Beaming type gasification or combustion nozzle and its industrial use

A combustion nozzle and cluster-type technology, which is applied in the field of syngas preparation devices, can solve the problems of reduced carryover and shortened flames, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

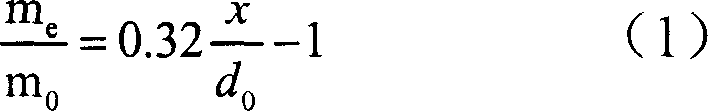

Method used

Image

Examples

Embodiment 1

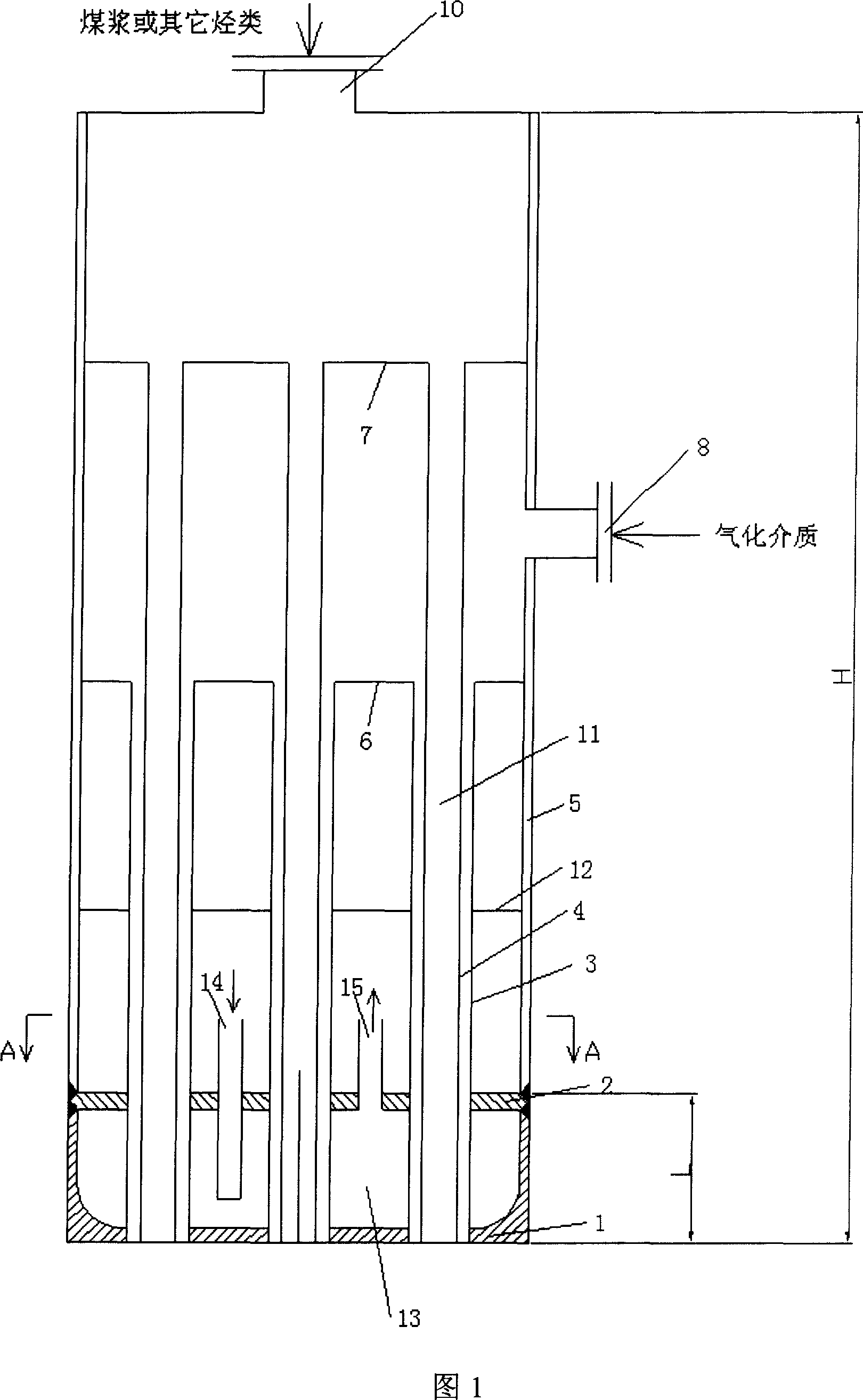

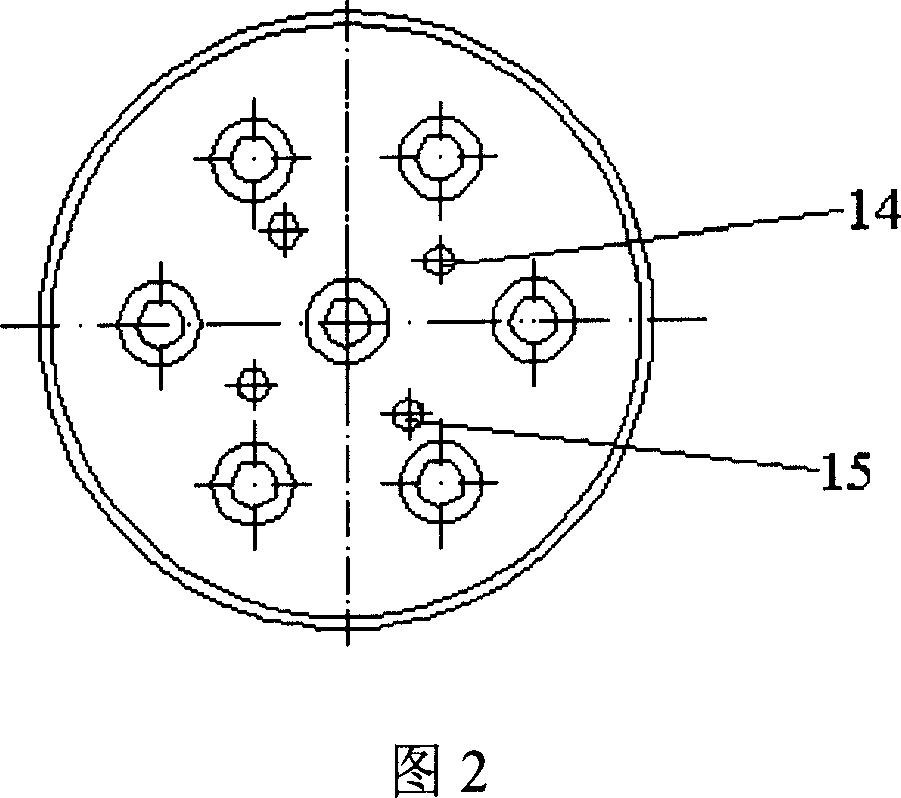

[0044] A methanol plant with an annual output of 100,000 tons uses coal-water slurry as raw material, and adopts a gasifier gasifier equipped with cluster gasification or combustion nozzles as shown in Figure 1 and Figure 2. The device produces 303 tons of methanol per day and processes coal every day. 400 tons;

[0045] Structural parameters of cluster gasification or combustion nozzles:

[0046] The outer diameter of the shell 5 is 260mm, and 7 nozzles are used. The diameter of the inner casing is 31×3mm, the diameter of the outer casing is 39.6×3, and the center-to-center distance between the outer casing 3 is 80mm; the nozzle height H is 2000mm, and the U-shaped piece The fixed position L of 1 and cover plate 2 is 40mm;

[0047] In the inner casing, the velocity of the coal slurry outlet is ~2m / s;

[0048] In the outer casing, the gas outlet velocity is ~100m / s;

[0049] The pressure of the gasification furnace is 4.0MPa, the gasification temperature is 1300°C, the ash ...

Embodiment 2

[0051] A methanol plant with an annual output of 1.1 million tons uses coal-water slurry as raw material, with a daily output of 3030 tons of methanol and 3 gasifiers with a daily coal processing capacity of 1500 tons. The gasification furnace adopts the gasification furnace equipped with cluster gasification or combustion nozzles as shown in Fig. 1 and Fig. 2;

[0052] Structural parameters of cluster gasification or combustion nozzles:

[0053] The outer diameter of the shell 5 is 400mm, and 13 nozzles are used. The diameter of the inner sleeve is 31×3mm, the diameter of the outer tube is 39.6×3, and the center distance between the outer sleeves 3 is 80mm; the height H of the nozzle is 2000mm, and the U-shaped piece The fixed position L of 1 and cover plate 2 is 40mm;

[0054] In the inner casing, the velocity of the coal slurry outlet is ~4m / s;

[0055] In the outer casing, the gas outlet velocity is ~125m / s;

[0056] The pressure of the gasifier is 6.5MPa, the gasificatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com