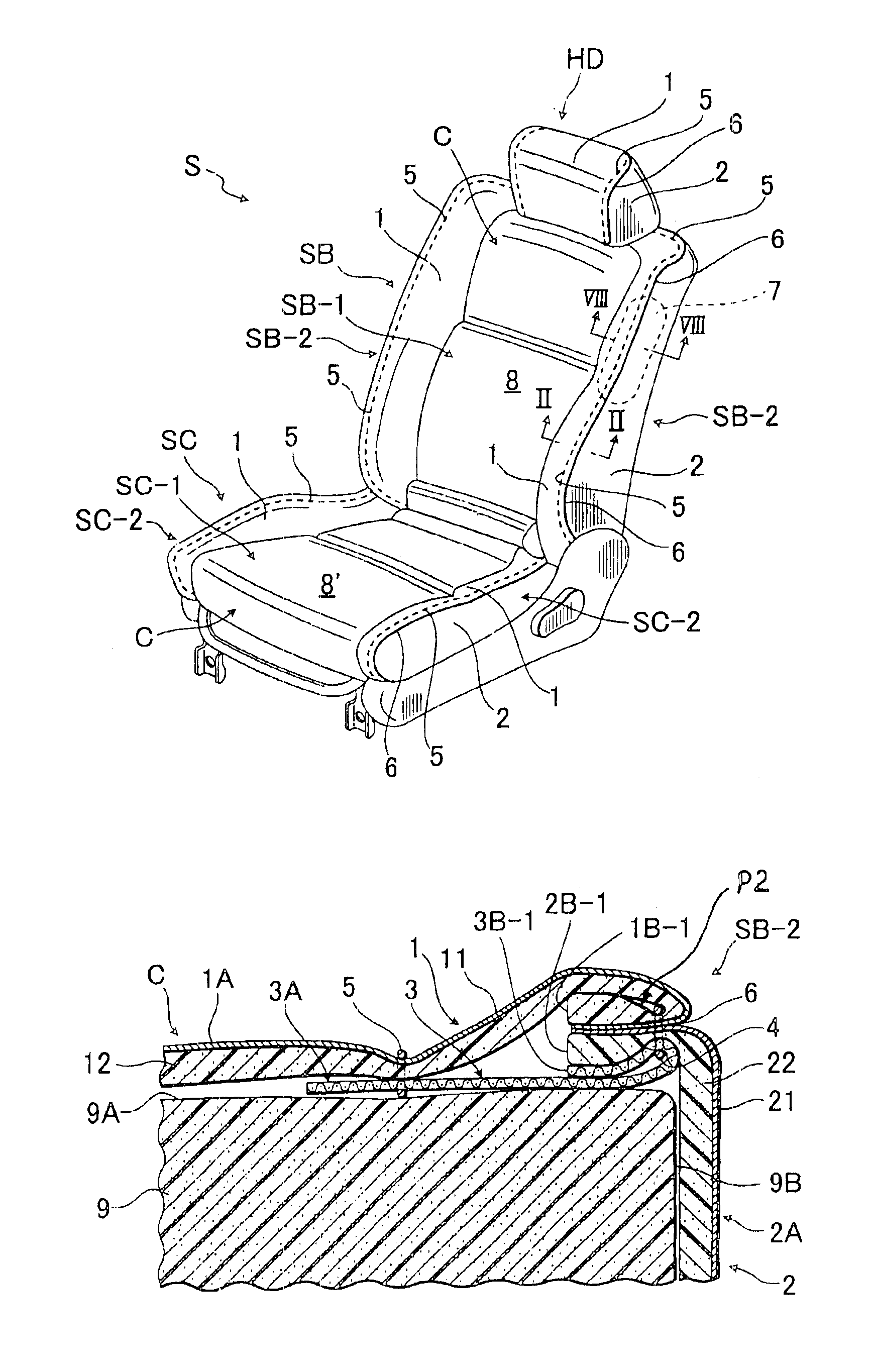

Offset seam sewing process

InactiveUS6997126B2Good lookingReducing knuckling along upholstery seamsSeat coveringsLeather sewingEngineeringLateral offset

A process for joining adjacent panels of plural layered upholstery, including the steps of adjacently positioning first and second panels, each having an offset backing and exterior layers, and substantially aligning longitudinal peripheries of the first and second panels. Stitching the panels together along a first stitching line positioned inboard of the longitudinal peripheries and substantially parallel thereto, and stitching portions of the first and second panels outboard of the first stitching line to an inboard portion of one or more of the panels along at least a second stitching line. In a preferred embodiment, the exterior layer in the first panel is offset laterally relative to the backing layer in an inboard direction, wherein the lateral offset imparts a substantially regular contour to portions of the exterior layer proximate the first stitching line and inboard thereof.

Owner:IRVIN AUTOMOTIVE PROD LLC

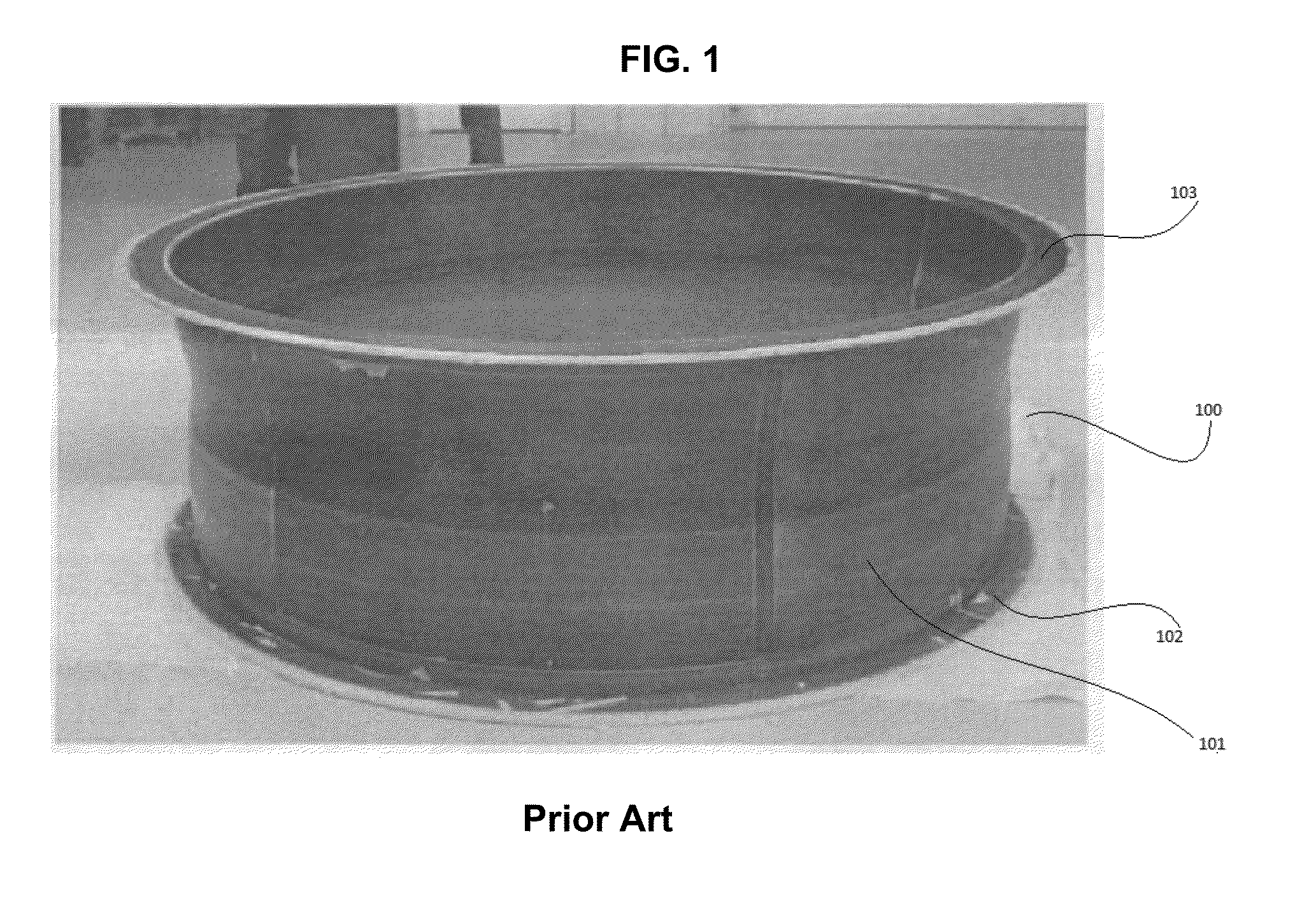

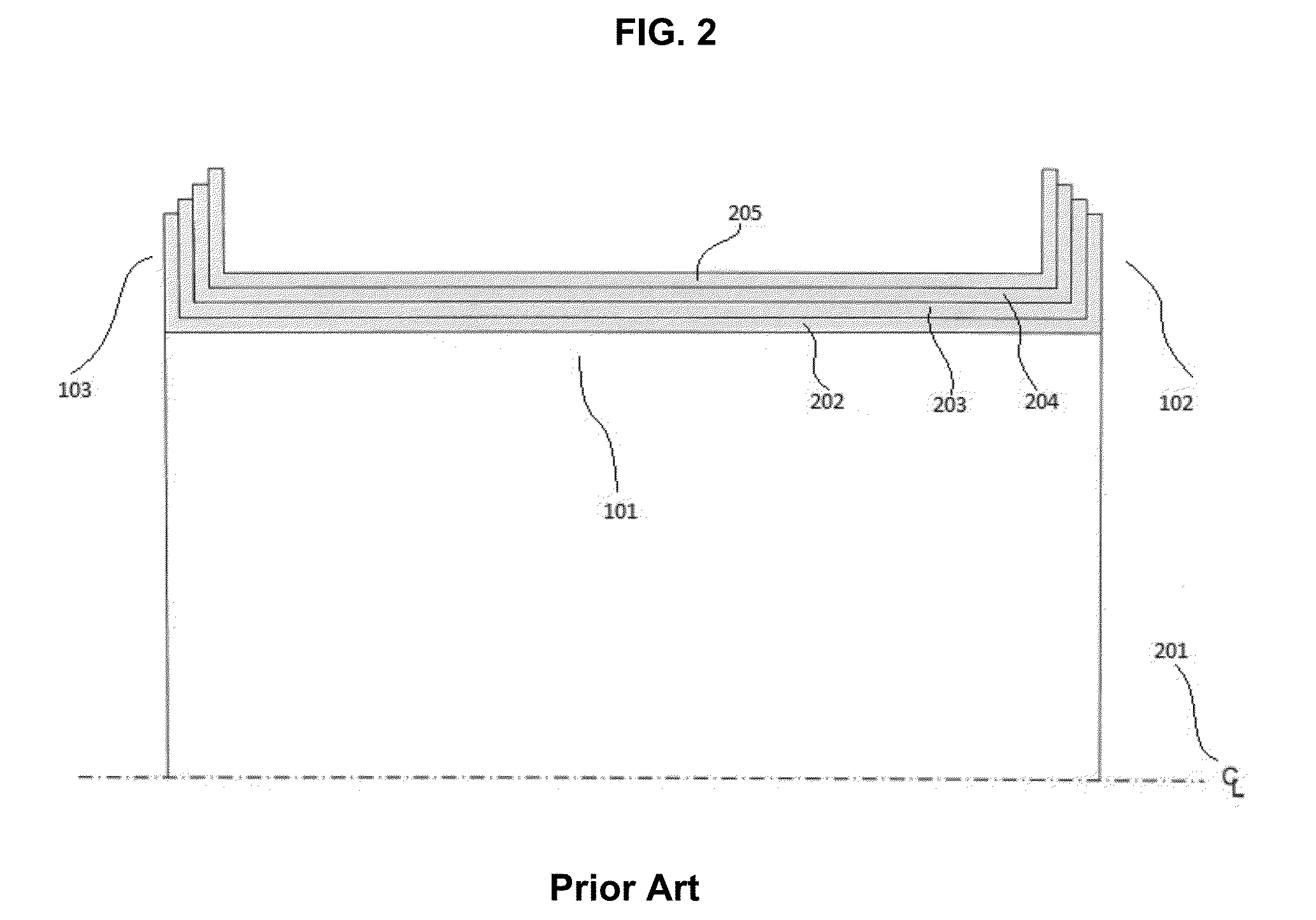

Circumferential stiffeners for composite fancases

ActiveUS20140113088A1Improve dynamic performanceGood strength performanceCeramic layered productsPreformed elementsEngineeringBiomedical engineering

Woven preforms, for example those used for jet aircraft engine fancases, may need additional stiffeners to improve the strength and / or dynamic performance of the preform assembly, as well as to serve as attachment points. The present invention describes several improved woven preforms that include circumferential or axial stiffeners, as well as methods of manufacturing the same. One embodiment includes circumferential stiffeners added to a woven preform. Another embodiment includes sub-preforms with integral flanges that combine to make integral stiffeners. A further embodiment includes an intermediate stiffener wrapped onto a base sub-preform wrap, wherein the intermediate stiffener wrap incorporates intermediate stiffeners. Another embodiment incorporates bifurcations in one or more layers of an outermost wrap of a multi-layer fabric composite that forms a preform, wherein the bifurcated outer wrap is folded to form stiffeners that may be oriented circumferentially or axially.

Owner:ALBANY ENGINEERED COMPOSITES

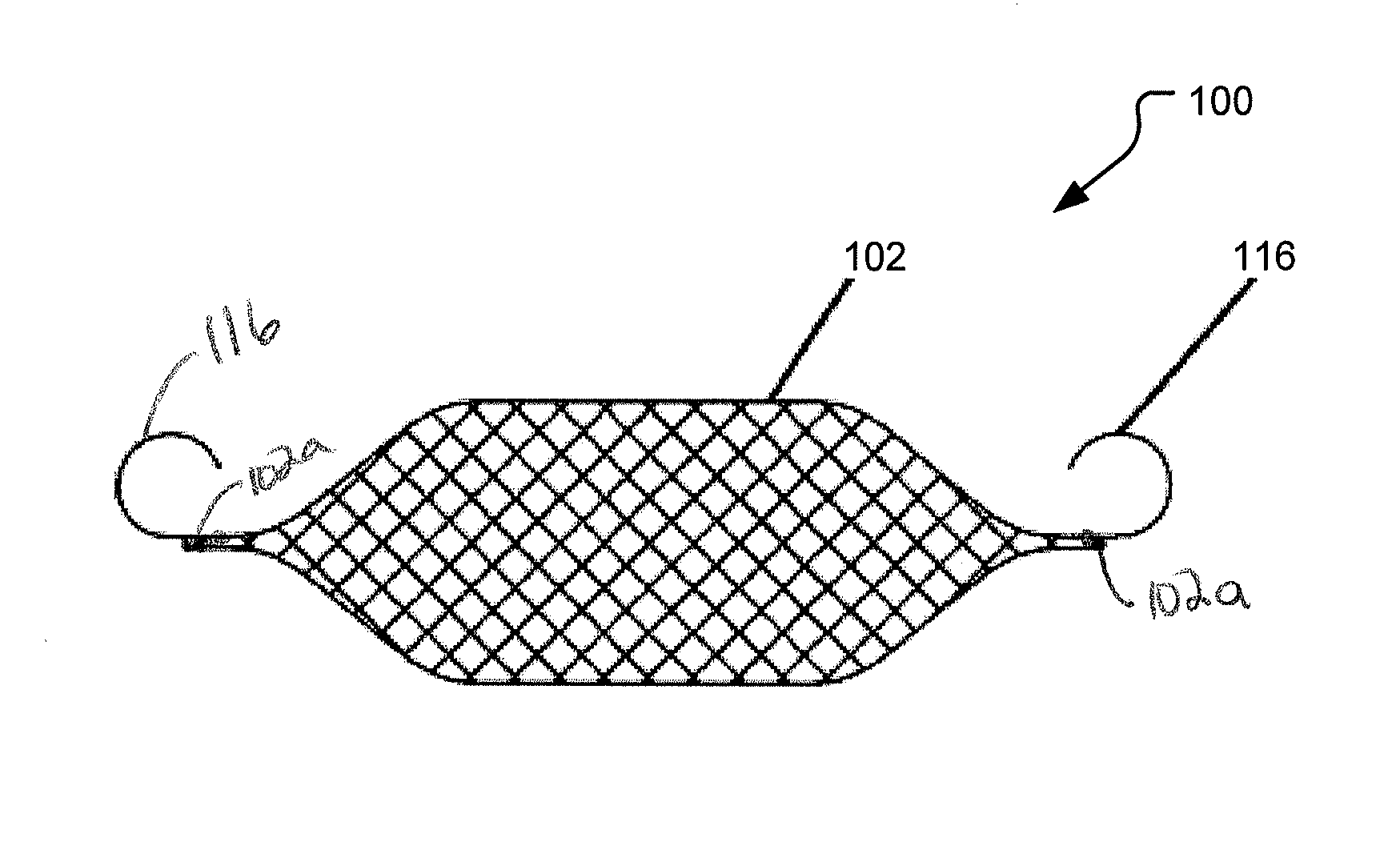

Neck pillow having a strap

InactiveUS20150059098A1Cure neck stiffnessRelieves pain in a person's neck or shoulderPillowsLeather sewingPhysical medicine and rehabilitation

The present invention relates to a neck pillow having a strap to support and comport the neck and the lower head of a user for providing support, comfort, safety, convenience and convenient carriage. The neck pillow includes first and second fabric layers, having a central portion, a left side portion, a right side portion, and a strap portion. The neck pillow further includes an elastic band placed between the strap portions. The central portion is constructed in a substantially hemispheric form and the left and right side portions extend and taper upwardly from the central portion. Additionally, the strap portion is configured to form a hemispheric shape and extends towards the left and right side portions.

