High-safety lithium ion battery positive electrode and preparation method for positive electrode active material slurry

A cathode active material, lithium-ion battery technology, applied in battery electrodes, batteries, secondary batteries, etc., can solve the problems of poor safety reliability, high melting point, flammability, etc., to prolong the service life, improve the charging voltage value, The effect of improving safety and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

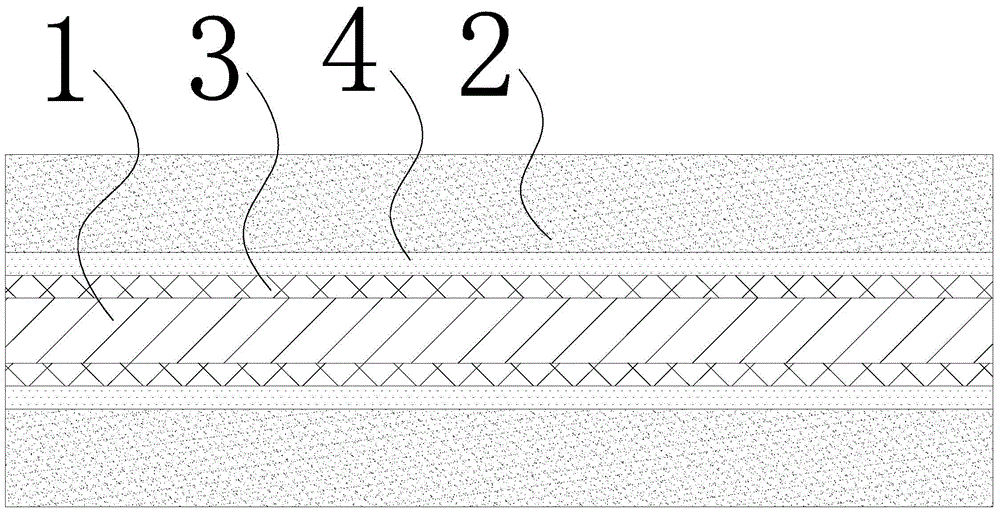

[0019] Such as figure 1 As shown, a lithium-ion battery positive electrode with high safety performance of the present invention includes a positive electrode current collector 1, and the positive electrode current collector 1 is a stainless steel foil that can maintain stability within the battery charge and discharge window and has a melting point higher than 1000 ° C. The surface of the current collector 1 is provided with a positive electrode current collector coating 3 of aluminum, and a positive electrode current collector conductive coating 4 is provided outside the positive electrode current collector coating 3, and the surface of the positive electrode current collector conductive coating 4 is coated with a positive electrode active material coating. 2, wherein the thickness of the positive electrode current collector coating 3 is 0.005mm, and the thickness of the positive electrode current collector conductive coating 4 is 0.002mm.

[0020] A preparation method of a ...

Embodiment 2

[0026] The positive current collector 1 is an iron foil that can maintain stability within the battery charge and discharge window and has a melting point higher than 1000°C. The thickness of the positive current collector coating 3 is 0.008mm, and the thickness of the positive current collector conductive coating 4 is 0.005mm. All the other parts are identical to Example 1.

[0027] An electric vehicle of the present invention includes the positive electrode of lithium-ion battery with high safety performance in Example 1 and the preparation method of the positive electrode active material slurry.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com