Dry ice blasting method and dry ice blasting device

A technology of dry ice and bursting discs, which is applied in earth drilling, discharge machinery, ground mining, etc., can solve problems such as gas outburst accidents and gas explosions, and achieve the effects of small blasting vibration, low cost, and fast construction requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Embodiment 1: The dry ice blasting method and device described in the present invention utilizes the high-pressure gas generated by the thermal sublimation of dry ice in a limited space as the blasting energy source, and achieves the purpose of blasting through the rapid release of the high-pressure gas.

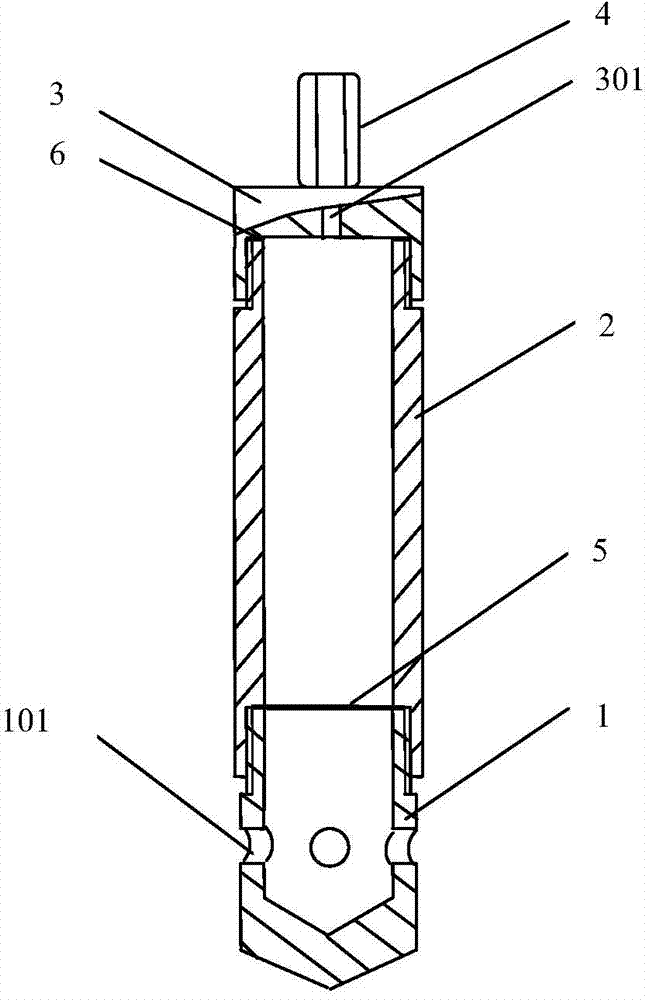

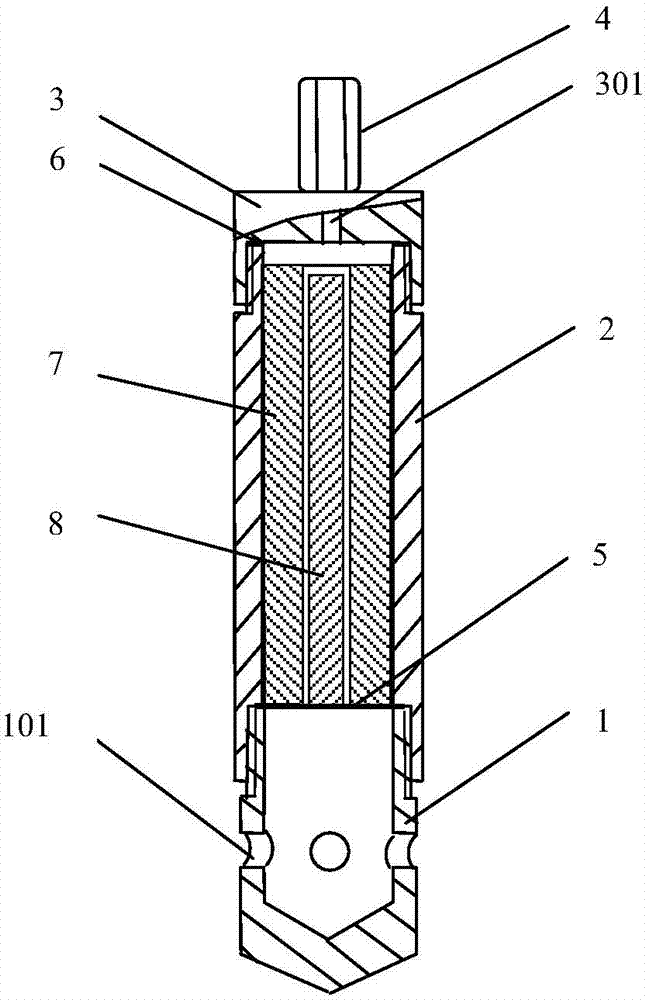

