Swirling flow premixing type burner

A flow premixing and burner technology, which is applied in the direction of burners, gas fuel burners, combustion methods, etc., can solve the problem of increased pure oxygen consumption of the secondary reformer, lower reformer furnace temperature, and increased energy consumption for methane conversion, etc. problems, to achieve the effect of improving heat transfer characteristics, increasing heat transfer rate, and reducing smoke emission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

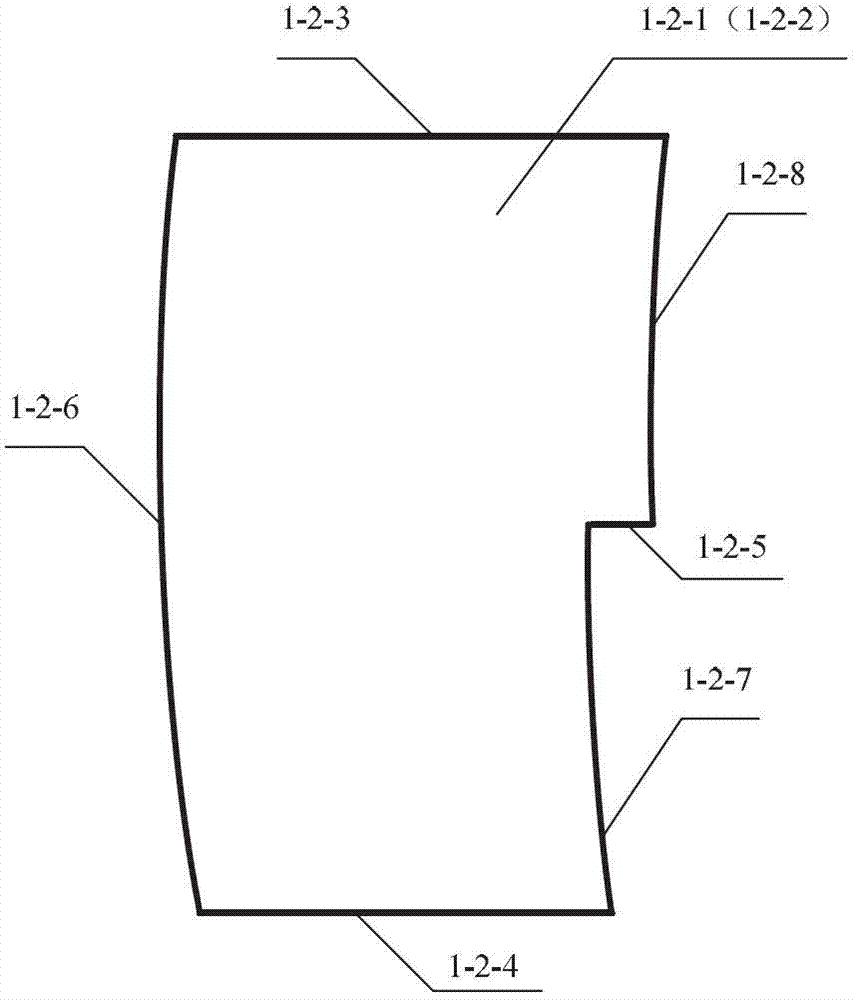

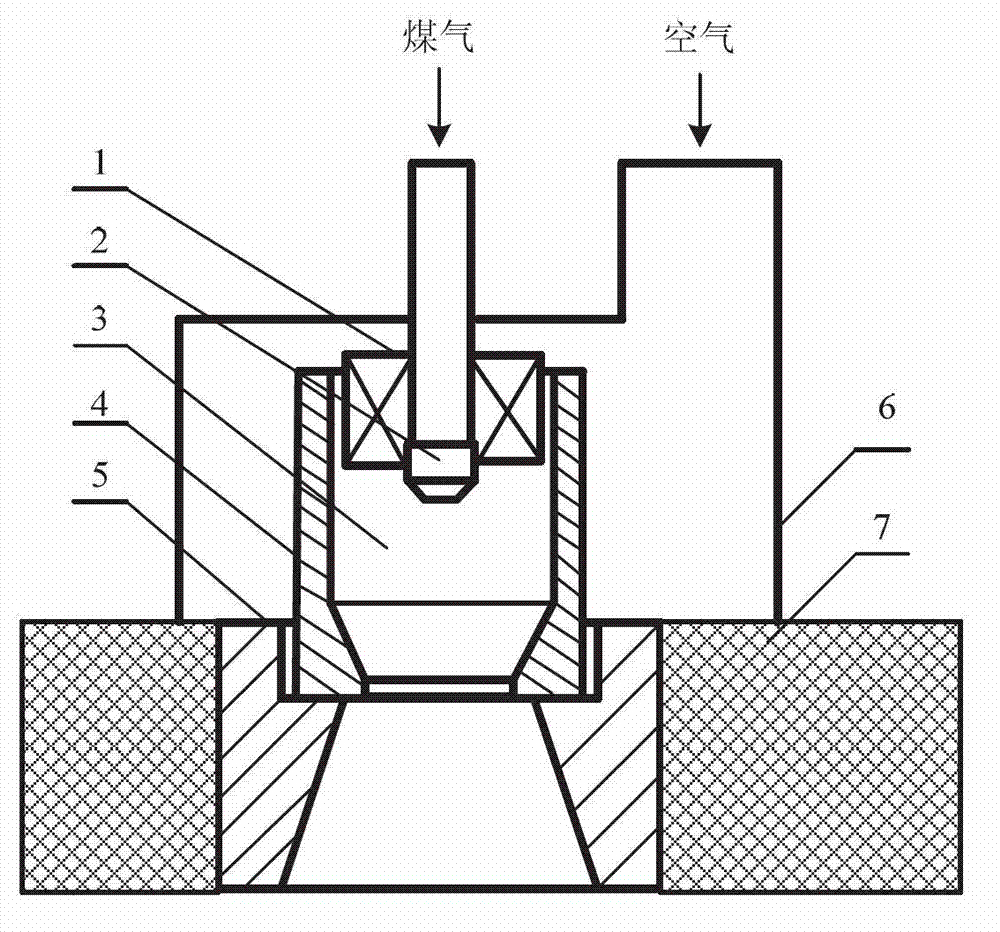

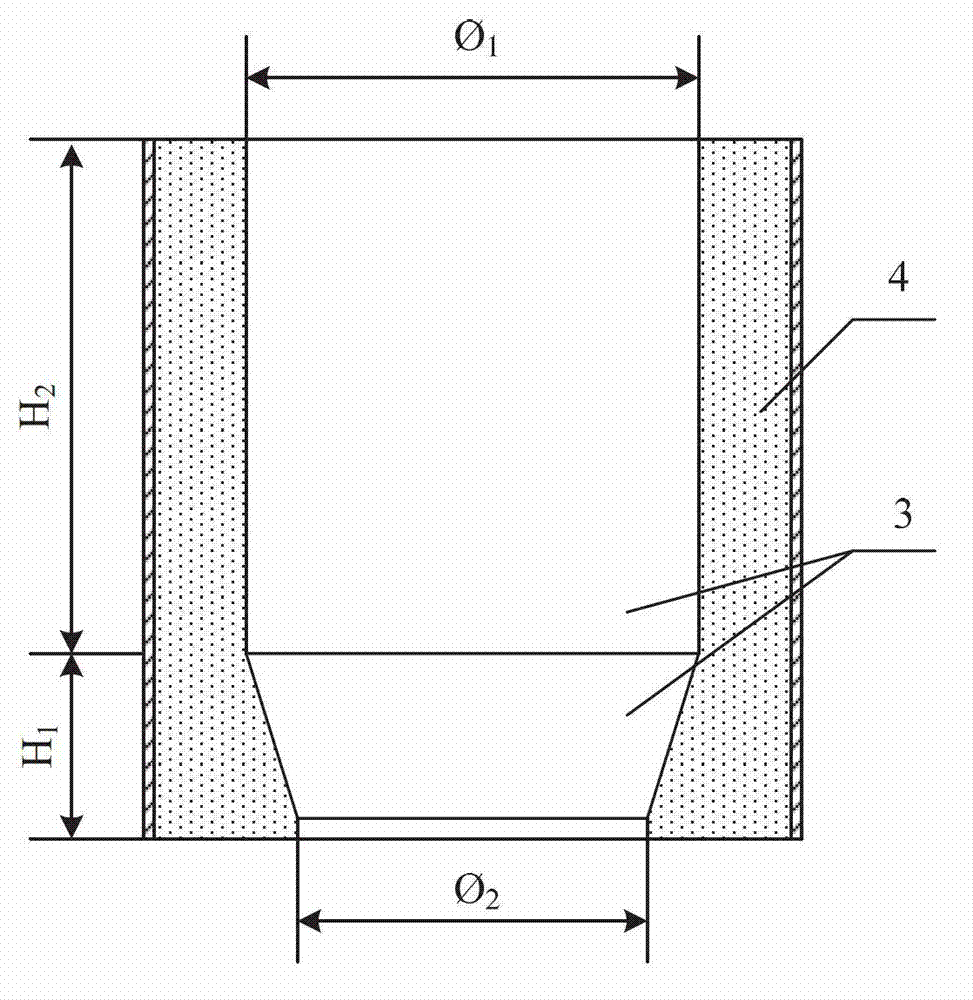

[0027] In this embodiment, the structure of the swirl premix burner is as follows figure 1 As shown, it is composed of the first burner brick 5, the second burner brick 4, the combustion air chamber 6, the air cyclone 1 and the gas nozzle 2; the shape and structure of the second burner brick 4 are as follows figure 2 As shown, its outer contour shape is cylindrical, and its center is provided with a swirl premixing chamber 3, which is a combination of a cylindrical hole and a truncated conical hole on the same center line, and the truncated conical hole Below the cylindrical hole, the height H of the cylindrical hole 2 : Height H of the frustoconical hole 1 = 3: 1; the diameter of the cylindrical hole? 1 : The diameter of the lower end of the truncated cone hole? 2 =1.4:1; the shape and structure of the first burner 5 are as figure 1 As shown, its outer contour shape is cylindrical, and the upper section of its central hole matches the outer contour shape and size of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com