A rotary hc-scr denitrification reactor

An HC-SCR and denitration reactor technology, applied in the field of rotary HC-SCR denitration reactors, can solve the problems of inability to effectively use and reduce NOx, low denitration efficiency, etc., and achieve the effect of improving efficiency and denitration efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Further description will be given below in combination with specific embodiments.

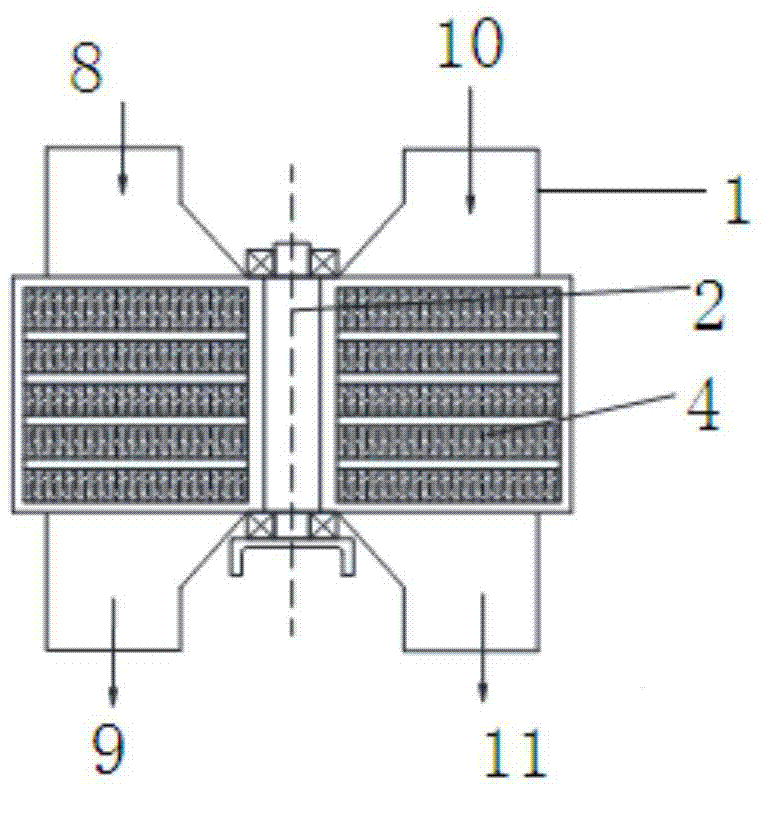

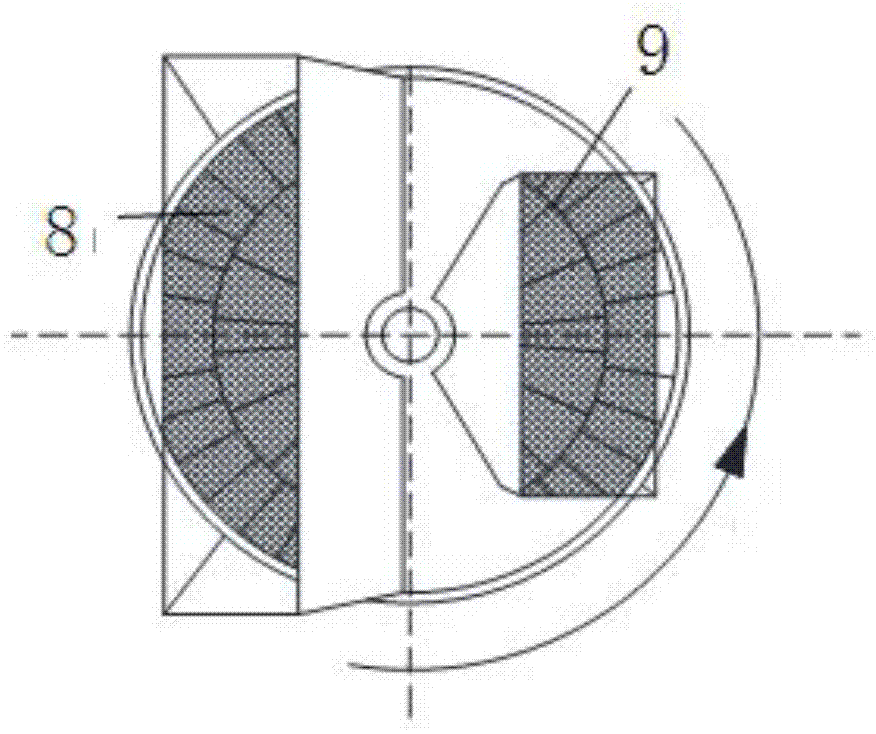

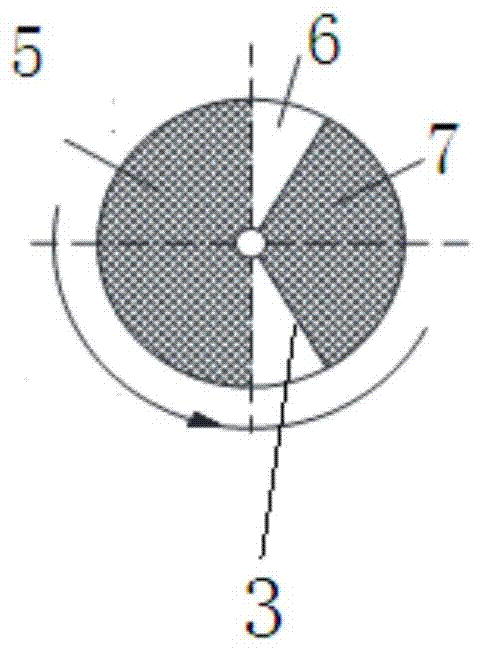

[0022] A rotary HC-SCR denitrification reactor, including a catalyst body structure and a shell 1 outside the catalyst body structure, the catalyst body structure is cylindrical, including a central axis rotor 2, a multi-layered circular structure that can rotate around the central axis rotor 2 Catalyst layer 4, multi-layer circular catalyst layer 4 is divided into adsorption zone 5 and reduction zone 7 by radial sealing plate 3 and axial sealing plate, there is transition zone 6 between adsorption zone 5 and reduction zone 7, adsorption zone 5, The reduction zone 7 and the transition zone 6 are shown as different fan-shaped areas on each circular catalyst layer 4. The adsorption zones of each circular catalyst layer are connected up and down, and the reduction zones of each circular catalyst layer are connected up and down. There are air inlets and air outlets respectively corresponding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com