Owner:JUNG HYOUNG SOOK

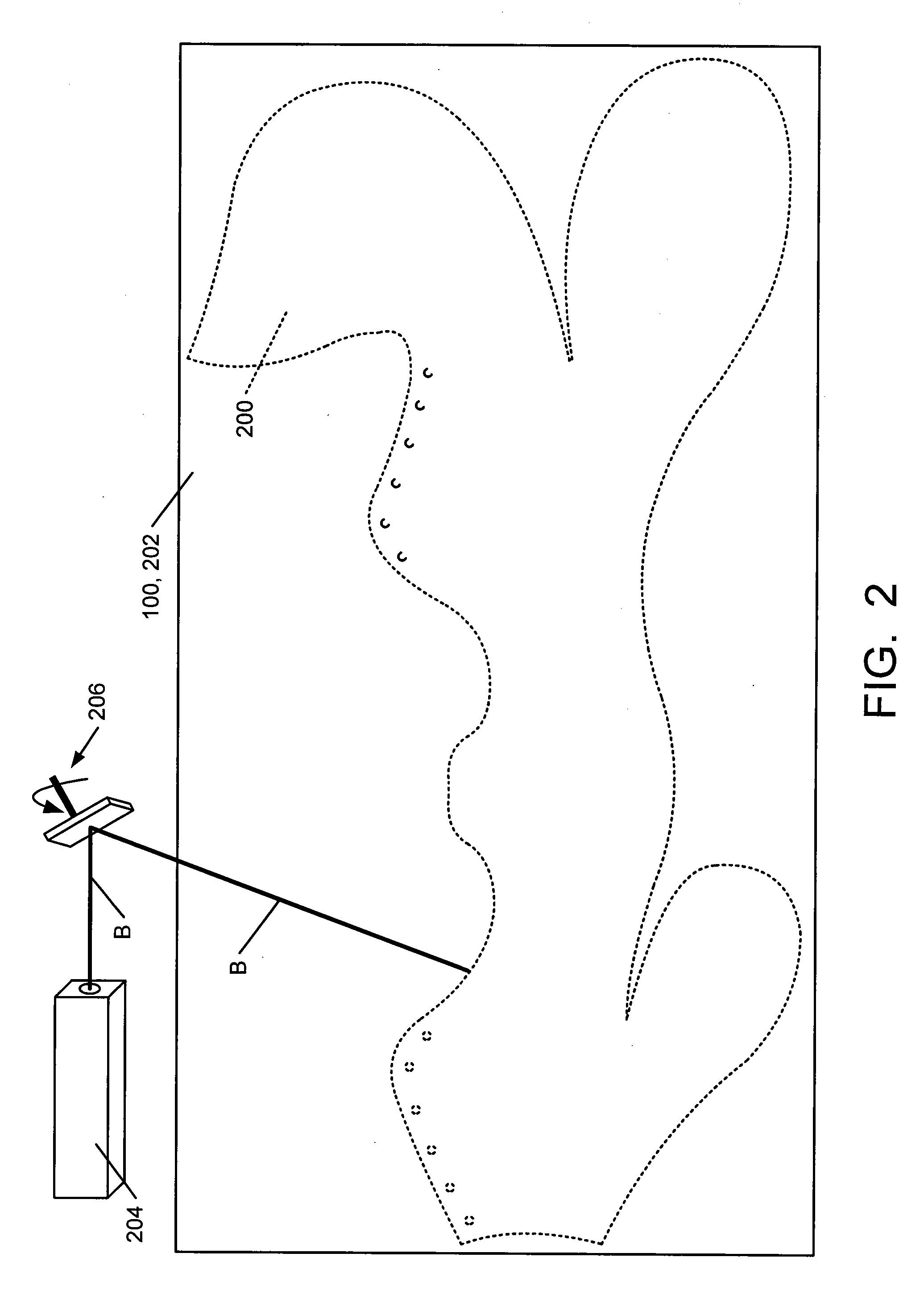

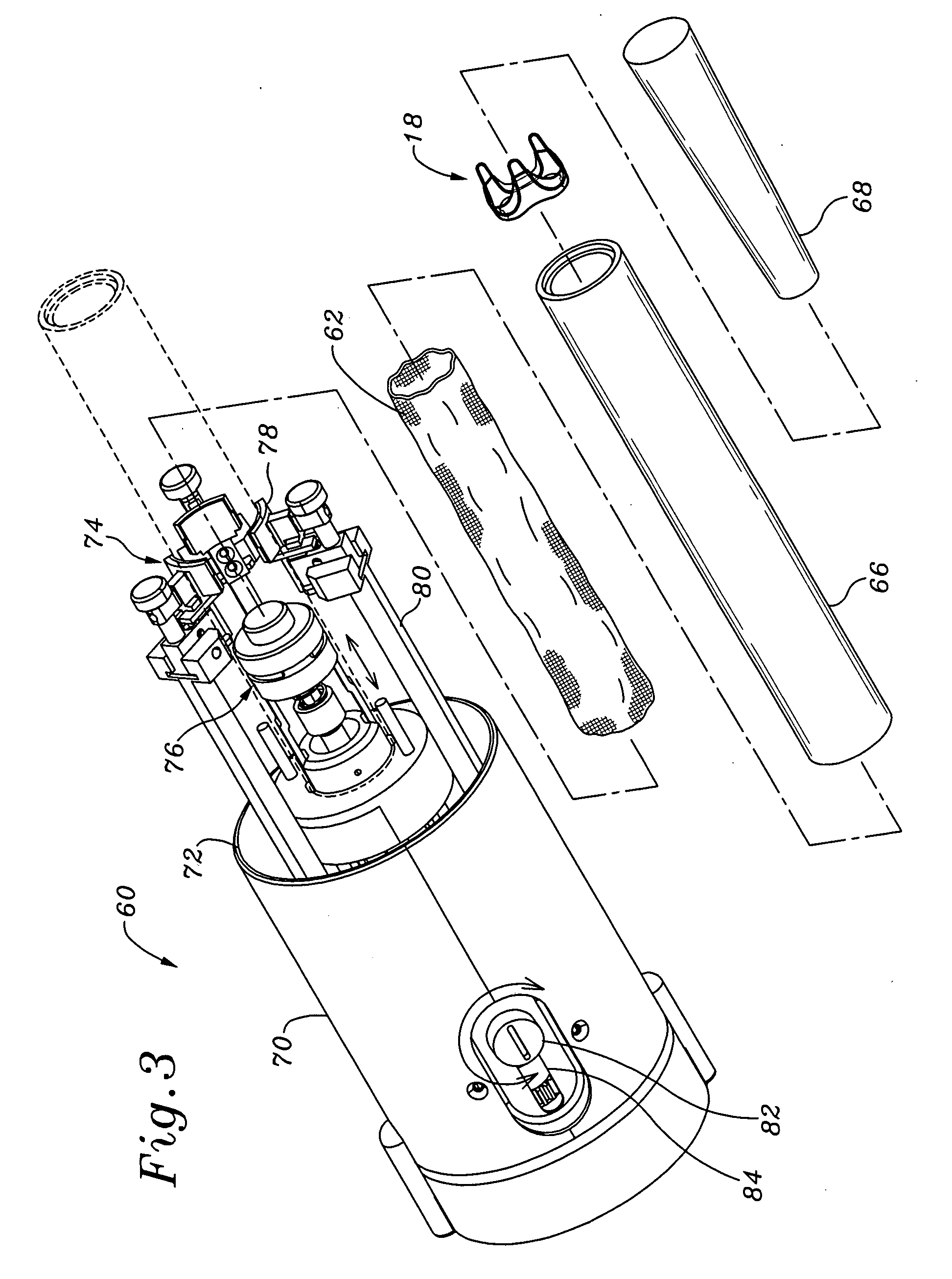

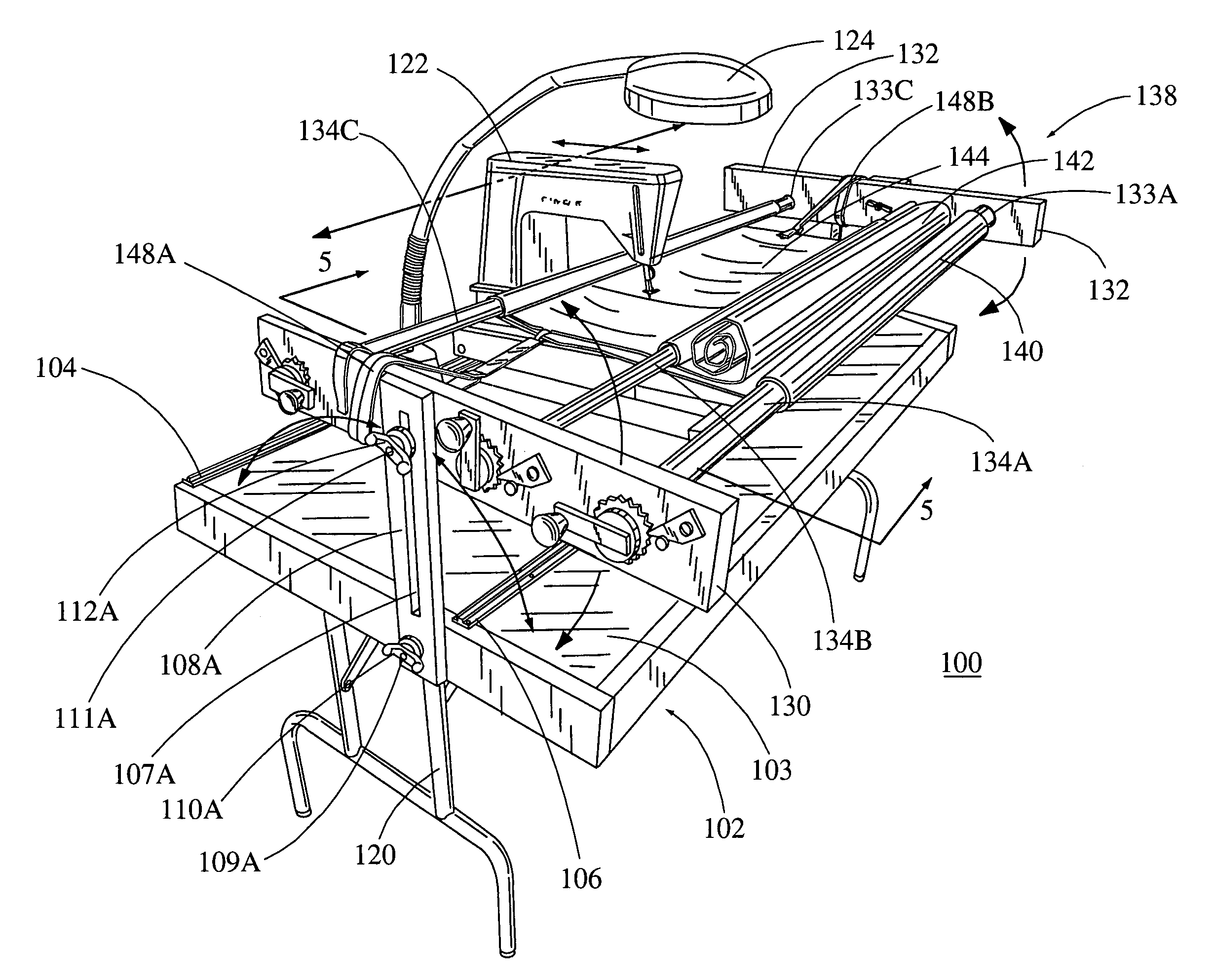

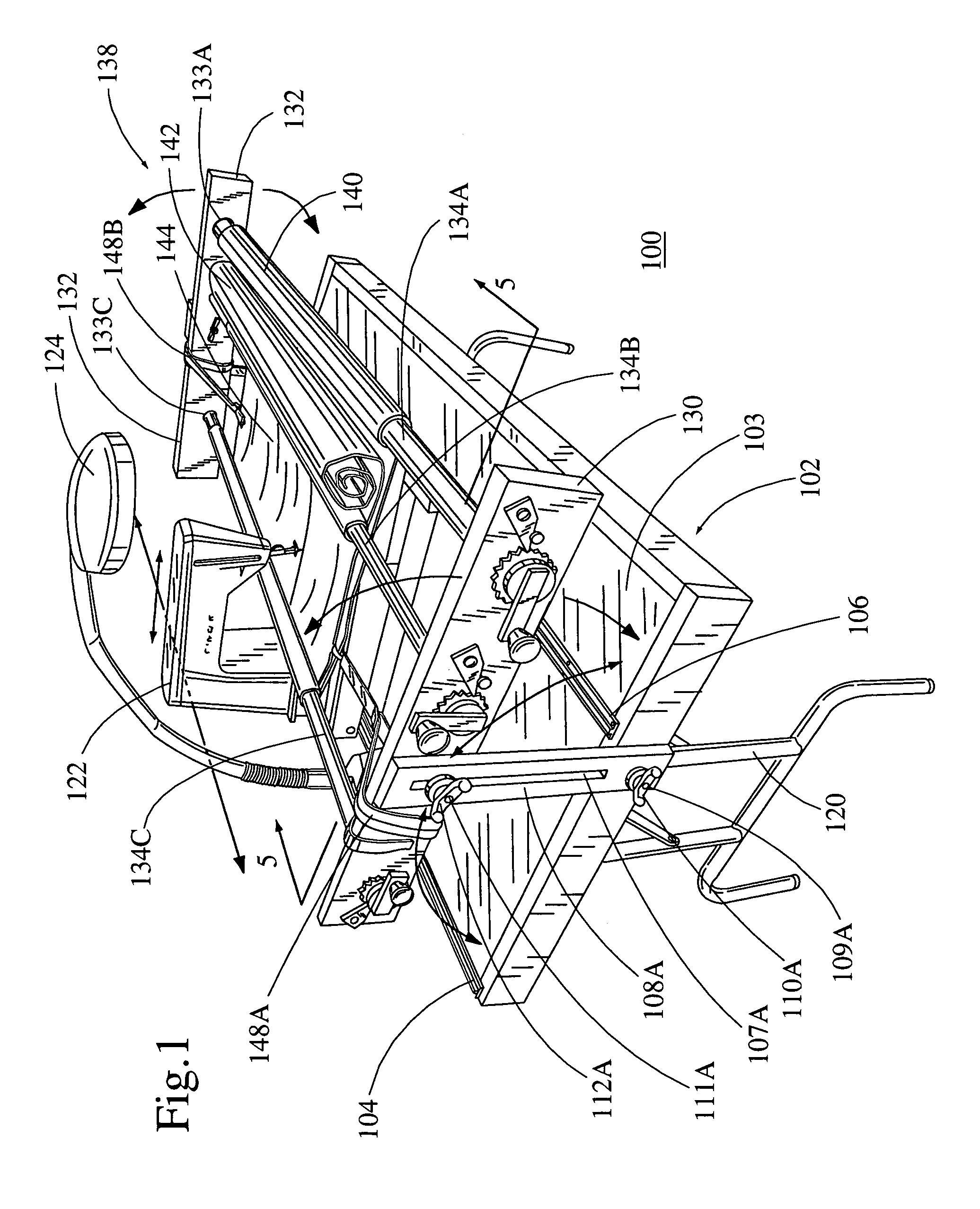

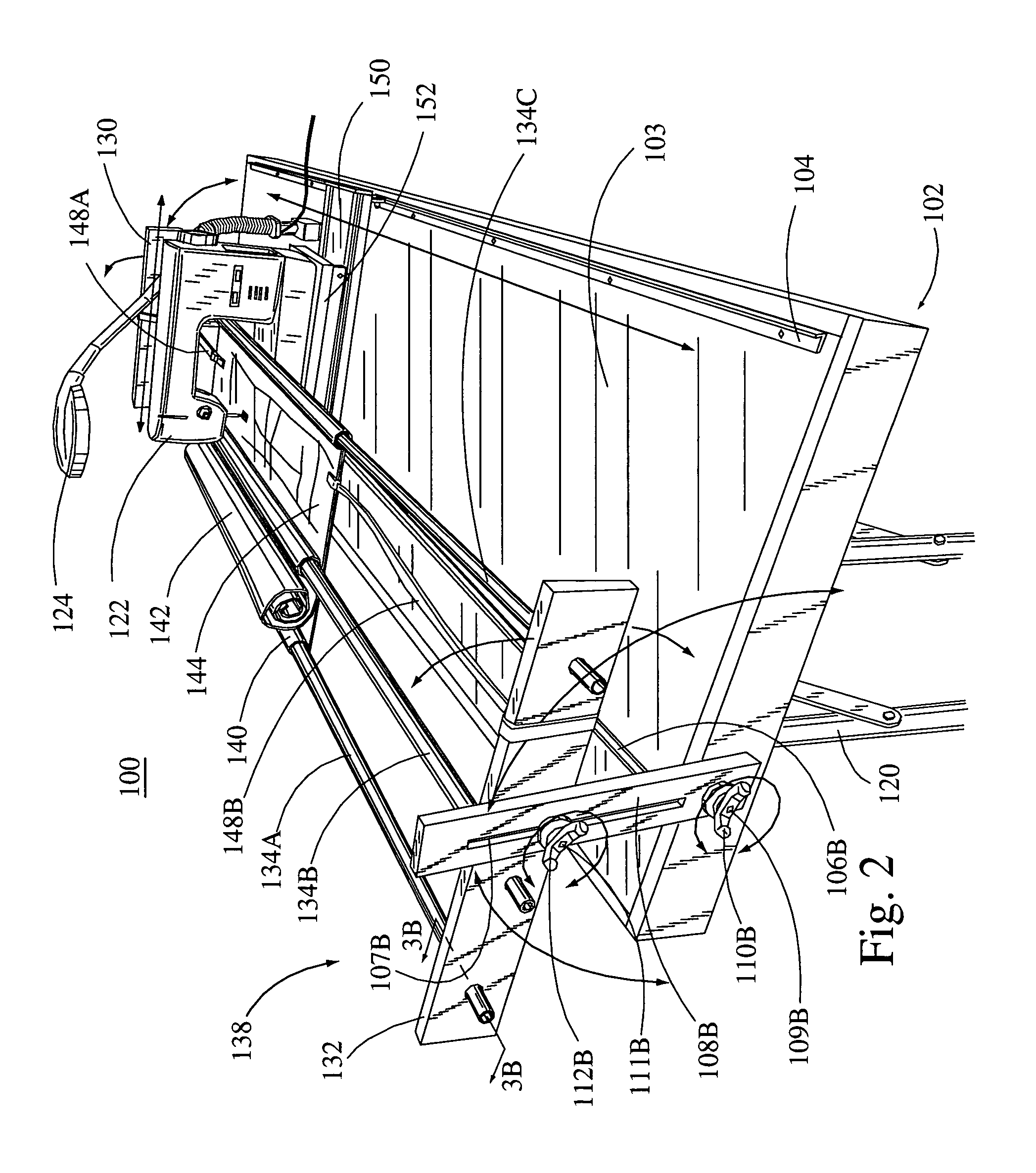

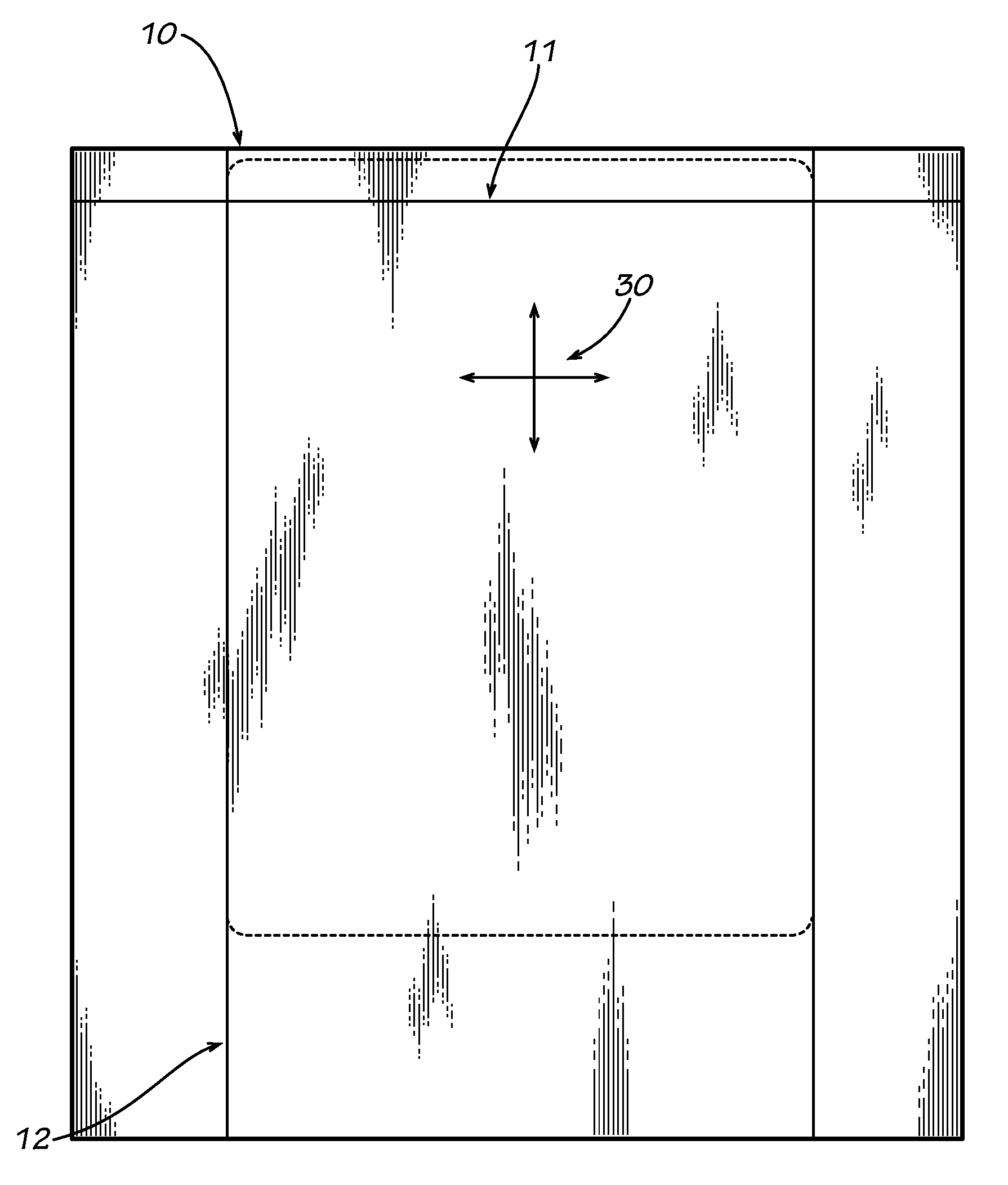

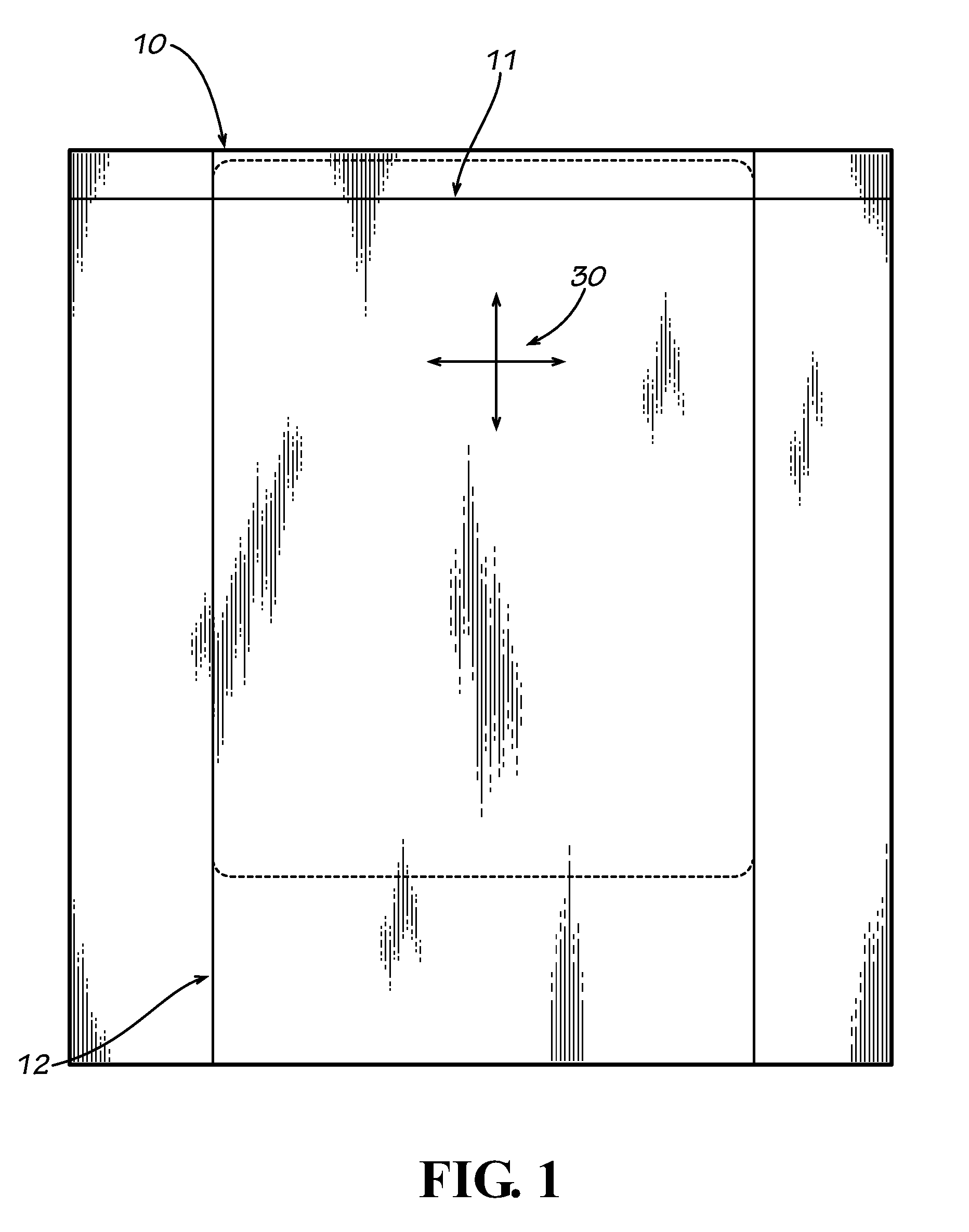

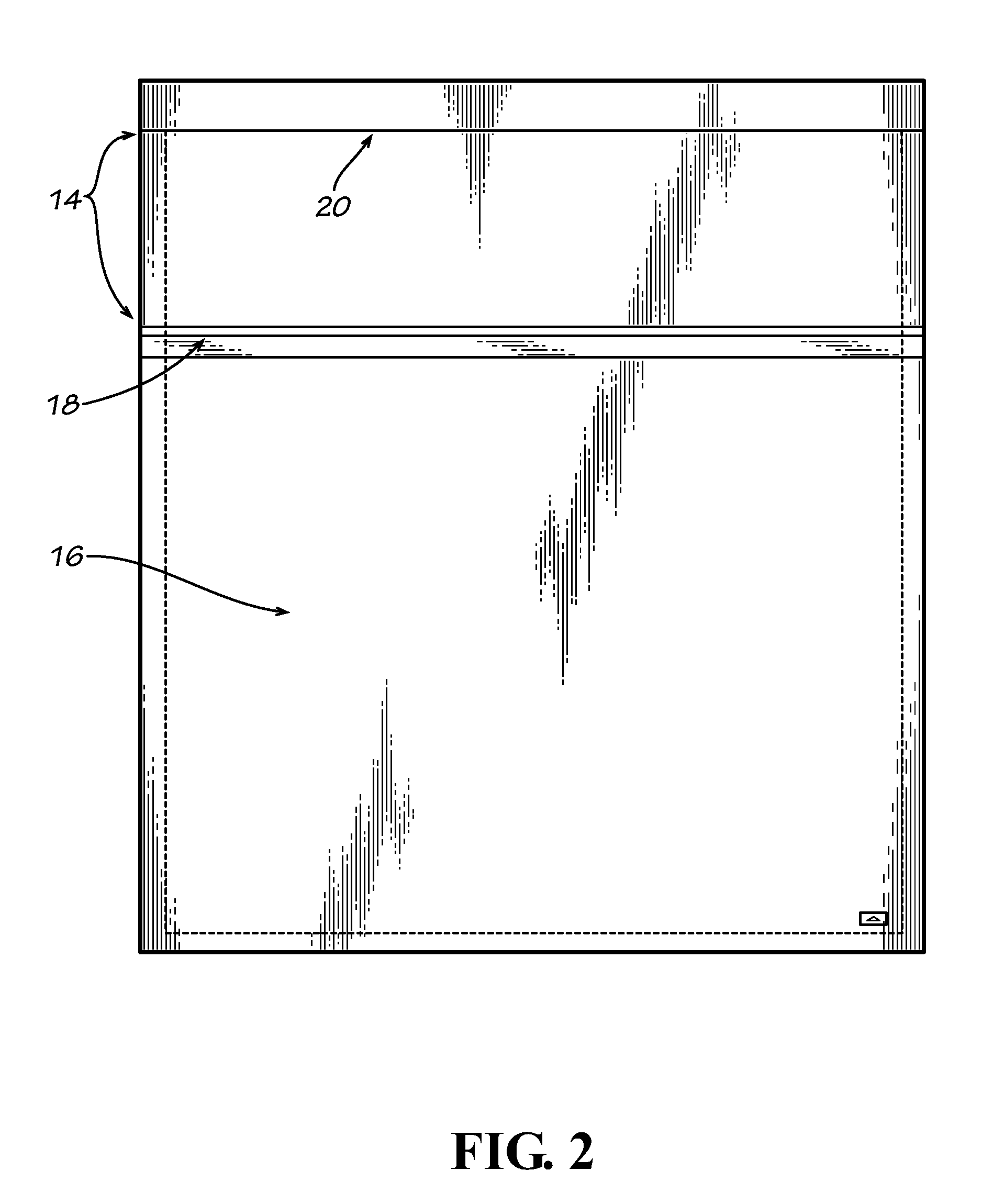

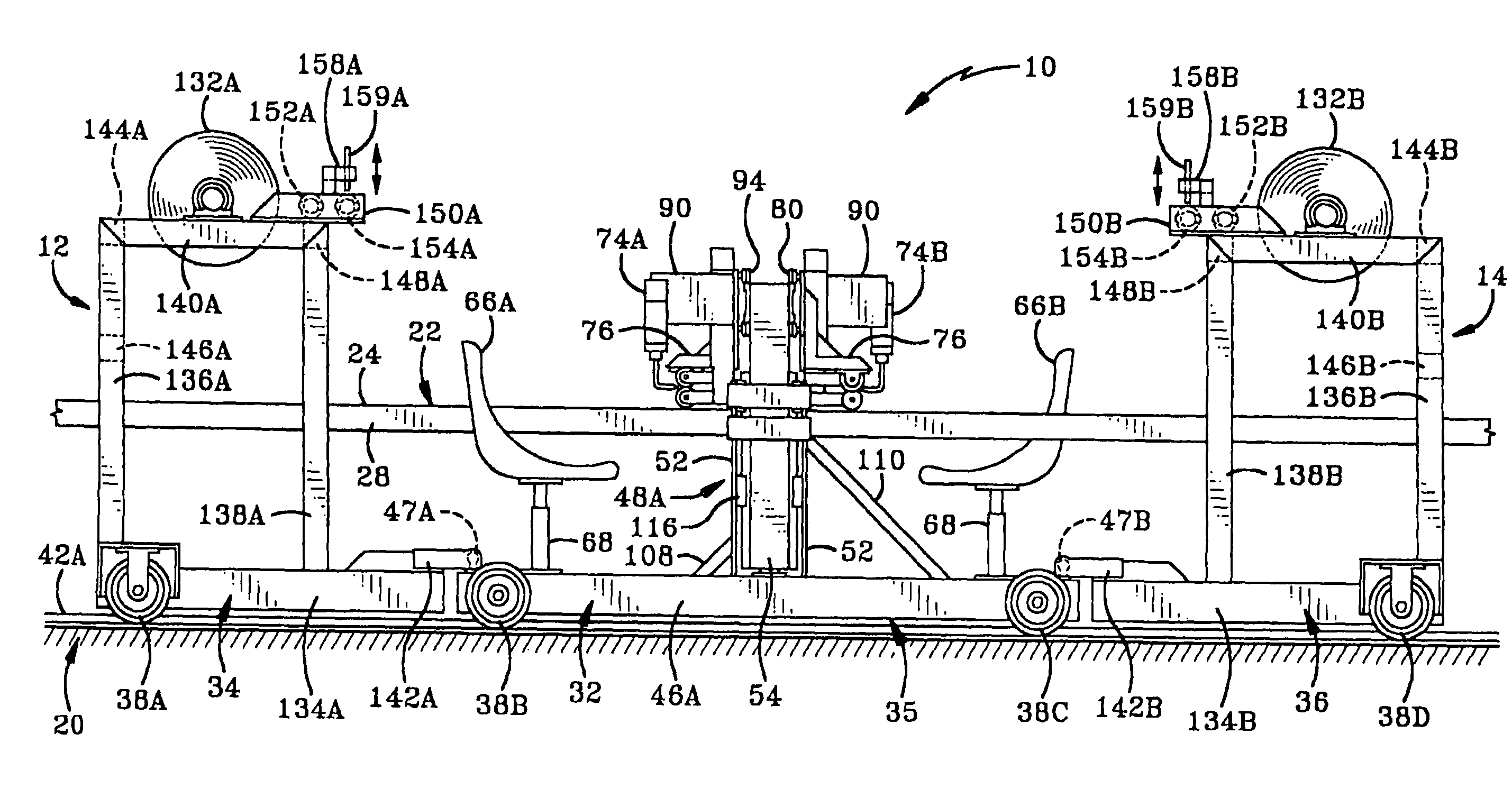

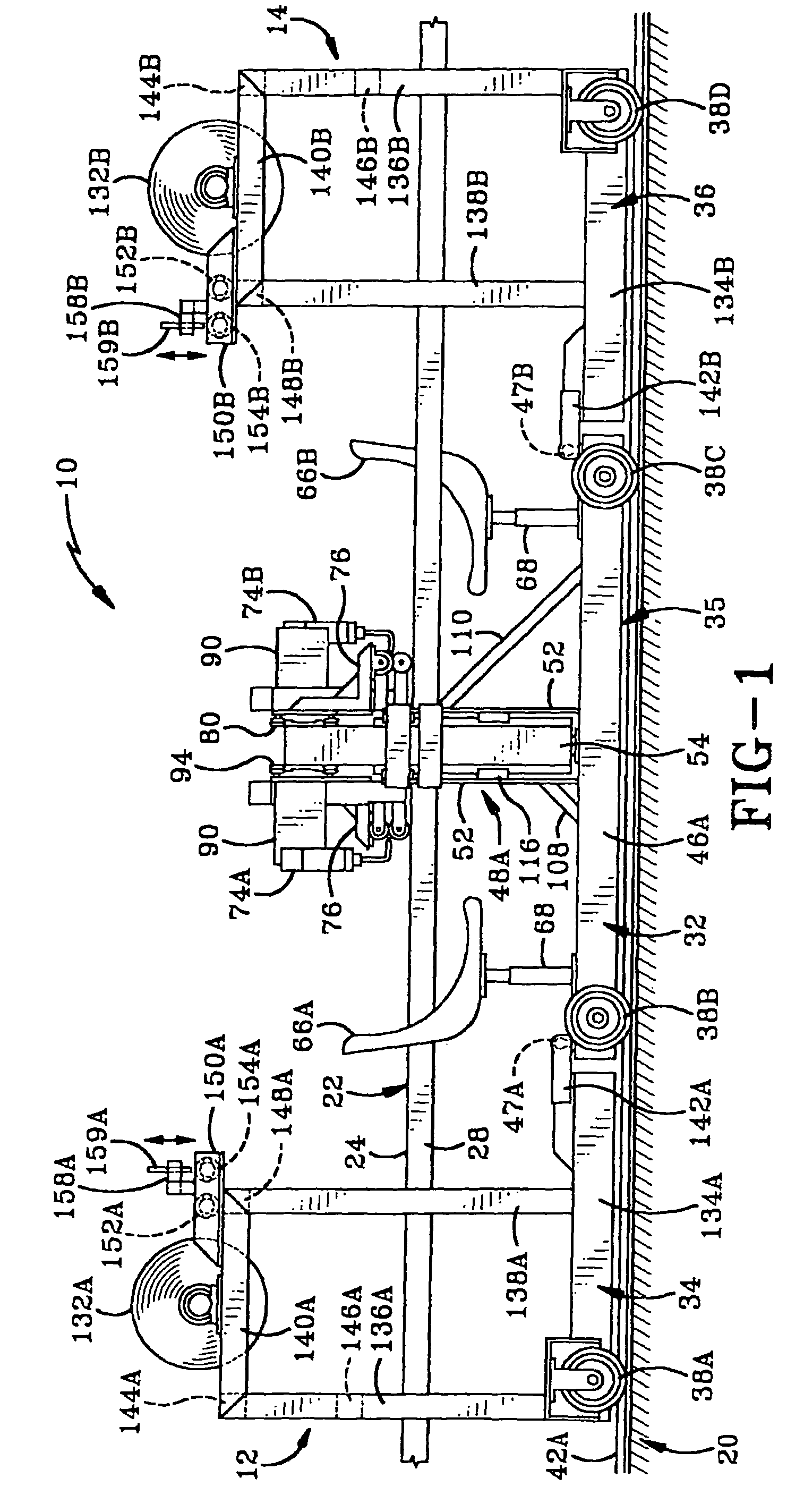

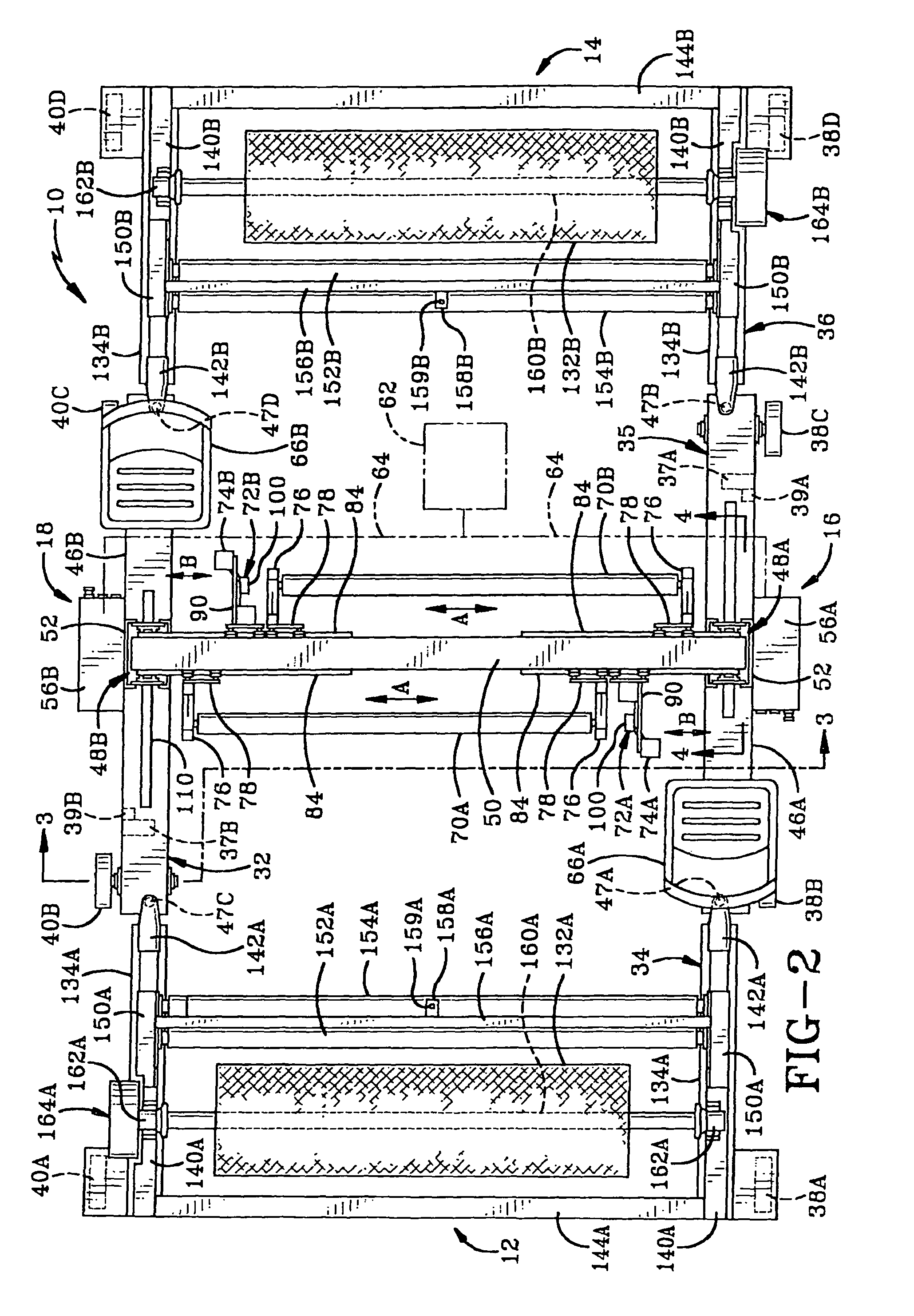

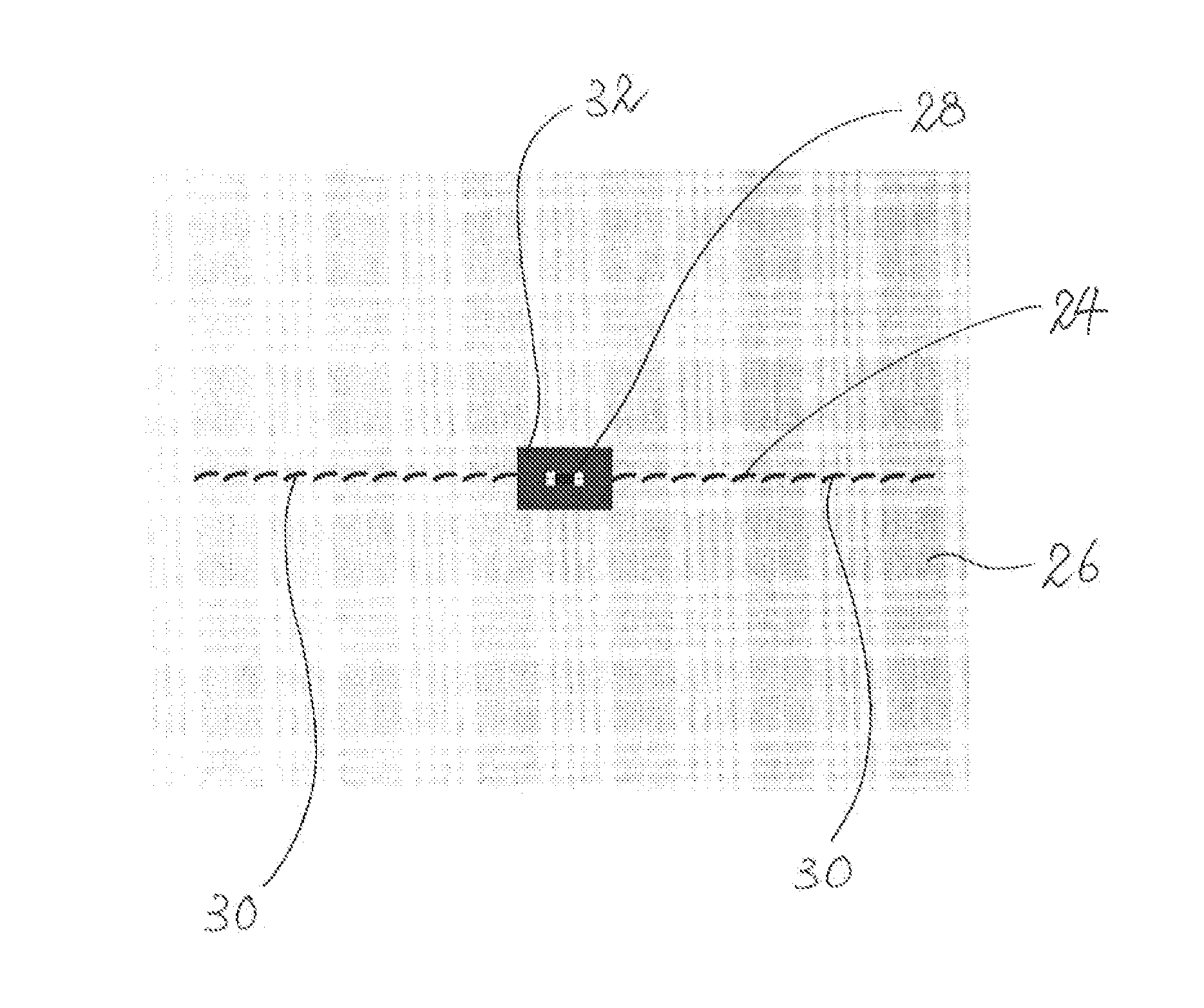

Adjustable quilting machine

InactiveUS7011031B1Precise positioningLeather sewingWork-feeding meansDirect illuminationEngineering

An improved quilting machine includes a table having a carriage for supporting a sewing machine on the table and translating the sewing machine in two axes, a quilting rack for supporting one or more layers