Dry-stack gas desulful-izing method using position regulatable water sprag atomization method

A technology of dry flue gas desulfurization and desulfurization agent, which is applied in chemical instruments and methods, separation methods, and separation of dispersed particles. Rate and desulfurization efficiency and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

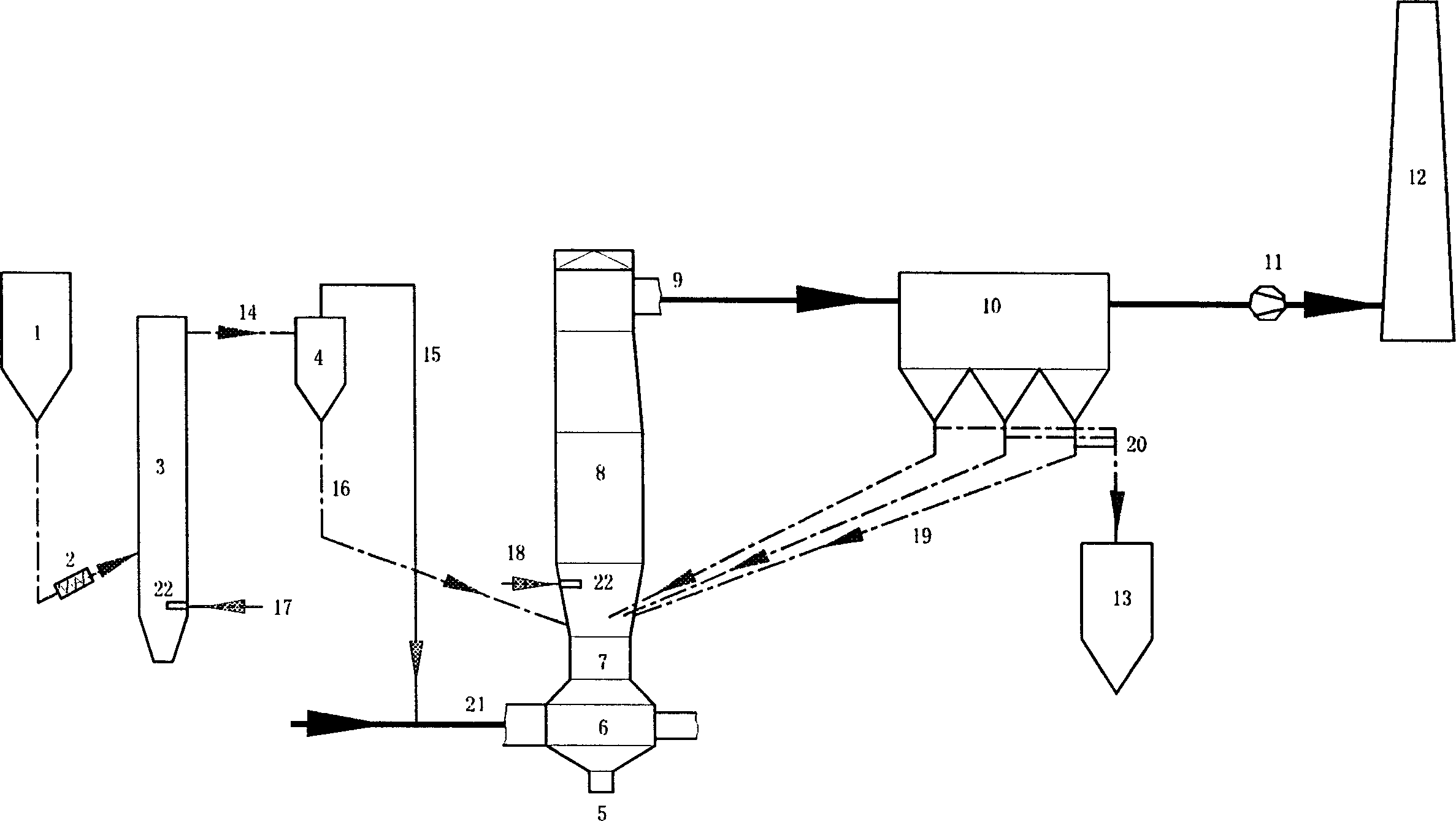

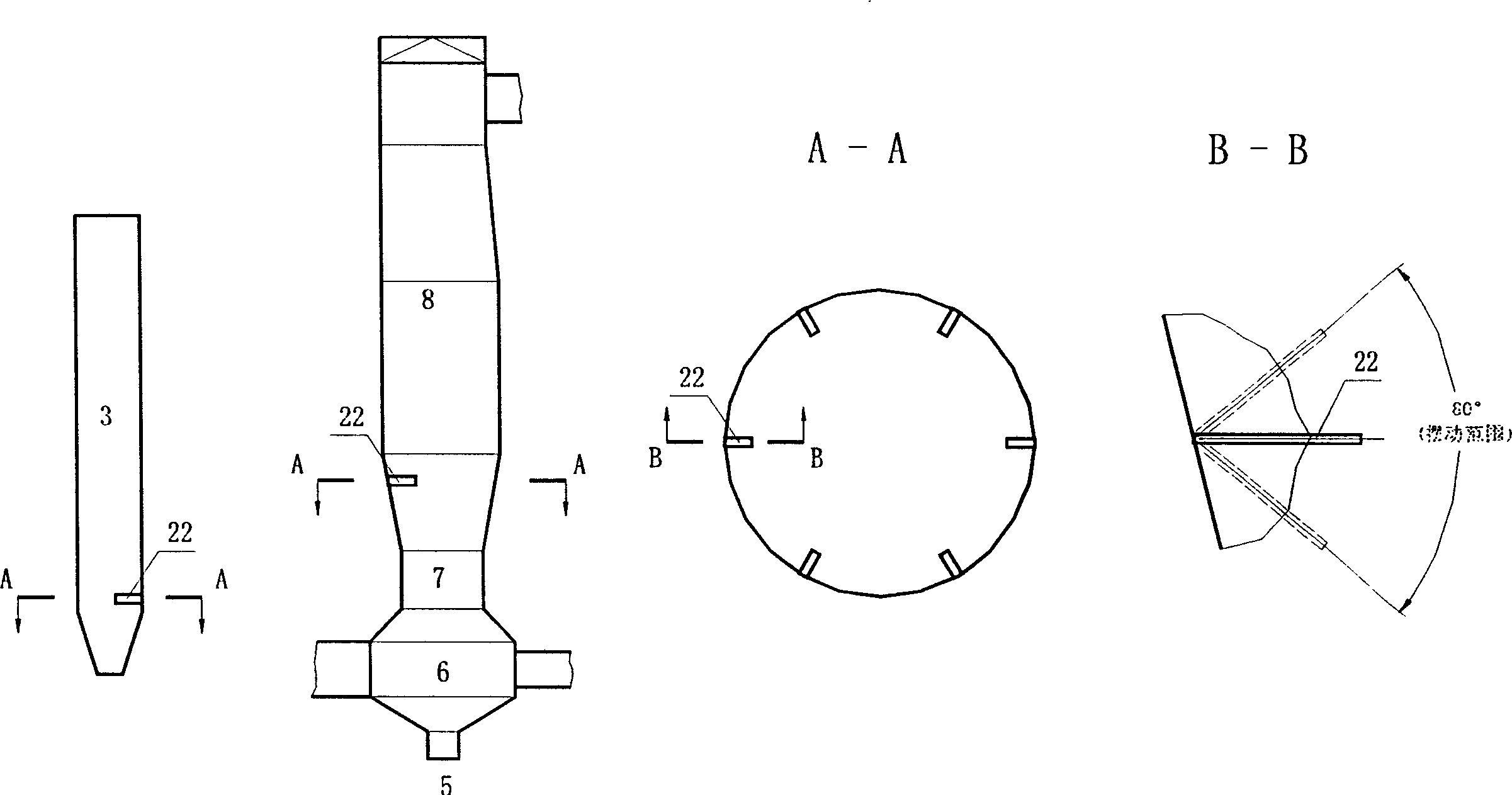

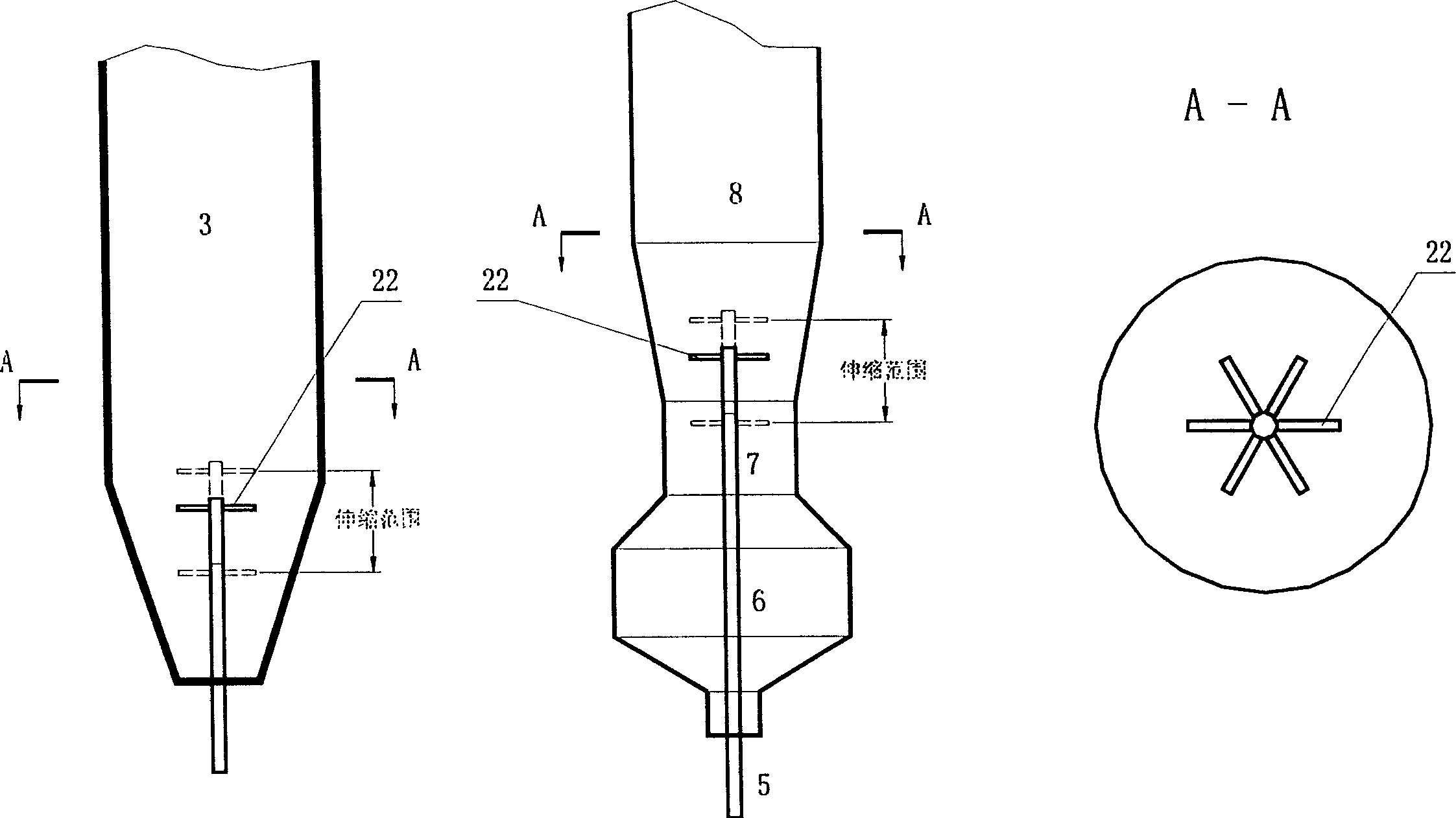

[0024] In the present invention, the untreated flue gas from boilers or other combustion equipment is first passed through different forms of particle separators (such as cyclone separators, louver type inertial separators, electrostatic precipitators, bag dust collectors, etc., such separators or used alone or in combination) for pre-dust removal, and then the flue gas with reduced soot concentration is sprayed into the desulfurization reaction tower where the slaked lime Ca(OH)2 generated after being fully digested by the digestion reaction tower is used as a desulfurization agent, in the desulfurization reaction The middle and lower part of the tower adopts the position-adjustable water spray atomization method, so that the SO2 in the flue gas and the slaked lime Ca(OH)2 react in the desulfurization tower to form solid calcium sulfite and calcium sulfate, and then discharge the desulfurization system, along with the desulfurization tower Part of the incompletely reacted desu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com