Gas burner for premixing automatically-sucked air

A gas burner and pre-mixing technology, applied to gas fuel burners, burners, combustion methods, etc., can solve the problems of low thermal efficiency of burners, reduce production costs, etc., achieve fast combustion speed, reduce production costs, and improve thermal efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0008] The specific embodiment: the present invention will be further described below in conjunction with accompanying drawing:

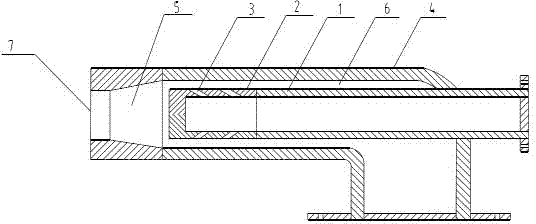

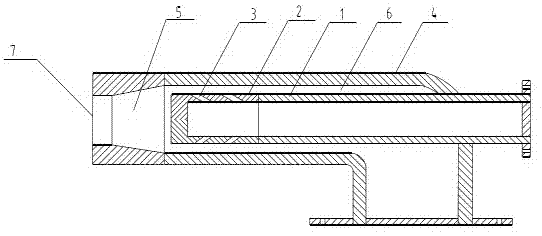

[0009] figure 1 Shown is the structure diagram of the present invention, as shown in the figure, the present invention comprises gas gun tube 1, air pipe 4, and gas gun tube 1 is positioned at the inner center of air tube 4, and front end has gas nozzle 2, and gas nozzle 2 sides are circumferentially provided with spray nozzles. Hole 3. The nozzle hole 3 on the side of the front end of the gas gun tube 1 is an oblique hole, and the oblique hole and the surface of the gas tube 1 form an oblique angle of 10° to 45°, so that the gas ejected from the gas gun tube 1 deviates to the left or right from the centerline of the gas gun tube Rotate around 10°~45° to spray. The annular cavity between the gas gun tube 1 and the air tube 4 is an air passage 6, the inside of the front end of the air tube 4 is tapered, and the space between the front end of the ga...

Embodiment 1

[0013] The present invention is used in Puyang Glass Factory with a furnace of 1.6 million kcal. The pressure of the natural gas raw material is 0.2Mpa, which is the natural pressure from the oil field. It is not additionally equipped with a compressed air, and the wind is natural wind. The natural gas side is used as the power side to design the gas gun barrel, air injection, suction port, gas nozzle and nozzle hole post-processing, installation, and ignition operation. Operation results: The natural gas injection volume of this system is 187 m3 / hour per hour, and the natural gas injection volume of the original system is 200 m3 / hour. Compared with the original system, 6.5% of natural gas can be saved. The air distribution system does not need a blower. While reducing the auxiliary equipment, it can also save electricity by 138 kW × 24 hours × 30 days × 11 months (ie 12 months-1 month maintenance period) = 1092960 kW. The operation process is safe and achieves the expected go...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com