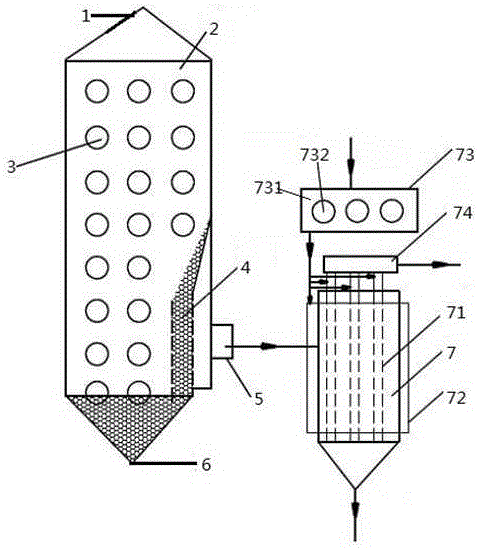

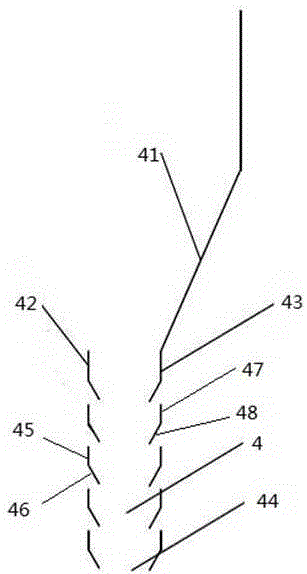

Pulverized coal pyrolysis dedusting system with granular bed and tubular filter inside

A particle bed and filter technology, which is applied in the field of coal classification and cascade utilization, can solve the problems of complex powder coke and pyrolysis oil and gas components, difficulty in direct utilization and storage, high solid content of coal tar, etc., and achieve high-efficiency dust removal problems, Good insulation effect and short residence time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] The pyrolysis reaction system is used to process Australian lignite, and the comparison between adding granular bed dust removal and cyclone dust collector is shown in Table 1.

[0058] serial number Pyrolysis gas dust removal method Dust content after dust removal 1 Cyclone dust removal 125mg / Nm 3 2 Granular bed + tube filter dust removal 20mg / Nm 3

Embodiment 2

[0060] The pyrolysis reaction system is used to process Indonesian lignite, and the comparison between adding granular bed dust removal and cyclone dust collector is shown in Table 2.

[0061] serial number Pyrolysis gas dust removal method Dust content after dust removal 1 Cyclone dust removal 132mg / Nm 3 2 Granular bed + tube filter dust removal 16mg / Nm 3

[0062] The pulverized coal pyrolysis dust removal system with built-in particle bed provided by the present invention has the advantages of high temperature resistance, good heat preservation effect and corrosion resistance, can work normally at a high temperature of 500-600 °C, and can effectively prevent condensation in the pyrolysis gas The dust-containing tar generated by the gas due to temperature changes causes it to adhere to the dust removal equipment, thereby effectively avoiding accelerated aging of the equipment or even making it useless under high temperature conditions. More...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com