of fabric in a substantially planer orientation relative to the sewing machine, and foldable legs. The quilting rack is suspended above the table on a rotatable vertical support, and is easily adjustable without tools for positioning the fabric in a convenient orientation for machine quilting, hand sewing, or access to the table. A lamp is attached through a flexible assembly to the carriage for directing illumination to the sewing machine. The lamp moves with the carriage so that illumination tracks the sewing machine. The quilting rack and legs are foldable and, combined with the rotatable vertical support, provide for convenient transportation and storage of the quilting machine.

Owner:BRADLEY JAMES

Vehicle side airbag device and manufacturing method of side airbag

ActiveUS20160114757A1Limit inflationReduce in quantityPedestrian/occupant safety arrangementSack sewingLateral airbagEngineering

The present disclosure provides a vehicle side airbag device including: a side airbag, housed inside a side support section of a vehicle seat, that inflates and deploys toward a vehicle front side upon being supplied with gas from an inflator, the side airbag including: a bag body that is formed in a bag shape; a front-rear left-right partitioning cloth that partitions the bag body into a front bag section and a rear bag section, and that partitions the rear bag section into a left and a right chamber in a row along a vehicle width direction in an inflated and deployed state of the bag body; and a tether, provided at at least one chamber of the left or the right chamber, that bears tension in the inflated and deployed state, and that restricts inflation of the at least one chamber toward the vehicle front side.

