Fully premixed fuel gas burner

A gas burner and premixing technology, applied in the direction of gas fuel burners, burners, combustion methods, etc., can solve the problems of incomplete combustion, large airflow resistance, poor safety, etc., and achieve easy ratio adjustment, high combustion intensity, Effects requiring little precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below in conjunction with specific embodiments.

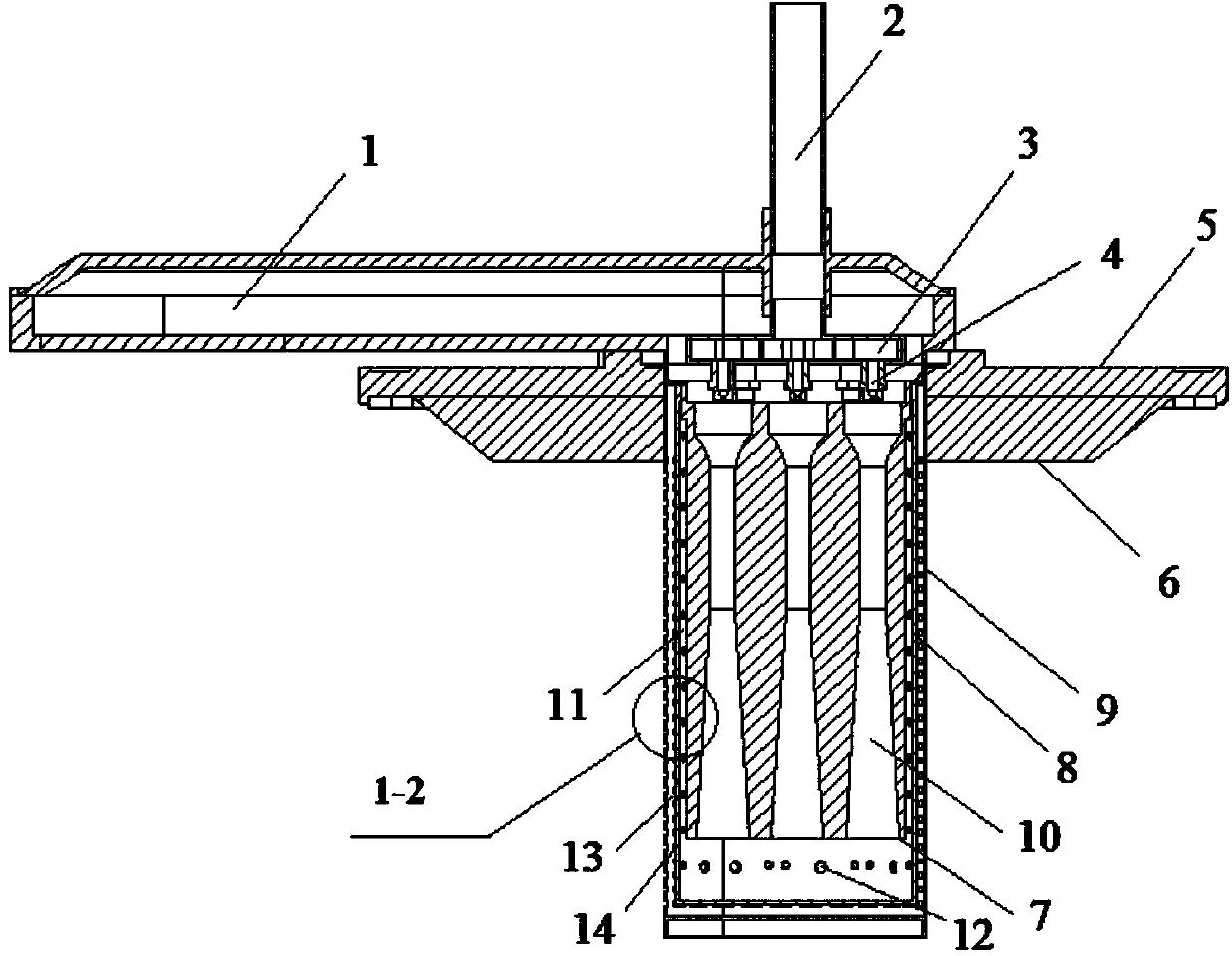

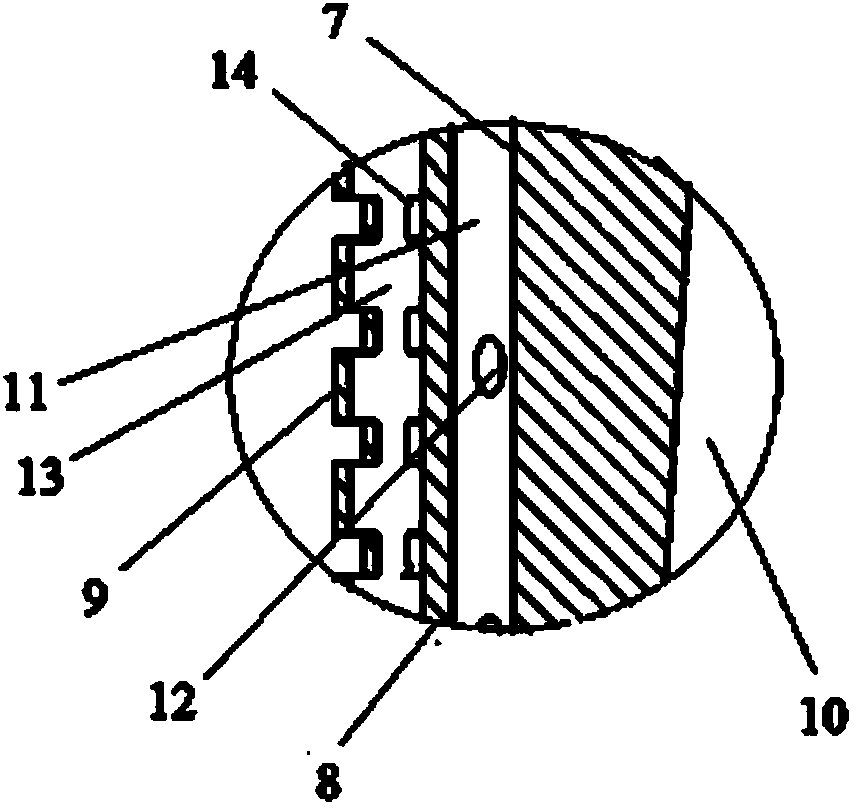

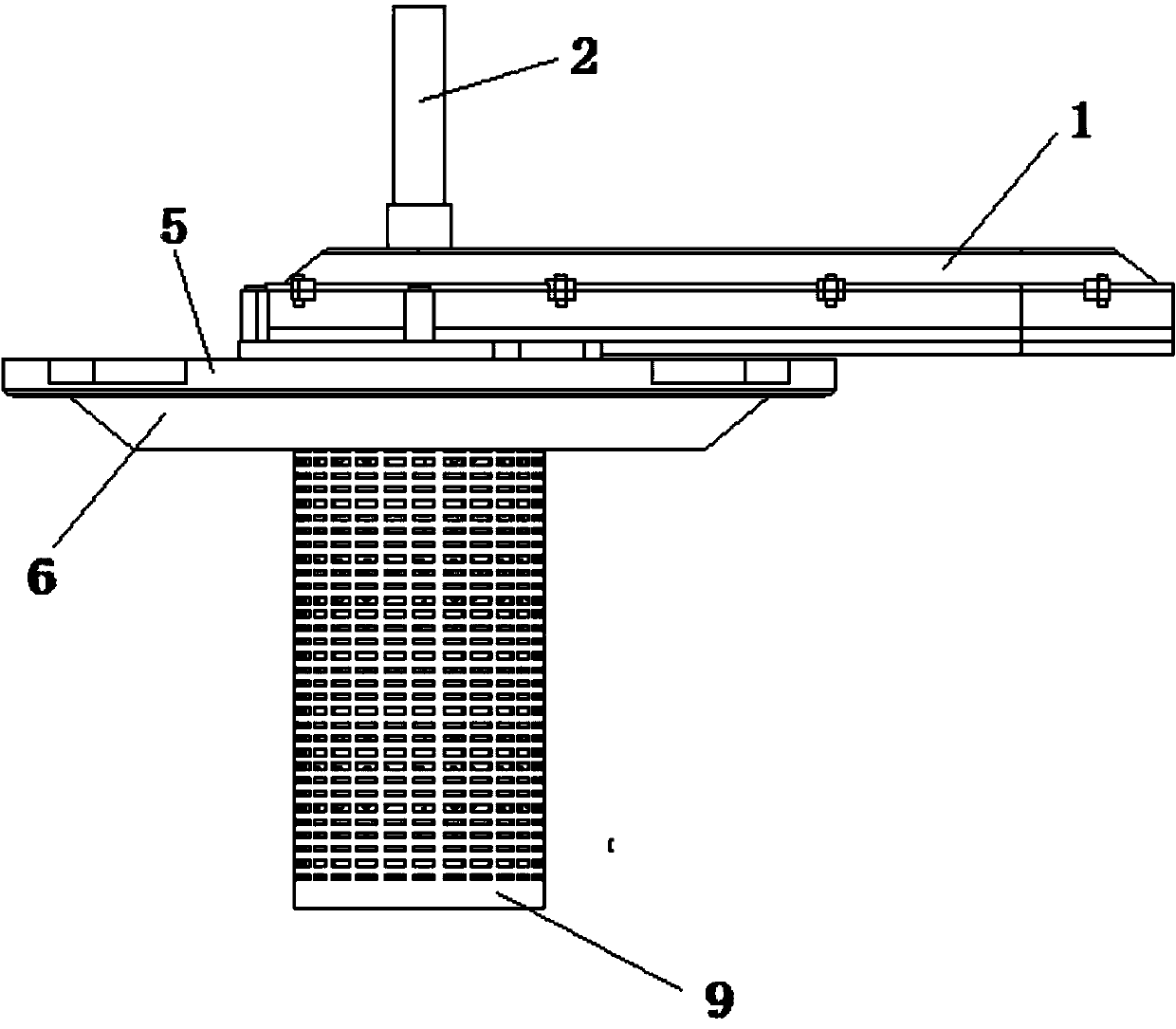

[0023] The complete premixed gas burner of the present invention as shown in the accompanying drawing, it comprises sealing plate 5, and it also comprises the mixing cylinder 7 that sets at intervals successively from inside to outside, gas and air distributing cylinder 8 and fire hole circle Cylinder 9, a distribution cavity 11 is formed between the mixing cylinder and the gas and air distribution cylinder, and a thermal insulation cavity 13 is formed between the gas and air distribution cylinder and the fire hole cylinder, and the distribution cavity The upper part of the insulation chamber and the heat insulation chamber are both closed ends and the lower part is an open end. A plurality of injection chambers 10 penetrating through the mixing cylinder body are arranged in the mixing cylinder, and in the gas and air distribution circle A plurality of dispensing holes 12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com