Patents

Literature

32results about How to "Meet waste" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for producing large thickness and high intensity steel plate for boiler drum

InactiveCN101451213AImprove mechanical propertiesImprove performance qualityMolten metal pouring equipmentsRoll mill control devicesSteam drumAustenite

The invention discloses a production method for a high tensile steel plate used for a high thickness boiler drum. The production method comprises the following steps: (1) smelting: smelting molten steel in an electric furnace, the refining the molten steel in an LF finer, adding 300 to 500 meters of Al thread, and carrying out vacuum treatment in a bale VD furnace when the temperature of the bale is more than or equal to 1600 DEG C; (2) casting: keeping the temperature between 1,545 and 1,555 DEG C after damaging the vacuum; (3) heating: realizing the sending, clearing and filling of a steel ingot at a moderate temperature, cooling down the furnace for over 30 minutes before steel filling, and stewing the steel for one hour; (4) rolling: adopting II type rolling control technology, and setting a first stage as an austenite recrystallization stage and a second stage as an austenite non-recrystallization stage; (5) water cooling: cooling down the rolled steel plate on line, and keeping the red temperature between 700 and 750 DEG C; (6) heat treatment: carrying out the normalizing plus tempering treatment of the steel plate; and (7) shot blasting: carrying out shot blasting before storing the steel plate in a warehouse so as to completely remove the iron sheet produced during heating. The method shortens the steel rolling and heating time, reduces the consumption of production energy, and meets the requirements of a plurality of heat cycles during the boiler manufacturing process. The steel plate has good welding performance.

