Patents

Literature

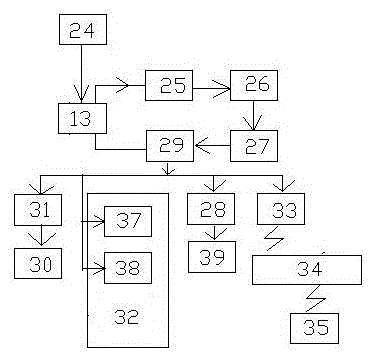

57results about How to "Will not cause an explosion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Dry ice blasting method and dry ice blasting device

InactiveCN104500068AOvercome potentially dangerous drawbacksWill not cause an explosionDisloding machinesUnderground miningToxic gasWater source

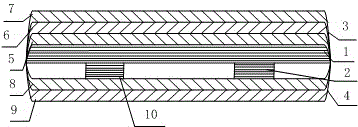

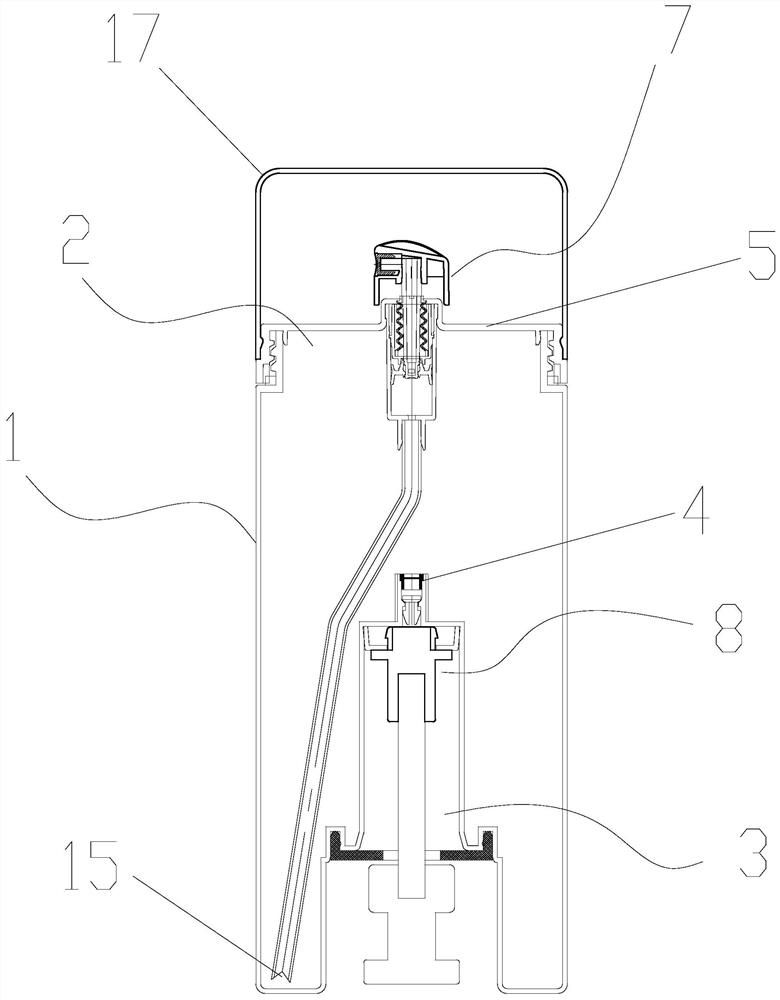

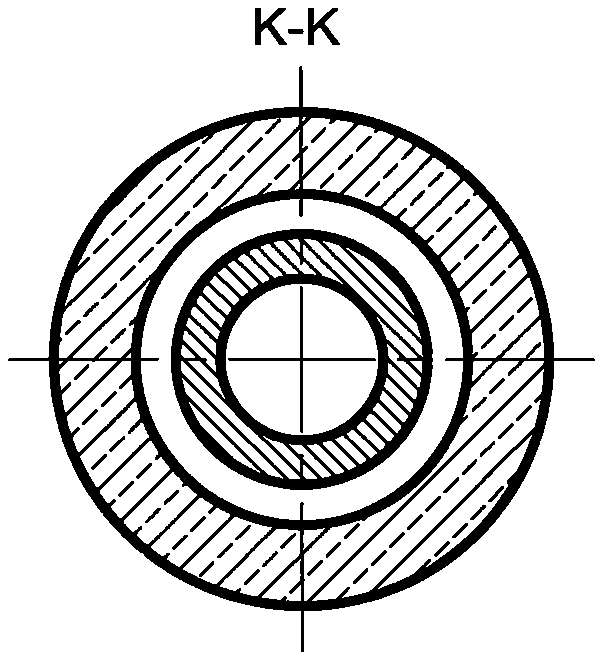

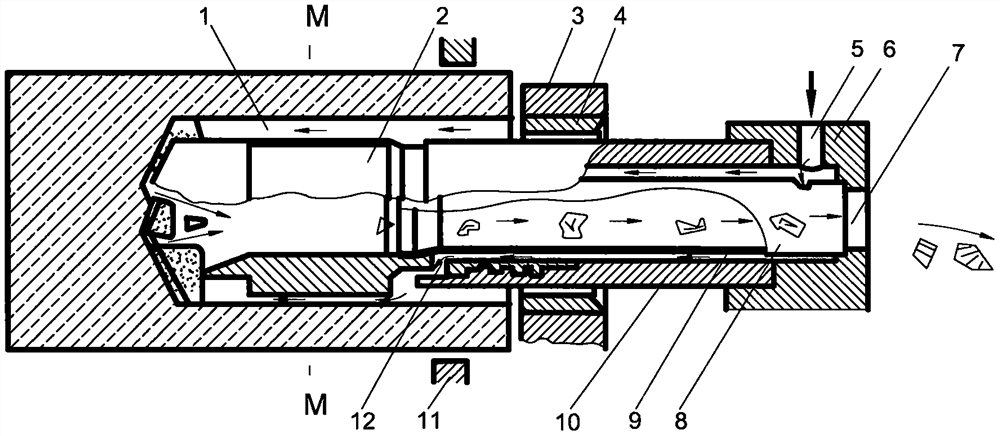

The invention relates to a dry ice blasting method and a dry ice blasting device, and belongs to the field of engineering blasting. The dry ice blasting device comprises a spray head, a cylinder body, a tail cover and a one-way valve, wherein the spray head is provided with an exhaust hole; the tail cover is provided with a water inlet hole; a sealing gasket is arranged between the cylinder body and the tail cover; a blasting sheet is arranged between the cylinder body and the spray head; and the tail cover is communicated with the one-way valve through the water inlet hole. The dry ice blasting method comprises the following steps: drilling in a coal bed; assembling the dry ice blasting device, and filling the dry ice blasting device with dry ice and a heating bag; connecting the dry ice blasting device with a water pipe, and placing into a blast hole; and communicating with a water source, and injecting water into the dry ice blasting device, wherein the heating bag inside the cylinder body fast releases heat when encountering water so as to urge the dry ice to be fast sublimated into carbon dioxide gas, when gas pressure exceeds the design pressure of the blasting sheet, the instant blasting of the blasting sheet is caused, and the carbon dioxide gas is fast discharged through the exhaust hole formed in the spray head to form impaction and expansion extrusion on the wall of the blast hole, so that the blasting is realized. The dry ice blasting method and the dry ice blasting device which are disclosed by the invention have the advantages of achieving the bursting at normal temperature, generating no flame or toxic gas and being suitable for a coal mine with gas and coal dust explosion risks.

Owner:CHINA UNIV OF MINING & TECH

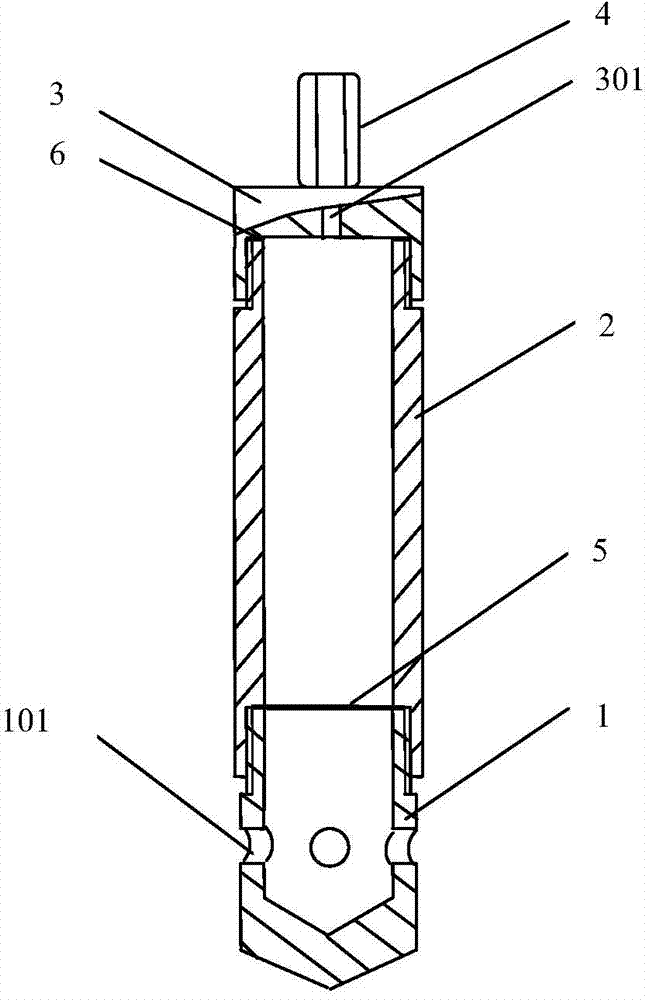

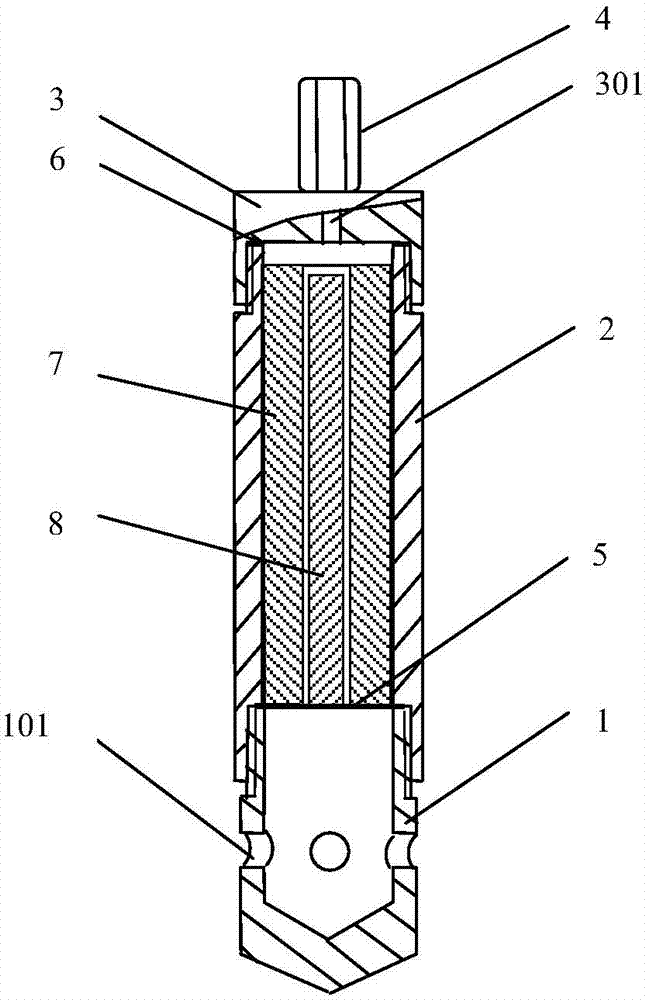

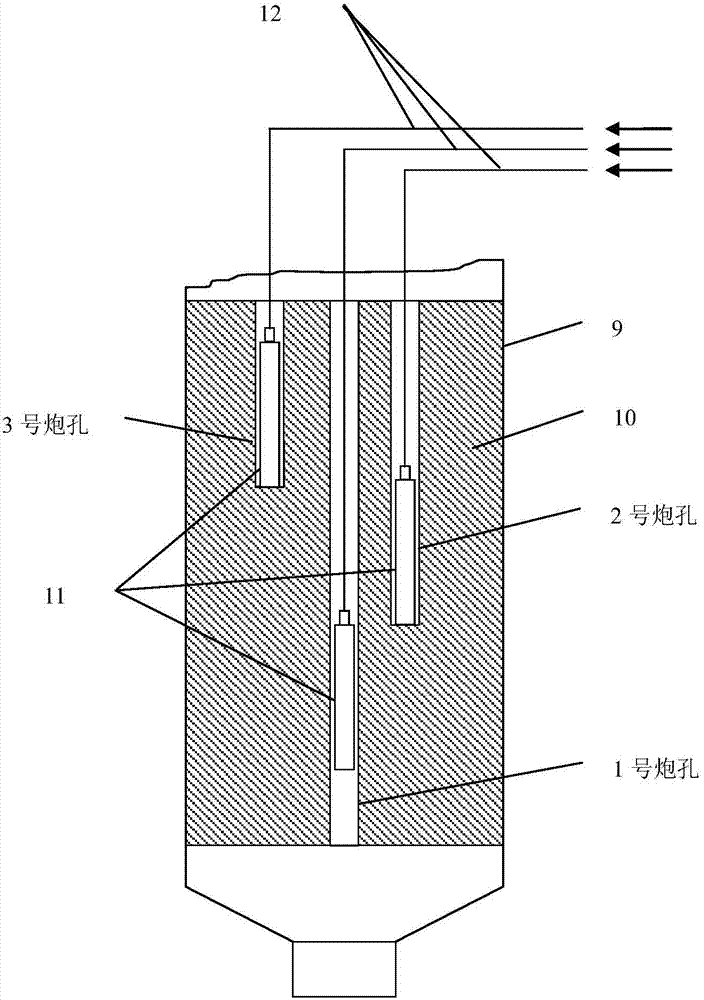

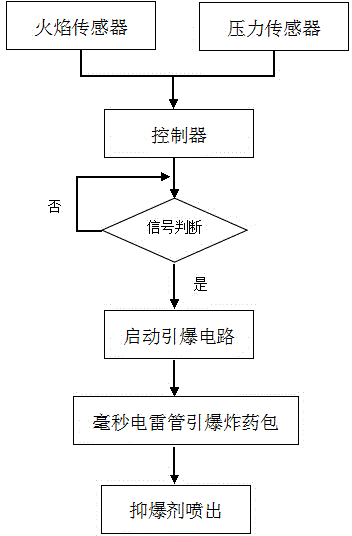

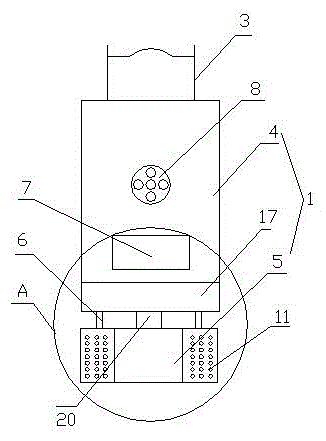

Automatic explosion suppressing device applicable to dust explosion in pipeline

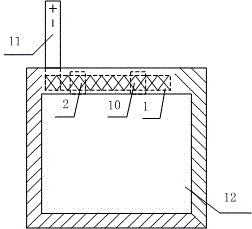

The invention relates to an automatic explosion suppressing device applicable to dust explosion in a pipeline. The automatic explosion suppressing device comprises flame sensors, pressure sensors, a high-pressure explosion suppression agent container and a small-sized detonation device, wherein a carbonate powder explosion suppression agent is placed in the small-sized detonation device, the high-pressure explosion suppression agent container is filled with a high-pressure N2 gas explosion suppression agent, a rupture disc is arranged between the high-pressure explosion suppression agent container and the small-sized detonation device and is used for separating high-pressure N2 gas of the high-pressure explosion suppression agent container, a rupture disc diaphragm is arranged between the small-sized detonation device and a powder conveying pipeline and is used for supporting the carbonate powder explosion suppression agent, the flame sensors and the pressure sensors are connected with a controller, and the controller is connected with the small-sized detonation device and is used for controlling to trigger the small-sized detonation device, so that the high-pressure N2 gas explosion suppression agent in the high-pressure explosion suppression agent container and the carbonate powder explosion suppression agent enter the pipeline at high speed, and thus, explosion suppression is realized. According to the automatic explosion suppressing device applicable to the dust explosion in the pipeline, quick response to an explosion accident in the pipeline can be carried out, so that the occurrence of the explosion accident or the further expansion of harm is avoided.