Owner:TOYOTA JIDOSHA KK

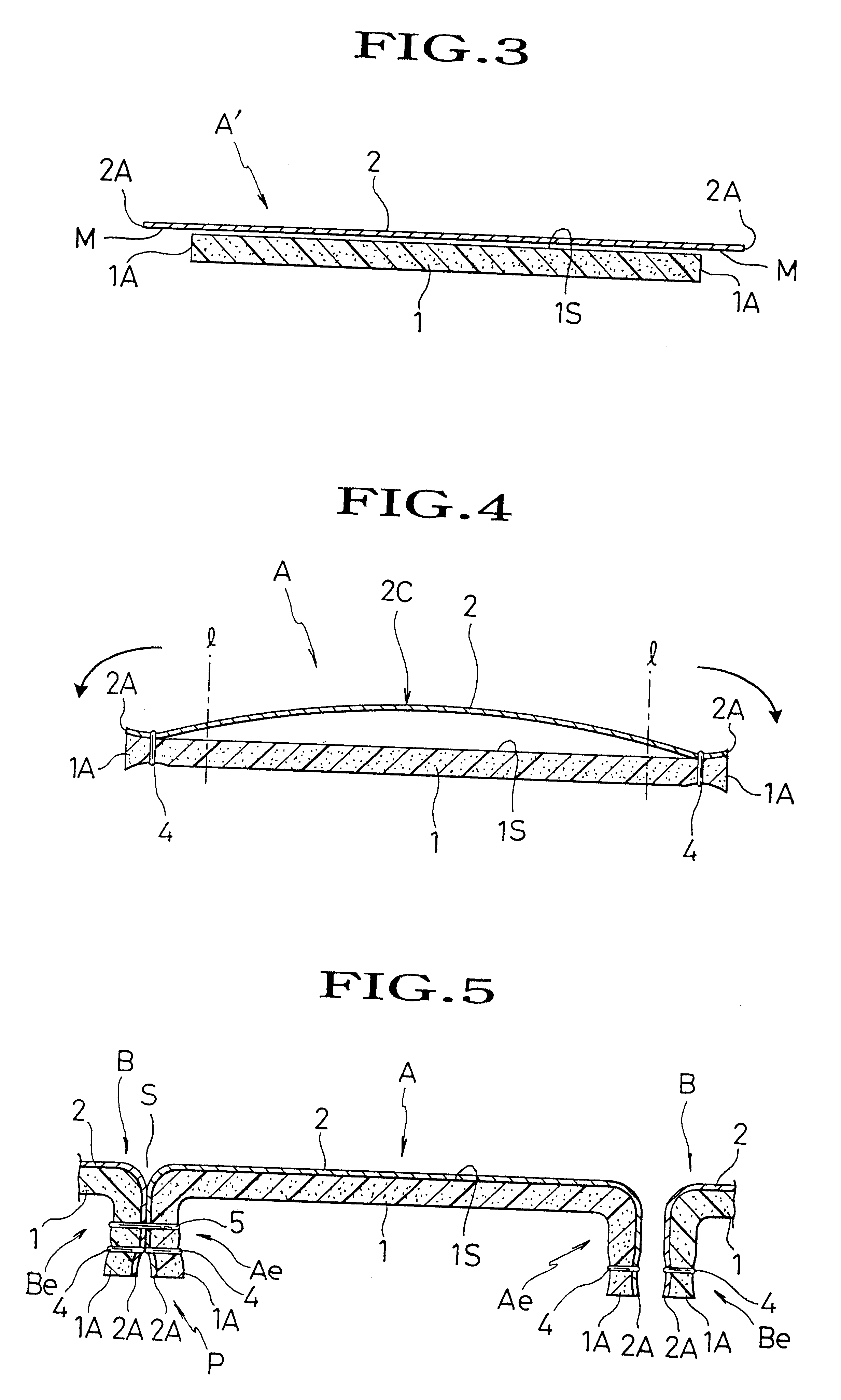

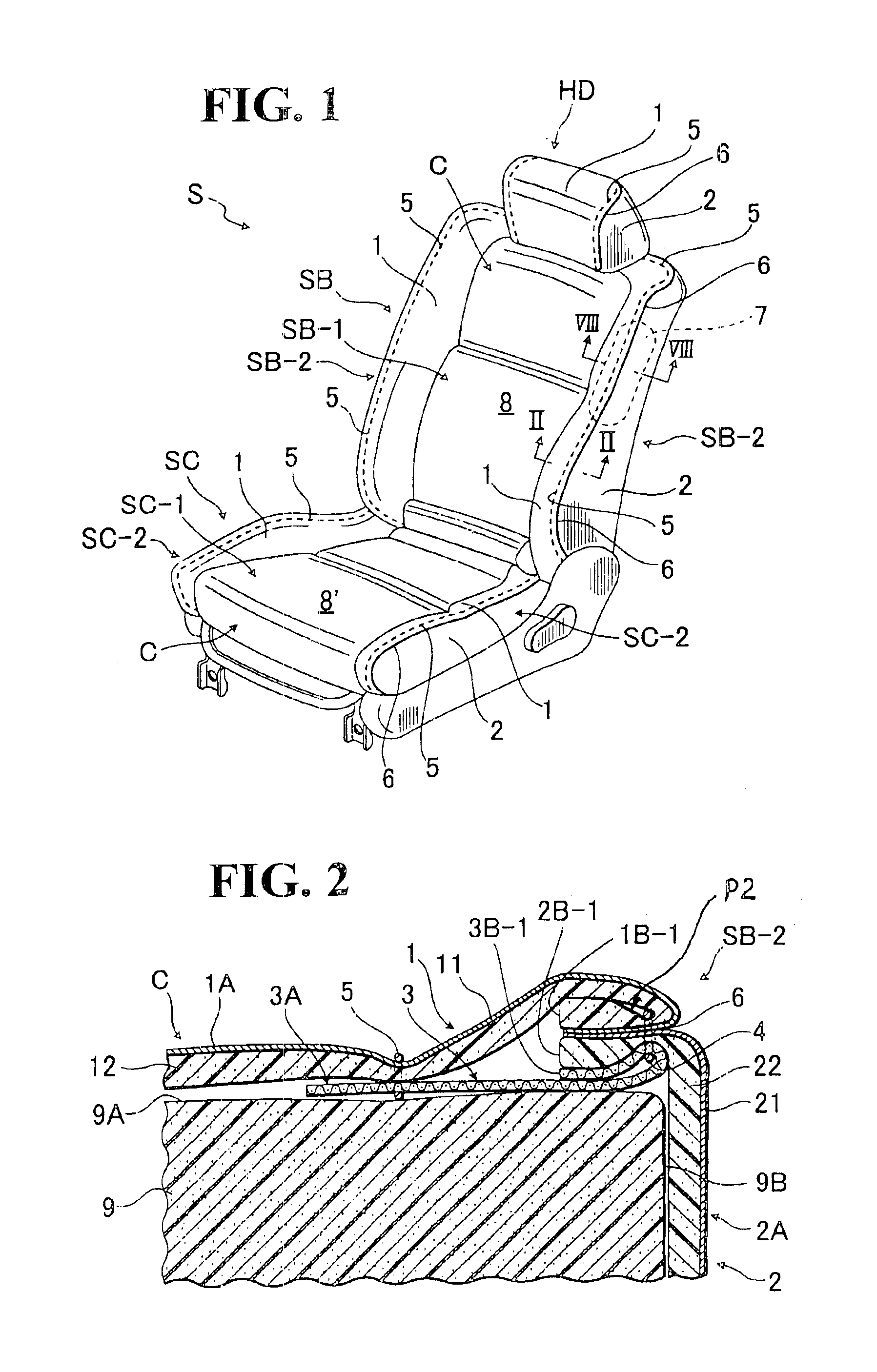

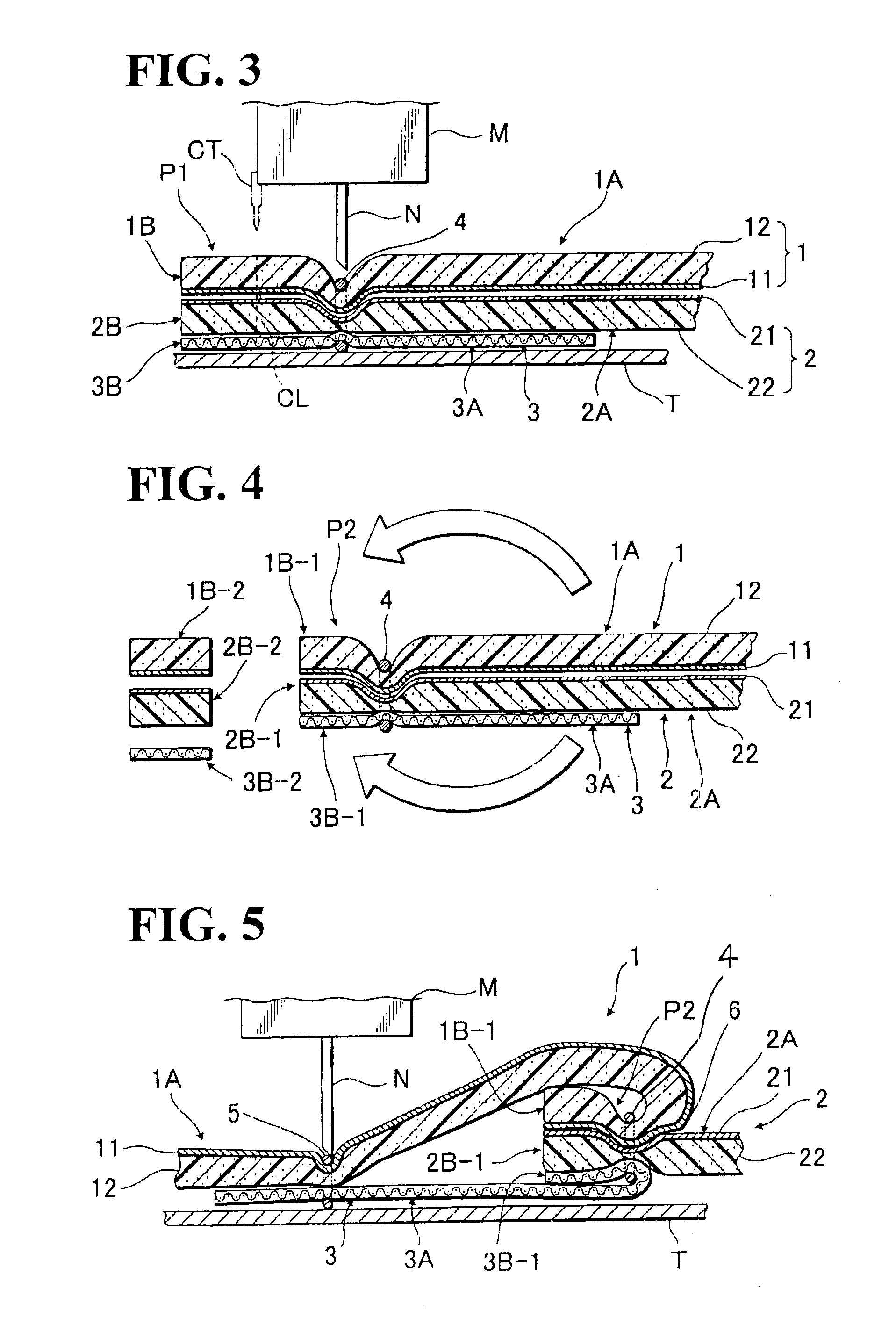

Sewing method to form a trim cover assembly and automotive seat using the trim cover assembly

InactiveUS6886479B1Good lookingReduce marginSeat coveringsLeather sewingEngineeringMechanical engineering

A sewing method to form a trim cover assembly for automotive seat, and an automotive seat using the trim cover assembly. Firstly, a first cover material, a second cover material and a backing tape are used and juxtaposed on one another, with their ends aligned with one another, and then sewn together to create a first seam and a sewn connection portion. Such sewn connection portion is cut off into a shortened sewn connection portion. Thereafter, the first cover material and backing tape are turned over relative to the shortened connection portion and sewn together, thereby forming one portion of the trim cover assembly. Another portion of the trim cover assembly may be formed by avoiding use of the backing tape and simply turning over the first cover material relative to the sewn connection portion, and sewing together the thus-turned portions of the first cover material.

Owner:TACHI S CO LTD

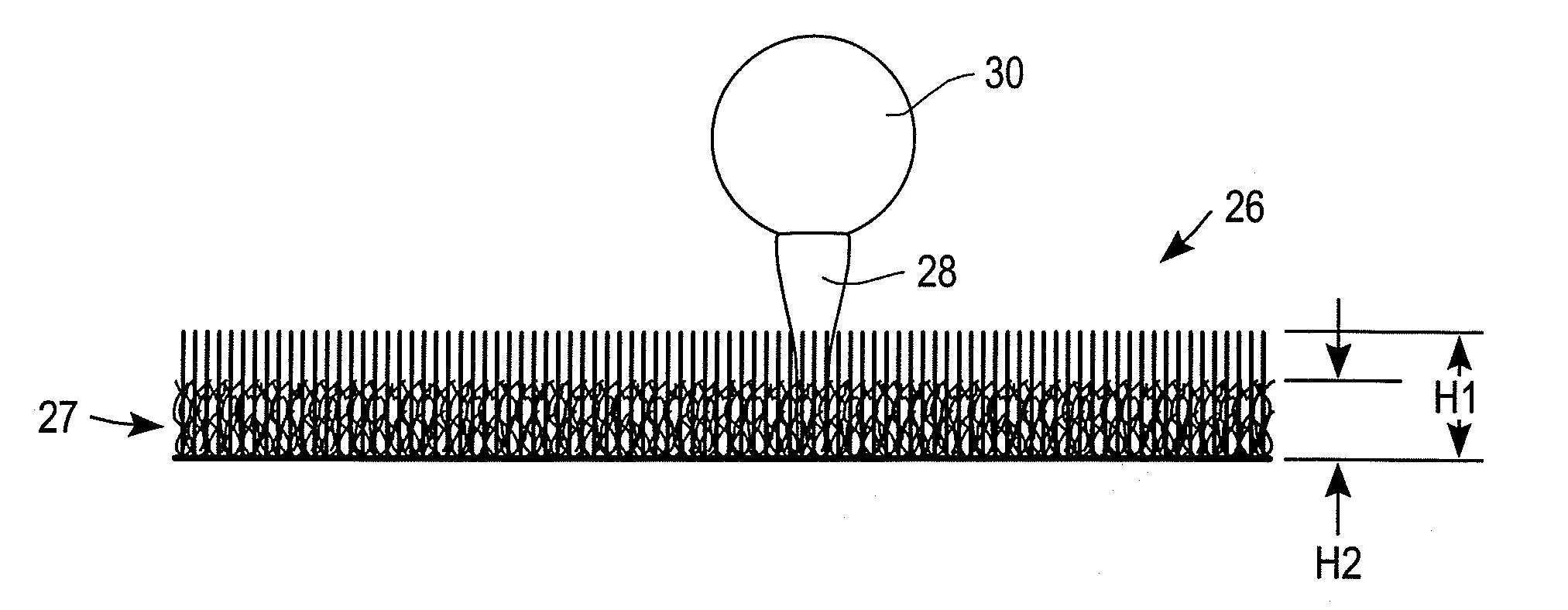

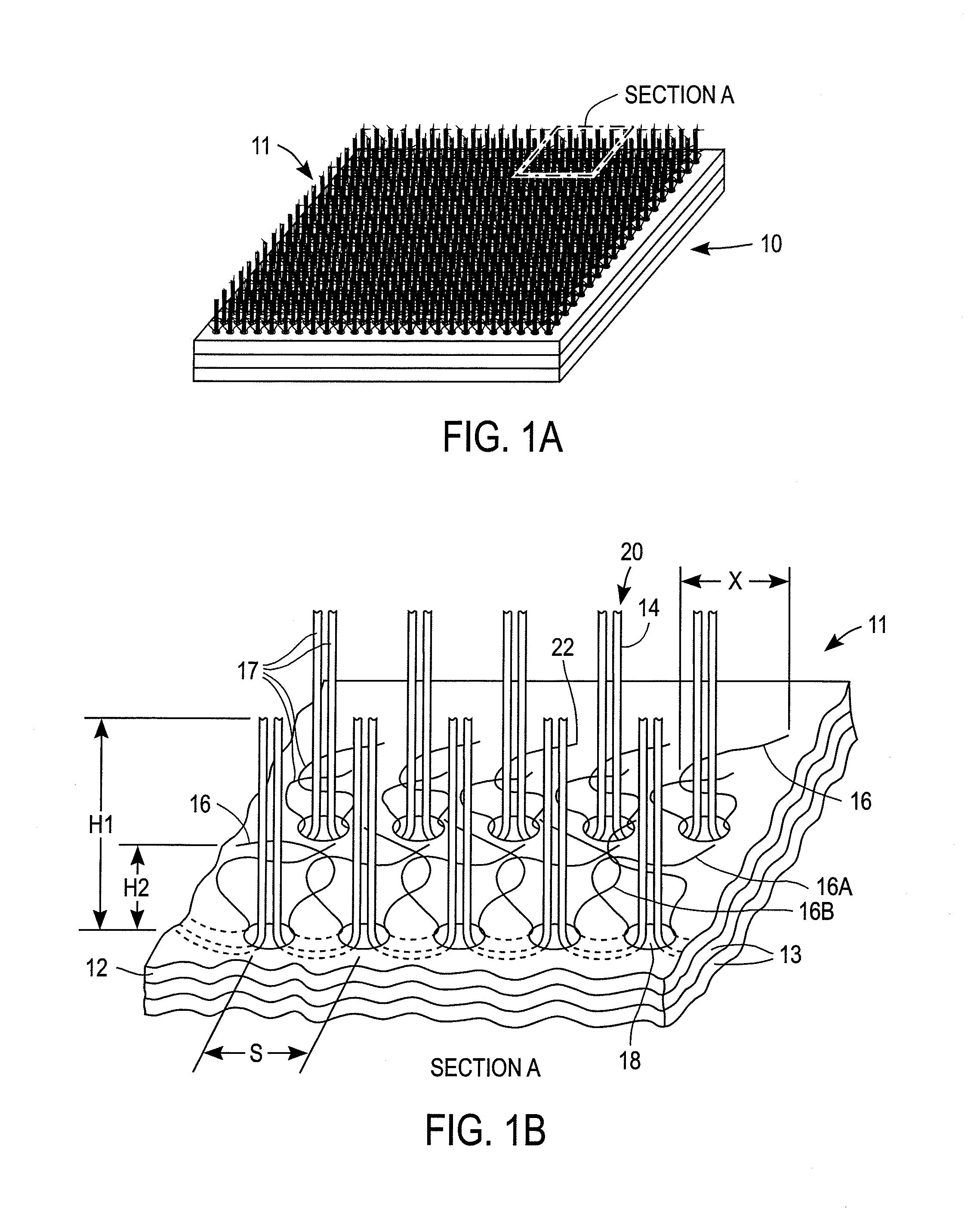

Golf mat

InactiveUS20080125237A1Improve stabilityIncreased durabilityLeather sewingArtificial flowers and garlandsFiberPre stress

A golf mat includes artificial grass fibers attached to and extending upward from a backing material, which may be one or more layers. The artificial grass fibers include groups of at least two different kinds of fiber sewn through a common path in the backing material. One of the kinds of fibers in each group is shaped so as to appear like a blade of grass. The other kind of fiber in each group is pre-stressed / crimped so that the relaxed shape of the fiber is nonlinear, resembling a curlicued or articulated form having lateral excursions. The lateral excursions cause portions of one such pre-stressed fiber to overlap and interfere with another, forming a mesh. The height of the pre-stressed fibers in their relaxed state in the turf is less than the height of the relatively unstressed artificial grass fiber(s). The crimped fibers form a resilient mat with impact characteristics similar to natural turf.

