Biomass composite combustion heat-exchange integrated furnace

A biomass and combustion chamber technology, applied in incinerators, combustion methods, combustion types, etc., can solve problems such as large excess air, pollute the environment, poor heat transfer, etc., and achieve the effect of solving slagging problems and reducing pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

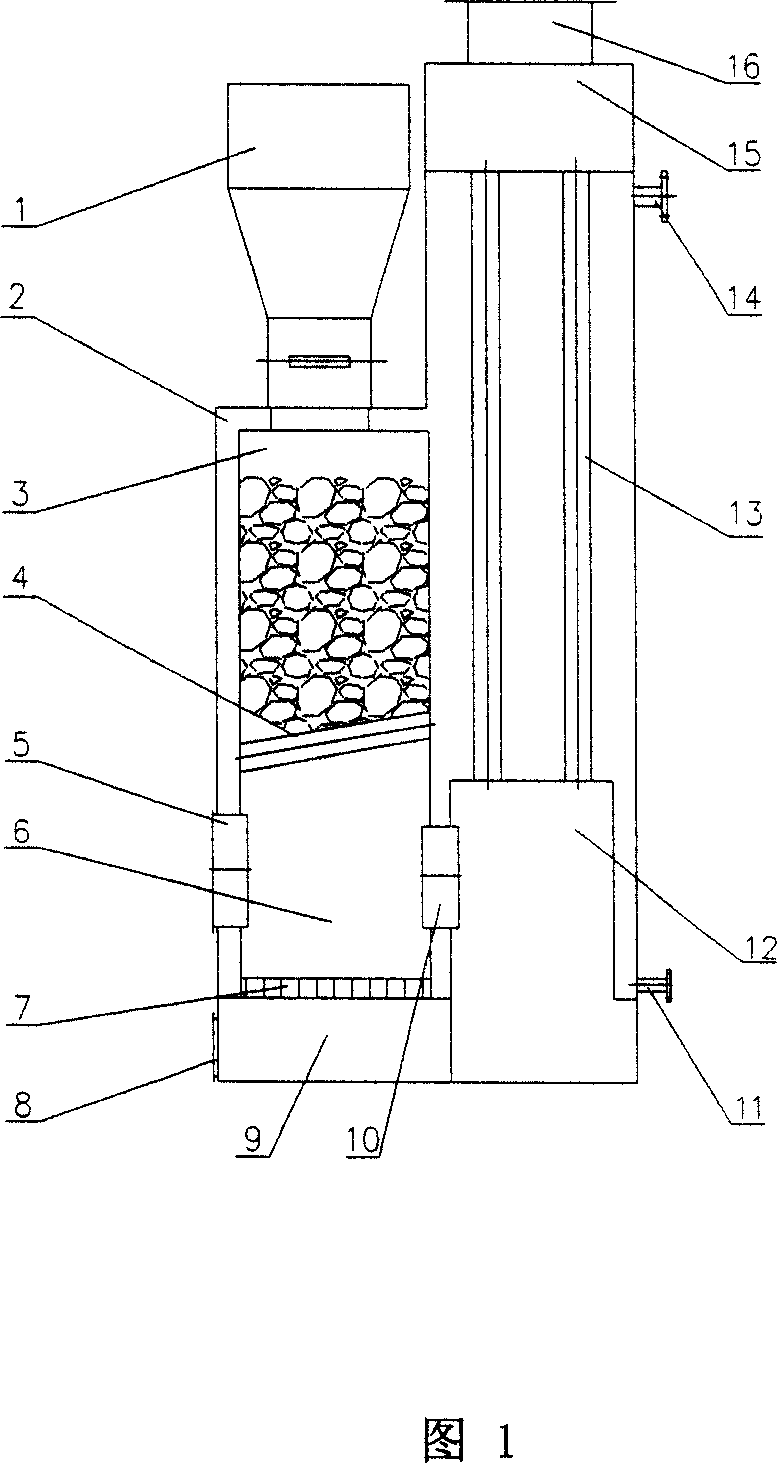

[0014] Below in conjunction with the embodiment shown in the accompanying drawings, further illustrate the content and working principle of the present invention.

[0015] As shown in Figure 1. This type of furnace adopts a two-in-one structure, and the upper part of the body is provided with a hopper 1 for storing biomass briquettes. The fuel enters the gasification combustion chamber 3 through the hopper 1 . The gasification combustion chamber 3 is cooled by the water interlayer 2 to absorb heat. A water-cooled fire grate 4 is provided at the bottom of the gasification combustion chamber 3 . There is a thicker fuel layer inside the gasification combustion chamber 3 . The fuel undergoes drying, pyrolysis, gasification and reduction reaction, and the pyrolysis gasification gas and reduction gasification gas of the fuel pass through the water-cooled grate 4 downwards at high temperature and burn in the layer combustion combustion chamber 6 . The unburned carbon in the gasif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com