Owner:SHANGHAI INST OF TECH

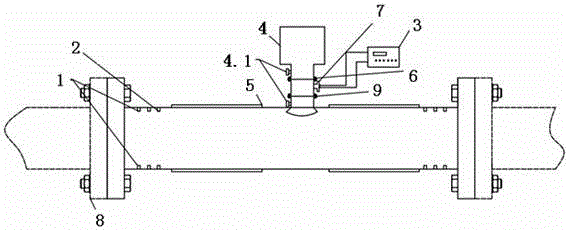

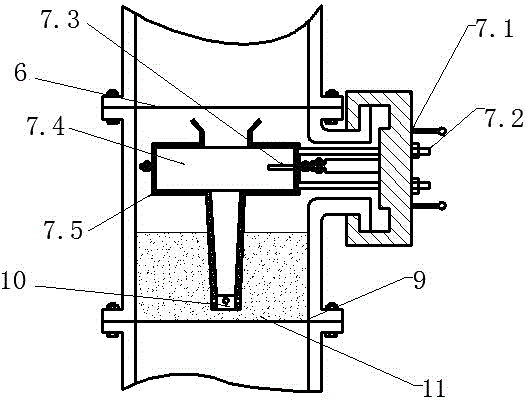

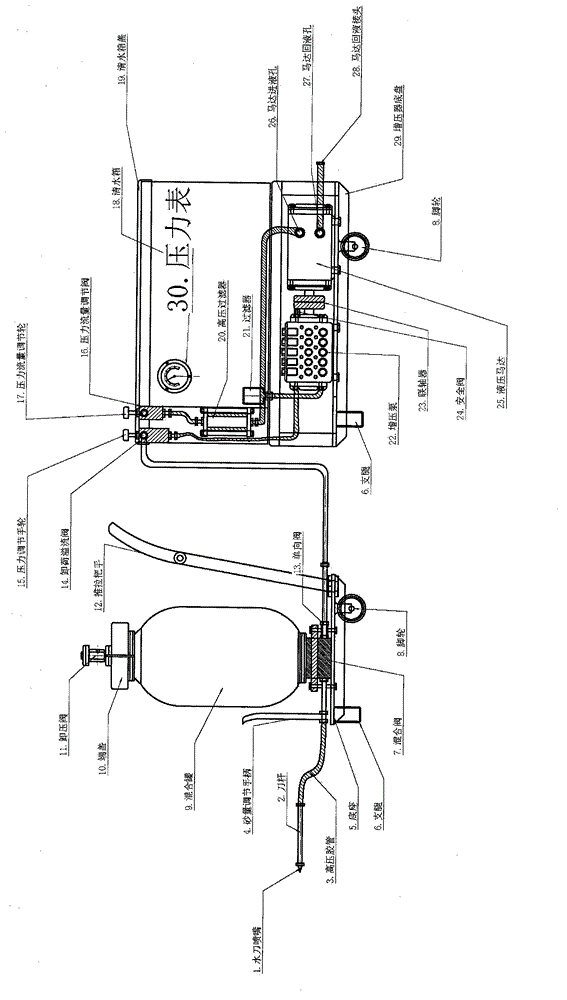

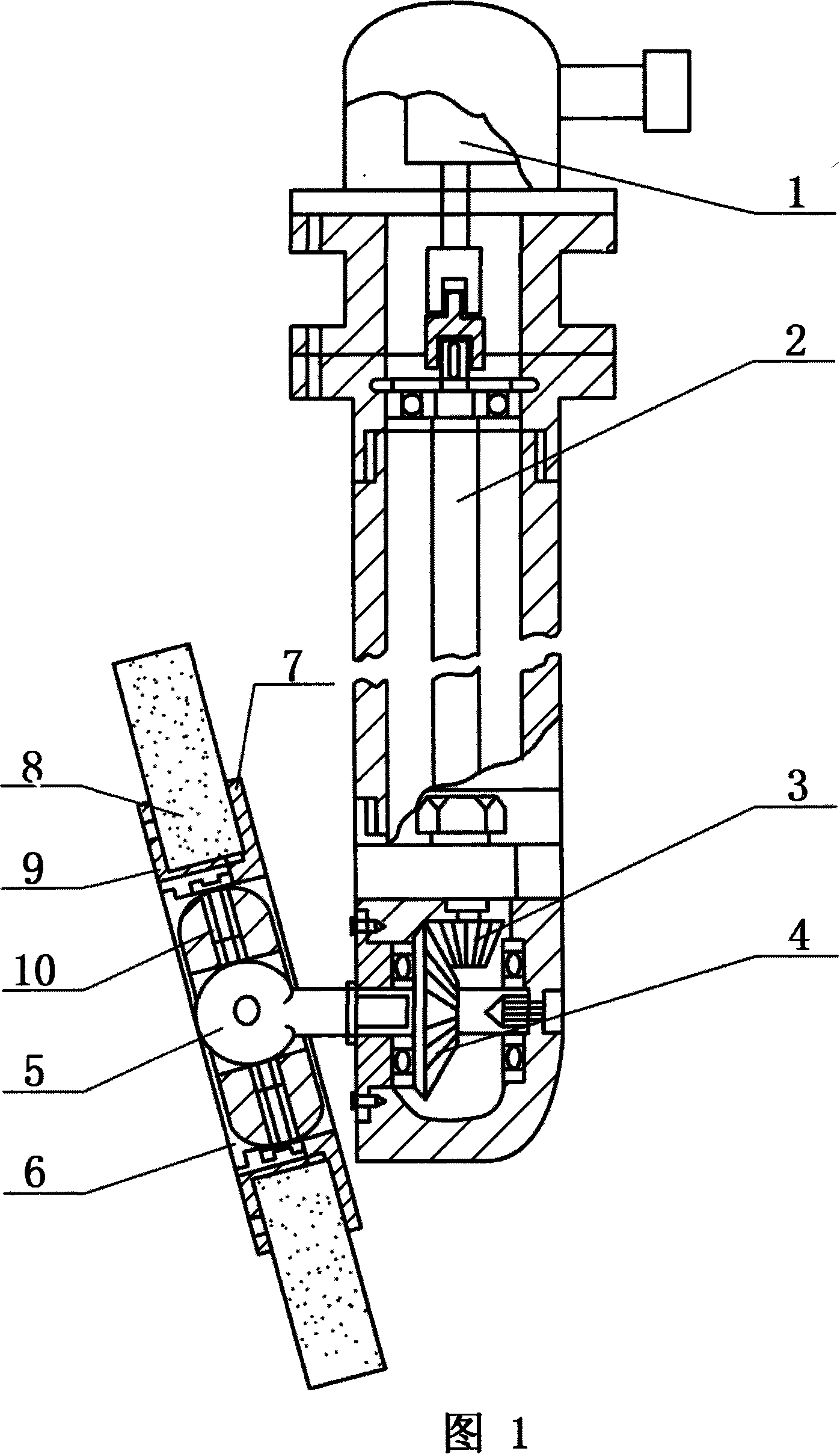

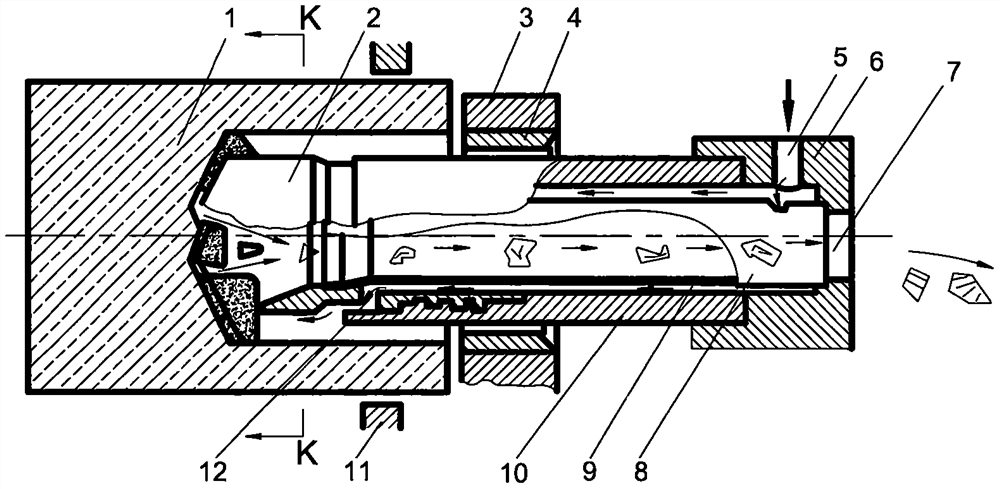

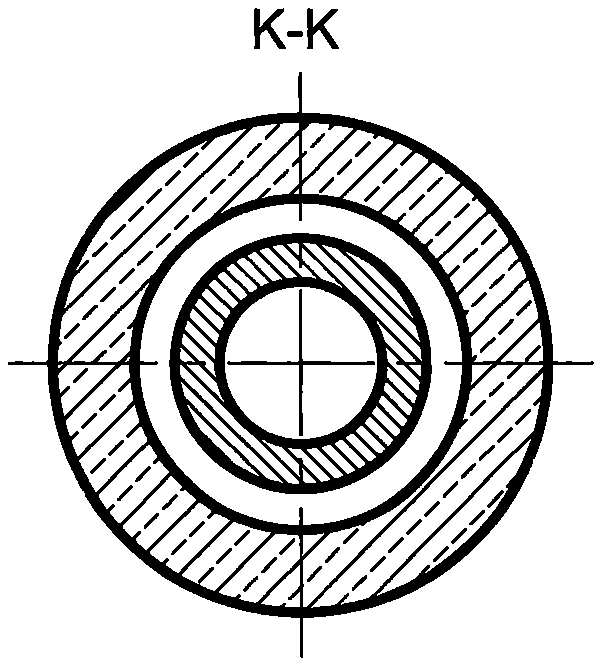

Mining mobile type power-supply-free water cutter

InactiveCN104625970AReduce manufacturing costPlay a role in energy saving and emission reductionAbrasive feedersAbrasive machine appurtenancesEngineeringHigh pressure water

The invention discloses a mining mobile type power-supply-free water cutter. The mining mobile type power-supply-free water cutter consists of components including a water cutter spray nozzle, a cutter bar, a high-pressure rubber tube, a sand amount regulating handle, a base, a supporting leg, a mixing valve, a foot wheel, a mixing tank, an end cover, a pressure relief valve, a pushing-pulling handle, a one-way valve, an unloading overflow valve, a pressure regulating hand wheel, a pressure flow rate regulating valve, a pressure flow rate regulating handle wheel, a clear water tank, a clear water tank cover, a high-pressure filter, a filter, a booster pump, a shaft coupler, a safety valve, a hydraulic motor, a motor liquid inlet, a motor liquid return hole, a motor liquid return joint, a booster chassis, and the like. The liquid passes through the high-pressure filter through the regulating valve to enter the hydraulic motor for rotating the hydraulic motor, the hydraulic motor drives the booster pump to rotate to generate high-pressure water; the high-pressure water enters the mixing valve through the unloading valve; the mixing valve is used for mixing the high-pressure water with a grinding material in proportion; mixed water is conveyed to the cutter bar through the high-pressure tube; the speed of the water cutter spray nozzle is instantly accelerated to 340m / min so as to generate great dynamic energy to cut a performing element.

Owner:天津艾浮瑞特科技有限公司

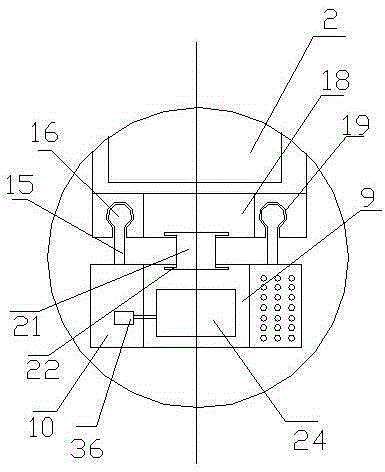

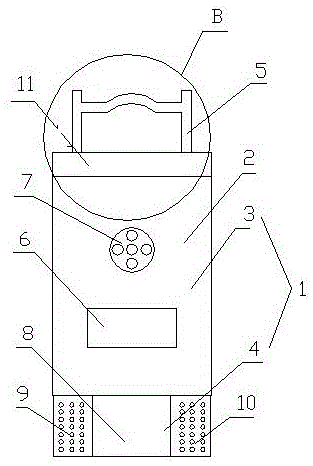

Multi-parameter sensor for GD5 coal mine

InactiveCN105203712AWith clock display functionWill not cause an explosionMaterial analysisElectrical batteryData acquisition

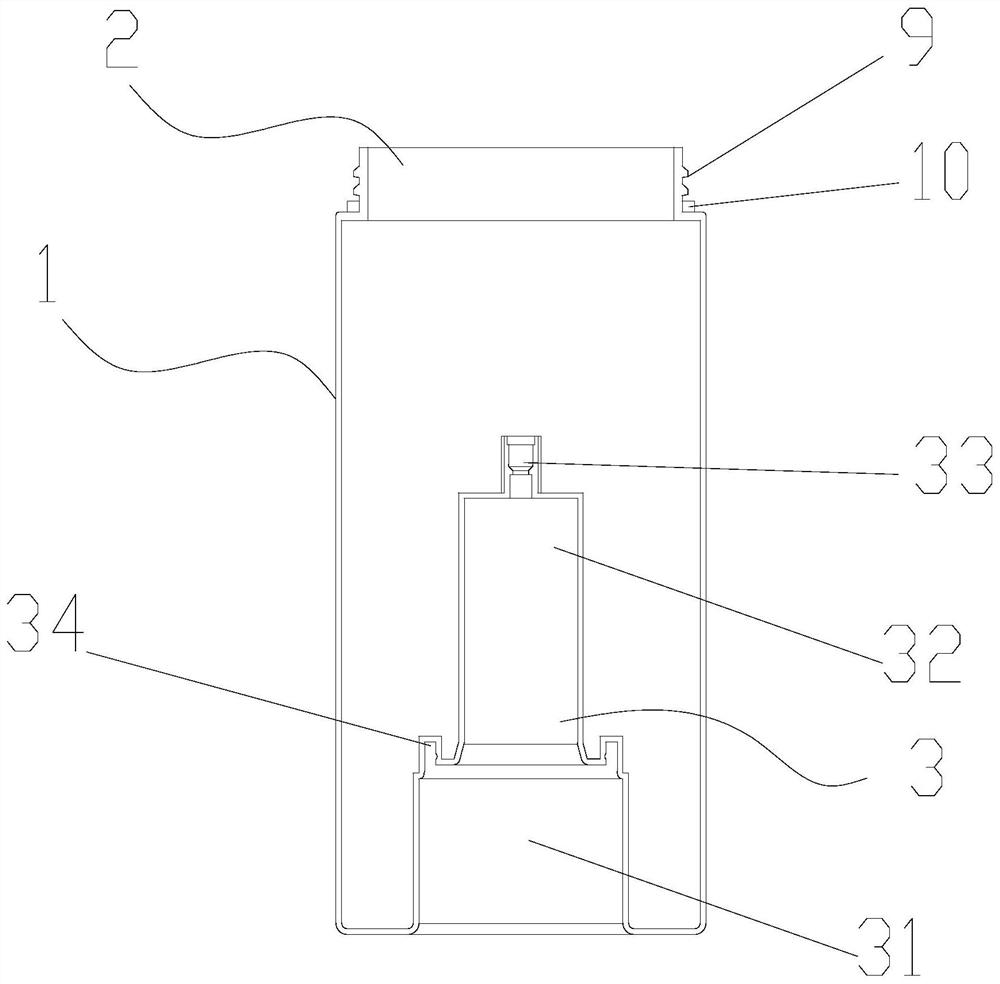

The invention relates to a multi-parameter sensor for a GD5 coal mine. The multi-parameter sensor comprises a shell and a monitoring device, wherein the shell is provided with a handle; the shell comprises an upper shell and a lower shell; the upper shell is connected with the lower shell through a supporting arm; the upper shell is provided with a display window and an alarming window; the lower shell comprises a sensor containing cavity and gas monitoring cavities formed in the two sides of the sensor containing cavity; and the monitoring device comprises a battery, a sensor, a signal converter, a signal amplifier, a filter, a data acquisition card, a data storage device, a CPU (Central Processing Unit), a digital tube display, a signal chip microcomputer, an alarm, a wireless transmission module, an Internet network and a remote monitoring host. An electronic instrument, which adopts an electrochemical principle, and is intelligently controlled by an embedded type controller and displayed by a digital tube, is simple to operate, is convenient to use, is safe and reliable, and is mainly used for detecting and alarming methane, oxygen, carbon monoxide, hydrogen sulfide and carbon dioxide.