Owner:TEXTILE MANAGEMENT ASSOCS

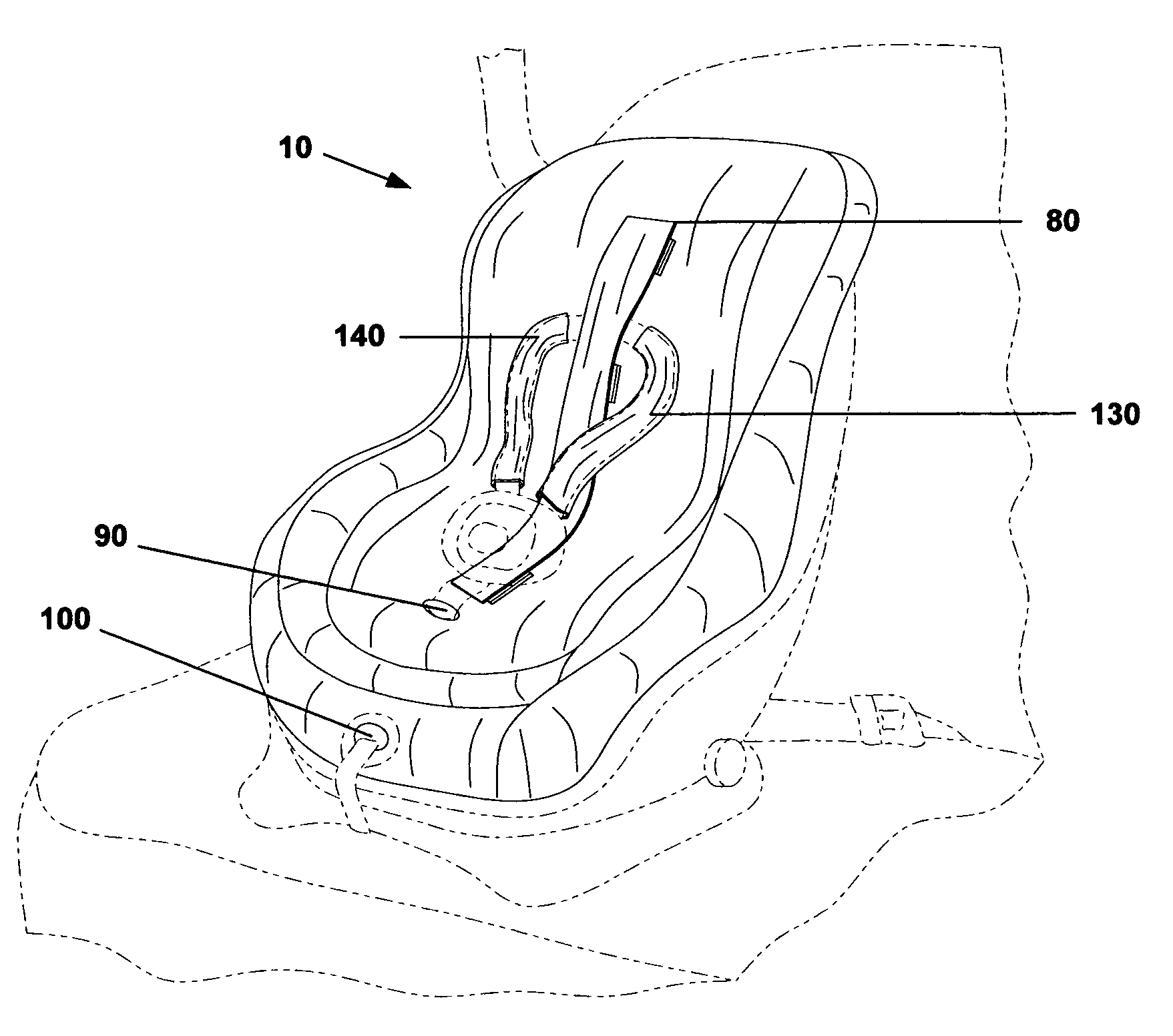

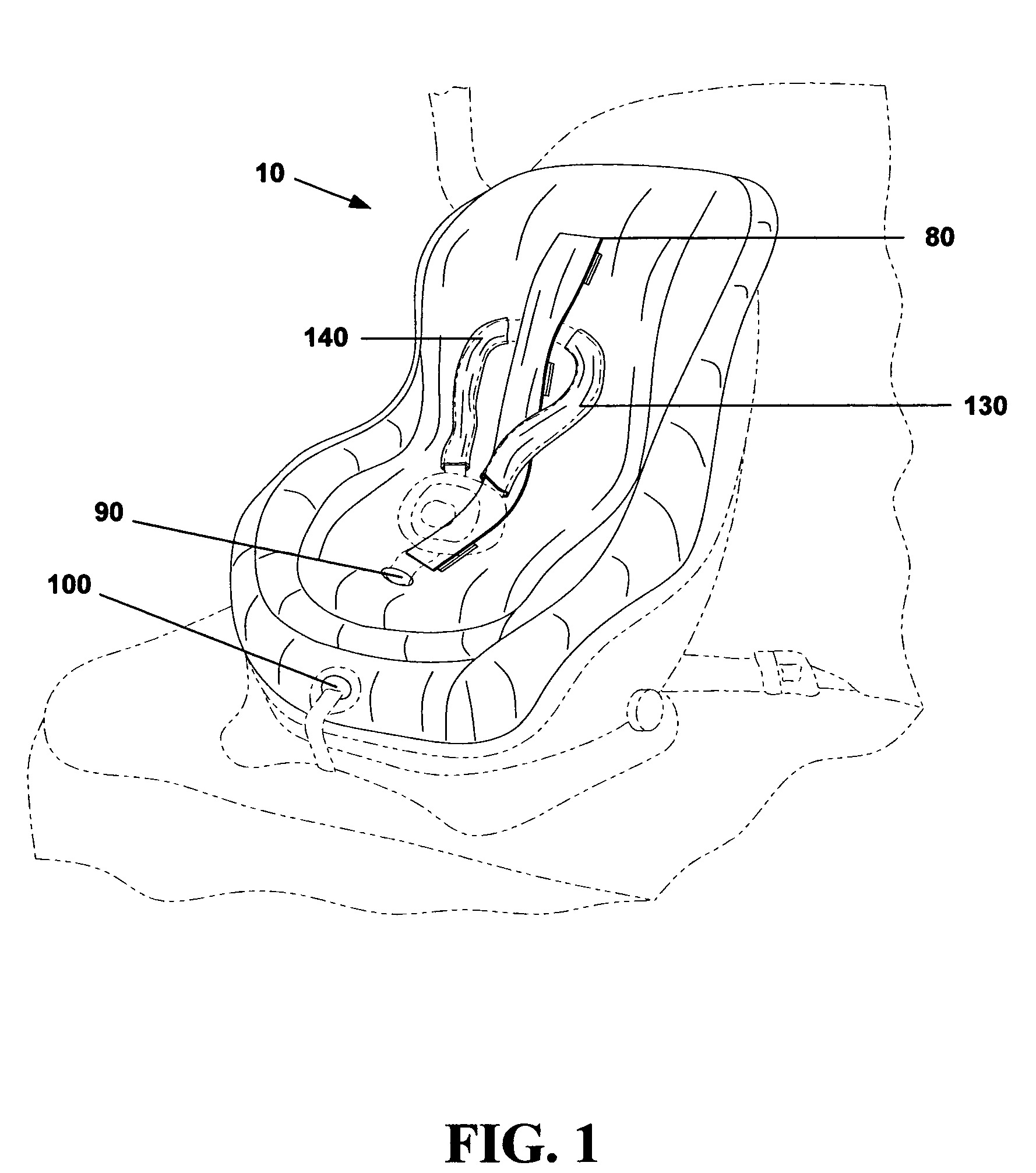

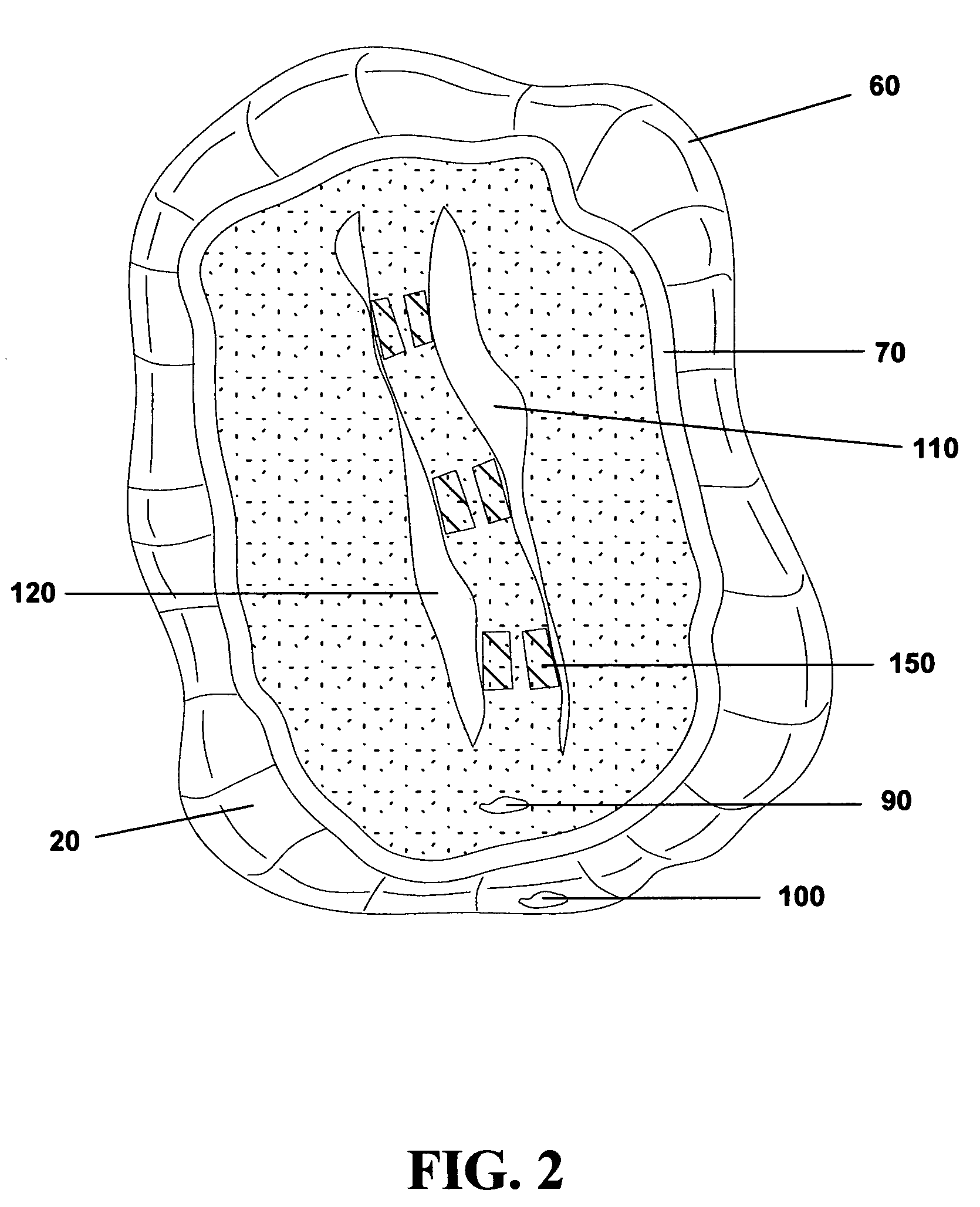

Child car seat cover

A child car seat cover is disclosed. This device provides an easily removable, cleanable and adjustable cover for a child car seat that restricts the passage of food, dirt and liquids to the car seat material. The device is comprised of multiple layers of fabric, strap covers, strap openings and strap closures.

Owner:EMMALU

Patch pocket sewing machine

InactiveCN105839299AOutstanding and Beneficial Technical EffectsImprove qualitySewing-machine casingsWork-feeding meansEngineeringSewing machine

The invention belongs to the technical field of sewing machines, and particularly refers to a patch pocket sewing machine, including a body, the table of the workbench is high at the rear and low at the front to form a forward inclination, and a bracket is provided on the body at the rear side of the workbench, and the left side of the workbench There are upper and lower molds on the support for folding and shaping the pockets. The right side of the workbench is equipped with a sewing machine head that sews the pockets on the fabric. Move the folded pockets and fabrics on the left side of the workbench to the presser foot on the head side of the sewing machine. The presser foot can be driven by the servo motor to move horizontally and vertically. The advantage is: the table top of the workbench is higher at the rear and lower at the front to form a forward tilt , when sewing plaid shirt pockets or striped shirt pockets, it is convenient for the operator to align the grid or stripes on the pocket with the grid or stripes on the fabric, so that there is no obvious splicing trace between the sewn pocket and the fabric, which improves the The sewing workmanship of the shirt pocket effectively improves the quality of the shirt.

