Golf mat

a golf mat and golf technology, applied in the field of golf mats, can solve the problems of air-born particles that can be irritating to the golfer, unfavorable variations in the infill depth, etc., and achieve the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018]While the present invention will be described herein with reference to particular embodiments thereof, a latitude of modifications, various changes and substitutions are intended, and it will be appreciated that in some instances some features of the invention will be employed without a corresponding use of other features without departing from the spirit and scope of the invention as described with respect to the preferred embodiments set forth herein.

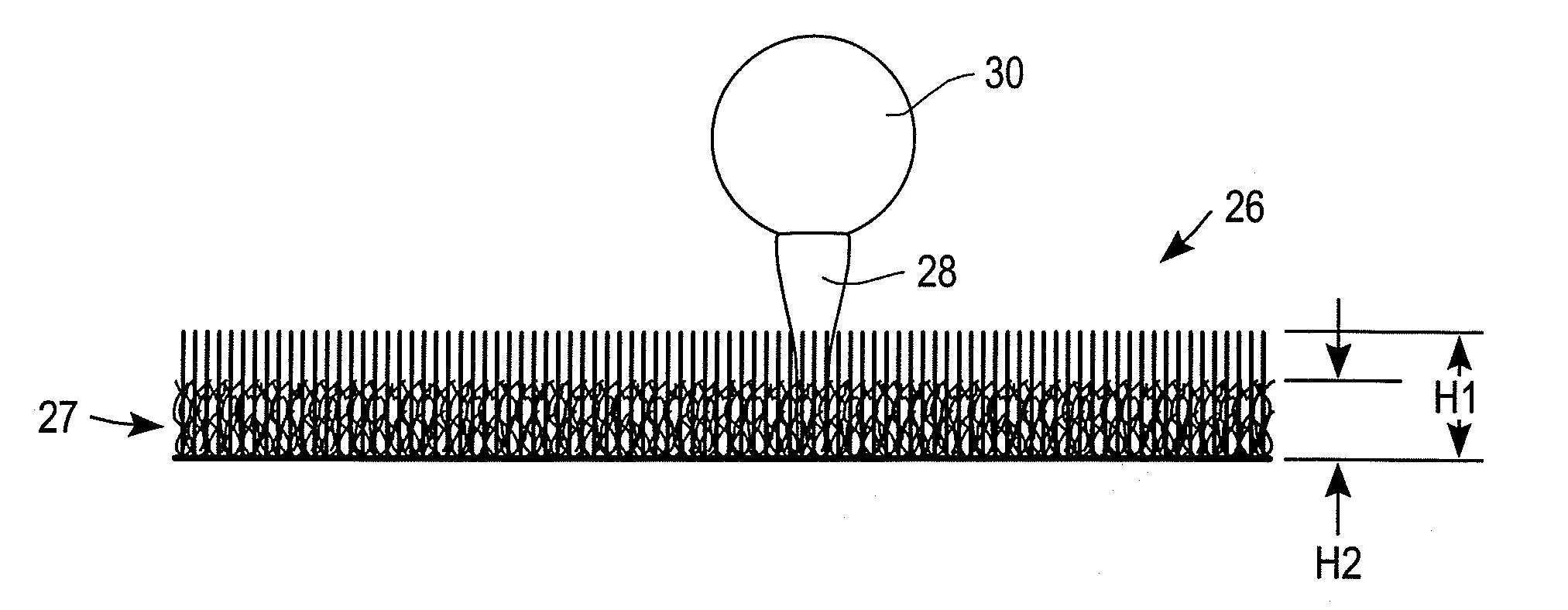

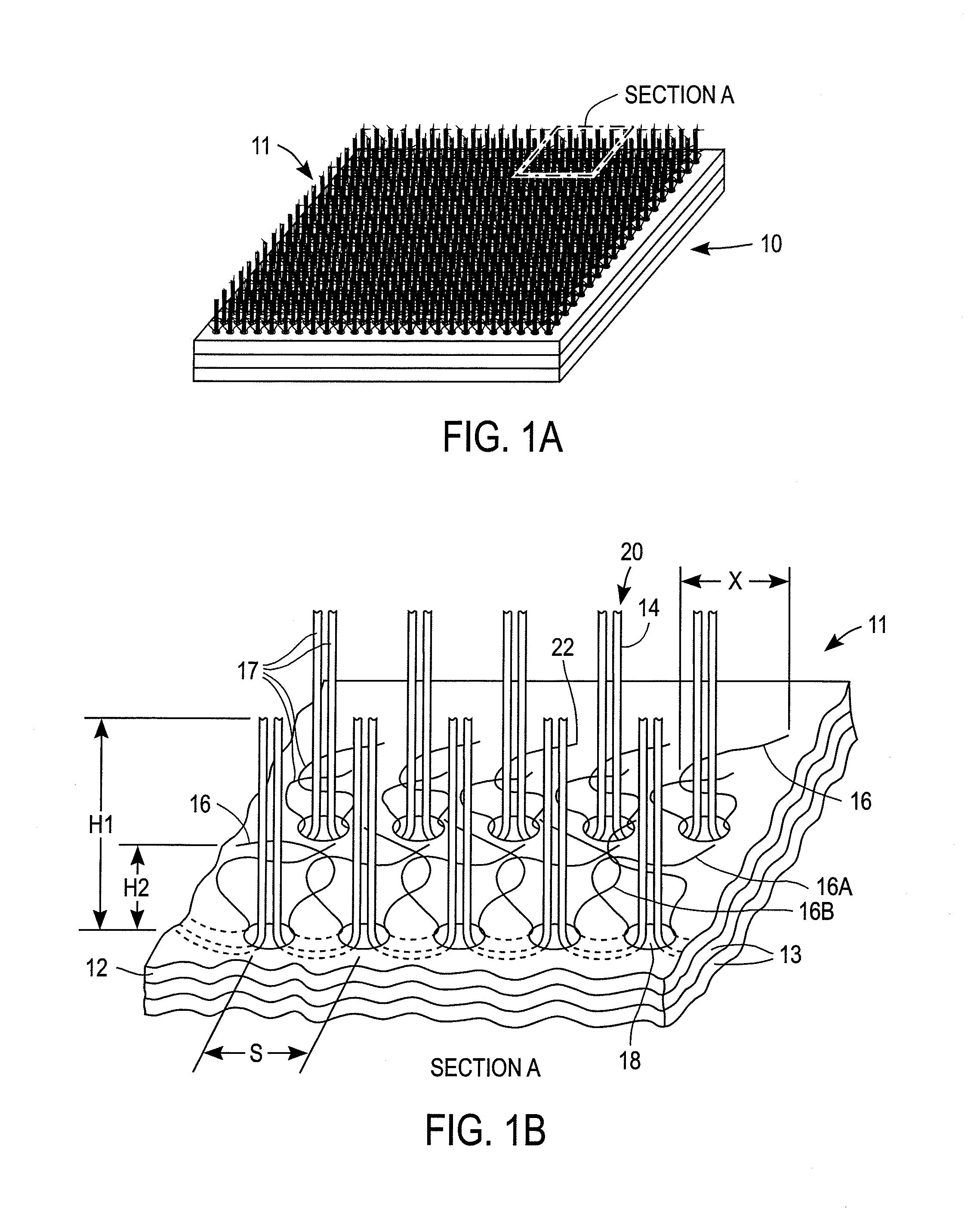

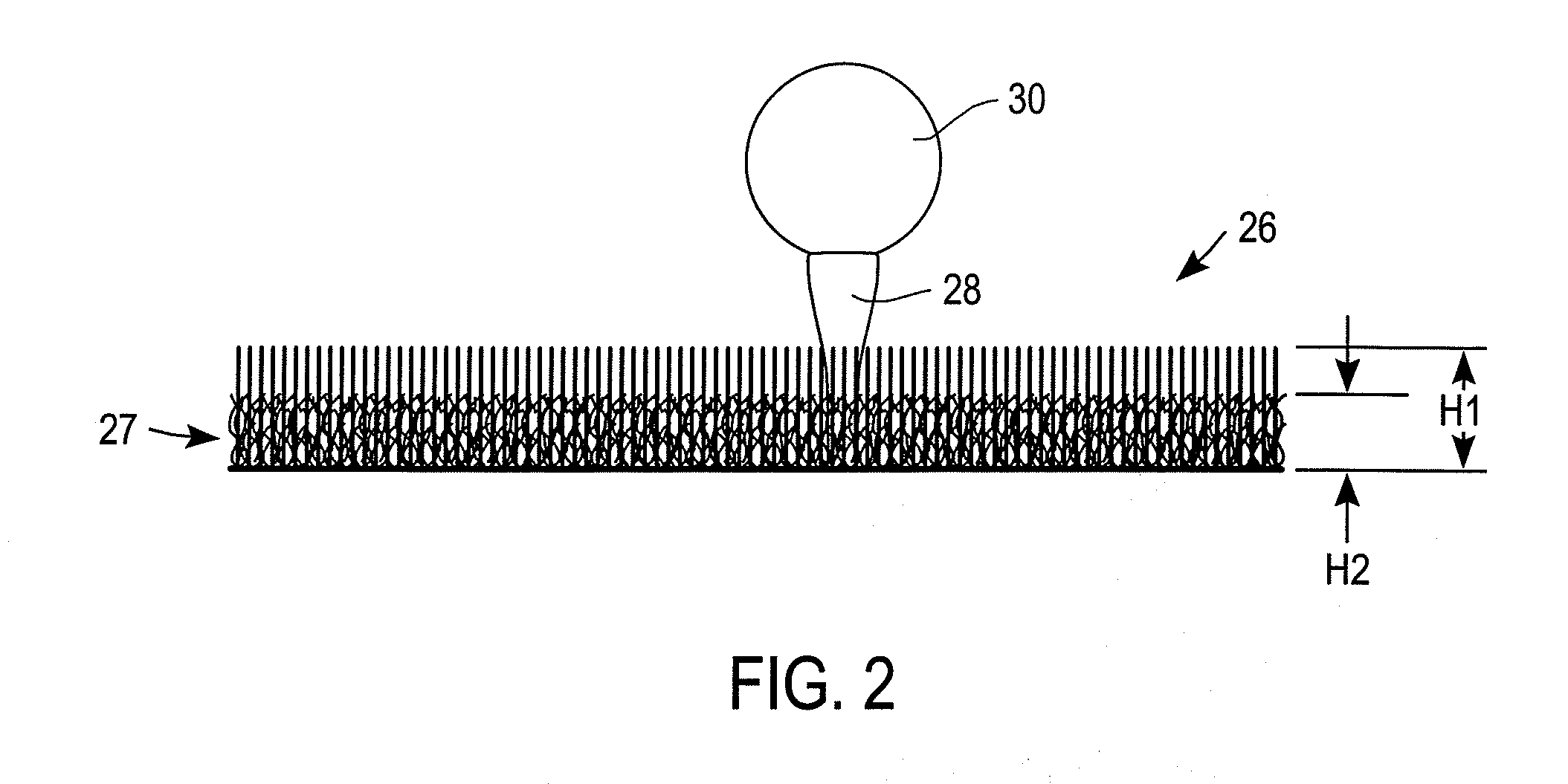

[0019]A golf mat 10 of the present invention is shown in FIG. 1A, having artificial turf 11. FIG. 1B is an enlargened view of a section “A” of the mat of FIG. 1A for illustrating the construction of the artificial turf 11, and also showing alternative base layers 13 which can be of any number, thickness and resiliency. The artificial turf 11 includes a backing material 12 with two different kinds of fiber 14 and 16 sewn into it. Groups of fibers, each group including at least one grass-like fiber 14 and one non-linear fiber 16 p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Time | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Distance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com