Owner:YANGZHONG SOUTH MINE ELECTRICAL

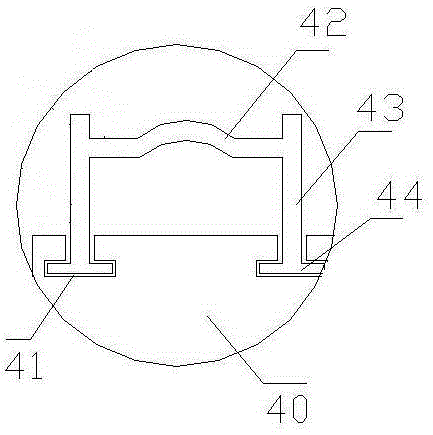

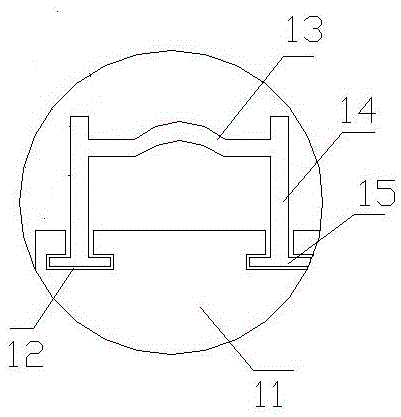

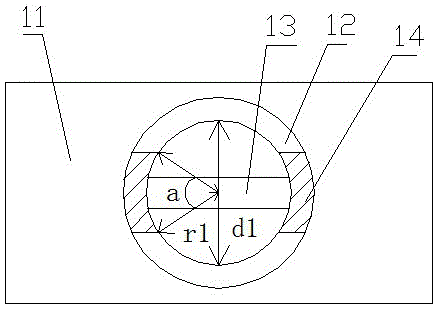

Ball float type liquidometer with vernier display

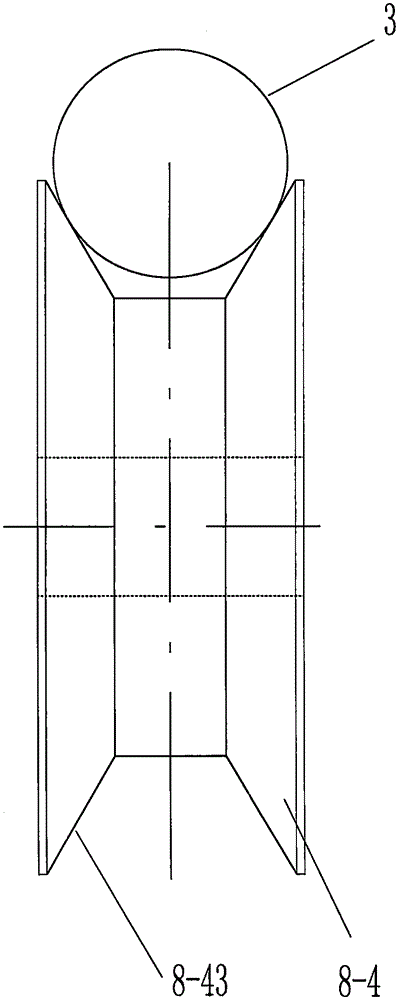

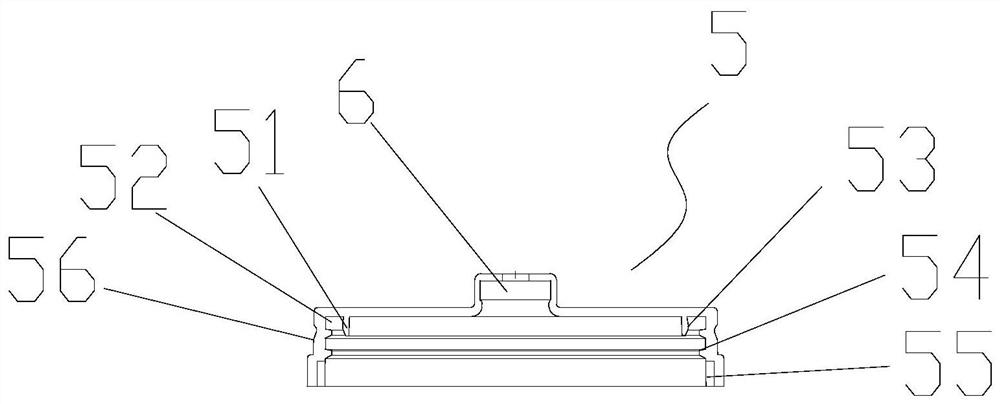

ActiveCN105277258AIncrease stiffnessGuaranteed measurement accuracyLevel indicators by floatsFloat chamberRolling-element bearing

The invention relates to a ball float type liquidometer with vernier display. The ball float type liquidometer comprises a ball float chamber and a ferromagnetic spherical floating ball arranged therein, a vernier outside the ball float chamber, a calibrated scale and a vernier guide rail. The vernier comprises magnetic steel, a frame and a rolling system which is horizontally fixed and sleeved in the frame; the rolling system comprises rolling wheels which are provided with radial grooves along a circumferential surface, rolling bearings and shafts; the magnetic steel is disposed between the ball float chamber and the frame and is fixed outside one side surface close to the ball float chamber on the frame, and the magnetic pole of the magnetic steel is right oriented towards the floating ball; the vernier guide rail is sleeved in the frame and is disposed between the magnetic steel and the rolling system; and the rolling system enables the rolling wheels to roll vertically along the vernier guide rail at groove positions through a magnetic coupling force between the magnetic steel and the floating ball. The ball float type liquidometer is simple and scientific in structure, reliable in application performance, easy to manufacture and low in cost, reduces defects in the prior art and effectively meets needs in correlation fields.

Owner:DALIAN JIAXIN ELECTROMECHANICAL INSTR CO TD

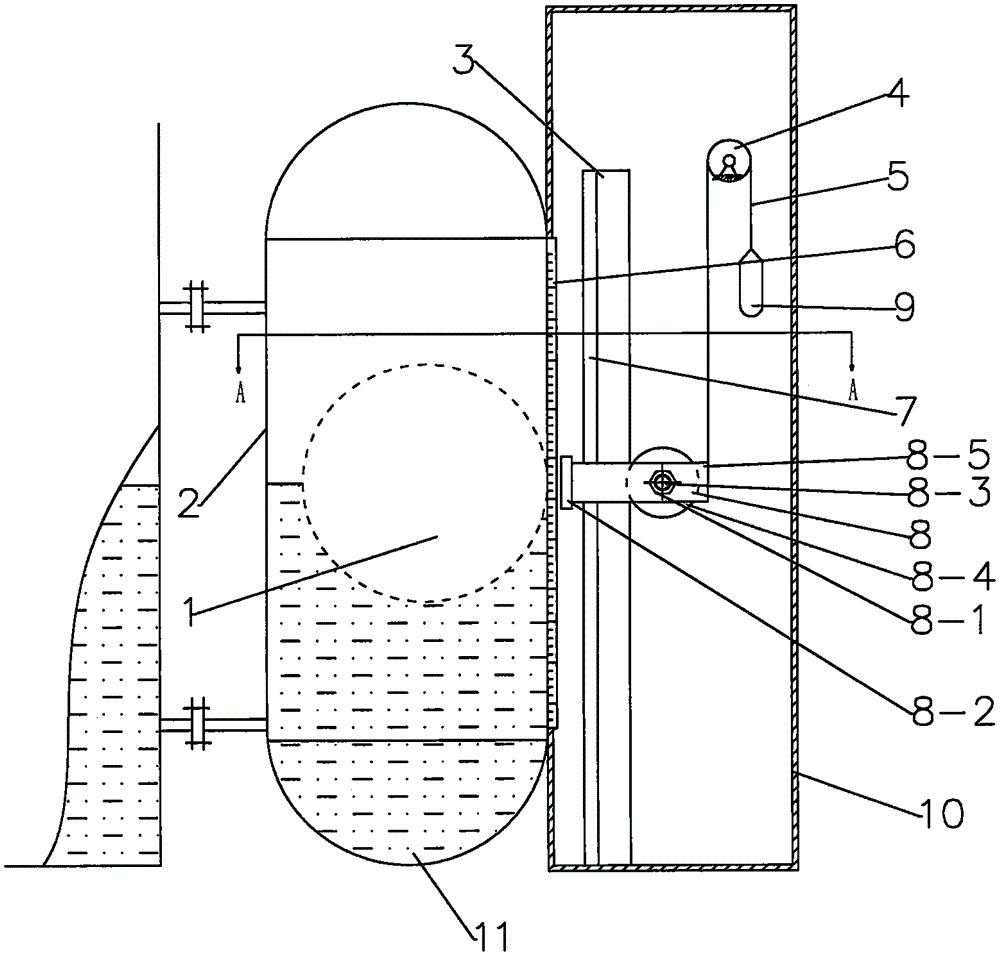

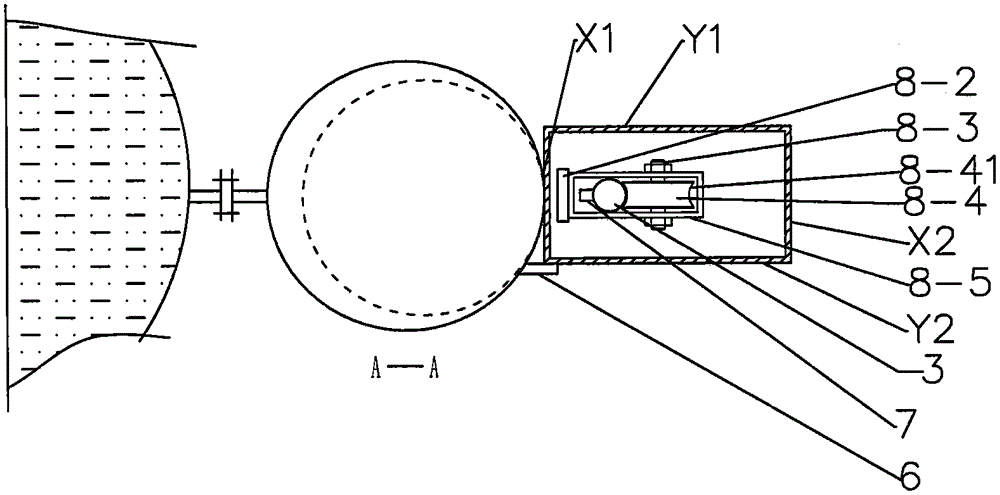

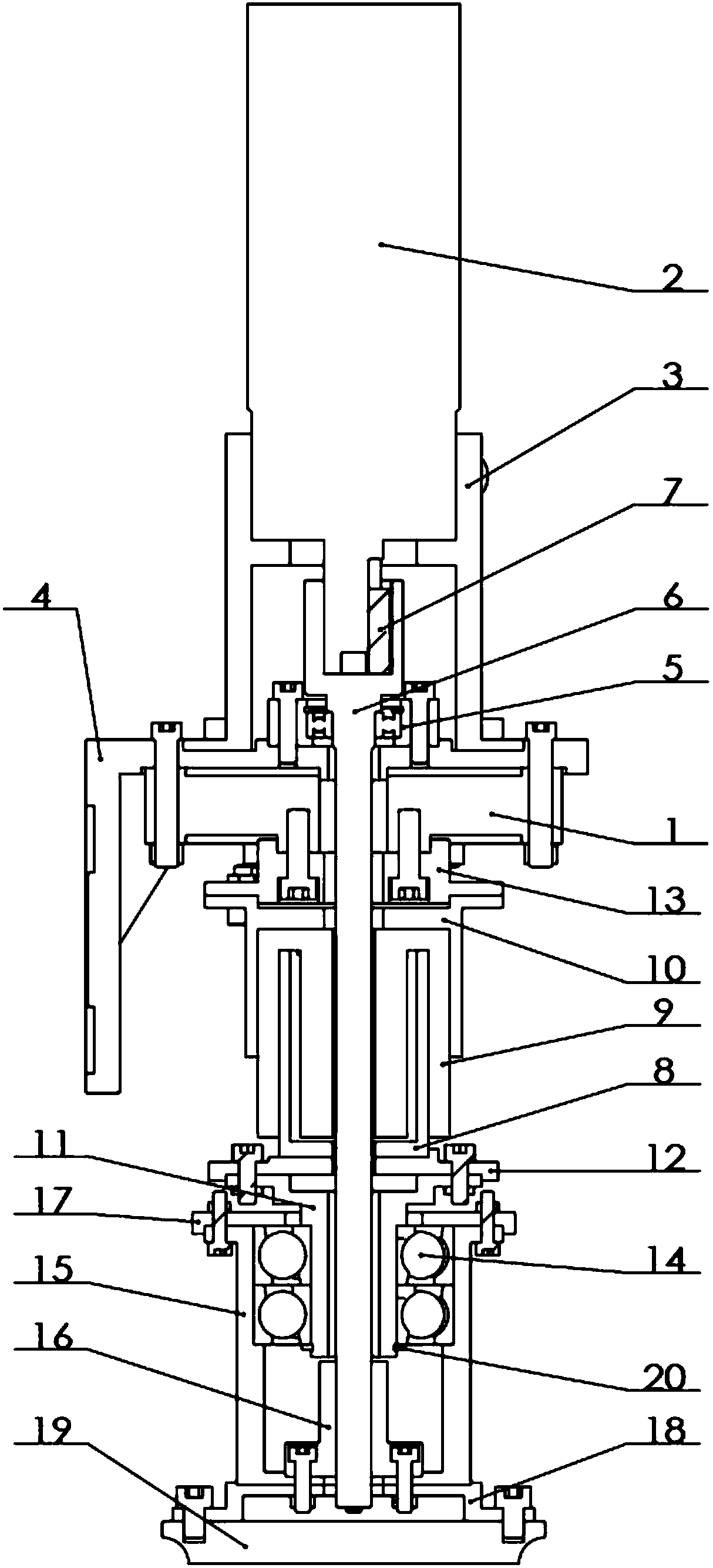

Robot polishing and grinding force control end effector

ActiveCN108818303AReduce the total massWill not cause an explosionGrinding drivesGrinding headsLinear motionRobotic systems

The invention discloses a robot polishing and grinding force control end effector. The robot polishing and grinding force control end effector comprises a rotation part, a linear motion part and a grinding head part. A pneumatic motor is adopted as a power source for the effector, and the total mass of the effector is effectively reduced. Usage of a coupler is avoided, accordingly, the complexityof the mechanism is reduced, and the structure is more compact. The rotation movement of the pneumatic motor is transmitted to a ball spline through a main shaft, and the ball spline transmits the rotation movement to the grinding head part. Since the ball spline has the functions of torque transmission and untight connection, mechanical decoupling of the two freedom degrees of a grinding head isachieved at the position of the ball spline. Compared with the current situation that connection of an effector and a macro robot system is conducted at the top end of the effector, by means of the robot polishing and grinding force control end effector, the polished and ground surface capsizing moment is effectively reduced, and the polishing and grinding quality is improved. By means of the robot polishing and grinding force control end effector, control over the polishing and grinding tool force, the polishing and grinding rotation speed and other important polishing and grinding parameterscan be achieved, the effector is simple in structure, small in mass and high in force control precision and response speed.

Owner:GUANGDONG UNIV OF TECH

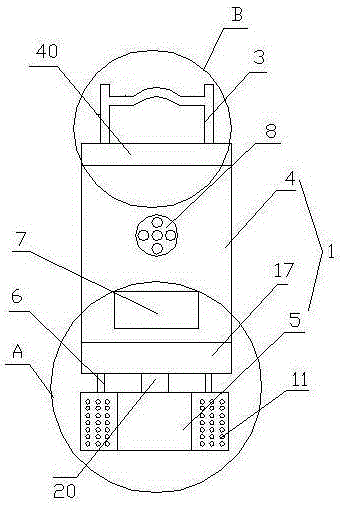

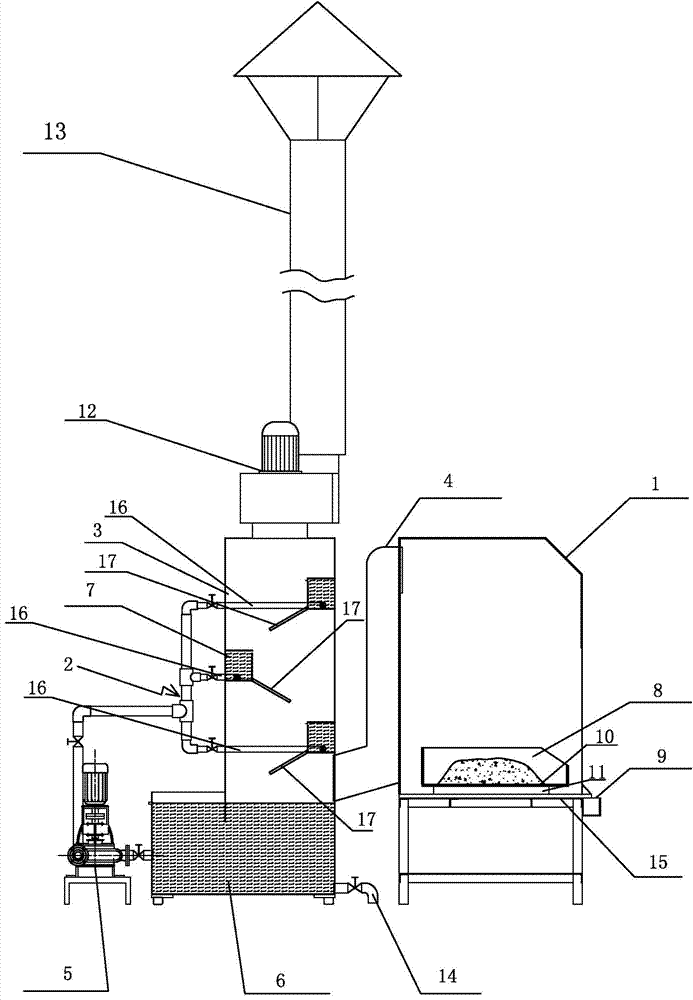

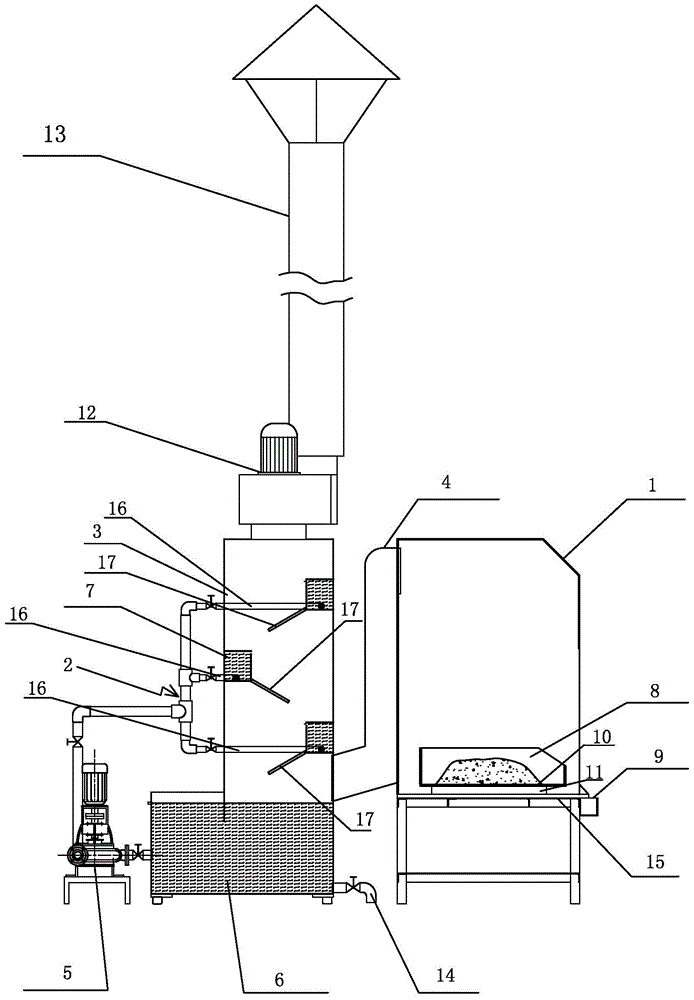

Potassium sodium lithium and lithium slag waste treating device

ActiveCN104764024AWill not cause an explosionSafe handlingProcess efficiency improvementIncinerator apparatusLithiumCombustion chamber