Owner:蔡丰俭

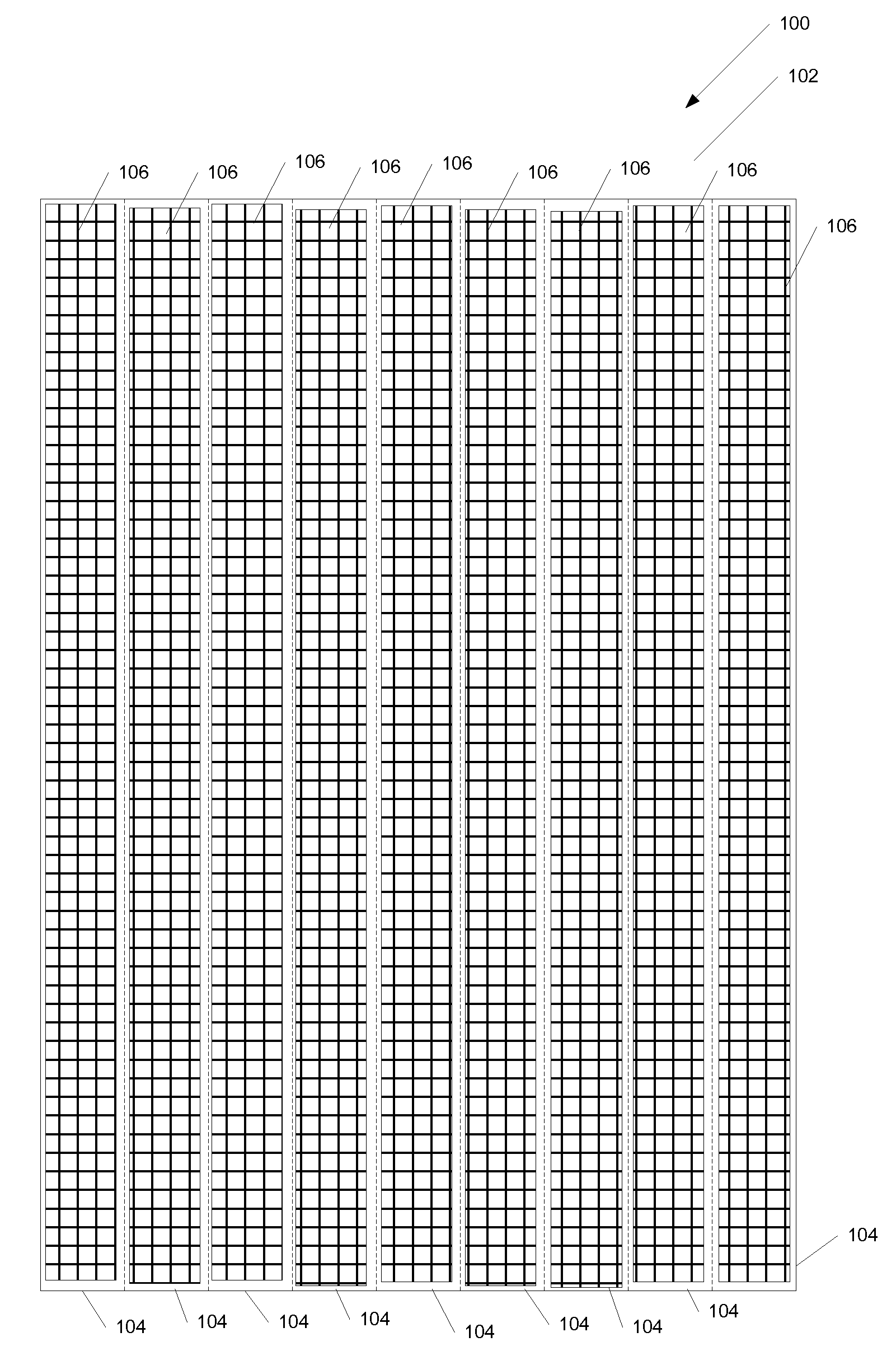

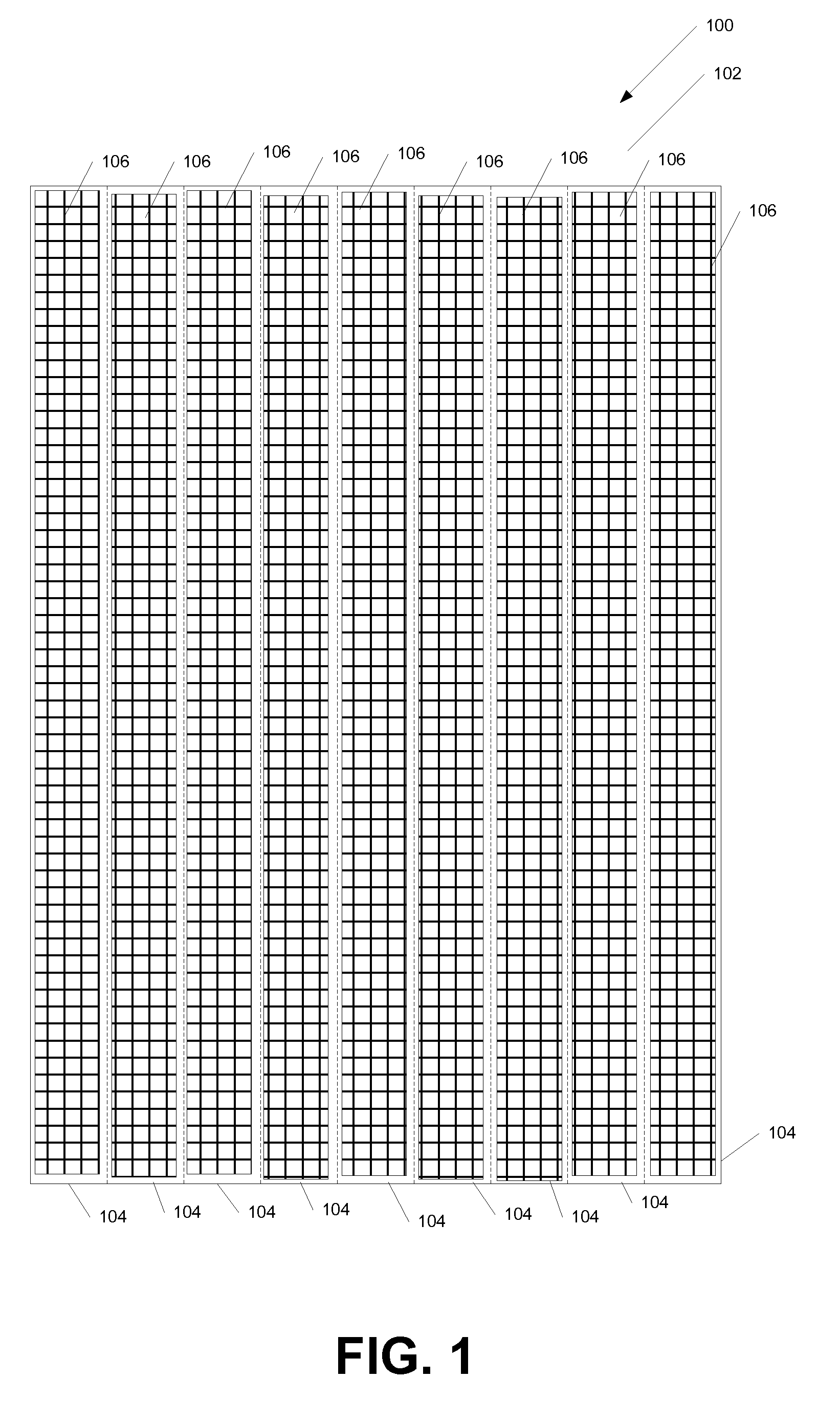

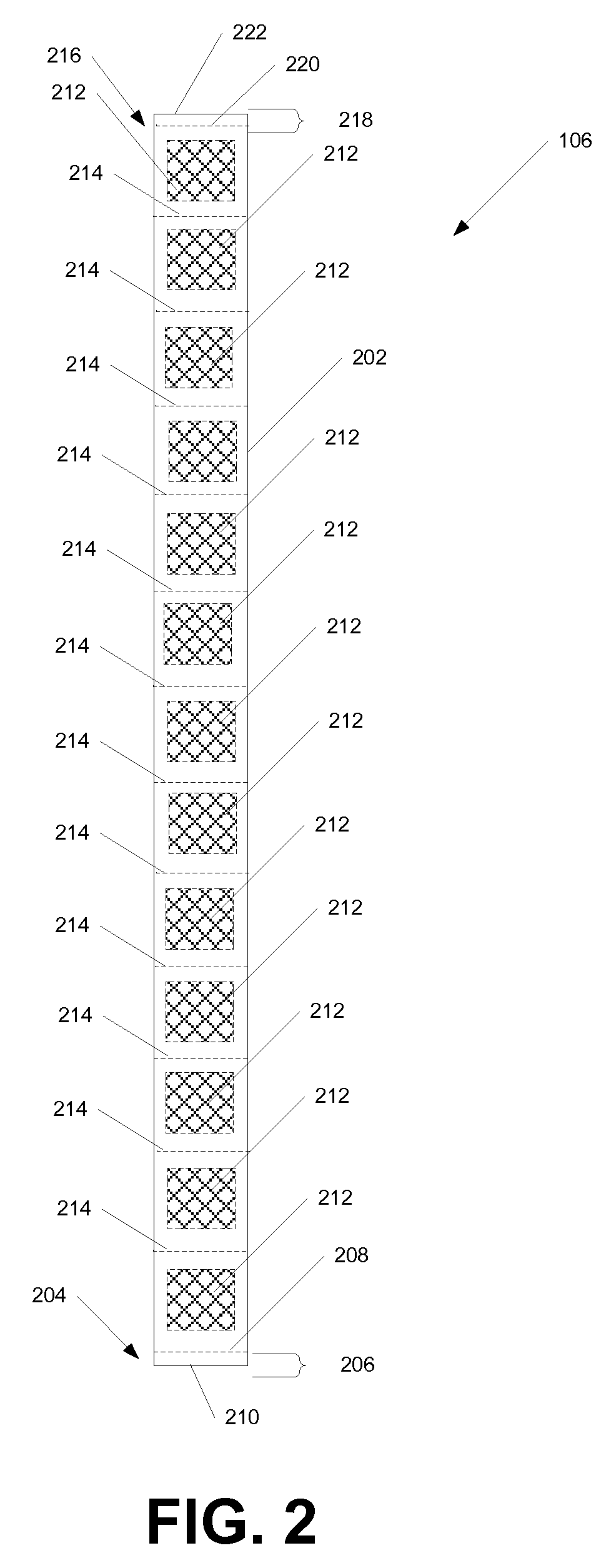

Fabric System

ActiveUS20110000020A1Improve heat transfer performanceCool to the touchLeather sewingBlanketEngineeringMoisture

Bedding material including a first fabric section manufactured from performance fabric and having a first and second side; and, a second fabric section attached to the first side of the first fabric section. Additionally, a third fabric section can be attached to the second side of the first fabric section. The first fabric section can be attached to the second fabric section through a flatlock stitch. The first fabric section can include a first zone and a second zone wherein the first zone contains different performance properties from the second zone and the first zone can have thermal or moisture wicking properties.