Owner:WUYANG IRON & STEEL

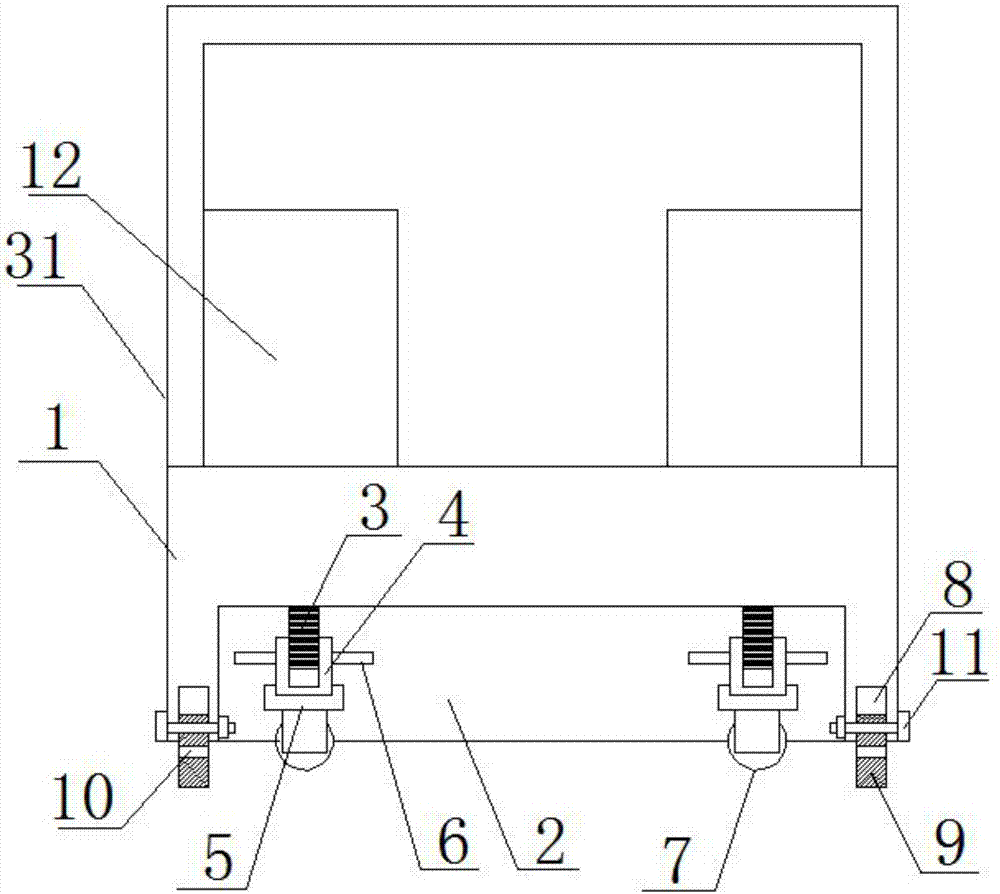

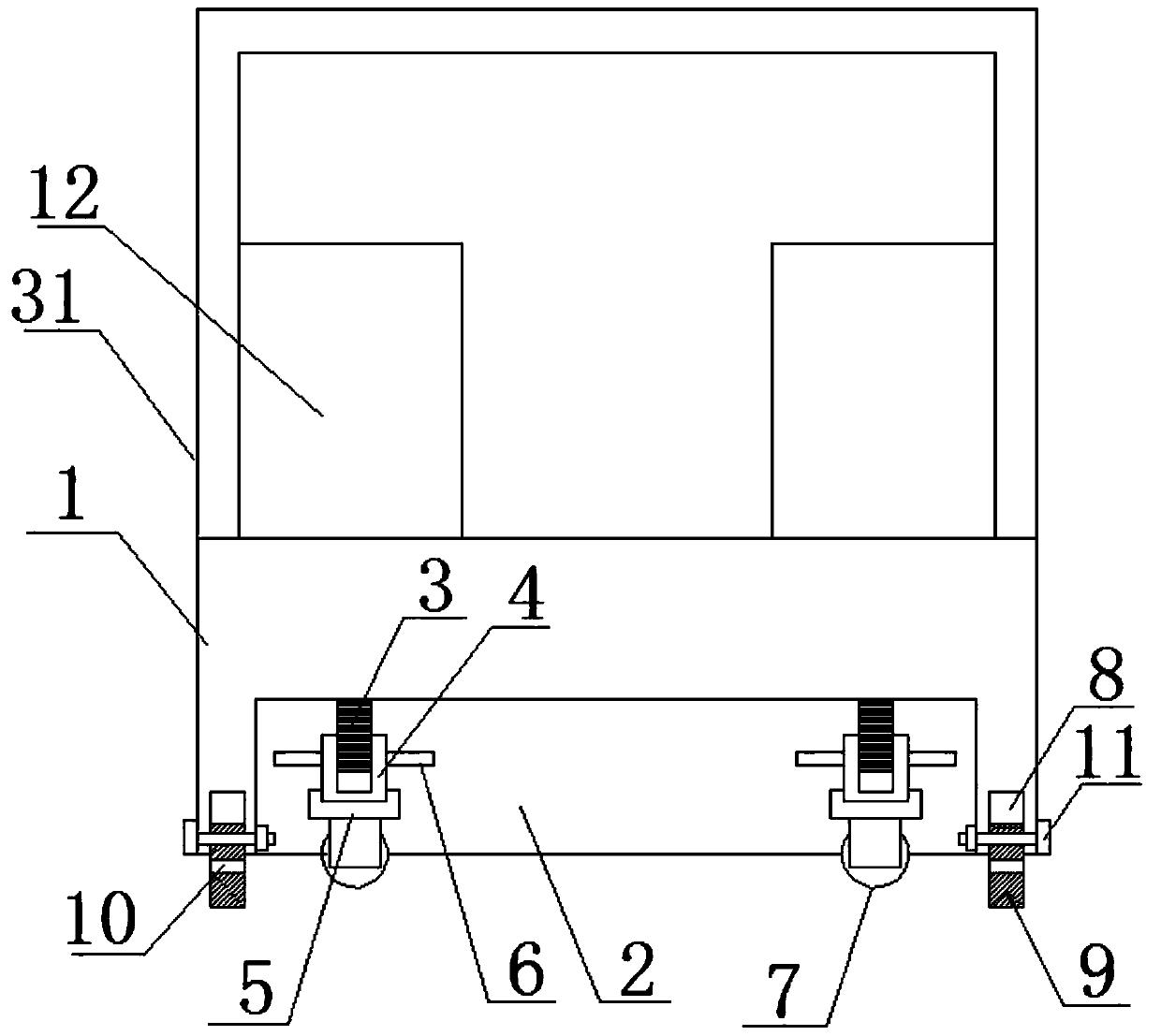

Modularized animal husbandry breeding shed

The invention discloses a modularized animal husbandry breeding shed. The shed comprises a base, a room body is arranged at the upper side of the base, the room body is composed of several wall bodies, several small room bodies are arranged inside the room body, each small room body comprises a supporting base and a breeding box, a cavity is formed in the lower side of the supporting base, electric telescopic rods are arranged inside the cavity, lifting plates are arranged at the lower sides of the electric telescopic rods, second universal wheels are arranged at the lower sides of the lifting plates, a rotary motor is arranged in the middle of the upper side of the supporting base, the output end of the rotary motor is connected with the lower end of the breeding box, supports are arranged at the lower side of the breeding box in a left-to-right symmetrical mode, the supports are provided with rotary wheels, annular bases are arranged at the upper side of the supporting base, annular grooves are formed in the upper sides of the annular bases, the lower portions of the rotary wheels are arranged in the annular grooves, a dung discharge base plate is arranged inside the breeding box, and a sealing plate is arranged at the right side of the breeding box through a rotary shaft. The modularized animal husbandry breeding shed is simple in structure, convenient to use, and easy to move, the cost is lowered, and the breeding effect is good.