The invention discloses a potassium sodium lithium and lithium slag waste treating device. The device comprises a combustion chamber, a smoke treating device and a smoke exhausting device; a material bin for storing potassium sodium lithium and lithium slag wastes, a lithium storing basin and a combustion platform are arranged in the combustion chamber from top to bottom in a sequence, wherein the material basin is erected on the lithium storing basin; a through lithium discharging leaking hole is formed in a bottom plate of the material basin; the material basin is communicated with the lithium storing basin through the lithium discharging leaking hole; the lithium storing basin is arranged on the combustion platform; the smoke treating device is communicated with the top part of the combustion chamber; the top part of the smoke treating device is communicated with the smoke exhausting device. The device is simple in structure, can safely treat the potassium sodium lithium and lithium slag wastes, is harmless to environment, and large in treatment quantity per unit of time; the lithium can be recovered during treating the wastes, so that the resource waste can be avoided; the economic benefit is increased.

Owner:YICHUN GANFENG LITHIUM IND

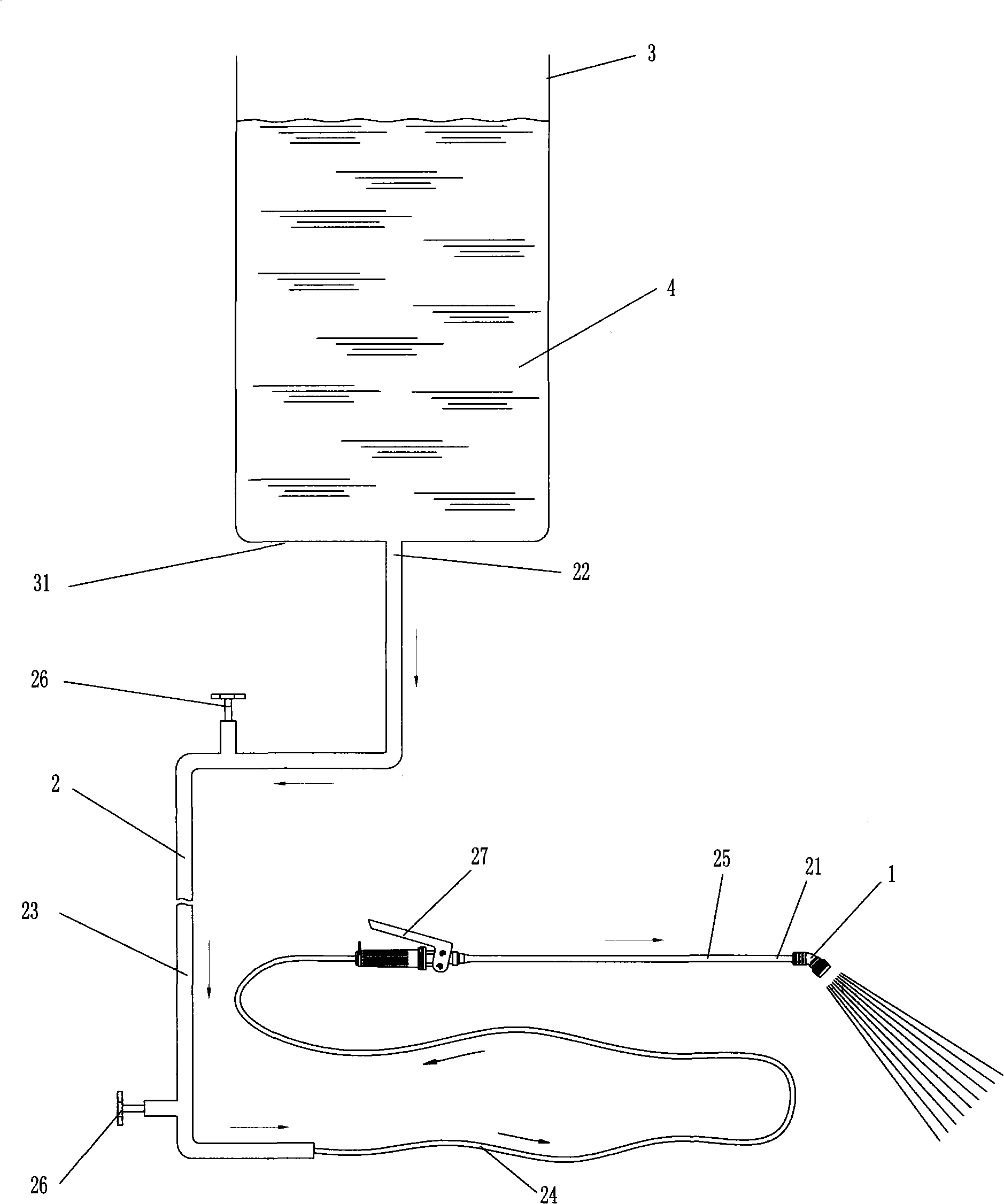

Wood bleaching device

InactiveCN101491909AWill not cause an explosionLow costWood treatment detailsBleachPulp and paper industry

The invention discloses a wood product bleaching device, which has the key technical points that: the device comprises a nozzle which is connected with an uptake pipe, and the top of the uptake pipe is connected with a retort which is higher than the nozzle and can make the nozzle produce a pressure high enough for injection; and the retort is open and contains a bleaching agent. The invention provides a wood product bleaching device which is safe, reliable, simple in structure, low in cost, aiming to overcome the drawback that the prior wood product bleaching device lacks safety.

Owner:中山市合兴奇典居家具有限公司

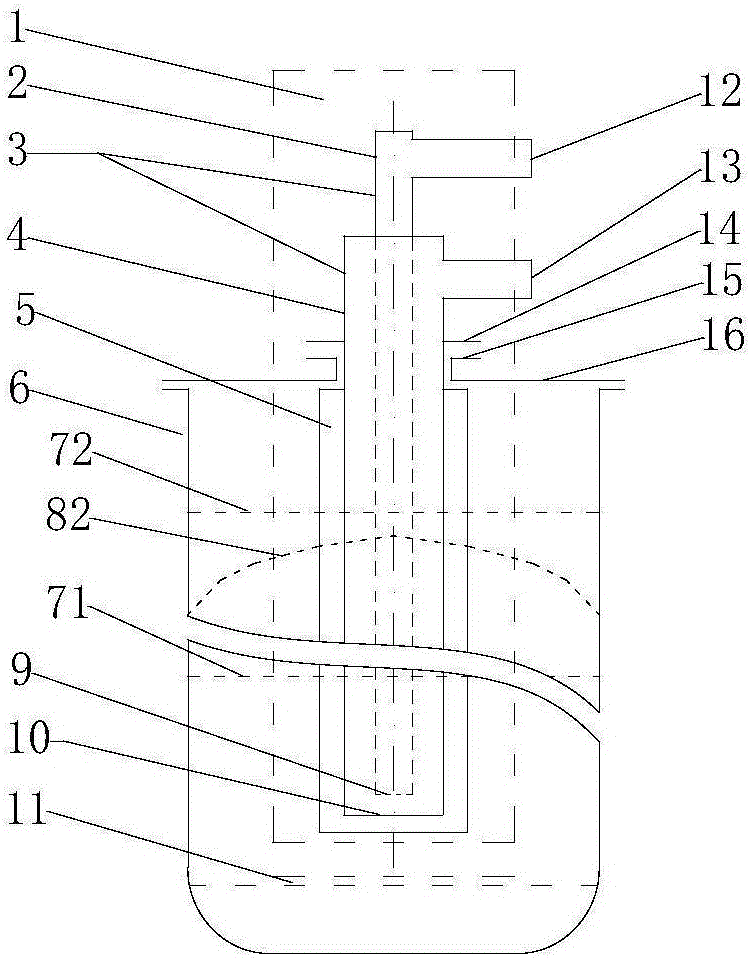

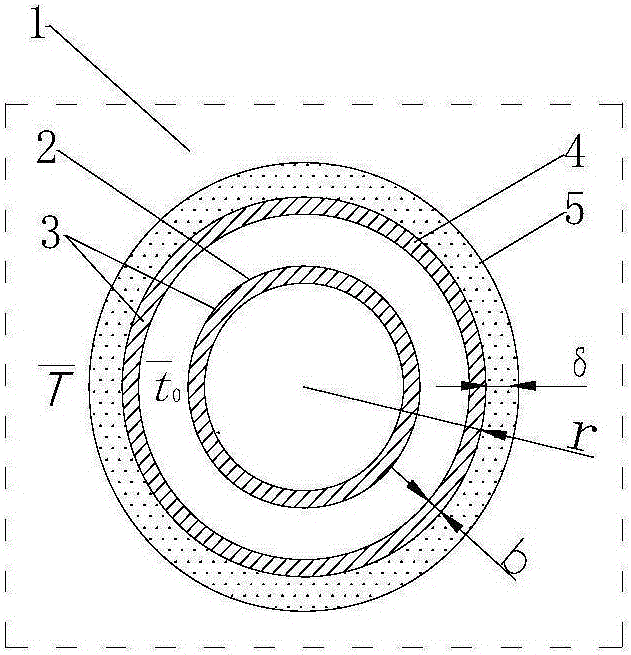

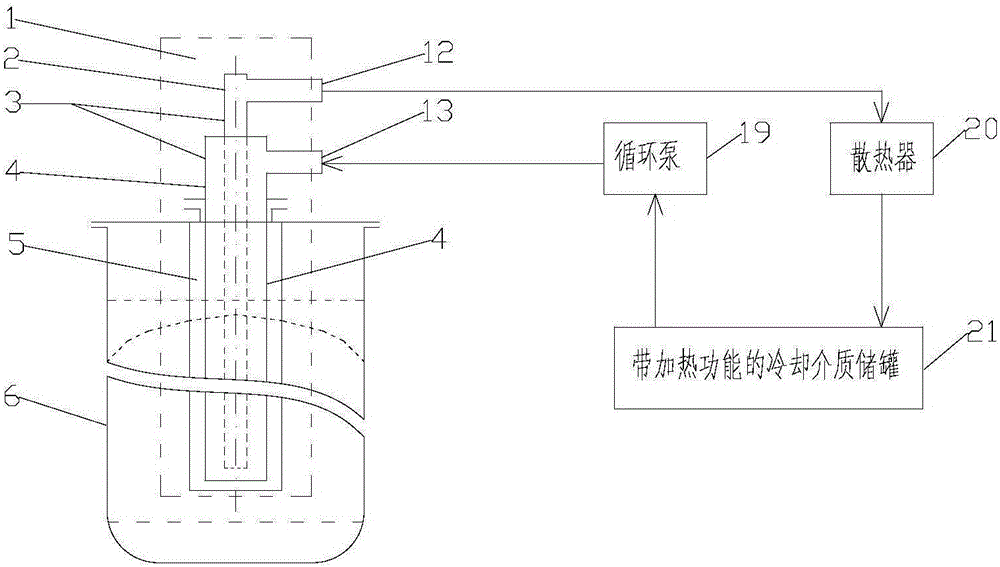

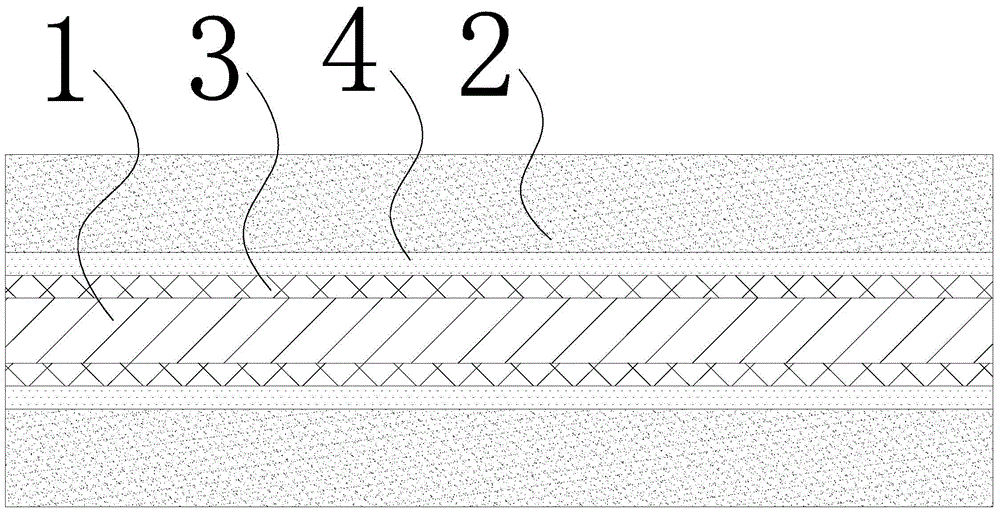

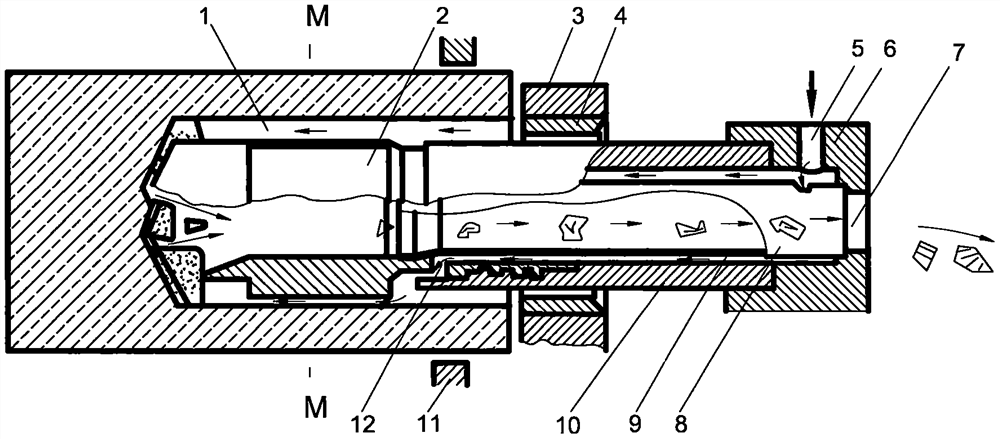

Tubular heat exchanger with inert coating layer and application to titanium sponge production

ActiveCN105925820AIncrease productivityImprove reduction efficiencyStationary tubular conduit assembliesTitanium tetrachlorideMagnesium

The invention discloses a tubular heat exchanger with an inert coating layer and application to titanium sponge production. The tubular heat exchanger can be used for quickly rejecting heat generated from a magnesiothermic reduction reaction and gathered in a liquid magnesium central area, so that the titanium tetrachloride feeding amount can be multiplied; meanwhile, the inert coating layer on the surface of the tubular heat exchanger always remains in a solidification state, thereby preventing formation, deposition and attachment of a titanium crystal on the metal surface of the tubular heat exchanger, and preventing bonding of a titanium lump and the metal surface of the tubular heat exchanger; and after the reduction is finished, the coating layer is melted and drops off, and a cavity is formed in the axis position of the titanium lump, so that the titanium sponge distillation period can be shortened by half or above. By adoption of the tubular heat exchanger provided by the invention, the titanium sponge production efficiency is multiplied, the power consumption cost is greatly reduced, and a prerequisite is provided for further enlargement of a furnace profile.

