Fastener protecting cover

A technology of fasteners and protective covers, which is applied to roads, tracks, buildings, etc., to achieve the effects of simple production process, reduced labor intensity and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

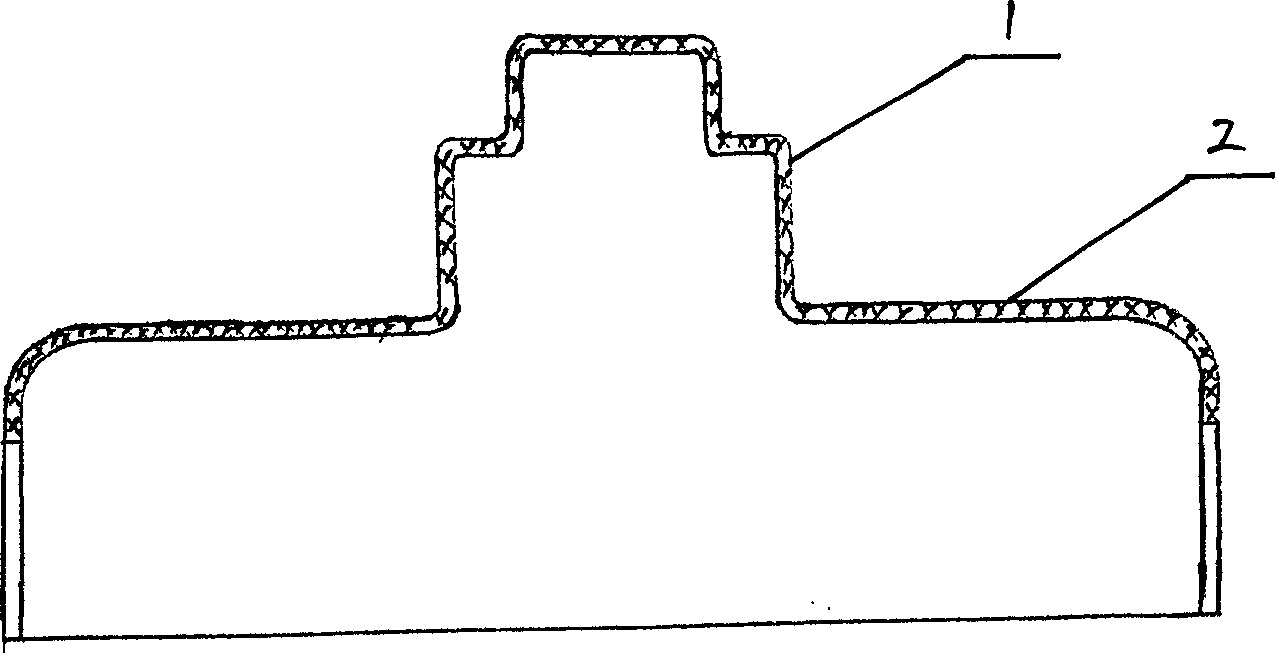

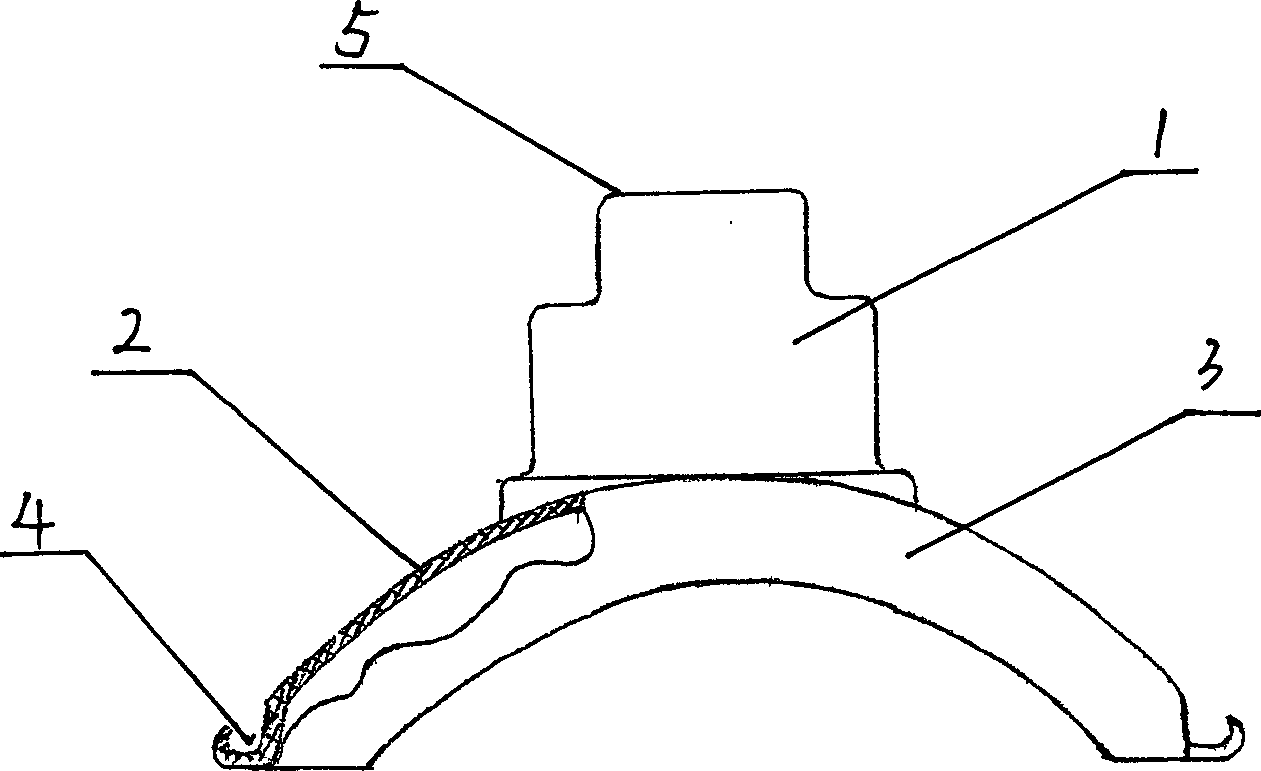

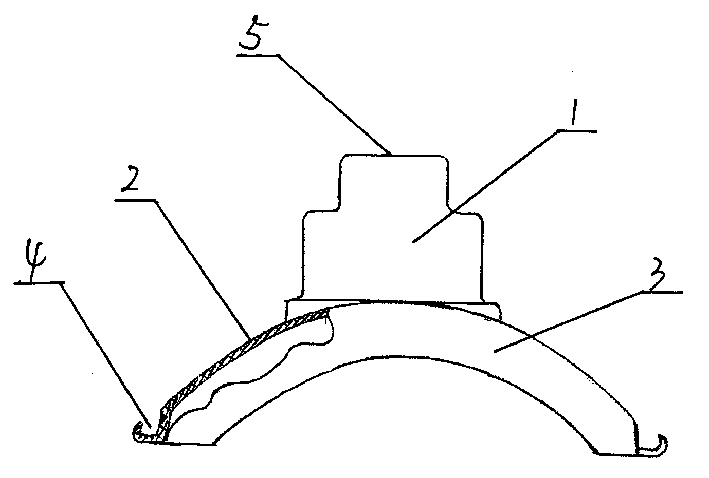

[0012] Referring to the accompanying drawings, a fastener cover for rails, the upper end of the cover is provided with a convex top cover 1, and the lower end of the top cover is extended into an arched protective cover 2, and the top cover is sealed and connected with the protective cover. integrally formed on the substrate. The lower edge of the protective cover is rolled with symmetrical long grooves 4 . The sides of the protective cover extend downwards with side plates 3 of the same shape. The top cover is circular. A hollow protrusion 5 is arranged above the top cover.

[0013] The fastener cover is a new type of rubber and plastic product. The hollow protrusion 5 on the top cover 1 matches and fixes the exposed screw nut. The rainwater drainage groove allows the water to flow away directly from the protective cover without contacting the fastener material, so as to achieve the isolation effect and avoid rusting. The fastener cover can be widely used in the fields of...

Embodiment 2

[0015] Referring to the accompanying drawings, a fastener cover for rails, the upper end of the cover is provided with a convex top cover 1, and the lower end of the top cover is extended into an arched protective cover 2, and the top cover is sealed and connected with the protective cover. integrally formed on the substrate. The lower edge of the protective cover is rolled with symmetrical long grooves 4 . The sides of the protective cover extend downwards with side plates 3 of the same shape. The top cover is hexagonal. A hollow protrusion 5 is arranged above the top cover.

Embodiment 3

[0017] Referring to the accompanying drawings, a fastener cover for rails, the upper end of the cover is provided with a convex top cover 1, and the lower end of the top cover is extended into an arched protective cover 2, and the top cover is sealed and connected with the protective cover. integrally formed on the substrate. The lower edge of the protective cover is rolled with symmetrical long grooves 4 . The sides of the protective cover extend downwards with side plates 3 of the same shape. The top cover is square. A hollow protrusion 5 is arranged above the top cover.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com