Owner:丁文海

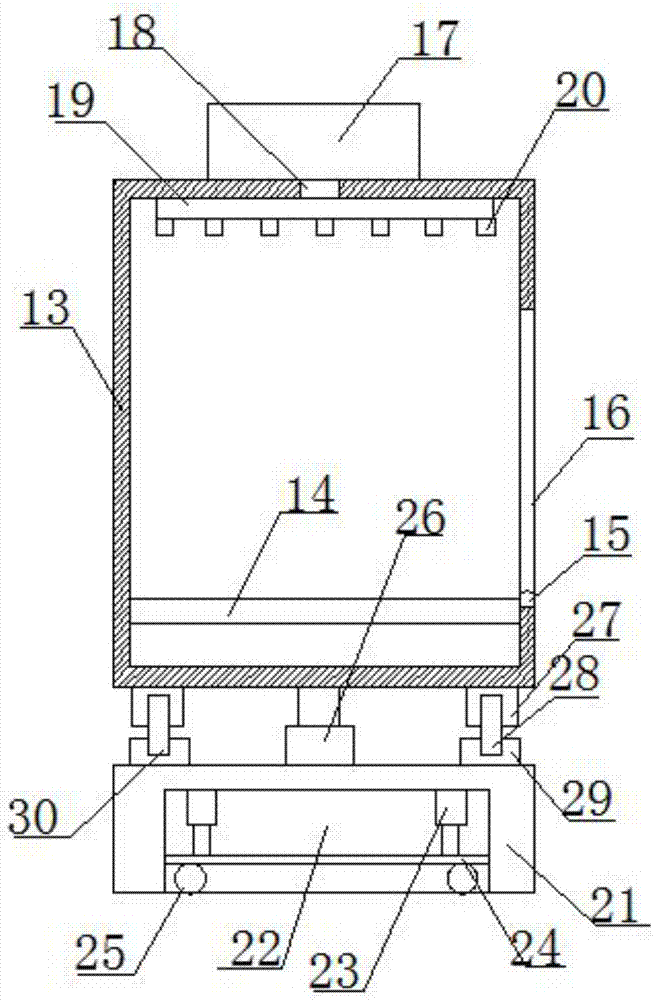

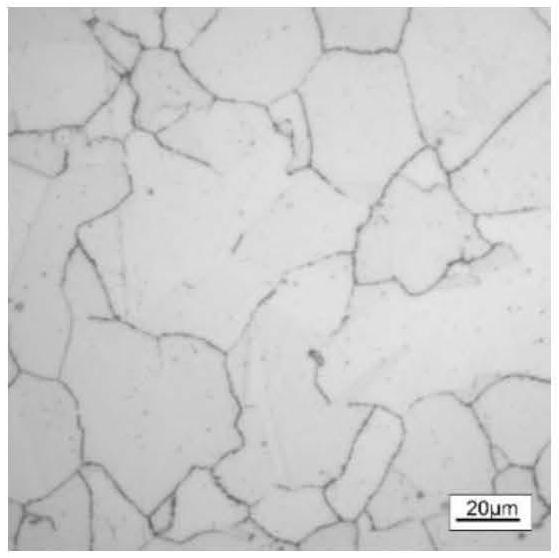

Hot working process of GH4738 nickel-based superalloy

PendingCN113560481AAvoid specimen crackingUniform tissueMetal-working apparatusWheelsVacuum induction meltingCrystallite

The invention discloses a hot working process of a GH4738 nickel-based superalloy. The process comprises the following steps that A, the GH4738 nickel-based superalloy is taken as a raw material, and is smelted by adopting a vacuum induction melting (VIM) process and a vacuum consumable remelting (VAR) process in sequence to obtain a vacuum consumable ingot; B, the vacuum consumable ingot is subjected to homogenization treatment and cogging forging treatment, and a GH4738 alloy bar blank is obtained; C, the GH4738 alloy bar blank is put into a gas furnace to be heated along with the furnace, flat anvil upsetting is conducted through a forging hammer after heat preservation, and a GH4738 alloy disc forge piece is obtained; and D, the GH4738 alloy disc forge piece is sequentially subjected to solution treatment, stabilizing treatment and secondary aging treatment, and the GH4738 nickel-based high-temperature alloy uniform in grain size and excellent in high-temperature erosion performance is obtained. According to the hot working process, the phenomena of mixed crystals, coarse crystals and the like in a GH4738 high-temperature alloy deformation structure can be avoided, the overall hardness and high-temperature erosion performance of a final forge piece are improved, and meanwhile the yield of the forge piece is increased.