Owner:王进民

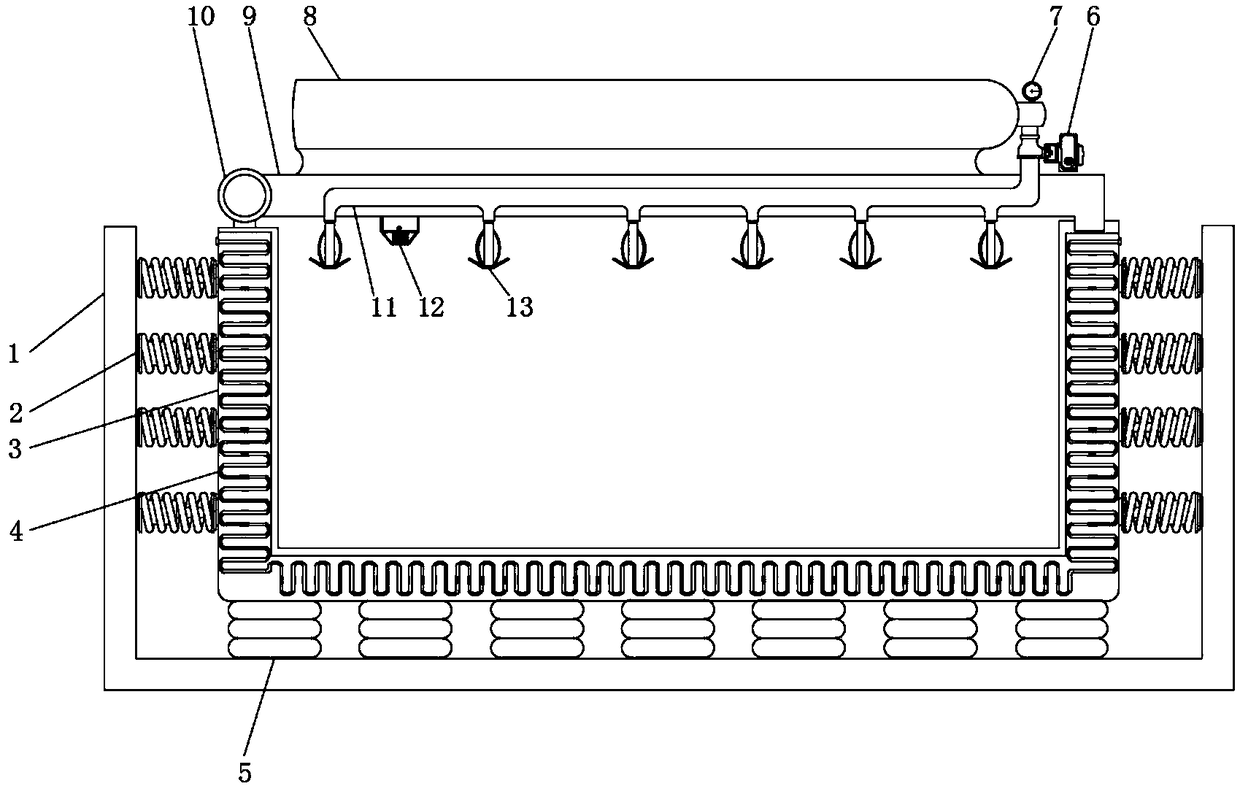

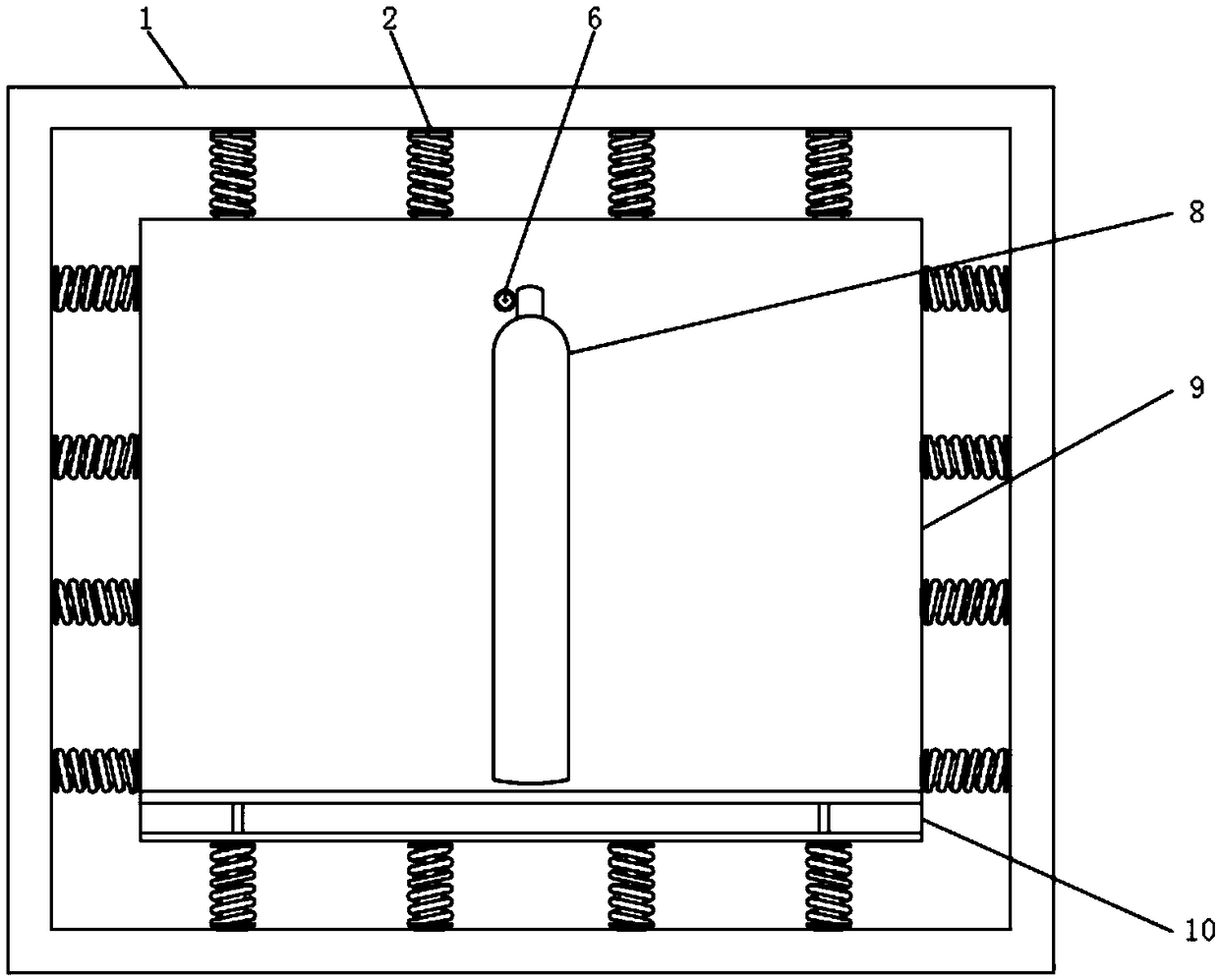

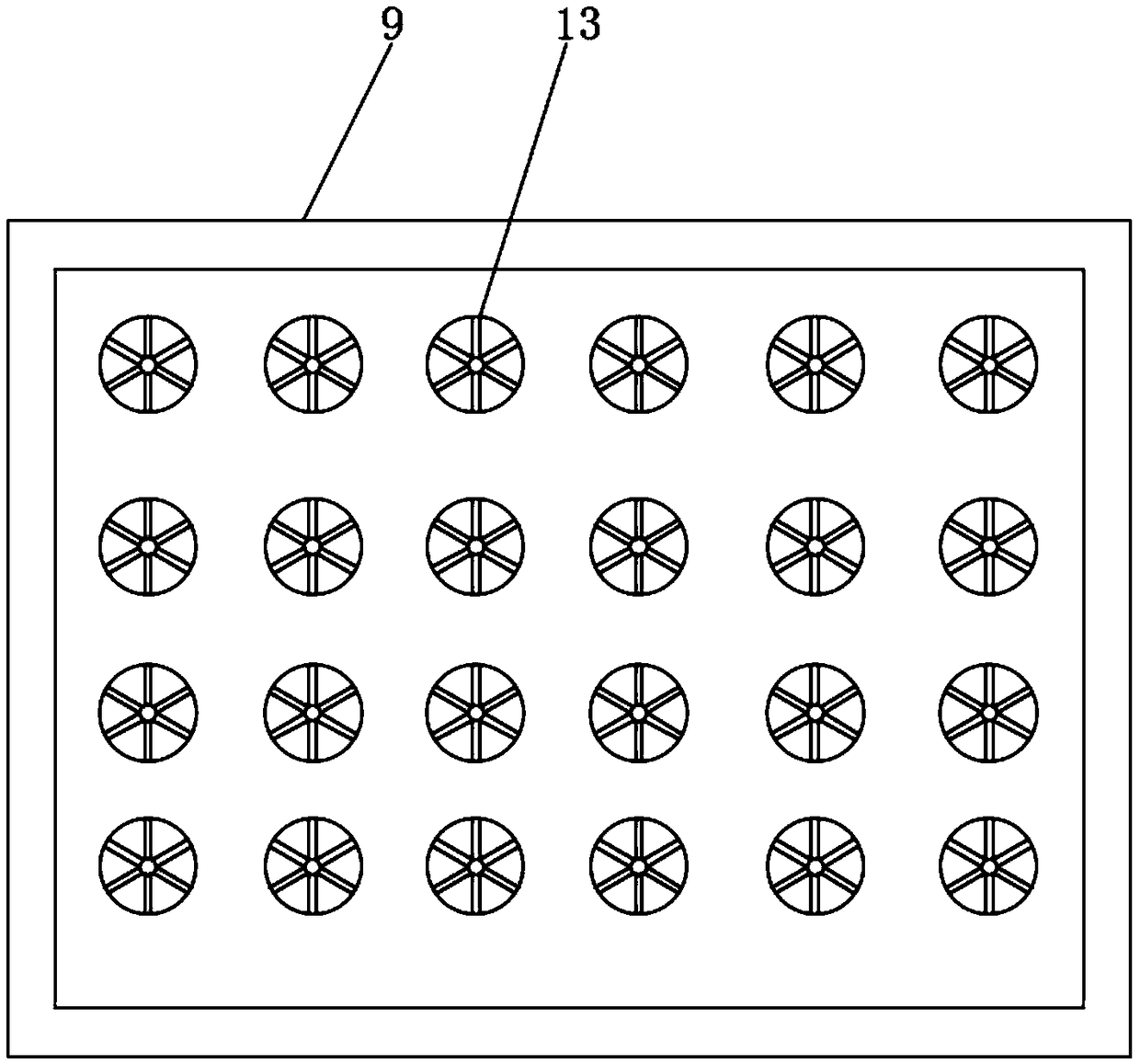

Lithium battery buffer device for new energy automobile

PendingCN108695469AAvoid instabilityPrevent spontaneous combustionFire rescueCell component detailsNew energyEngineering

The invention discloses a lithium battery buffer device for a new energy automobile. The lithium battery buffer device comprises a placing box of the buffer device and a placing box of the lithium battery, wherein the placing box of the lithium battery is arranged in the placing box of the buffer device; the bottom surface of the placing box of the lithium battery is connected with the placing boxof the buffer device through an air damping air bag; the side surface of the outer surface of the placing box of the lithium battery is connected with the inner wall of the placing box of the bufferdevice through a spring damper; a water cooling pipe is penetrated into the outer wall of the placing box of the lithium battery; a rotary shaft is arranged at the top surface of one side of the placing box of the lithium battery. The lithium battery buffer device has the advantages that by arranging the spring damper and the air damping air bag, the lithium battery can be vertically buffered anddamped by the air damping air bag, and can be horizontally buffered and damped by the spring damper, so that the all-bearing buffer and damping effect is realized on the lithium battery, thereby preventing the instability of the lithium battery due to excessive bumping.

Owner:WUHU SUNYANG INFORMATION CONSULTATION

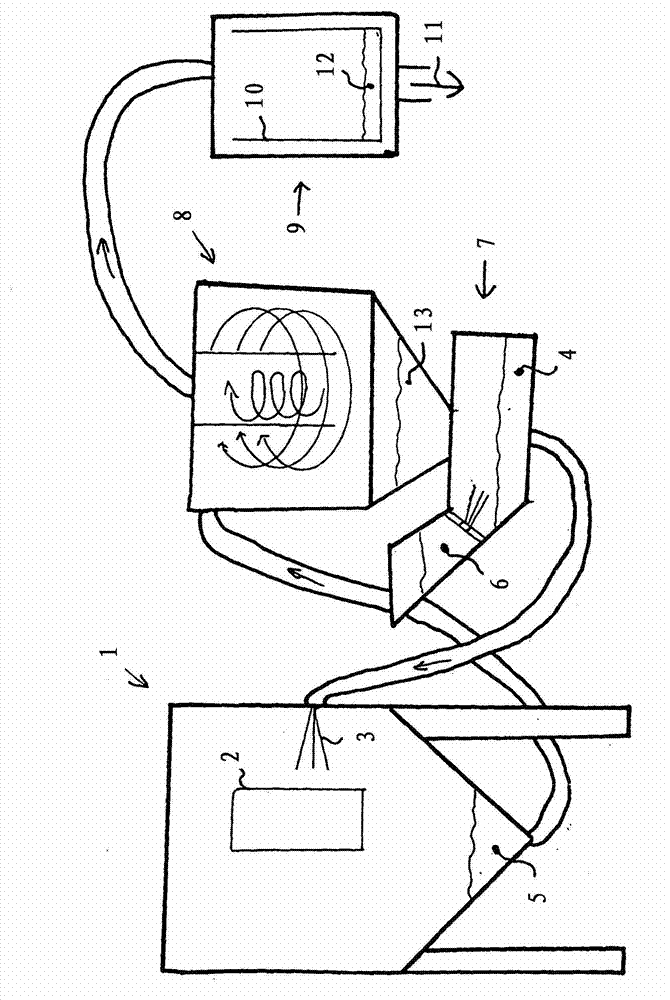

Application grinding method of abrasive wheel muller in valve

InactiveCN101176981AGrinding speed is fastImprove grinding precisionSeat surface grinding machinesFailure rateUniversal joint

The invention relates to a grinding method with the application of the grinding wheel muller in the valve; wherein, the grinding wheel muller comprises a pneumatic motor, a drive rod, a grinding wheel plate, and a plurality of grinding wheel heads. The compressed air drives the pneumatic motor connected with the drive rod through the joint shaft; a driving bevel gear and a driven bevel gear arranged on the lower end of the drive rod are meshed with each other; the universal joint is connected with the grinding wheel on the external part of the body; the grinding wheel heads are arranged at both ends of the grinding wheel. The grinding method applied in the valve can be normally used in the condition of steam, water and wet, and cold grinding is not needed in the high temperature of 400 to 500 DEG C; online grinding can be used when the large valve leaks; grinding wheel heads and transmission regulate rods matched with the sealing surface can be assembled on valves with different specification, and repairing can be used when valve sealing surface leaks. The invention has the advantages of fast grinding, lower material cost, high grinding precision, simple operation, safety and reliability, low failure rate, long time continuous operation under any bad environment, and application for grinding on various valves.

Owner:赵殿纯

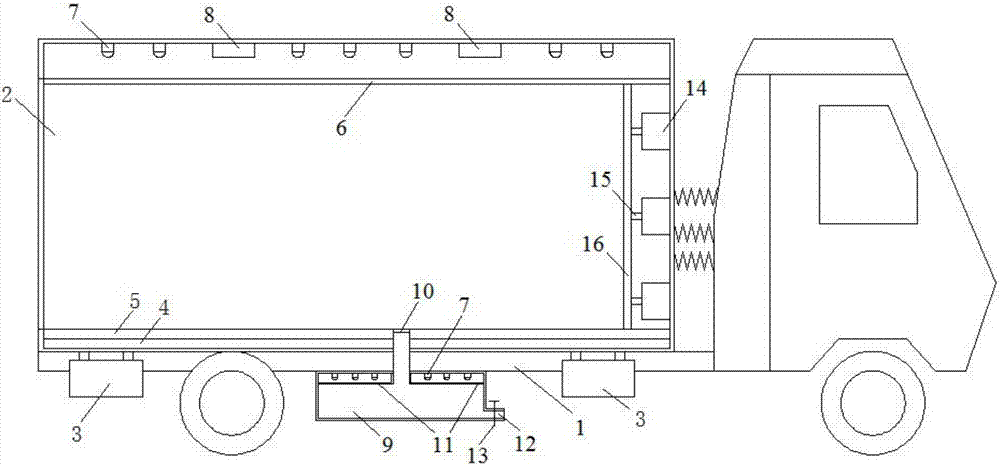

Household garbage transport automobile container

The invention relates to the field of household garbage processing and particularly relates to a household garbage transport automobile container. The household garbage transport automobile container comprises a container body fixed to a transport automobile chassis, and the front end and the rear end of the joint of the container body and the transport automobile chassis are each provided with a hydraulic device; the upper surface of the bottom of the container body is fixedly provided with a rubber buffering mat; a transparent ventilating plate uniformly provided with a plurality of ventilating holes is fixed below the top face of the container body, and inner top face, provided with a plurality of ventilating holes, of the container body is uniformly provided with a plurality of ultraviolet sterilizing lamps and air purification devices; the bottom face of the container body is fixedly provided with a sewage pool communicating the container body; and the inner front end face of the container body is fixedly provided with a vertical push plate through an electric stretching and contracting push rod. When the container is loaded with garbage, the hydraulic device located at the rear end is started, and the garbage enters the container body under the action of gravity; and when the garbage is dumped, the hydraulic device located at the front end is started and is matched with the vertical push plate, and the garbage is dumped out of the container body.

