Wear-resistant gas distributor

A gas distributor, wear-resistant technology, applied in chemical instruments and methods, chemical/physical processes, etc., can solve the problems of short service life, waste of resources, affecting production efficiency, etc., to achieve low manufacturing costs, prolong service life, The effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

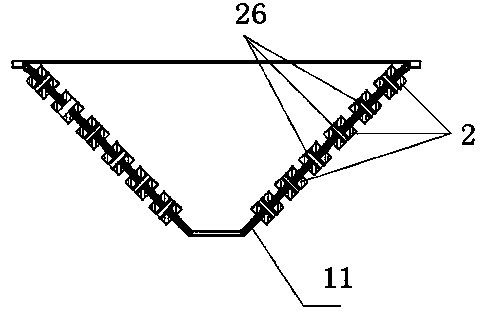

[0037] Combine below Figure 3 to Figure 7 , the present invention is further described:

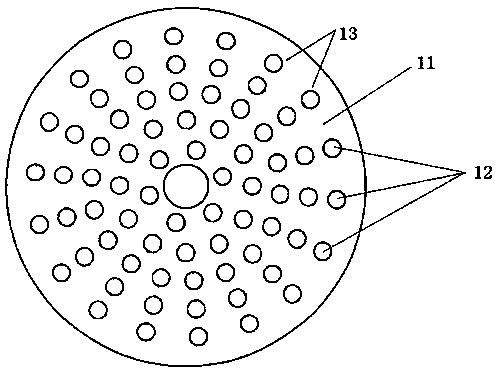

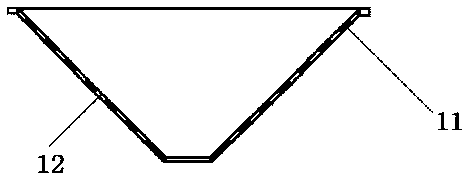

[0038] Such as image 3 As shown, a wear-resistant gas distributor includes a plurality of sieve holes 12, and a wear-resistant protrusion 2 is respectively arranged in the plurality of sieve holes 12, and a solid body is arranged at the center of the wear-resistant protrusion 2 Particle passage holes 26 . Since a wear-resistant protrusion 2 is respectively provided in the plurality of screen holes 12 of the gas distributor, when the silicon powder under high temperature and high pressure enters the gas distributor, it will directly act on the wear-resistant protrusion instead of directly acting on the gas. At the periphery of the sieve hole of the distributor, the silicon powder under high temperature and high pressure will wear off the wear-resistant protrusions on the periphery of the sieve hole first, thus prolonging the service life of the gas distributor and improving the working...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com