Owner:INNER MONGOLIA UNIV OF TECH

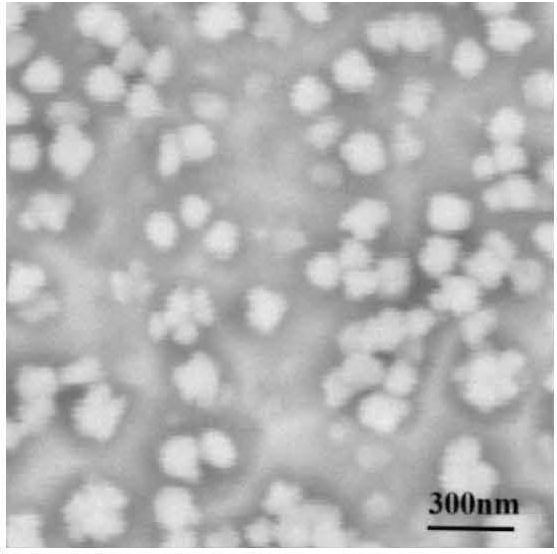

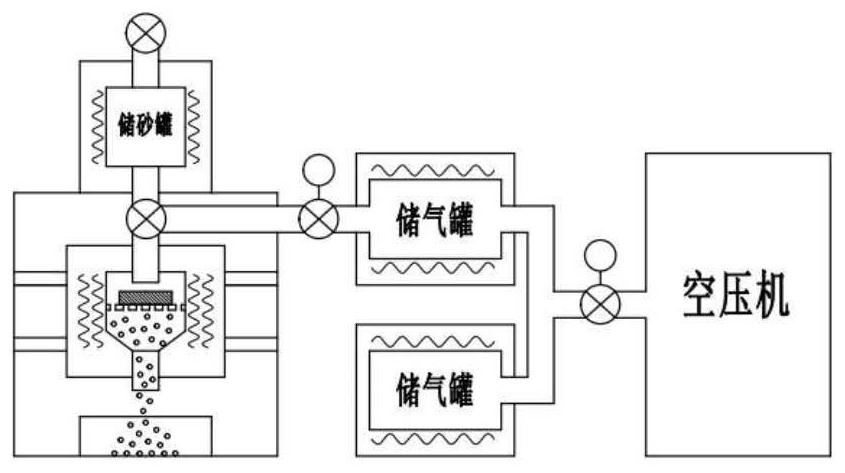

Preparation method of aluminum alloy semi solid-state slurry

The present invention discloses process of preparing semi-solid aluminum alloy slurry. The process includes the following steps: 1. preparing aluminum alloy powder through high pressure inert gas atomizing or jet molding; 2. heating partial aluminum alloy into melt and maintaining in semi-solidifying temperature region; and 3. mixing the aluminum alloy powder and the aluminum alloy melt through stirring to obtain semi-solid aluminum alloy slurry. The process of the present invention can produce semi-solid aluminum alloy slurry with fine structure in short period, simple apparatus and low cost.

Owner:临沂高新城乡发展有限公司

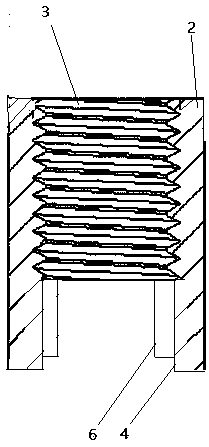

Layered shear-mode sealing filler for rotary pump and preparation method thereof

The invention relates to a filler for braided packing, and especially relates to a layered shear-mode sealing filler for rotary pumps and a preparation method thereof. The invention mainly solves the technical problems in the prior art that the packing sealing mode has great power consumption, severe shaft abrasion, and frequent pump body maintenance; a cooling device is required to be designed on a packing box, and heat is dissipated by the cooling device, which makes it difficult to realize generalized zero leakage; shutdown repair is required; inventory stock is performed for braided packing with various specifications; and thus the operation cost is increased, and resources are wasted. The preparation method of the invention comprises the following steps: adding asbestos-free mineral fibers, graphite, lubricating grease into a high speed mixer for mixing, fully stirring; performing kneading treatment of the mixture of asbestos-free mineral fibers, graphite, and lubricating grease; adding the kneaded mixture into a cavity of a plunger-type extrusion device for extrusion so as to obtain the finished product of a layered shear-mode sealing filler for rotary pumps.

Owner:浙江国泰萧星密封材料股份有限公司

Fiber composite material reinforced repairing adhesive and preparation method thereof

InactiveCN108102595ALow densityImprove mechanical propertiesNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesAdhesion forceAdhesive

The invention discloses a fiber composite material reinforced repairing adhesive and a preparation method thereof, wherein the repairing adhesive includes, by weight, 20-40 parts of a fiber compositematerial reinforced filler, 50-80 parts of reactive-type curing resin, 0.5-2 parts of a pigment, 0.3-1 part of a defoaming agent, and 0.01-1 part of a catalysis accelerant. The preparation method mainly includes the steps of: recycling wasted fiber composite materials and mixing and stirring components. In the invention, by crushing the wasted fiber composite materials into powders and replacing conventional inorganic filler with the fiber composite material to produce the repairing adhesive, mechanical performance and binding strength of the repairing adhesive are improved and demands of highstrength and adhesion force on fiber reinforced resin based composite material are satisfied, so that the adhesive can be used in the fiber reinforced resin based composite material, especially repairing the pores and recesses in surfaces of fiber reinforced polyurethane foaming composite material product. The adhesive further is suitable for a high-strength fiber reinforced resin based compositematerial system and can significantly improve the total performance of the composite material product.