Owner:林招枫

A sodium potassium lithium and lithium slag waste treatment device

ActiveCN104764024BWill not cause an explosionSafe handlingProcess efficiency improvementIncinerator apparatusLithiumCombustion chamber

The invention discloses a potassium sodium lithium and lithium slag waste treating device. The device comprises a combustion chamber, a smoke treating device and a smoke exhausting device; a material bin for storing potassium sodium lithium and lithium slag wastes, a lithium storing basin and a combustion platform are arranged in the combustion chamber from top to bottom in a sequence, wherein the material basin is erected on the lithium storing basin; a through lithium discharging leaking hole is formed in a bottom plate of the material basin; the material basin is communicated with the lithium storing basin through the lithium discharging leaking hole; the lithium storing basin is arranged on the combustion platform; the smoke treating device is communicated with the top part of the combustion chamber; the top part of the smoke treating device is communicated with the smoke exhausting device. The device is simple in structure, can safely treat the potassium sodium lithium and lithium slag wastes, is harmless to environment, and large in treatment quantity per unit of time; the lithium can be recovered during treating the wastes, so that the resource waste can be avoided; the economic benefit is increased.

Owner:YICHUN GANFENG LITHIUM IND

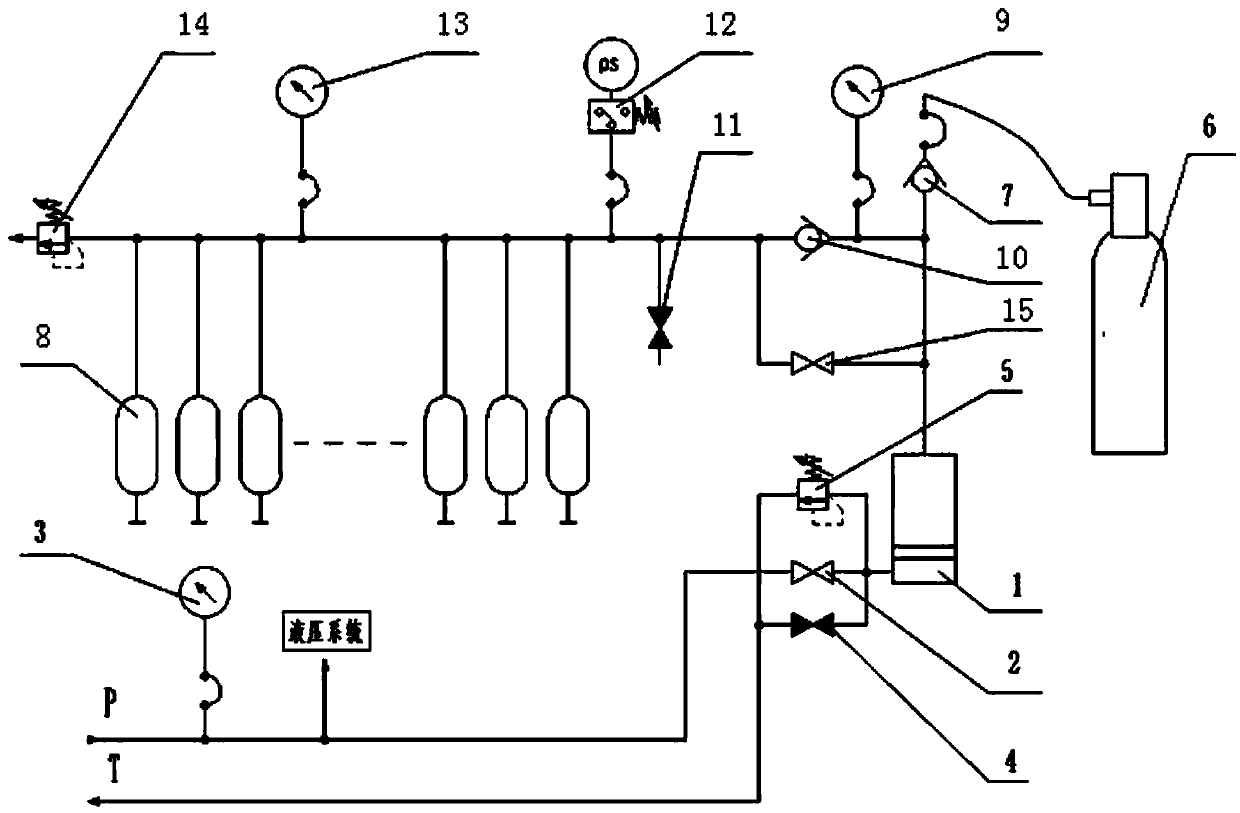

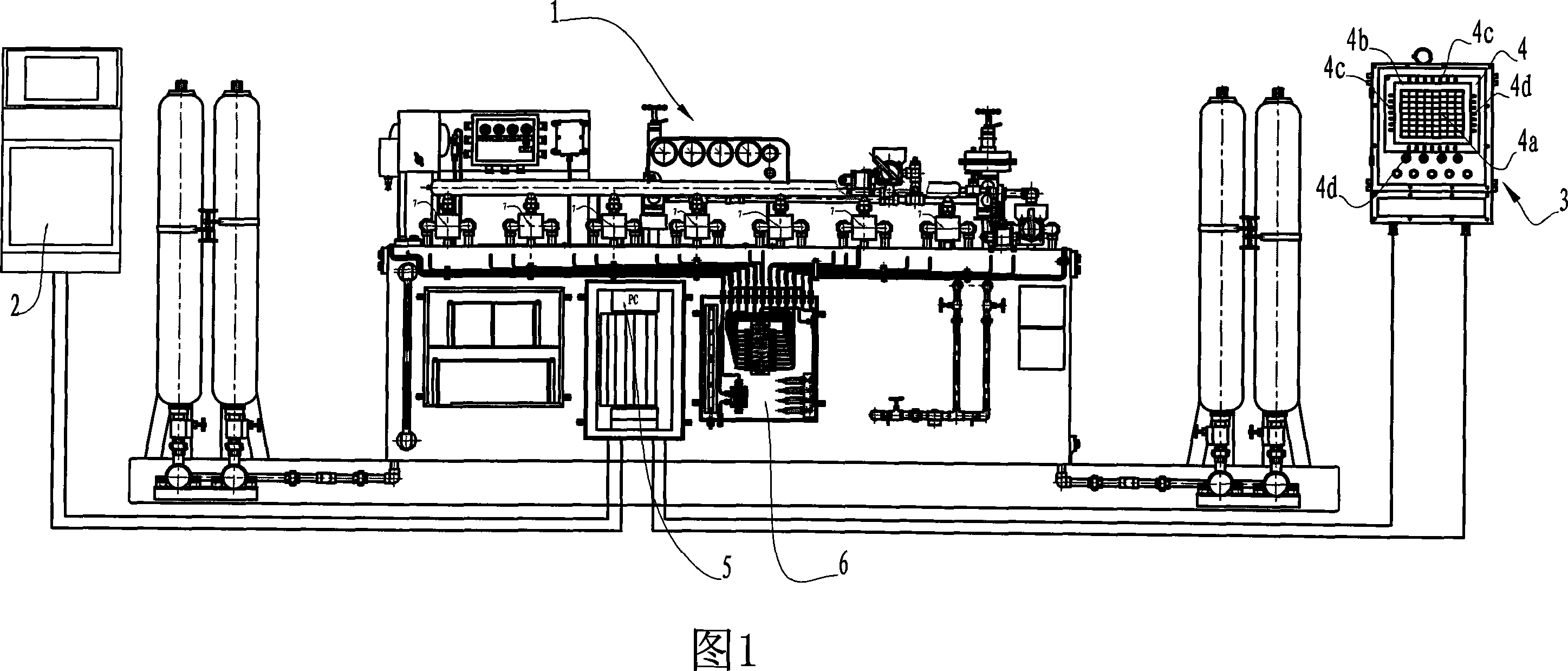

Hydraulic system energy accumulator station and nitrogen filling method using same

The invention discloses a hydraulic system energy accumulator station and a nitrogen filling method using the same. When pressure of the hydraulic system rises, oil liquid enters the energy accumulator, the nitrogen is compressed to be stored in to a nitrogen storage tank; and when the pressure of the hydraulic system declines, the nitrogen enters a piston type energy accumulator from a nitrogen storage tank, the oil liquid is pressed into a loop to release energy. The piston type energy accumulator has a high capacity, sensitive response, small inertia in movement part, long service life, light weight, easy installation, simple structure and convenient maintenance; the piston type energy accumulator is used as a gas pressurization cylinder to fill the nitrogen storage tank with the nitrogen; energy transfer is achieved between incompatible liquid and gas; and the piston type energy accumulator can be used as emergency power source and has functions of leakage supplementary, constant pressure keeping, hydraulic shock absorbing, pulsation absorbing and noise reducing. No additional nitrogen filling device is required; the nitrogen is stable, so that hazards fire, explosion and otherrisks are avoided; and safety and reliability are achieved and efficiency of the hydraulic system id improved.

Owner:BENGANG STEEL PLATES

GYH25 oxygen sensor for mine

ActiveCN105136997AWith clock display functionWill not cause an explosionTransmission systemsAlarmsOxygen monitoringThe Internet

The invention relates to a GYH25oxygen sensor for a mine. The oxygen sensor comprises a shell and an oxygen monitoring device. A handle is arranged on the shell. The shell comprises an upper shell body and a lower shell body. The upper shell body and the lower shell body are connected through a supporting arm. The upper shell body is provided with a display window and an alarm window. The lower shell body comprises a sensor containing cavity and gas monitoring cavities arranged on the two sides of the sensor containing cavity. The oxygen monitoring device comprises a battery, an oxygen sensor body, a signal converter, a signal amplifier, a filter, a data collecting card, a data storage, a CPU, a nixie tube displayer, a single-chip microcomputer, an alarm device, a wireless transmission module, an internet and a remote monitoring host. According to the method, an electronic device in the electro-chemistry principle, intelligently controlled through an embedded controller and carrying out displaying through a nixie tube is adopted, operation is easy, use is convenient, the oxygen sensor is safe and reliable and is mainly used for oxygen detection and alarm, and the oxygen detection range can reach 0-25%O2.

Owner:YANGZHONG SOUTH MINE ELECTRICAL

Ground blowout preventing control apparatus

The invention discloses a ground blowout preventer controller, comprising: energy storer, remote controller and auxiliary remote controller, where the remote controller and the auxiliary remote controller are equipped with touch screens, LCD screen is separated from the touch screen and externally equipped with the touch screen of toughened glass, the upper and lower directions of the touch screen are installed with multiple tube groups of infrared transmitting and receiving tubes, the touch screen is connected with PC, the signals received by the touch screen is transmitted to the PC, and the PC is connected with a valve controller of the energy storer and sends instructions to the valve controller to control its action. And the invention has good explosion prevention performance; besides, the touch screen of toughened glass separates the LCD screen from the outside so that the LCD screen can adapt to lower environmental temperature, resist impact and be unafraid against scraping.

Owner:GUANGZHOU DONGSU PETROLEUM D&E EQUIP

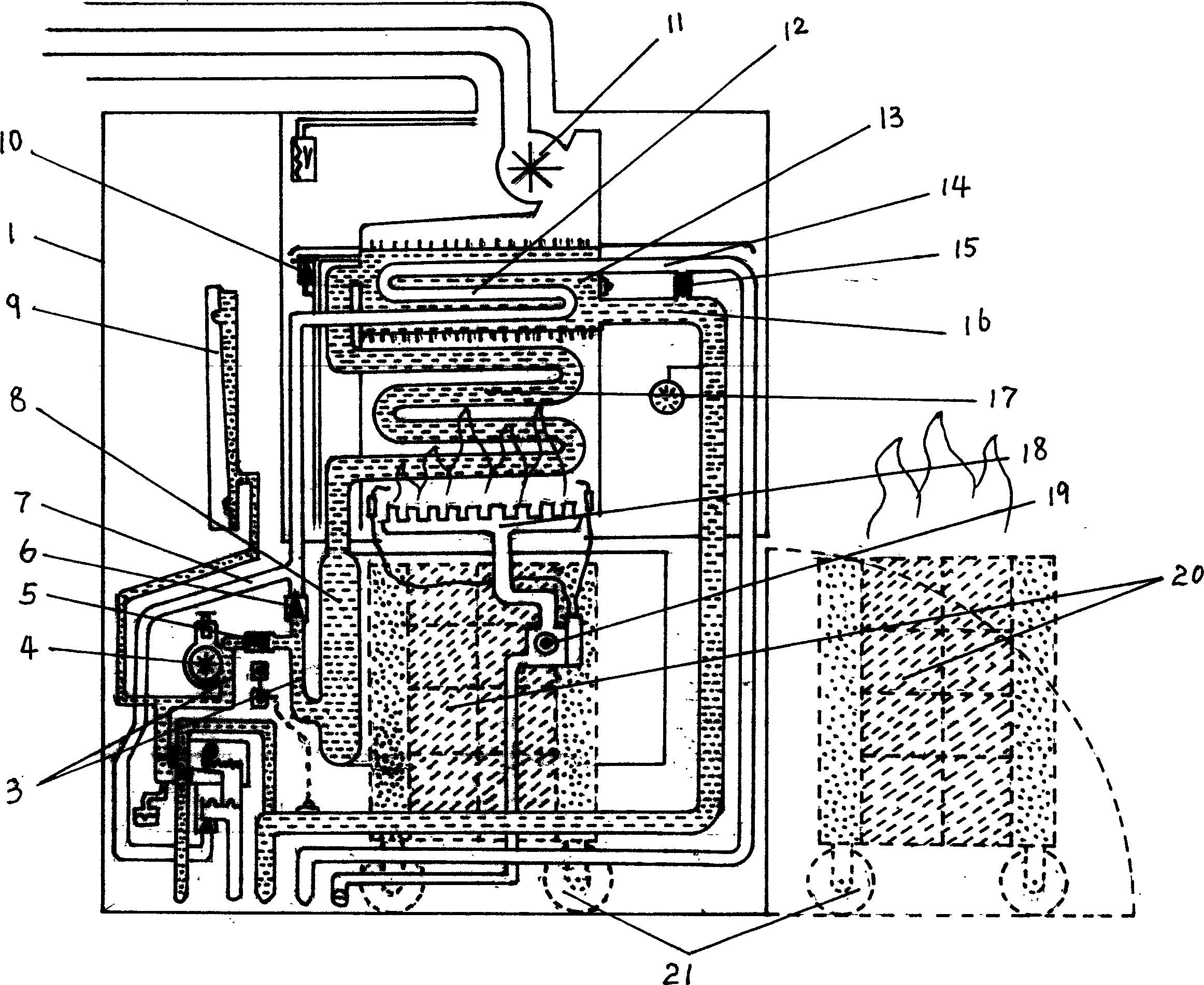

Movable water boiling stove for heating and cooking with double layer heat exchanger

InactiveCN1648542AWill not cause an explosionLarge specific surface areaDomestic stoves or rangesWater heatersAutomatic controlCoal

The movable heating and cooking water heater with double layer heat exchanger consists of housing, door, double layer heat exchanger, automatic control valve connected in the pipeline, detachable and replaceable stove, etc. The present invention has the advantages including capacity of replacing various kinds of stove, including gas burning stove, coal stove, electric stove, etc., capacity of taking the stove out of the water heater for cooking, raised heat efficiency owing to the double layer heat exchanger, and capability of using all the year round.

