Inlet gas mixing device used for plasma enhanced chemical vapor deposition (PECVD) equipment

A technology of mixing device and equipment, applied in the field of intake mixing device, can solve the problems of coating process deviation, affecting the uniformity of film thickness, insufficient mixing of process gas, etc., and achieve the effect of improving the mixing degree and prolonging the mixing channel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The principle and structure of the present invention will be described in detail below in conjunction with the drawings and embodiments.

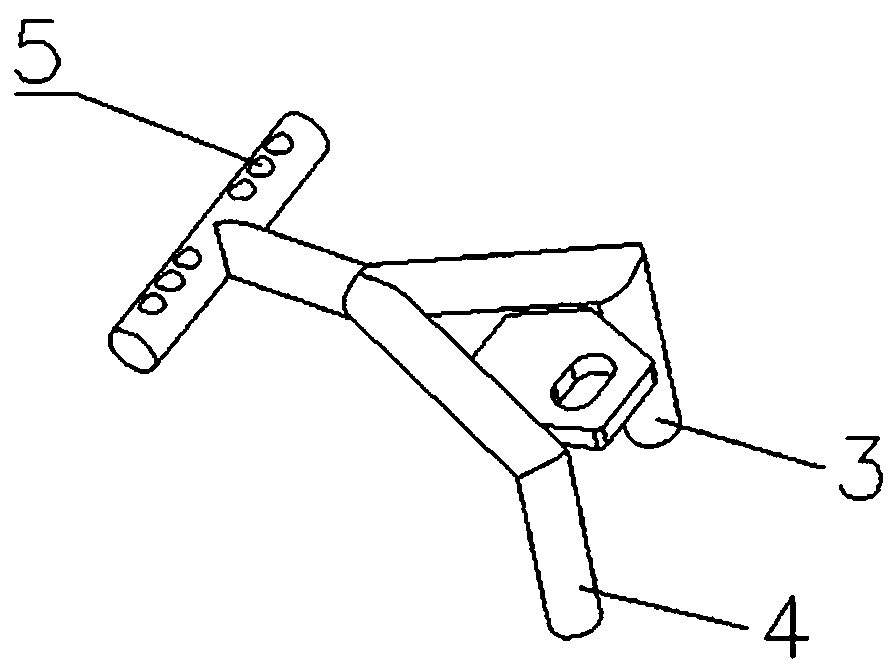

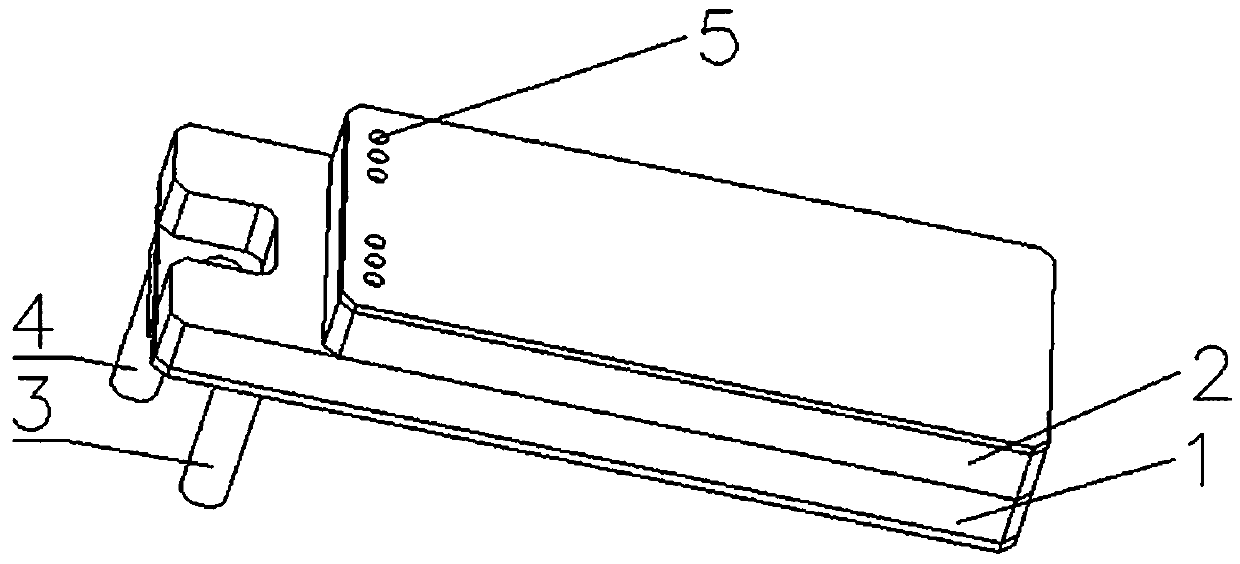

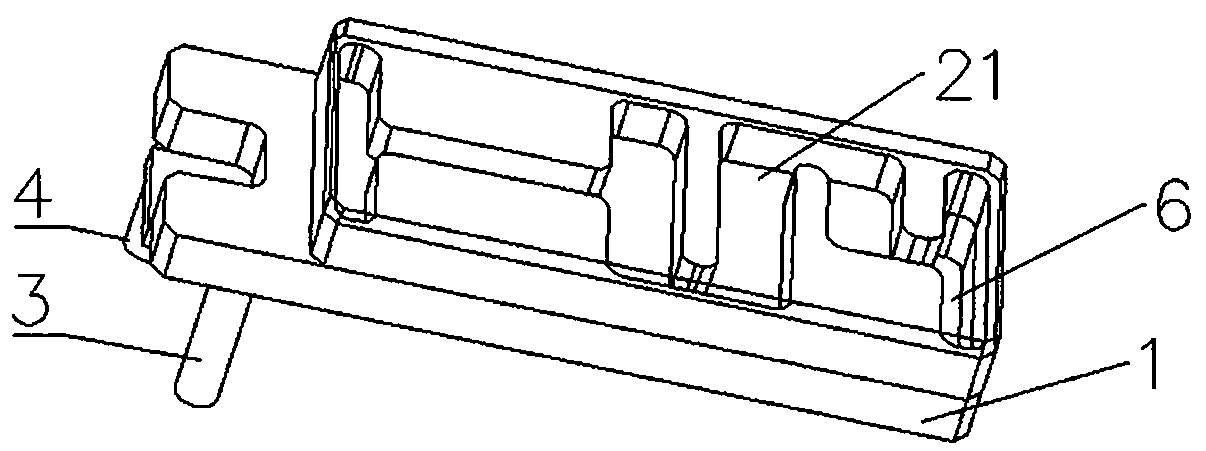

[0018] Such as figure 2 , image 3 , Figure 4 As shown, the present invention proposes a kind of air intake mixing device for PECVD equipment, including the first air intake guide pipe 3, the second air intake guide pipe 4, the gas outlet 5 and the gas mixing box, and the inside of the gas mixing box is equipped with There is a labyrinthine air mixing channel, the first air intake guide pipe 3 and the second air intake guide tube 4 are fixed on the air mixing box, and communicate with one end of the air mixing channel inside the air mixing box, and the air outlet 5 is arranged on the air mixing box. On the gas box and communicate with the other end of the gas mixing channel. The process gas can be fully mixed through the labyrinth gas mixing channel to achieve the best reaction state, and then discharged from the gas outlet 5 in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com