Owner:铁科腾跃科技有限公司

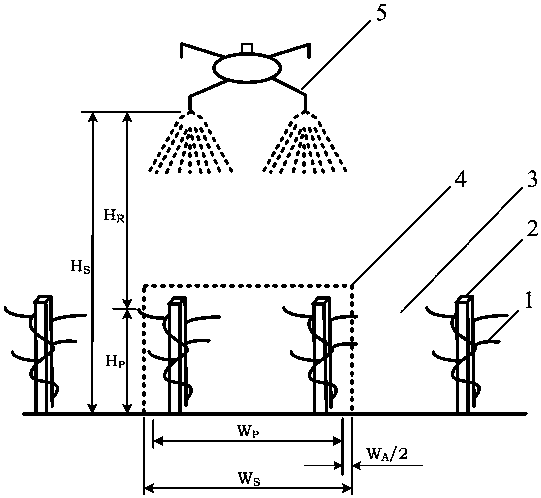

Single arm fence type vineyard aerial drug delivery operation method based on agricultural machinery and agronomy integration

InactiveCN109445461AMeet wasteMeet the real needs of pollutionPosition/course control in three dimensionsAviationAgricultural engineering

The invention provides a single arm fence type vineyard aerial drug delivery operation method based on agricultural machinery and agronomy integration. Compared with the prior art, the method of the invention has the following characteristics (1) from the technical point of view, the effective sprinkling width of a plant protection unmanned aerial vehicle during a single-line operation flight process just covers or slightly exceeds the average width of the grapes in the width direction of the two adjacent independent planting rows, actual needs that growers do not want to spray liquid too muchin the ventilation and lighting rows among wide fences, and also do not want to cause the waste of the liquid and soil pollution can be satisfied, and precise, drug-saving and green work is realized;and (2) the effective sprinkling widths of the plant protection unmanned aerial vehicle at different working heights and a single-arm fence type grape cultivation rack generally adopted in the YellowRiver Basin carry out corresponding cooperation so as to realize the agricultural machinery and agronomy integration in the spraying process of the plant protection unmanned aerial vehicle, which accords with the national requirement of the agricultural machinery and agronomy integration.

Owner:SHANDONG UNIV OF TECH

Special automobile exterior material prepared from TPO skin reclaimed material and preparation method thereof

PendingCN112048114AGood solvent resistanceAccelerated corrosionSuperstructure subunitsFenderAntioxidant

The invention discloses an automobile exterior trimming special material prepared from a TPO skin reclaimed material and a preparation method thereof. Raw materials comprise: a TPO skin reclaimed material, copolymerized PP, a molecular weight regulator, a flexibilizer, a compatilizer, a weather-resistant agent, a filler, an antioxidant and a colorant. The preparation method comprises the followingsteps: mixing and stirring the TPO skin reclaimed material and the molecular weight regulator, adding the copolymerized PP, the flexibilizer, the weather-resistant agent, the compatilizer, the antioxidant, the filler and the colorant, mixing and stirring the components; and feeding the mixture into a double-screw extruder for perfomring extrusion, cooling, drying and granulation. The TPO skin regenerated material is creatively applied to production of special materials for automobile exterior decorations such as automobile fenders and wheel covers, so that the product can completely meet theworking condition performance requirements of the automobile exterior decorations such as the automobile fenders and the wheel covers, so that high-impact-resistance PP or PE materials are replaced, the problems of resource waste, environmental pollution and the like can be relieved, the production cost can be effectively reduced, and economic benefit is increased.