Owner:马国实

Blasting agent and blasting method

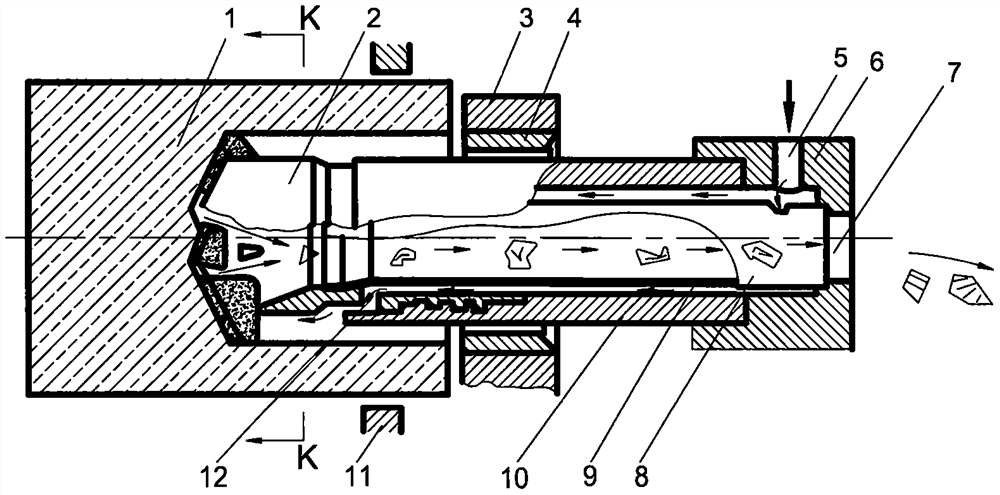

ActiveCN102791429AMinimal crushing strengthEasy to separateAbrasive machine appurtenancesAbrasive blastingStructural engineering

The invention relates to a blasting agent (4), which has at least one means for mechanically processing surfaces, in particular steel or cast beads. An additive (6) for degreasing and cleaning the surface (2) to be blasted and / or the blasting agent is provided, said additive comprising a granular material, which has a lower fracture strength than the at least one means for mechanically processing surfaces itself under the mechanical loads to which the blasting agent (4) is subjected during the blasting method.

Owner:KOMPOFERM

Lithium ion battery with built-in protective plate

PendingCN106532128AExtended service lifeWill not cause an explosionFinal product manufactureElectrolyte accumulators manufactureWhole bodyEngineering

The invention discloses a lithium ion battery with a built-in protective plate, and relates to the technical field of the lithium ion battery. The lithium ion battery comprises a protective plate, a positive electrode tab, a negative electrode tab, an inner membrane and an outer membrane, wherein the protective plate, the positive electrode tab and the negative electrode tab are packaged between the inner membrane and the outer membrane; the protective plate is welded above the positive electrode tab and the negative electrode tab; the inner membrane is packaged below the positive electrode tab and the negative electrode tab, and the outer membrane is packaged above the protective plate; the two sides of the inner membrane and the outer membrane are packaged into a whole body; the protective plate is used for protecting the lithium ion battery; and the inner membrane and the outer membrane are used for the protective plate, the positive electrode tab, the negative electrode tab and the lithium ion battery. By arranging the protective plate in the inner membrane and the outer membrane of the lithium ion battery, a packaging process is reduced, so that the cost is lowered, and a good waterproof function is realized; meanwhile, the service life of the protective plate is prolonged, and the service life and the safety in use of the lithium ion battery are prolonged and improved; in addition, the protective plate is not in contact with an external environment, so that gas explosion can be avoided; and therefore, the lithium ion battery has high weather fastness.

Owner:四川赛尔雷新能源科技有限公司

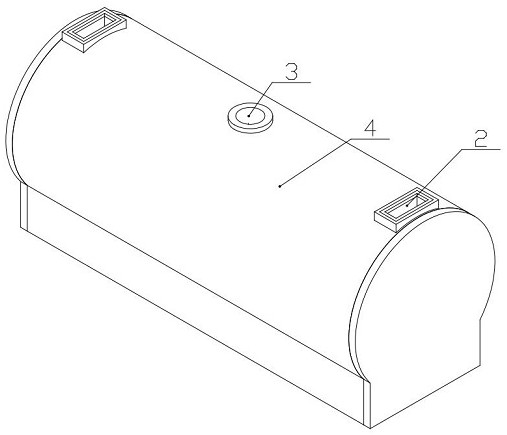

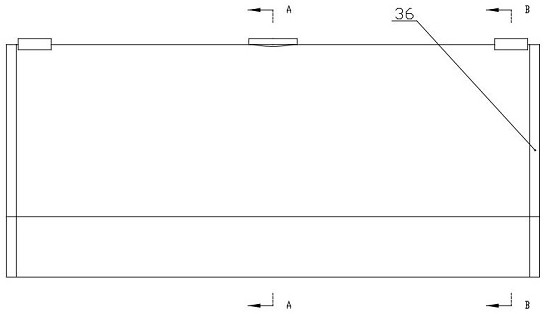

Wave-resistant self-pressure-discharging storage tank for petroleum highway-railway transportation

The invention discloses a wave-resistant self-pressure-relief storage tank for petroleum highway and railway transportation. The wave-resistant self-pressure-relief storage tank comprises a self-adaptive variable-diameter wave-resistant partition plate, a flame-retardant self-adaptive constant-pressure mechanism, an exhaust cylindrical storage tank assembly and a double-layer external protective shell. The invention belongs to the technical field of petroleum transportation, and particularly relates to an anti-wave self-pressure-discharging storage tank for petroleum highway-railway transportation. The self-adaptive variable-diameter wave-resistant partition plate is creatively provided, when liquid vibrates at a high speed during rapid starting or sudden braking and the like, the liquid impacts the self-adaptive variable-diameter wave-resistant partition plate at a high speed, the variable-diameter valve elastic valve clack can be bent inwards when subjected to high-speed impact, the area of the variable-diameter valve elastic valve clack is reduced, and the self-adaptive variable-diameter wave-resistant partition plate is formed. The amount of liquid passing through the self-adaptive variable-diameter wave-resistant partition plate is reduced; on the basis of an air pressure and hydraulic structure principle, a flame-retardant self-adaptive constant pressure mechanism is creatively provided, the storage volume of internal gas is changed through a lifting type pressure regulating mechanism capable of freely sliding, and the air pressure is reduced by increasing the volume.

Owner:XUZHOU HENGAN OIL STORAGE & TRANSPORTATION TECH

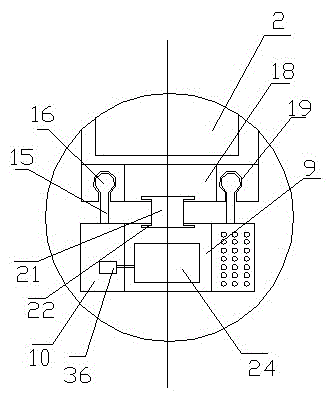

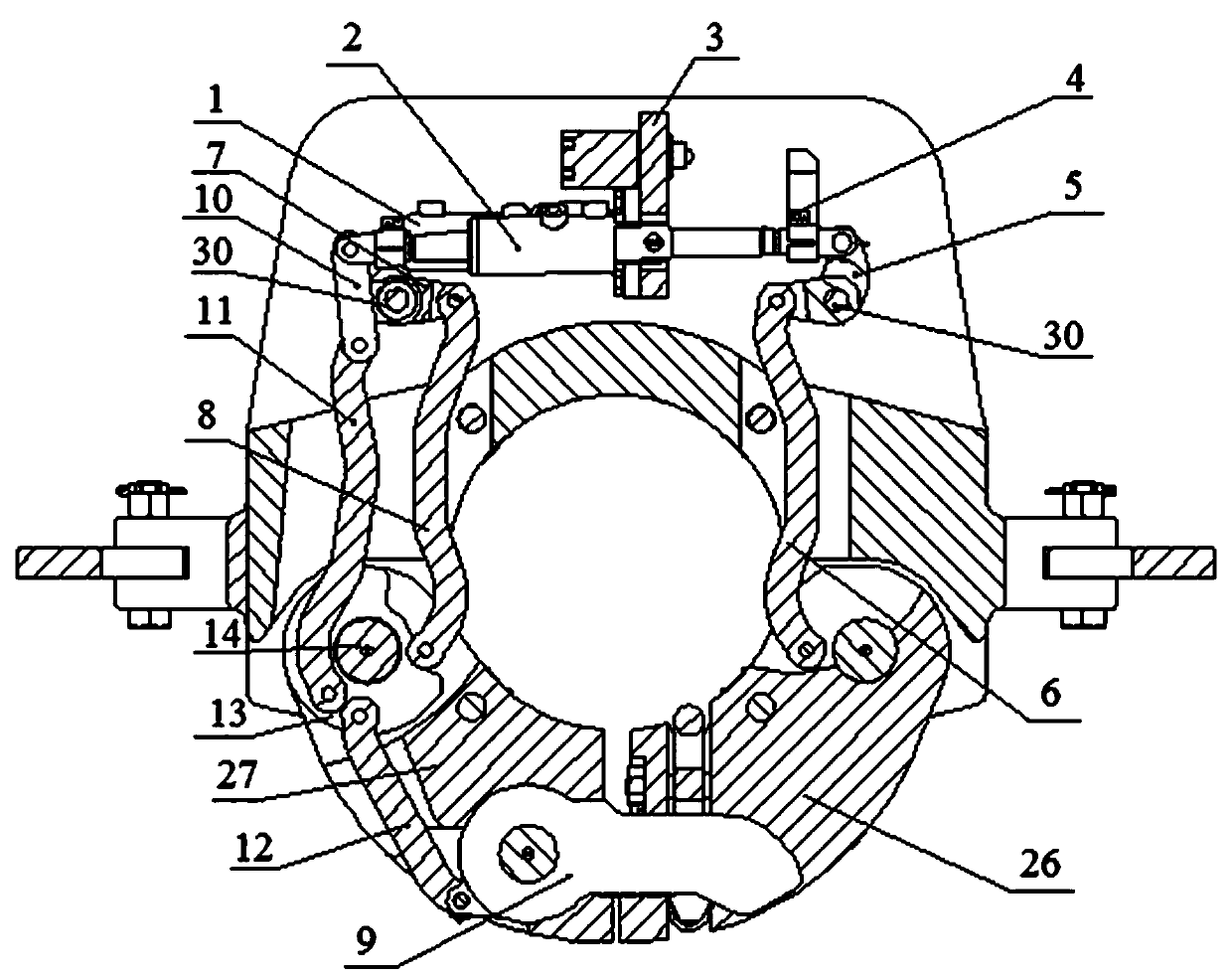

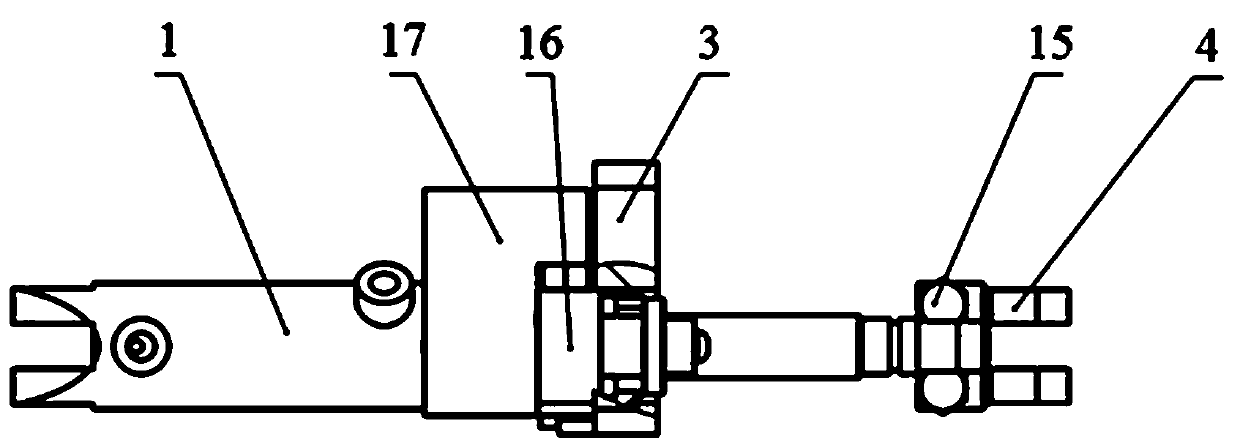

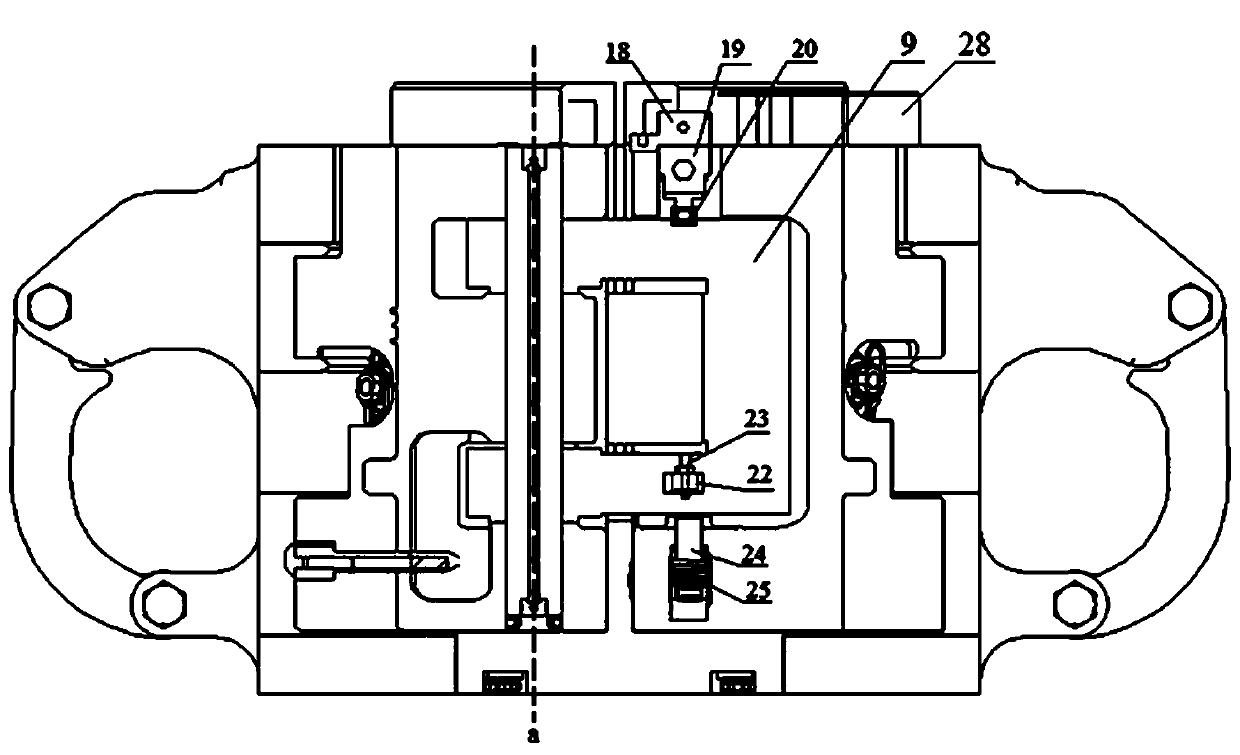

Novel hydraulic elevator with opening-closing signal indication function

PendingCN110424905AAvoid invalid operationsPlay the role of double insuranceDrilling rodsDrilling casingsHydraulic cylinderLocking mechanism

The invention discloses a novel hydraulic elevator with an opening-closing signal indication function. The novel hydraulic elevator comprises a left door body, a right door body, a hydraulic cylinderI and a hydraulic cylinder II; one end of the hydraulic cylinder I is connected with the right door body through a right connection rod and a first pull rod, and the other end of the hydraulic cylinder I is connected with the left door body through a left connection rod and a second pull rod; a plunger latch is connected between the left door body and the right door body and provided with a locking mechanism; and the end of a piston rod II of the hydraulic cylinder II is connected with the plunger latch through a pull head, a third pull rod and a fourth pull rod in sequence. The whole device is provided with three signal output parts, when a door body is opened, whether a door is completely opened or not can be determined, only when the door body is completely opened, a door opening hydraulic signal is emitted, and invalid operation that the elevator door is not completely opened is completely eradicated; and after the door is closed, a plunger latch closing signal and a plunger latchpin locking signal are emitted, double insurance is achieved, in addition, the signals are output in a hydraulic signal mode, an operator can be clear about the working state of the elevator, and themal-operation possibility is reduced.

Owner:江苏如东联丰石油机械有限公司

Carbon dioxide sensor for GRH5 coal mine

InactiveCN105134297AExtended service lifeSimple structureMining devicesSignal amplifierCarbon dioxide sensor

The invention relates to a carbon dioxide sensor for a GRH5 coal mine. The carbon dioxide sensor comprises a shell and a carbon dioxide monitoring device, wherein the shell comprises an upper shell, a lower shell and a handle; a display window and an alarm window are arranged on the upper shell; the lower shell comprises a sensor accommodating chamber and gas monitoring chambers arranged at two sides of the sensor accommodating chamber; a plurality of air vents are uniformly formed in the gas monitoring chambers; the carbon dioxide monitoring device comprises a battery, a carbon dioxide sensor, a signal converter, a signal amplifier, a filter, a carrier catalyzing element, a data acquisition card, a data memory, a singlechip microcomputer, a Nixie tube displayer, an alarm apparatus and a wireless transmission module. According to the carbon dioxide sensor, an electronic sensor in intelligent control of an embedded microcontroller unit and four-bit Nixie tube display is adopted, and the sensor is simple to operate, convenient to use, and safe and reliable, is mainly used for carbon dioxide detection and alarm, and can achieve a detection range of 0-5%CO2 for the carbon dioxide.

