Underground tunnel punching apparatus

A drilling device and tunnel technology, applied in drilling/drilling equipment, portable drilling rigs, metal processing equipment, etc., can solve the problems of inconvenience, waste of manpower, high labor intensity, etc., and achieve a small working angle range and easy operation. , the effect of avoiding errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

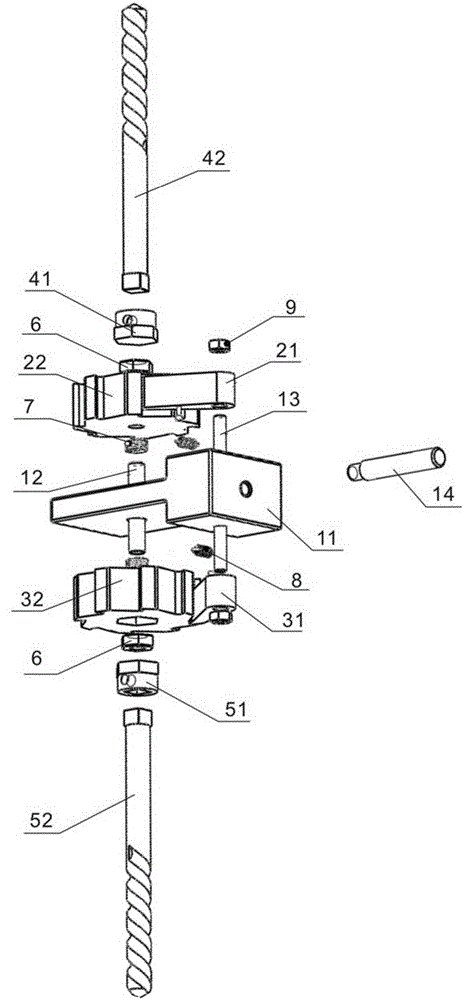

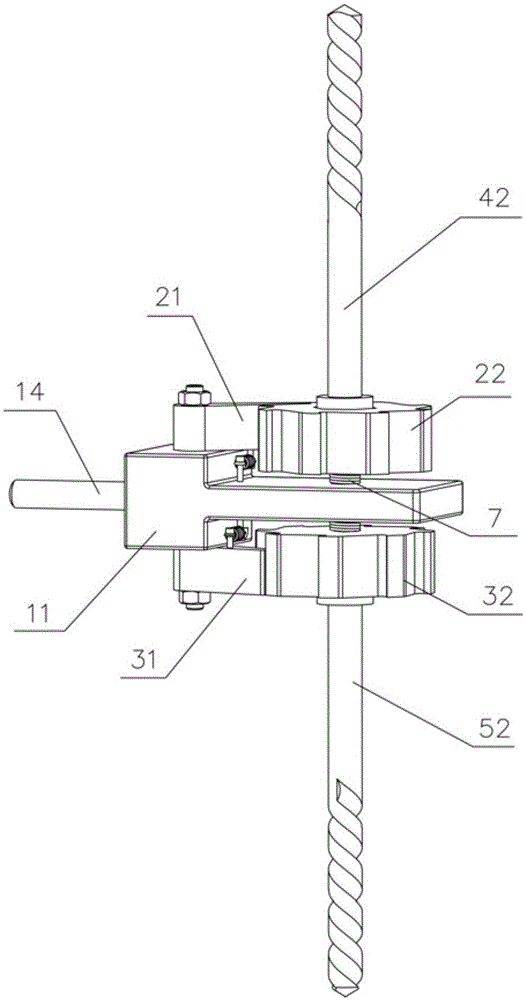

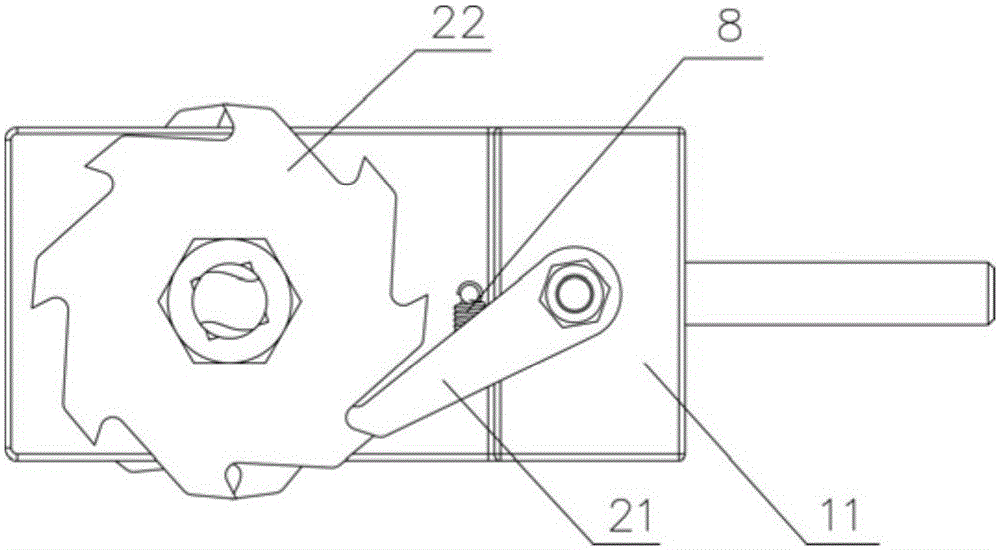

[0021] Such as Figure 1 to Figure 4 As shown, the underground tunnel drilling device of the present invention includes a handle assembly, an upper ratchet structure, a lower ratchet structure, an upper drill bit assembly and a lower drill bit assembly, and the handle assembly includes a handle 11, a stud 12, a stud 13 and a handle handle 14 , the middle section of the stud bolt 12 and the middle section of the stud 13 are all pierced through the handle 11, and the handle 14 is arranged on the side of the handle 11; the upper ratchet structure and the lower ratchet structure are respectively arranged at the upper and lower ends of the handle 11, and the upper ratchet structure It includes an upper ratchet 21 and an upper ratchet 22 that cooperate with each other. The lower ratchet structure includes a lower ratchet 31 and a lower ratchet 32 that co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com