Double-stage injection type pre-film pneumatic atomizing nozzle

An atomizing nozzle and ejector technology, which is applied in the field of two-stage ejector pre-film pneumatic atomizing nozzles, can solve the problems of difficult application in industrial heating occasions, easy wear and tear of oil pumps, and poor fuel atomization quality. Improves fuel atomization and combustion performance, eliminates fuel pumps, and reduces air pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

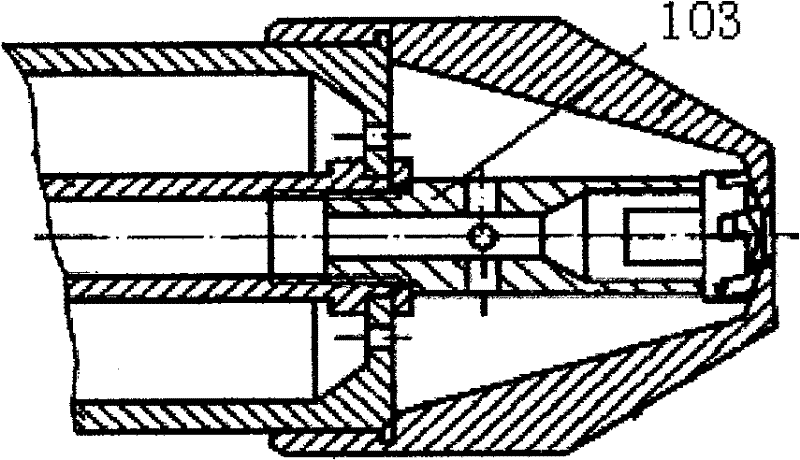

[0050] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

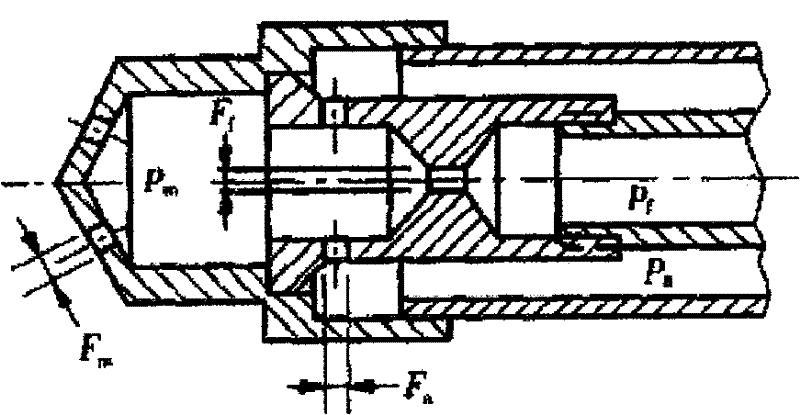

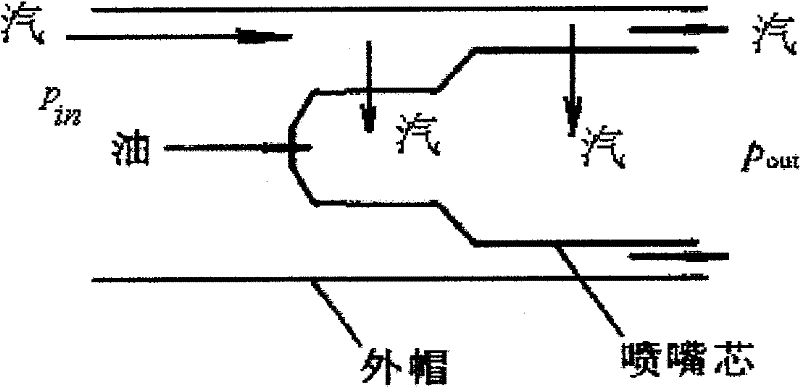

[0051] attached Figure 12 It is a schematic diagram of a two-stage injection pre-film pneumatic atomizing nozzle, which consists of a compression nut 1, an atomizing sheet 2, a guide sheet 3, a fixing piece 4, an oil and gas distributor 5, a central tube 6, and an air chamber seat 7 , air inlet 8, outer air inlet 9, inner air inlet 10, oil inlet 11, oil groove 12, tangential groove 13, swirl chamber 14, outer air ring port 15, oil ring outlet 16, inner air outlet Hole 17, spout 18 forms.

[0052] The compression nut 1 and the fixing part 4 are connected with the oil-gas distributor 5 through threads, and the atomizing sheet 2 and the deflector 3 are compressed through the compression nut 1 and the fixing part 4; the outlet of the atomizing sheet 2 is pressed against the compression nut 1 Tight, the inlet is pressed against the deflector 3; the upstr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com