Owner:广西鑫深科技有限公司

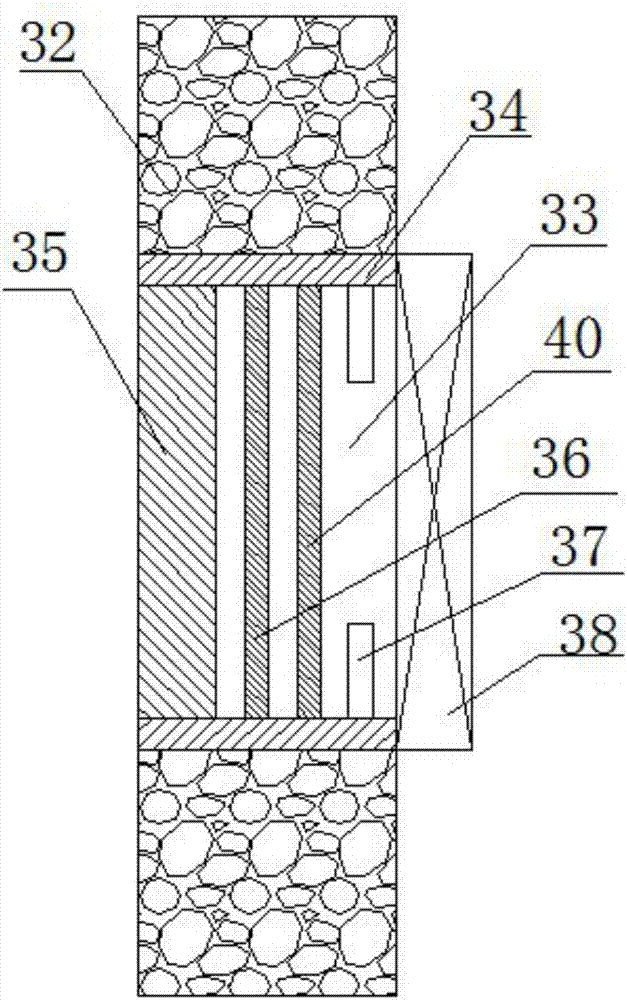

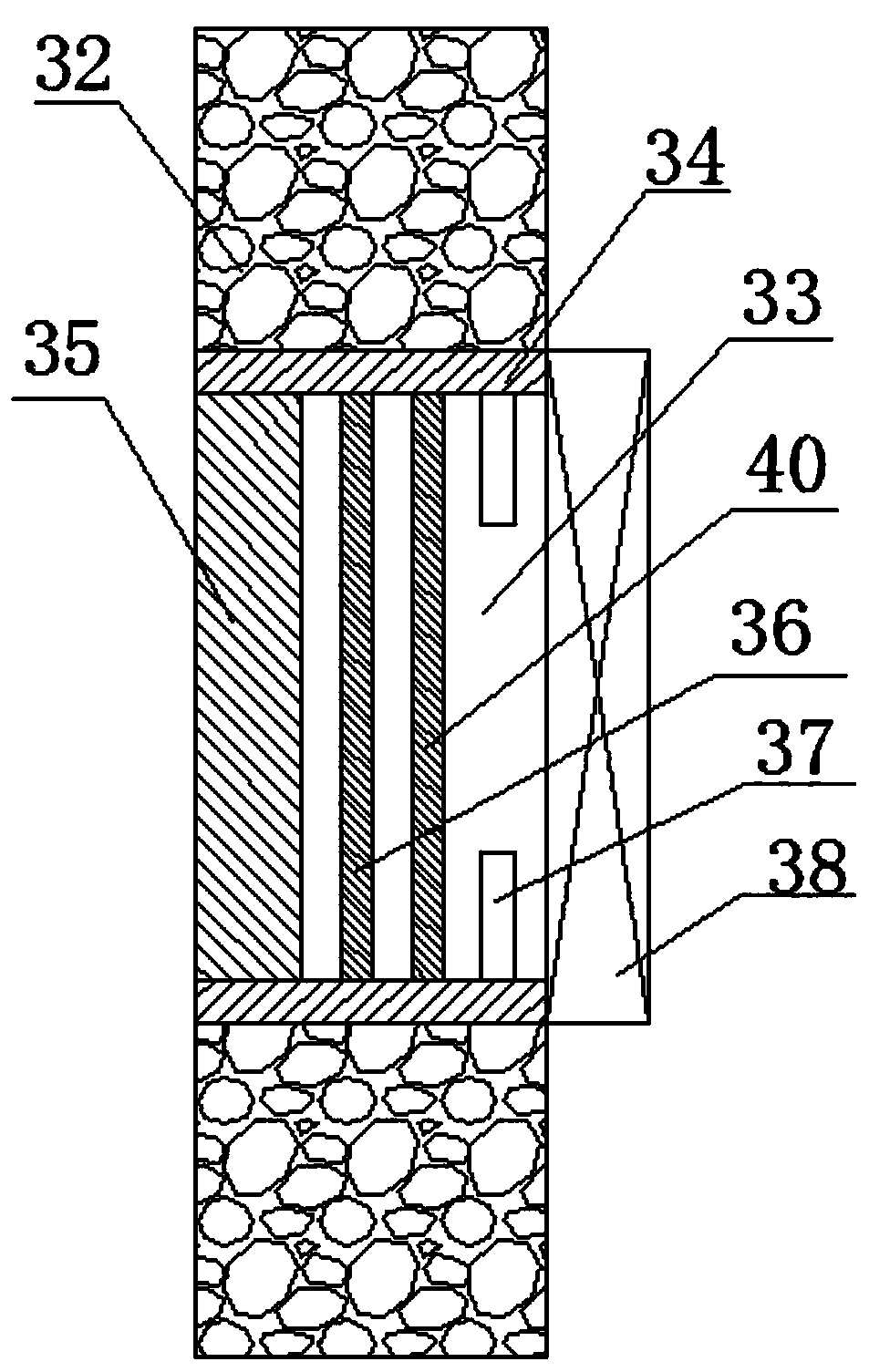

Cable hole blocking apparatus and blocking process

InactiveCN107845988AGuaranteed fire