Owner:SHEEX

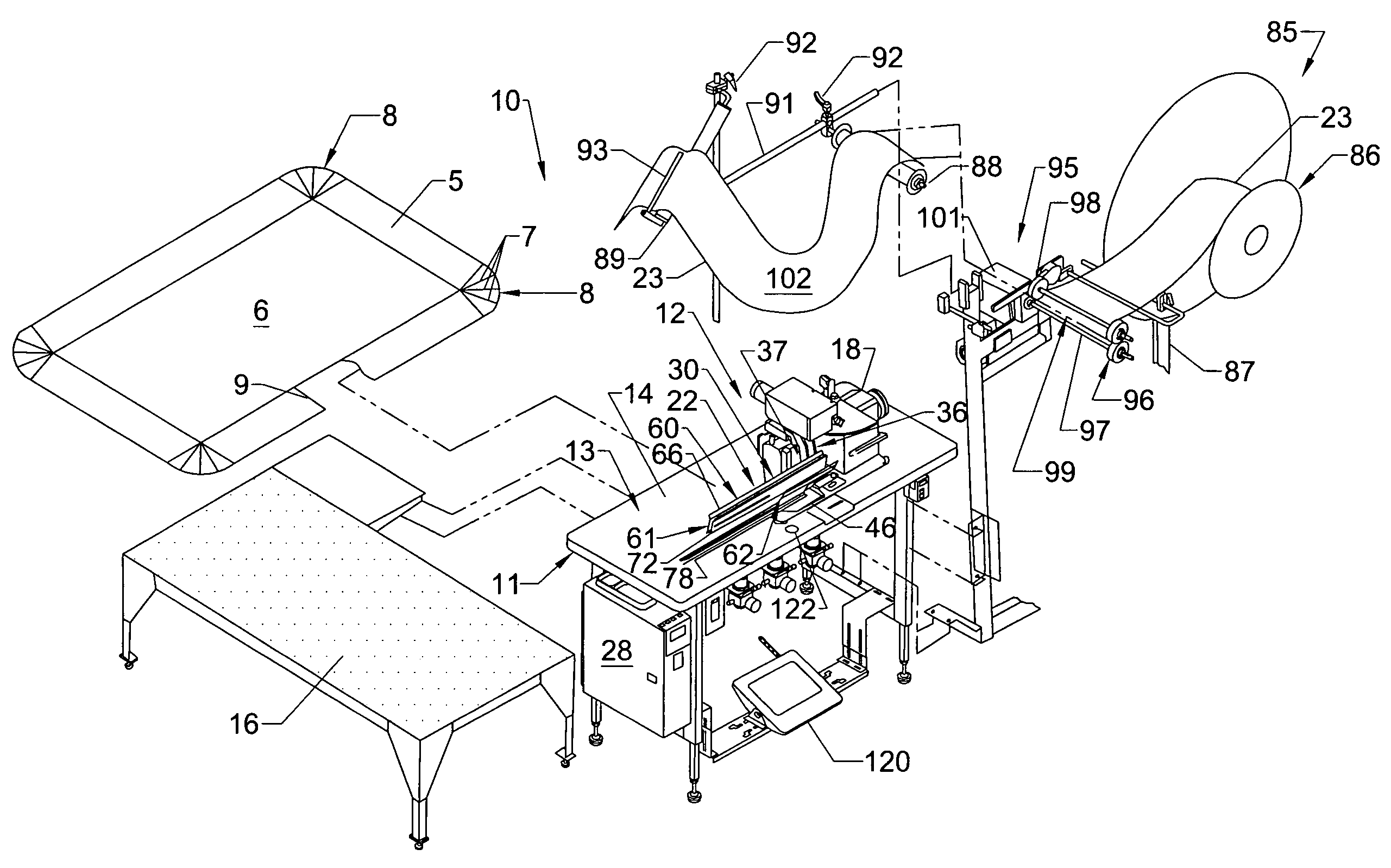

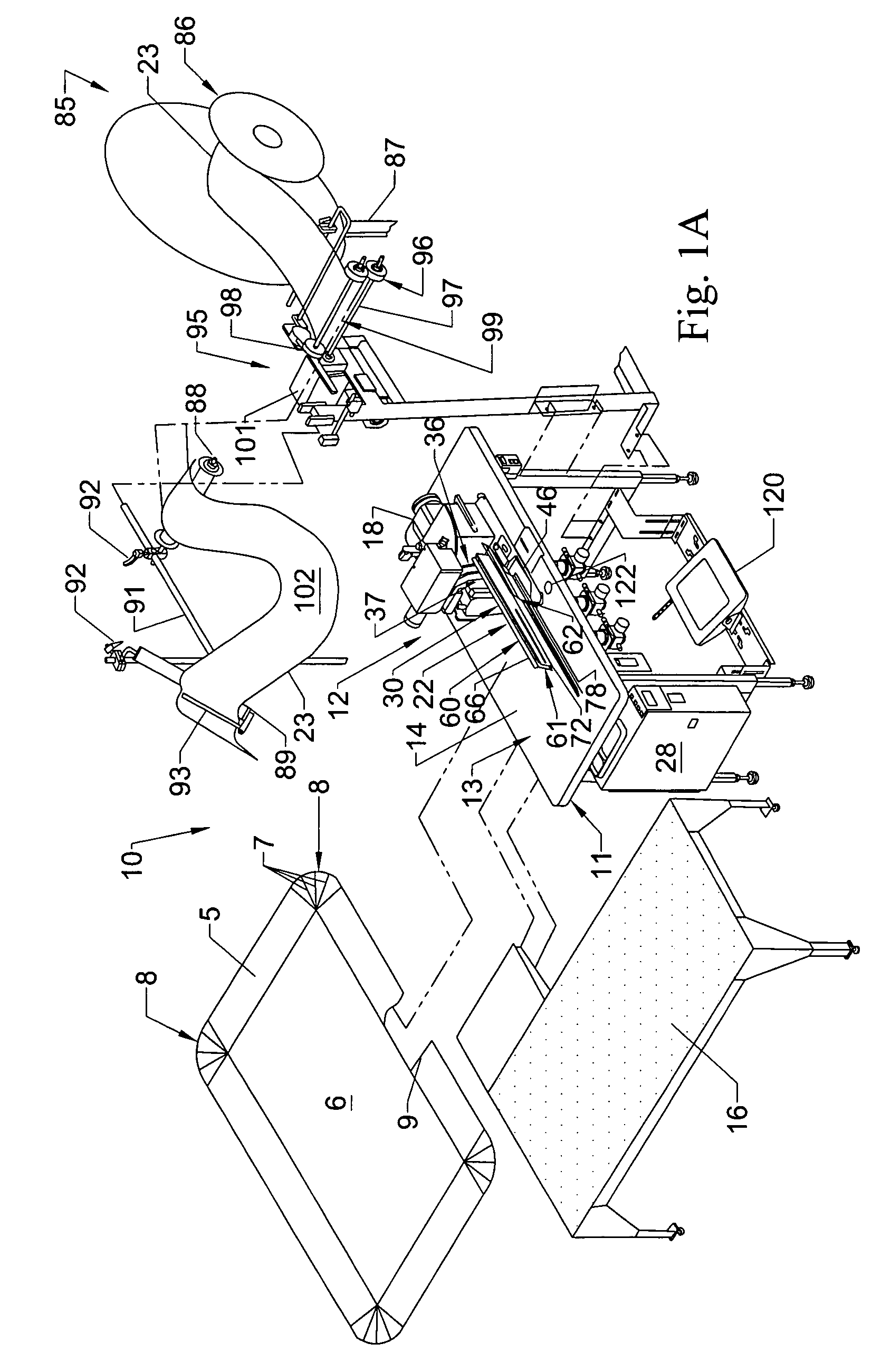

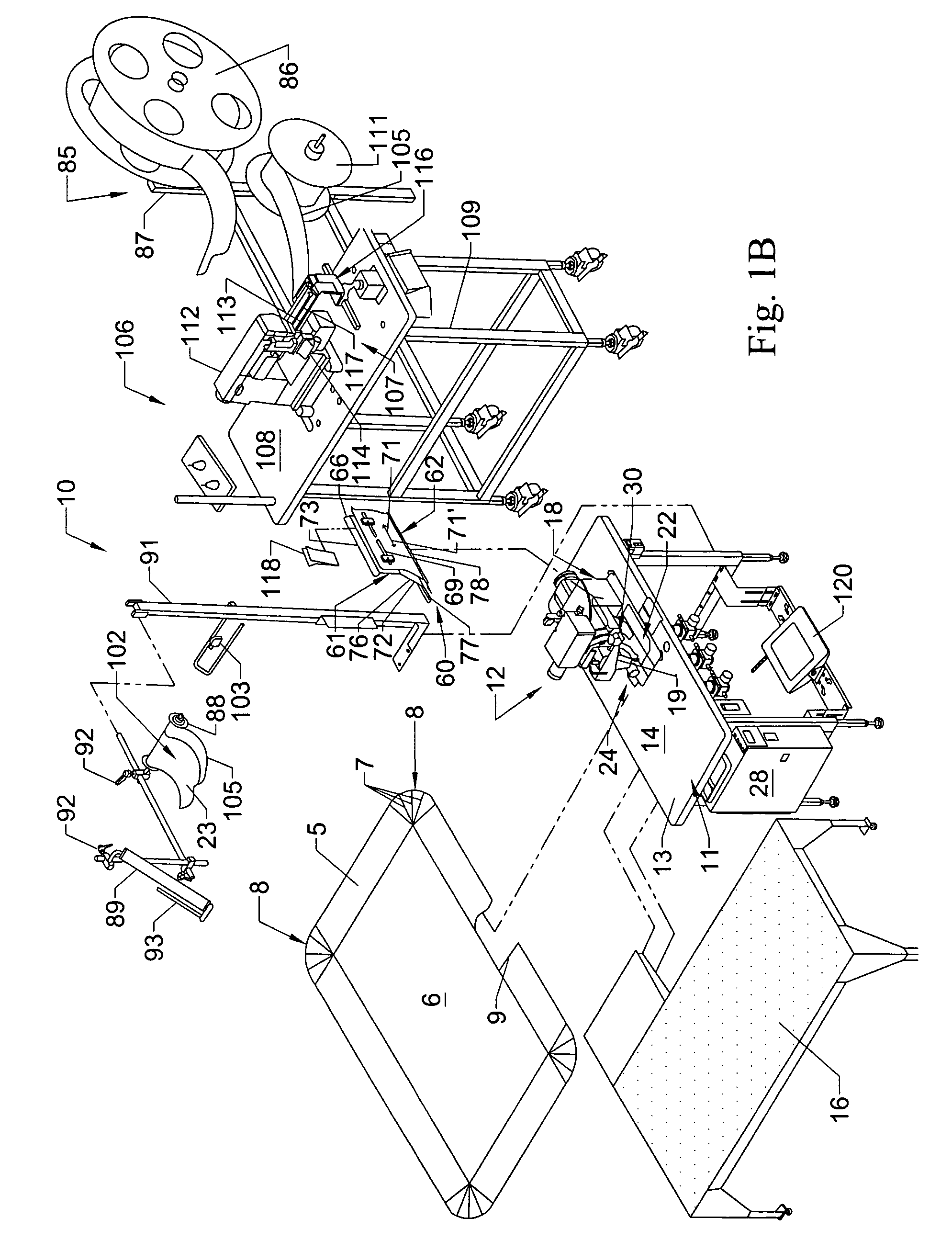

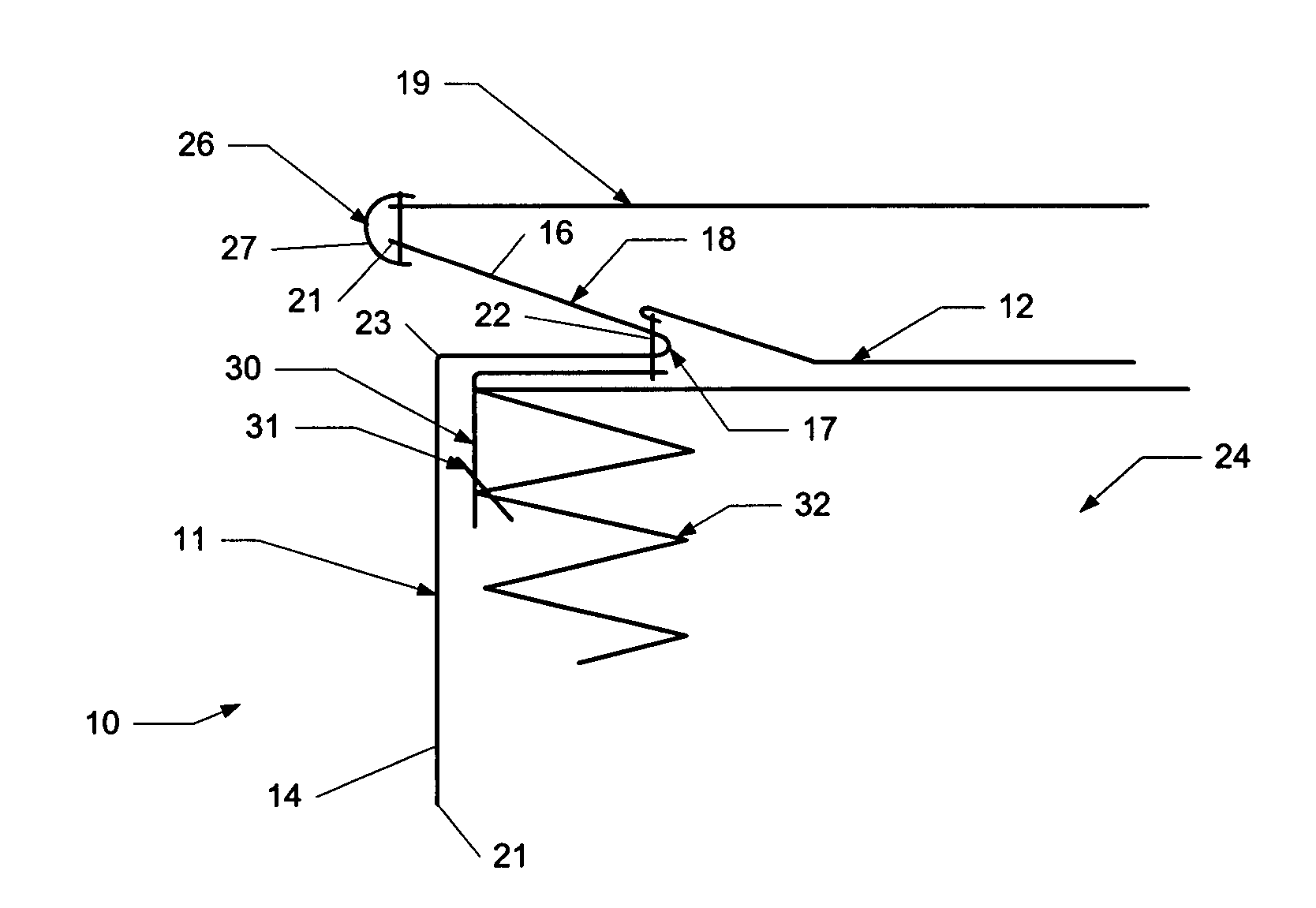

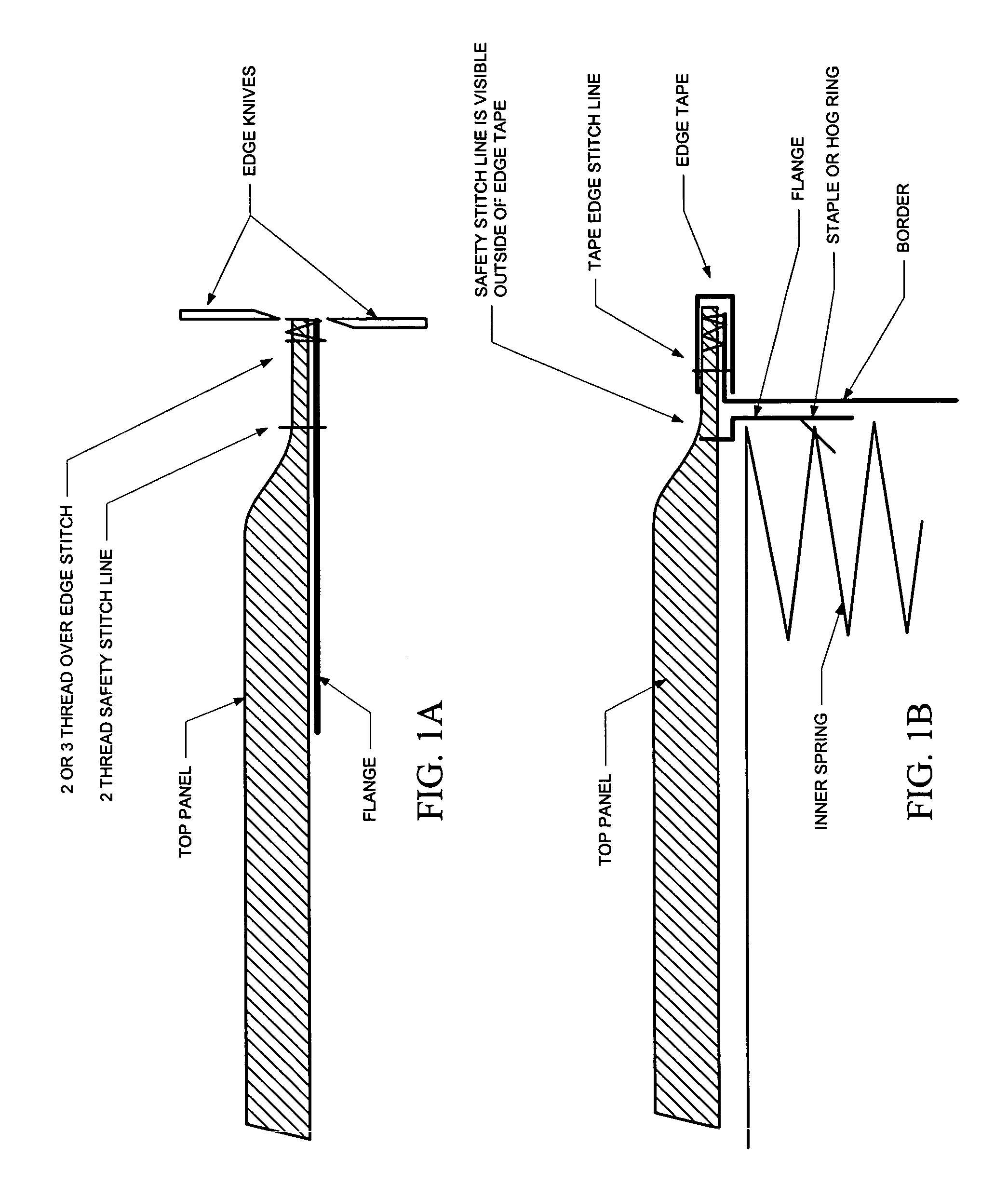

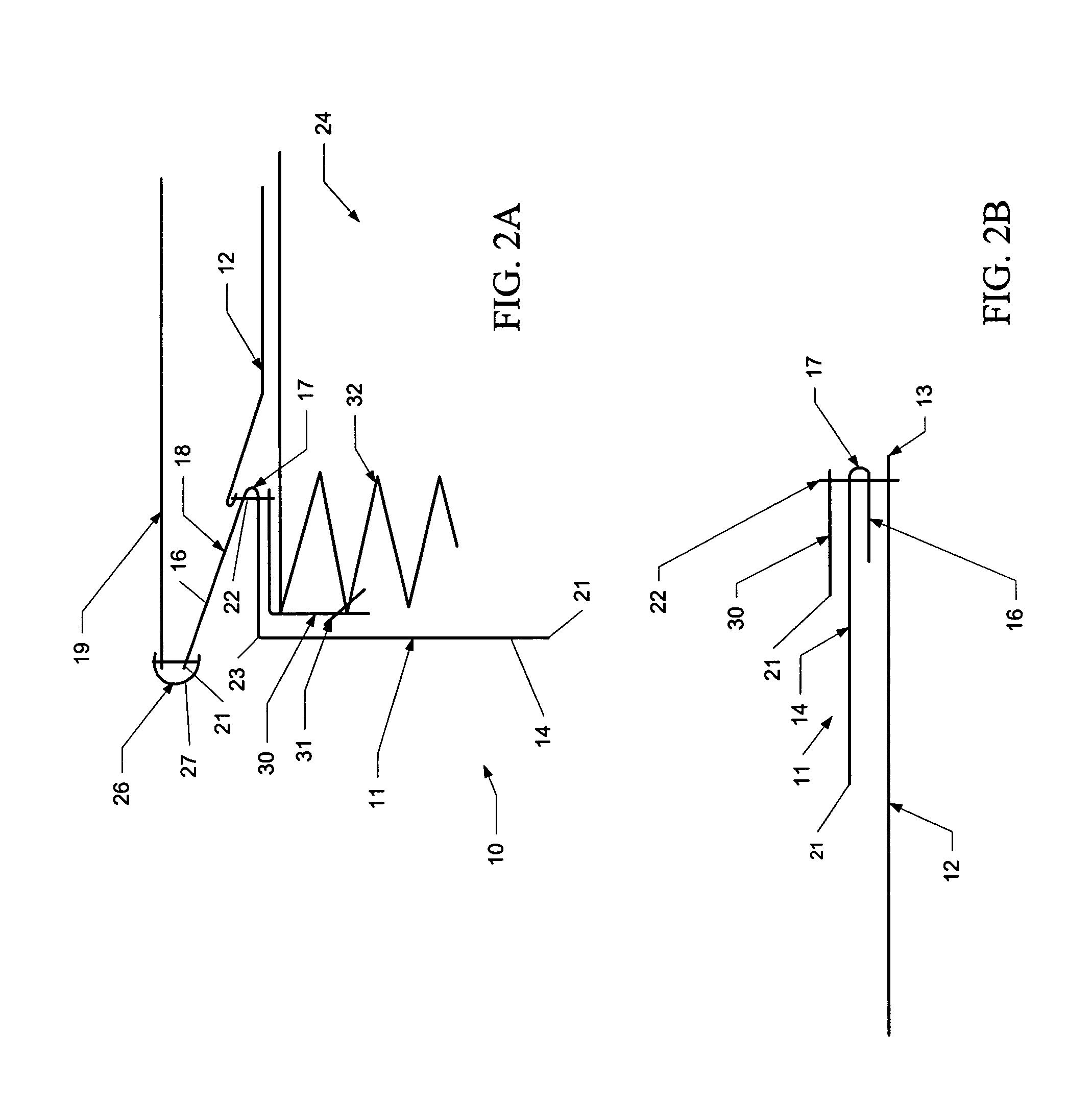

System and method of finishing ruffled gussets/borders

A system for forming and attaching pillowtop attachment gussets and borders to panels, with the gusset or border material being fed from a supply into a sewing station. The gusset or border material is passed through a folder assembly that directs the gusset or border material into a sewing zone where it is attached to the panel. A ruffler mechanism engages and forms a series of ruffles in the gusset or border material as it is sewn about the corners of the panel.

Owner:ATLANTA ATTACHMENT

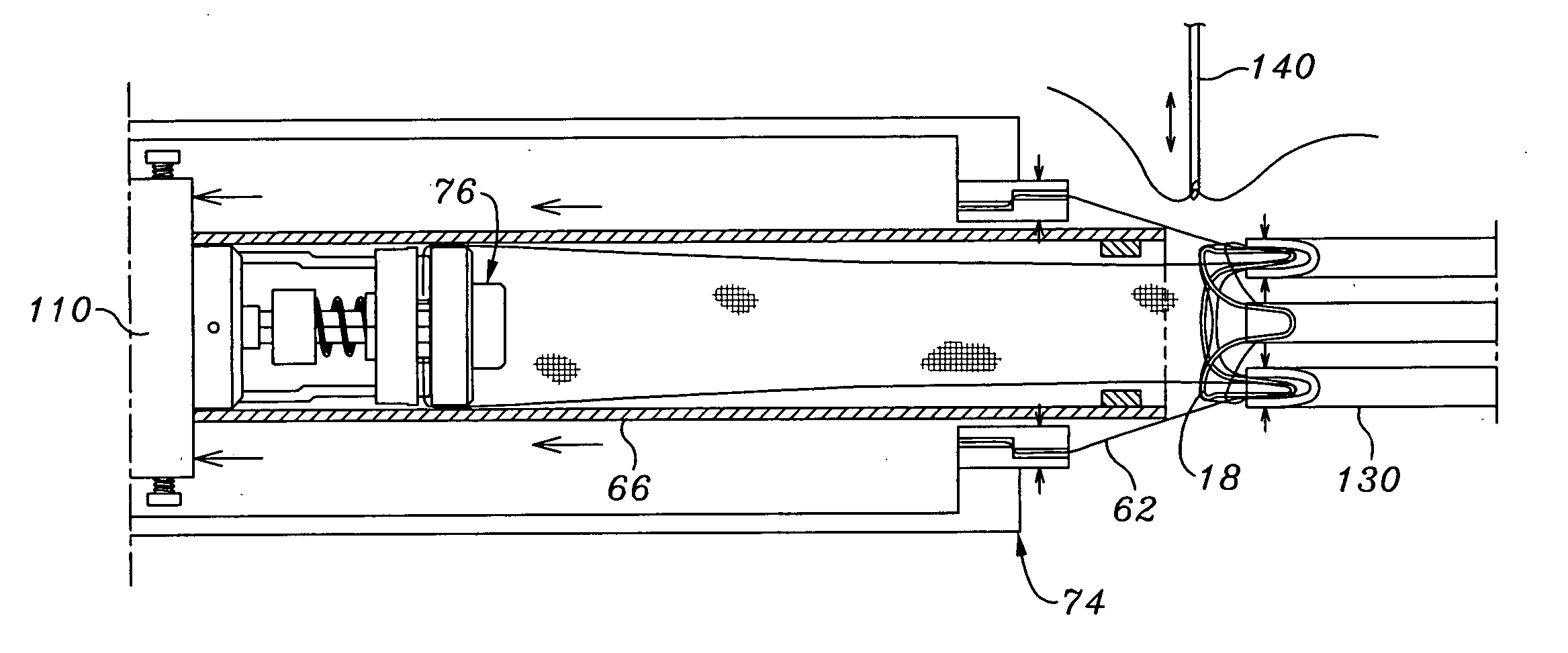

Method of forming a mattress

A method of forming a mattress, with a reduction in the number of sewing operations required, in which a border and gusset or an extended portion of the border will be integrally formed and attached to a mattress panel, with a flanging material also being attached as needed, to form a mattress cover or sleeve. A tape edge also can be applied for providing a more decorative appearance. Thereafter, the mattress cover or sleeve can be applied over a mattress spring set.

Owner:ATLANTA ATTACHMENT

Bi-directional seaming machine

Owner:MILLER WELDMASTER CORP

Radio Frequency Identification (RFID) Tag

A radio frequency identification (RFID) tag is disclosed as including an integrated circuit and at least one antenna connected with the integrated circuit, wherein the antenna is formed of an at least partly metalized thread.

Owner:CONVERGENCE SYST

Bone growth promotion systems and methods

This disclosure describes systems and methods for providing a novel delivery system for implantation in a patient. Further, this disclosure describes a delivery system including a carrier that is made of at least one monolithic bone tissue for retaining one or more substances.

Owner:ZIMMER BIOMET SPINE INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com