Inflatable sprayer

A sprayer, inflatable technology, used in liquid distribution, sustainable manufacturing/processing, sustainable packaging, etc., which can solve the problem that sprayers cannot simultaneously achieve filling ports, bottle volume usage limitations, and space utilization maximization, etc. problem, to achieve the effect of repeated use, simple structure and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

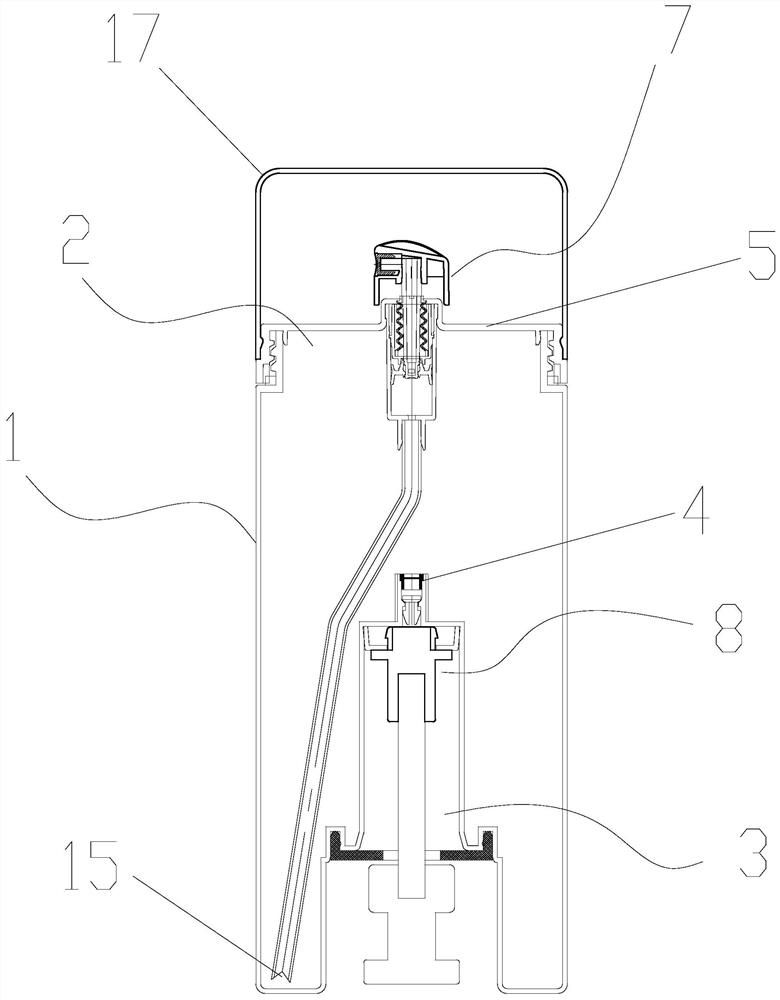

[0042] exist figure 1 In the illustrated embodiment, an inflatable sprayer comprising:

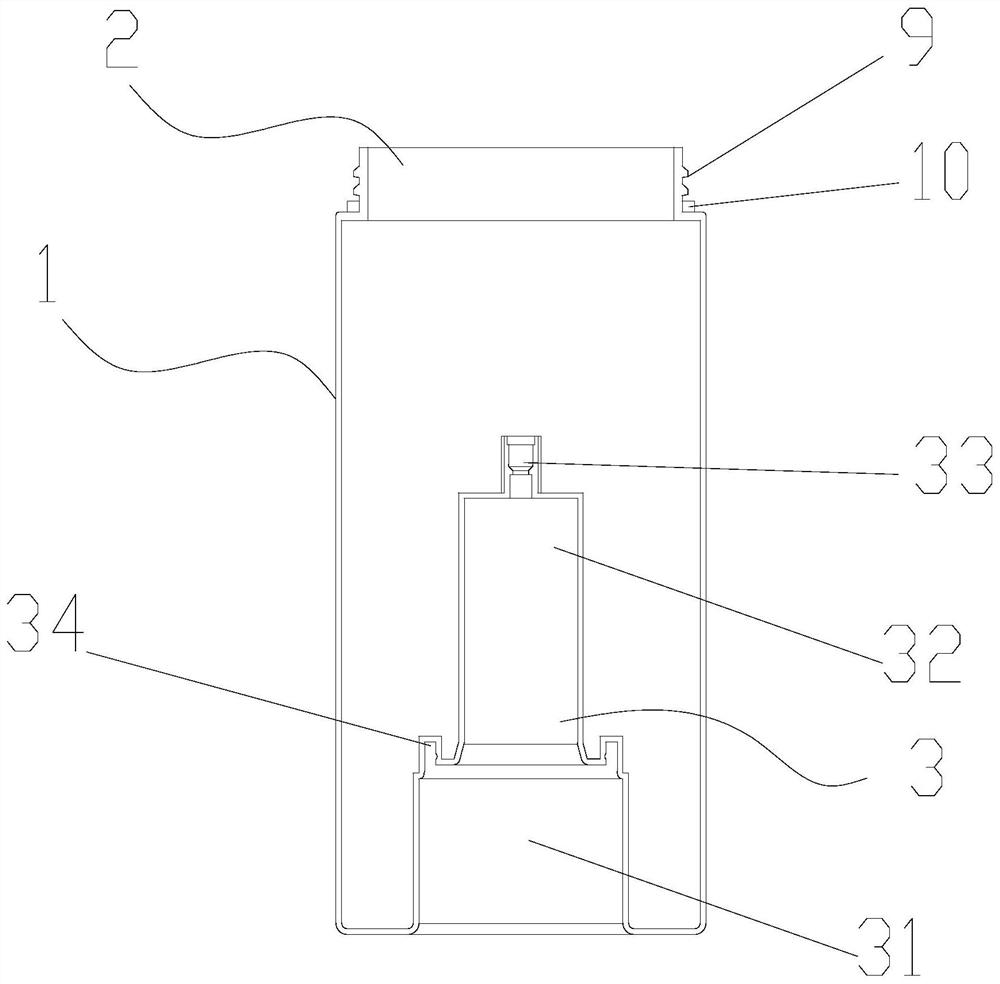

[0043] The bottle body 1 is the main body used for filling liquid and filling gas to realize spraying. The upper end of the bottle body 1 is provided with a liquid filling port 2, and the lower end of the bottle body 1 is integrally recessed with an inflatable cavity 3; The upper end of the inflatable chamber 3 communicates with the inside of the bottle body with a waterproof and breathable device 4;

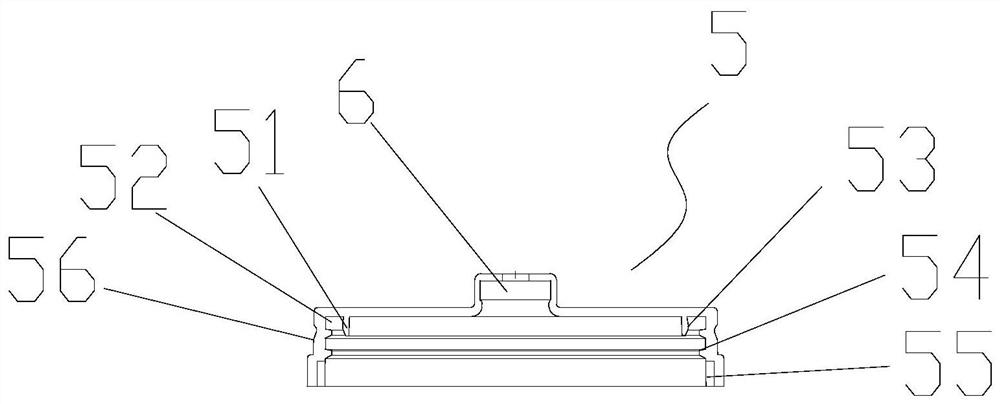

[0044] The sealing cover 5 is connected to the liquid filling port 2 of the bottle body 1 with a non-rotating thread, and is used for liquid filling and sealing installation of the spray pump assembly; the sealing cover 5 is integrally provided with an installation cavity 6 upward;

[0045] The spray pump assembly 7 is the main part used to realize the spraying of the upper liquid. The spray pump assembly 7 is arranged inside the installation cavity 6 and extends upward through the top of t...

Embodiment 2

[0065] Figure 7 , Figure 8 The technical scheme in the illustrated embodiment is basically the same as that of Embodiment 1, except that the spray pump assembly 7 includes a nozzle 71 with at least one spray hole 11, a spring 73, a piston rod 74, a pump body 77 and an output Pipe 78, all the components of the spray pump assembly are all plastic components; the inside of the piston rod 74 is provided with a gas-liquid channel 13 .

[0066] The spring 73 is made of PP resin material. In this embodiment, a built-in spring structure is adopted. During the use of the built-in spring structure, the liquid is ejected from the inside of the spring, and the spring is in contact with the liquid. This solution is simpler and more convenient in design and can also meet the requirements of use. In this embodiment, the nozzle is an integrated structure of the press-type cap and nozzle, that is, the nozzle 71, the press head and the cover are integrated in this embodiment.

Embodiment 3

[0068] Figure 9 , Figure 10 The technical solution in the shown embodiment is basically the same as that of embodiment 1, except that the spring 73 in the spray pump assembly is a steel spring with an external spring structure, and the nozzle adopts a push-type cap split structure. That is, the nozzle, the press head and the cover are set separately. At the same time, the nozzle and the press head are embedded in the cover, and there is a spout on the cover. The cover does not need to be removed during use. The nozzle, the press head and the cover are pressed together. use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com