Owner:YANGZHONG SOUTH MINE ELECTRICAL

High-safety lithium ion battery positive electrode and preparation method for positive electrode active material slurry

InactiveCN105702965ADoes not cause combustionWill not cause an explosionElectrode carriers/collectorsSecondary cellsBattery chargeElectrical battery

The invention discloses a lithium ion battery and provides a high-safety lithium ion battery positive electrode and a preparation method for a positive electrode active material slurry; the lithium ion battery positive electrode is high in melting point and capable of greatly improving the safety and reliability of the battery and prolonging the service life of the battery; the technical problems of inflammable positive electrode, probability of explosion, relatively low safety and reliability and the like of the lithium ion battery existing in the prior art are solved. The high-safety lithium ion battery positive electrode comprises a positive electrode current collector and a positive electrode active material coating layer coating the surface of the positive electrode current collector, wherein the positive electrode current collector is metal or alloy which can be kept stable within a battery charging-discharging window and has the melting point of greater than 1,000 DEG C.

Owner:CHAOWEI POWER CO LTD

Hydrophilic oleophobic adsorption particle for chemical industry

InactiveCN110354537AWill not cause an explosionAchieve the effect of only absorbing water but not oilIon-exchange process apparatusOther chemical processesChemical industryActive agent

The invention relates to a hydrophilic oleophobic adsorption particle for the chemical industry. The hydrophilic oleophobic adsorption particle comprises skin and at least one inner core wrapped by the skin, wherein the skin is a hydrophilic oleophobic layer which is synthesized through a bonding reaction of hydrophilic groups with a polar group contained in a fluorocarbon active agent; the skin is of a two-layer structure, an outer hydrophilic oleophobic layer is a of membrane structure, and an inner hydrophilic oleophobic layer is of a porous structure; and the inner core is made of a water-absorbing material. The adsorption particle is put into the lubricating oil, and the skin of the adsorption particle can isolate oil and permits permeation of water; and water that has entered the adsorption particle through the skin is adsorbed by the inner core.

Owner:佛山振业润滑材料有限公司

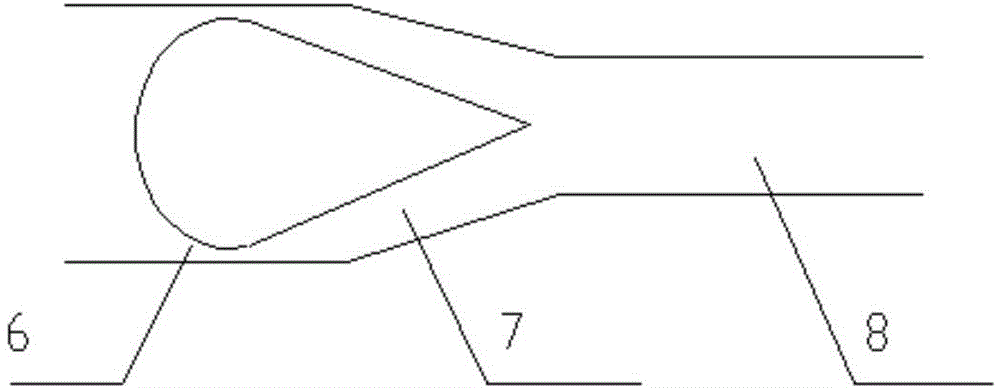

Spray-suction type hole machining method

PendingCN112589153APowerfulHigh self-centering accuracyMaintainance and safety accessoriesBoring/drilling machinesMachine toolCutting fluid

The invention belongs to the field of hole machining, and particularly relates to a spray-suction type hole machining method which is used for improving hole machining capacity and quality. One part of cutting fluid flows to a cutting edge part, and the other part of the cutting fluid is obliquely sprayed backwards. A plurality of wedge-shaped protrusions are arranged on a drill bit along the circumference, the wedge-shaped protrusions and the inner wall of a machined deep hole form a wedge-shaped space, and a wedge-shaped oil film is formed when oil flows through the wedge-shaped space. The distance between the wedge-shaped protrusions and the inner wall of the machined deep hole is very small or equal to zero. Self-centering force of the drill bit is finely adjusted through an adjustingcushion block, a positioning piece and a screw rod as required. The length of the drill bit is larger than that of a drill bit of an existing corresponding spray-suction drill. The machining method comprises the steps that firstly, a spray-suction drill system and the drill bit thereof are assembled; secondly, the spray-suction drill system, the drill bit and a workpiece are installed on a machinetool; and thirdly, the drill bit is rotated, and the cutting fluid is brought into the wedge-shaped space. The force of the liquid is large, and estimation is convenient. The drill bit is high in self-centering precision and good in self-correcting effect. The precision of a cutter system is easy to guarantee, and high-speed rotation can be achieved.

Owner:ZHONGBEI UNIV

Oxygen feeding device, and corresponding methane tri-reforming reaction device and method

ActiveCN104525054AWon't flowReduced strength requirementsHydrogenHydrogen/synthetic gas productionForming gasProduct gas

The invention relates to the technical field of methane tri-reforming, in particular to an oxygen feeding device, and corresponding methane tri-reforming device and method for preparing a synthetic gas. The oxygen feeding device comprises a conical core and an outer pipe, wherein the conical core is provided with a hemispherical bottom; two straight pipes which are different in diameters are arranged at two ends of the outer pipe; a conical pipe which is connected with the straight pipes at two ends is arranged on the middle part of the outer pipe; the conical core is fixed in the outer pipe and comprises a conical hemispherical bottom and a conical body; and at least part of the conical body is arranged in the conical pipe. According to the oxygen feeding device, low-temperature high-speed feeding is achieved; the traditional oxygen feeding mode is changed; oxygen can rapidly react with carbon deposit on the surface of the catalyst, so that carbon deposit is removed; and the oxygen is prevented from staying for a long period of time to react with CO and H2 in the synthetic gas.

Owner:SHENWU TECH GRP CO LTD

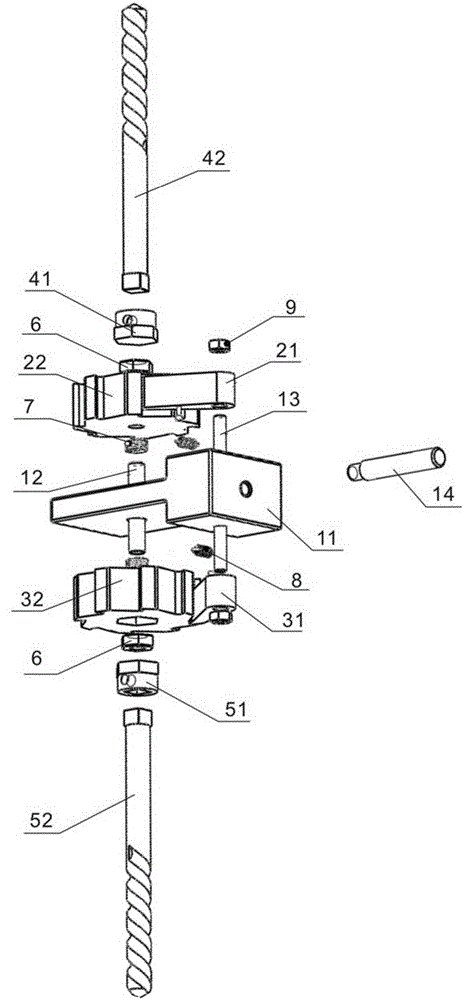

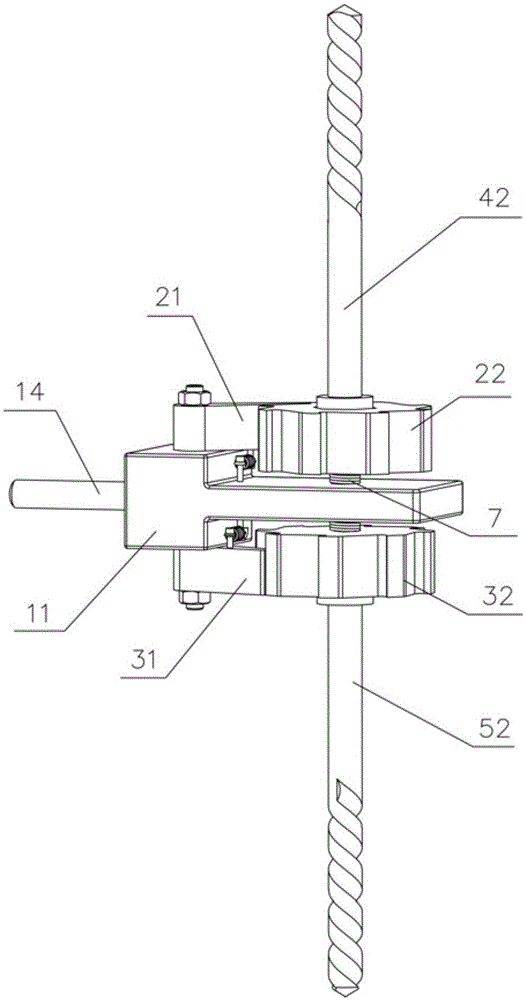

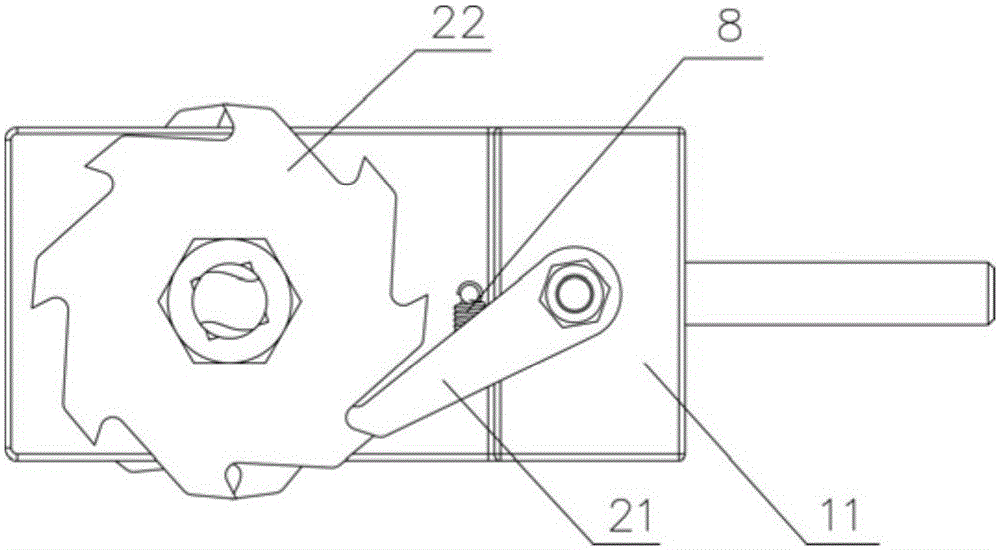

Underground tunnel punching apparatus

InactiveCN105108205AAvoid errorsSmall range of working anglesPortable drilling machinesGas explosionEngineering

The invention discloses an underground tunnel punching apparatus comprising a handle assembly, an upper ratchet structure and a lower ratchet structure. The upper ratchet structure comprises an upper pawl and an upper ratchet. The lower ratchet structure comprises a lower pawl and a lower ratchet. The upper and lower ratchets are mounted according to a demand that the upper and lower ratchets rotate oppositely in a working state. An upper drill bit assembly and a lower drill bit assembly are respectively and movably connected to the upper ratchet and the lower ratchet. The upper drill bit assembly can only move in the vertical direction relative to the upper ratchet. The lower drill bit assembly can only move in the vertical direction relative to the lower ratchet. The upper drill bit assembly and the lower drill bit assembly are located on the same straight line. By employing the punching apparatus in a working cycle process, holes punched by upper and lower drill bits are located on the same straight line, so that errors caused by a condition that holes in the upper and lower parts are independently punched are avoided; the working angle range is small when the handle rotates, and the operation is convenient; the handle can be manually wrenched, and effective work can be obtained by wrenching in the positive and negative directions, so that stroke waste does not occur; and gas explosion does not occur, so that the punching apparatus is applicable to special occasions.

Owner:CHENGDU UNIV

Inflatable sprayer

PendingCN112407623ASimple structureTake advantage ofPackage recyclingLiquid dispensingSprayerEngineering

The invention discloses an inflatable sprayer. The inflatable sprayer comprises a bottle body, wherein the bottle body is a main body used for filling liquid, inflating gas and realizing spraying, a liquid filling opening is formed in the upper end of the bottle body, and an inflation cavity is integrally formed in the lower end of the bottle body in an inward concave mode, and a waterproof and breathable device is arranged at the communication position of the upper end of the inflation cavity and the inside of the bottle body; a sealing cover, wherein the sealing cover is in threaded connection with the liquid filling opening of the bottle body in a rotation stopping mode and is used for filling the liquid and sealing and installing the spray pump assembly, and an installation cavity is integrally formed in the sealing cover in an upward convex mode; a spray pump assembly, wherein the spray pump assembly is a main body component used for realizing liquid feeding and spraying, and thespray pump assembly is arranged in the installation cavity and upwards penetrates out of the top of the installation cavity to extend out of the bottle body; and an inflation pump assembly, wherein the inflation pump assembly is an assembly which is arranged in the inflation cavity and is used for inflating compressed gas into the bottle body. According to the inflatable sprayer, the design that the liquid filling opening is formed in the upper portion and the inflation structure is arranged in the lower portion is realized, the waterproof and breathable device is adopted, so that the sealingperformance is good, safety and reliability are achieved, and repeated utilization can be achieved.

Owner:NINGBO SHENGJIE SPRAY

Hole machining ejector drill system and drill bit thereof

PendingCN112453503APowerfulHigh self-centering accuracyTransportation and packagingTrepanning drillsMechanicsCutting fluid

The invention belongs to the field of hole machining, and particularly relates to a hole machining ejector drill system and a drill bit thereof, which are used for improving the machining capacity andquality of holes. The drill bit is connected to a drill rod, an inner pipe is a scrap iron discharge channel, an annular channel for chip liquid to flow in is formed between the inner pipe and an outer pipe for oil supply, oil through holes are distributed in the drill bit along the circumference, one part of cutting fluid flows to the cutting edge part, the other part of the cutting fluid is obliquely sprayed backwards, a plurality of wedge-shaped protrusions are arranged on the drill bit along the circumference, the wedge-shaped protrusions and the inner wall of a machined deep hole form awedge-shaped space, and a wedge-shaped oil film is formed when oil liquid flows through the wedge-shaped space. The distance between the wedge-shaped protrusions and the inner wall of the machined deep hole is very small or equal to zero, the self-centering force of the drill bit is finely adjusted through an adjusting cushion block, a positioning piece and the screw rod as required, the liquid force is large and convenient to estimate, the drill bit is high in self-centering precision and good in self-correcting effect, the precision of a cutter system is easy to guarantee and high-speed rotation can be realized, and the length of the drill bit is larger than that of an existing corresponding drill bit of the ejector drill.

Owner:ZHONGBEI UNIV

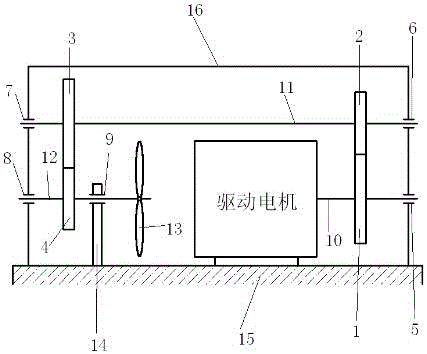

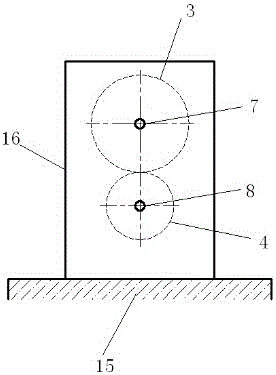

Drive motor heat-dissipation device for mining electric locomotive

InactiveCN106612047AWill not cause an explosionWill not cause a fireMechanical energy handlingCooling/ventillation arrangementDrive shaftEngineering

The invention discloses a drive motor heat-dissipation device for a mining electric locomotive, and the device comprises a heat-dissipation device housing, gears, transmission shafts, rolling bearings, fan blades, and a rack. A drive motor is disposed in the heat-dissipation device housing, and a drive motor output shaft is provided with the drive motor, the first gear and the first rolling bearing from the left to the right. The first transmission shaft is connected with the third rolling bearing, the third gear, the second gear and the second rolling bearing from the left to the right. The second transmission shaft is provided with the fourth rolling bearing, the fourth gear, the fifth rolling bearing and the fan blades from the left to the right. The first gear is engaged with the second gear, and the third gear is engaged with the fourth gear. The device can be suitable for an occasion with the high gas density, cannot generate a large amount of heat after long-time operation, and can save the electric energy.

Owner:罗浩

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com