Multifunctional grain sampling machine

A multi-functional, grain-based technology, applied in the direction of sampling, sampling device, test sample preparation, etc., can solve the problems of increased workload, deformation of the dust compartment, deformation of the sealing cover, etc., to reduce cost loss, simple structure, Versatile Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with accompanying drawing description and specific embodiment:

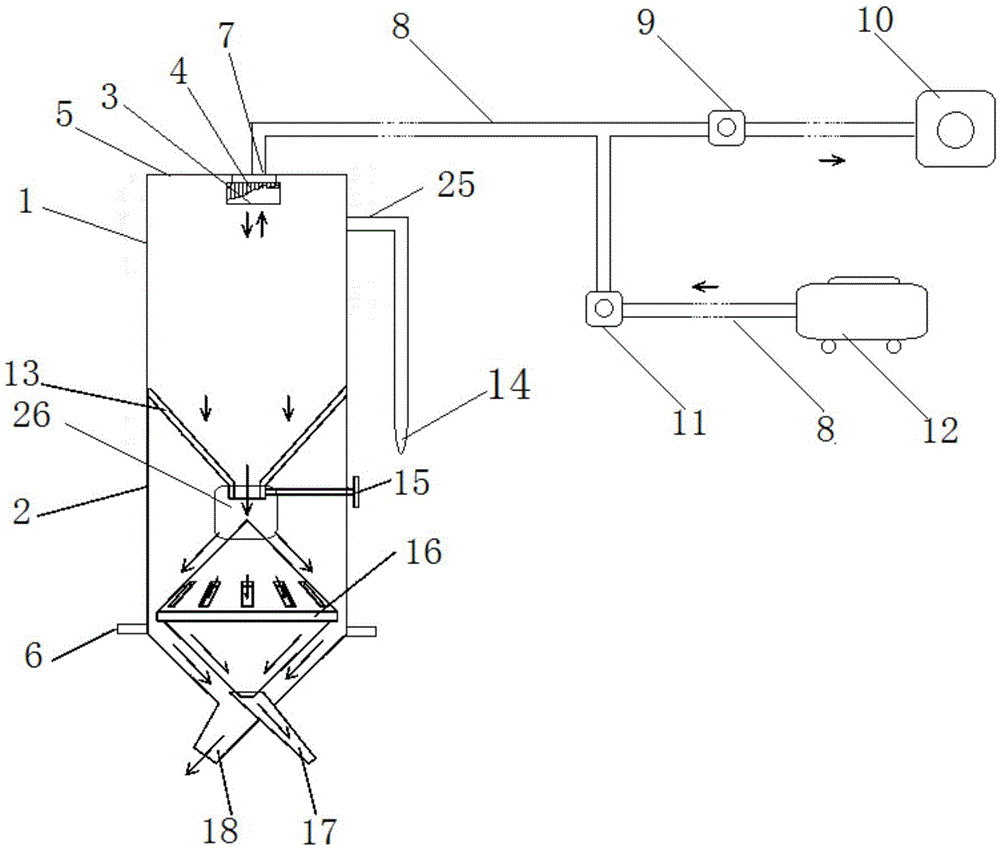

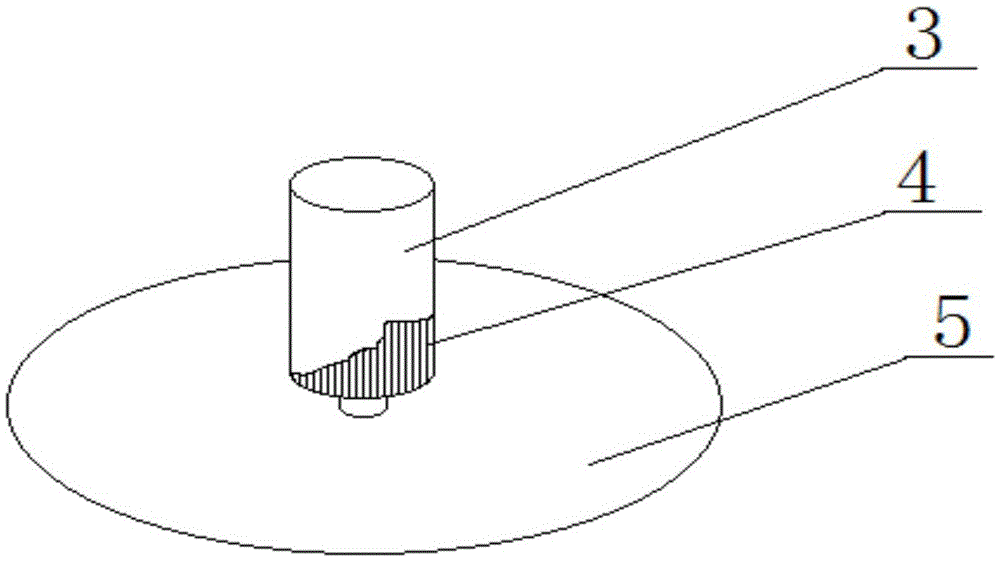

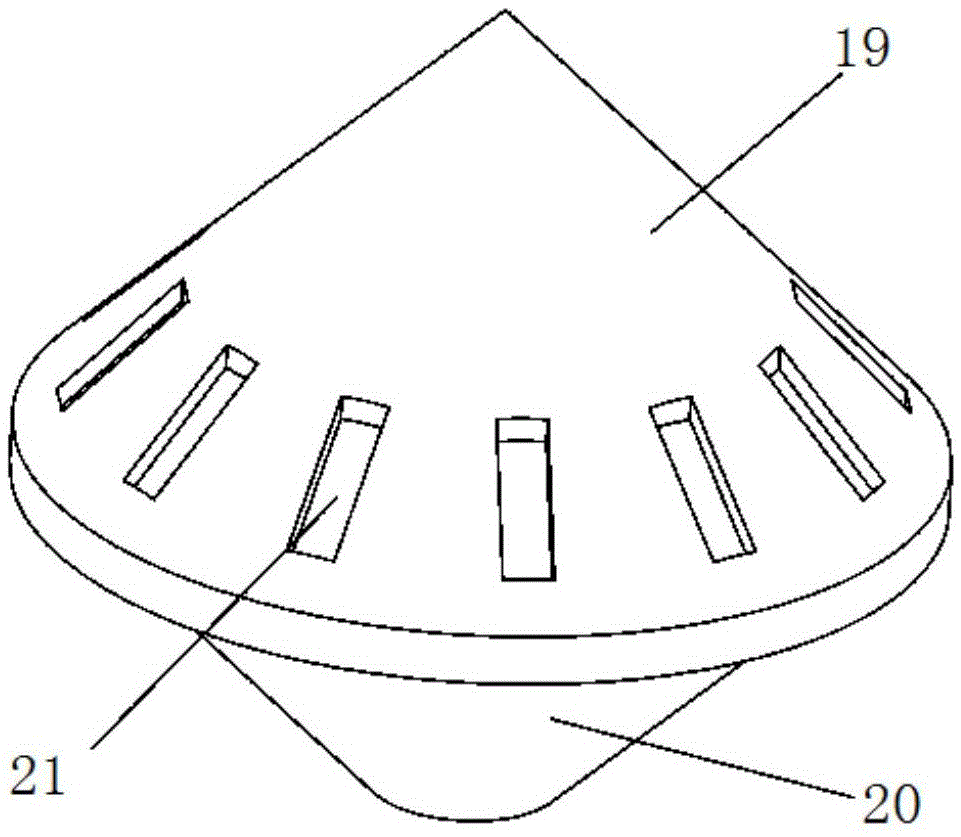

[0028] Such as figure 1 , figure 2 A kind of multi-functional grain sampling machine shown in , comprises sampling part 1, sample dividing part 2, and sampling part 1 is fixedly arranged on the top of sampling part 2; It is characterized in that: the tube of described sampling part 1 The center of the bottom 5 is provided with an air inlet and outlet 7, and a cylindrical filter tank 4 is connected to the inside of the bottom 5, and a filter cover 3 is set on the outer surface of the filter tank 4; In the process of using the grain suction cylinder, the dust filtering effect can be greatly improved through the double cooperation of the filter cover 3 and the filter element tank 4, and the overall structure is simple, small, durable, and the cost in the use process is greatly reduced.

[0029] The air inlet and outlet 7 are con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com