Continuous powder surface modification system

A powder surface modification and powder modification technology, which is applied to conveyor objects, loading/unloading, conveyors, etc., to achieve the effect of simplifying the production process, advanced concepts, and uniform monolayer adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

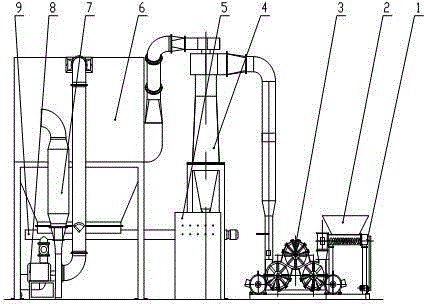

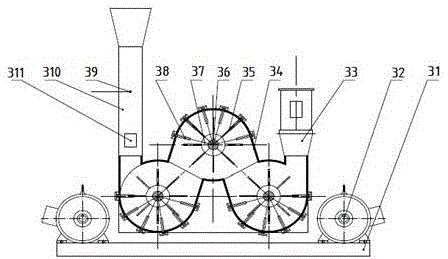

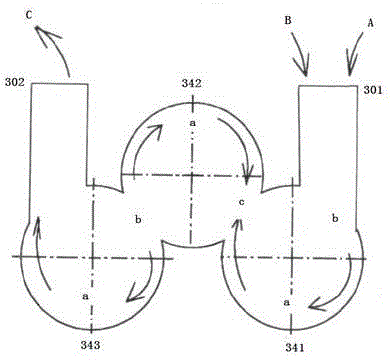

[0021] see figure 1 , which is a continuous powder surface modification system of the present invention. As shown in the figure: it includes double screw feeder 1, raw material hopper 2, continuous powder modification machine 3, cyclone powder collector 4, electric control cabinet 5, pulse dust collector 6, silencer 7, centrifugal fan 8. Finished product screw conveyor 9; wherein: a double-screw feeder 1 is set at the outlet of the raw material hopper 2, and the output end of the double-screw feeder 1 is set at the feeder of the continuous powder modification machine 3 Above the port 301, the discharge port 302 of the continuous powder modification machine 3 is connected to the cyclone powder collector 4 through a pipeline, and the finished product outlet of the cyclone powder collector 4 is set on the finished product screw conveyor 9; the cyclone powder collector The negative pressure end of the device 4 is connected to the pulse dust collector 6 and the centrifugal fan 8 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com