[0033] Such as figure 1 As shown, the dry ice blasting device of the present invention is composed of a spray head 1, a cylinder body 2, a tail cover 3 and a one-way valve 4. Wherein, the nozzle 1 is provided with an exhaust hole 101, the tail cover 3 is provided with a water inlet 301, the nozzle 1 and the barrel 2 are provided with a burst disc 5, and the tail cover 3 and the one-way valve 4 are communicated through the water inlet 301. Seal gasket 6 is used to seal between tail cap 3 and cylinder body 2 .

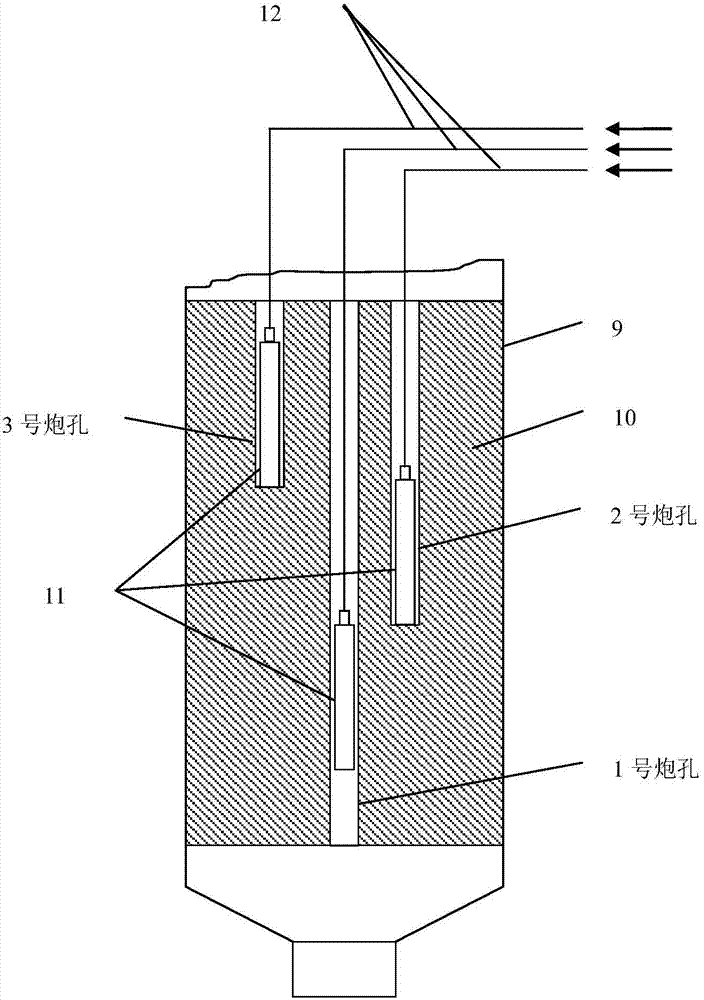

[0034] Attached below figure 2 , 3 And embodiment dry ice blasting method of the present invention is described in further detail:

[0035] The coal chute ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com