Premixed type blast combustion device

A kind of combustion equipment, premixed technology, applied in the direction of burner, combustion method, combustion type, etc., can solve the problems of high carbon monoxide and nitrogen oxide emissions, insufficient fuel combustion, large air excess coefficient, etc., to reduce emissions , Consistent combustion state, faster burning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

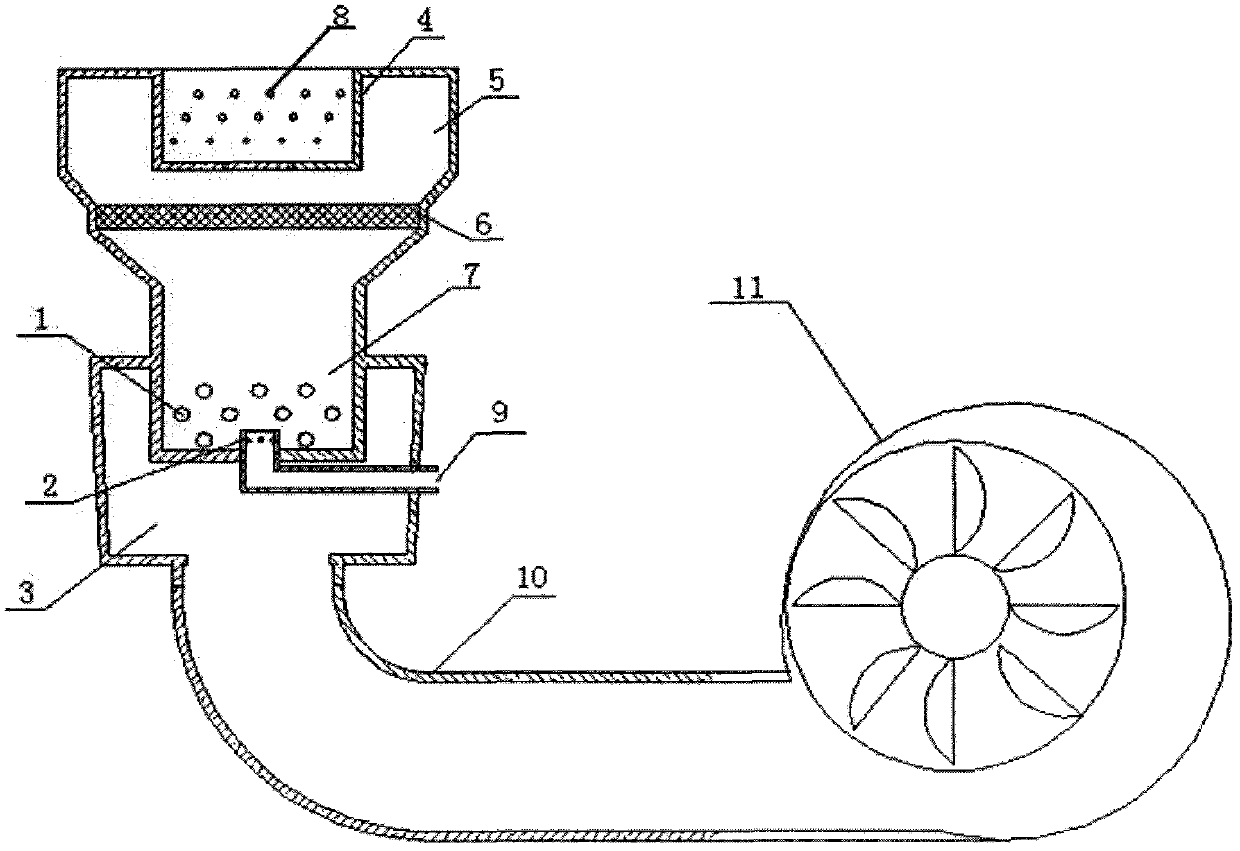

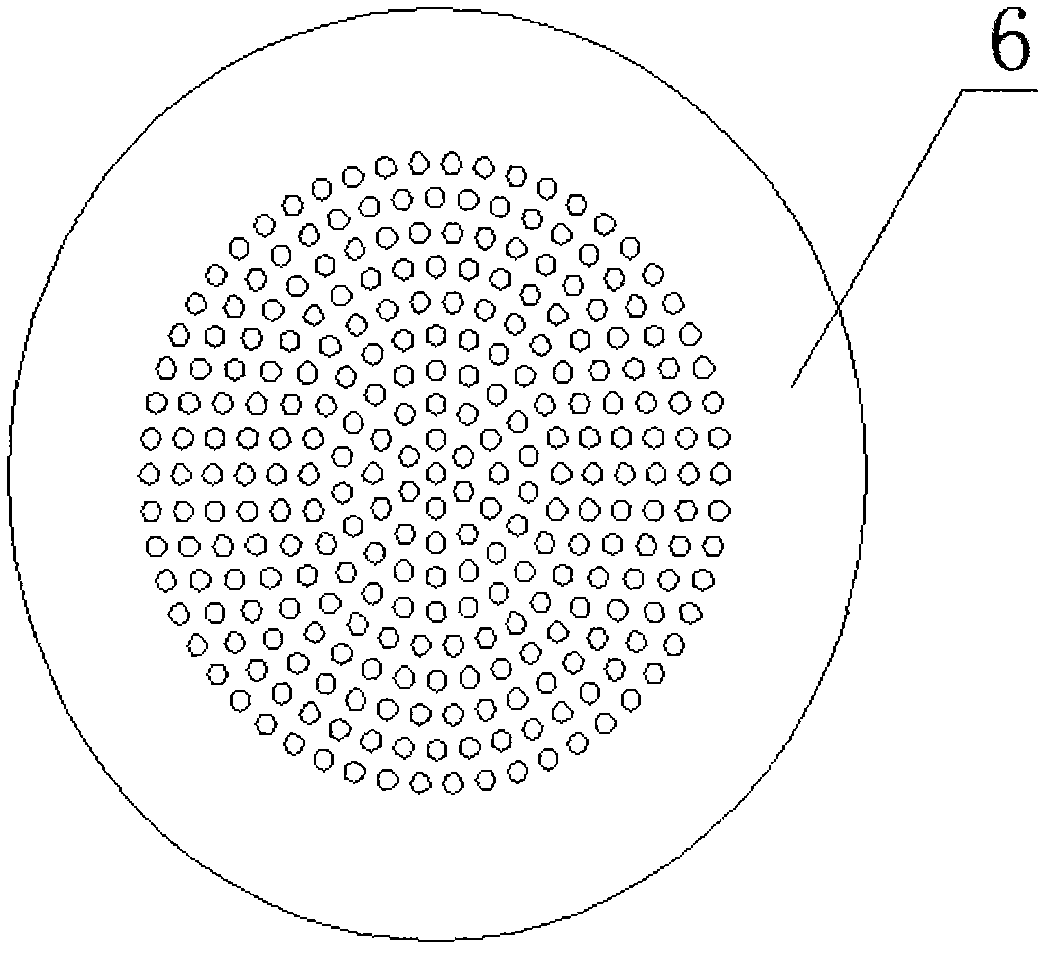

[0022] Such as figure 1 As shown, it is a schematic diagram of the combustion structure provided by the present invention. The air blown out by the blower 11 enters the air chamber 3 through the air duct 10; After 3, enter the gas mixing chamber 7 through the air injection hole 1; gas (fuel) enters through the gas inlet 9, and enters the gas mixing chamber through the gas nozzle 2; the gas nozzle 2 is located in the center of the gas mixing chamber 7, and the gas (fuel) passes through the gas The nozzle 2 sprays out to the surroundings, and the air is sprayed to the middle through the air nozzle 1, and the gas (fuel) and the air form a strong convection, so that they can be quickly mixed into a combustible mixed gas; the combustible mixed gas in the gas mixing chamber 7 passes through the stabilizing plate 6 enters the diffuser chamber 5 after further mixing and steady flow, and then enters the combustion chamber 4 to burn through the flame holes evenly distributed on the inne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com