performancePlay a supporting roleApparatus for laying cablesEngineeringElectric cables

Owner:STATE GRID ZHEJIANG HANGZHOU XIAOSHAN POWER SUPPLY CO +3

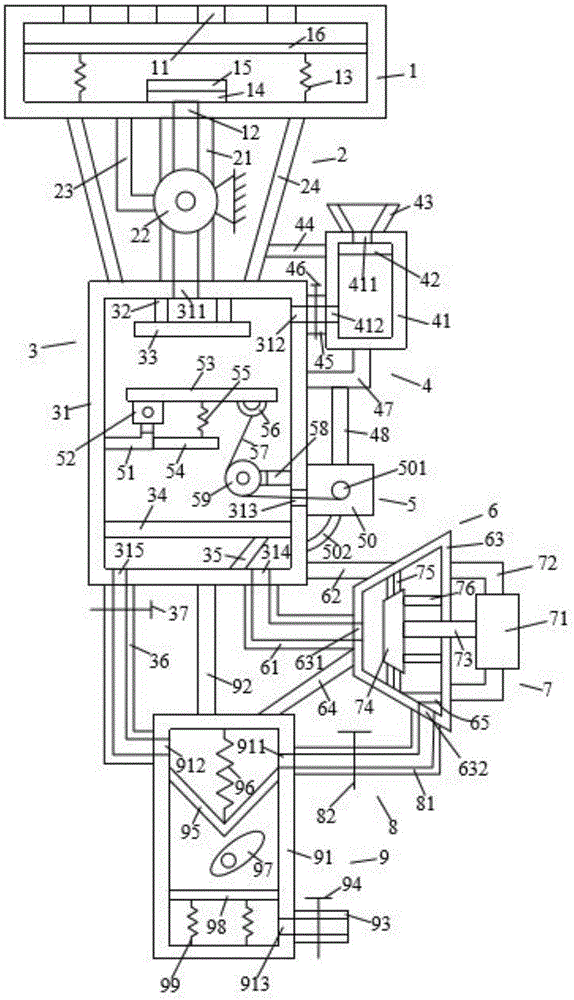

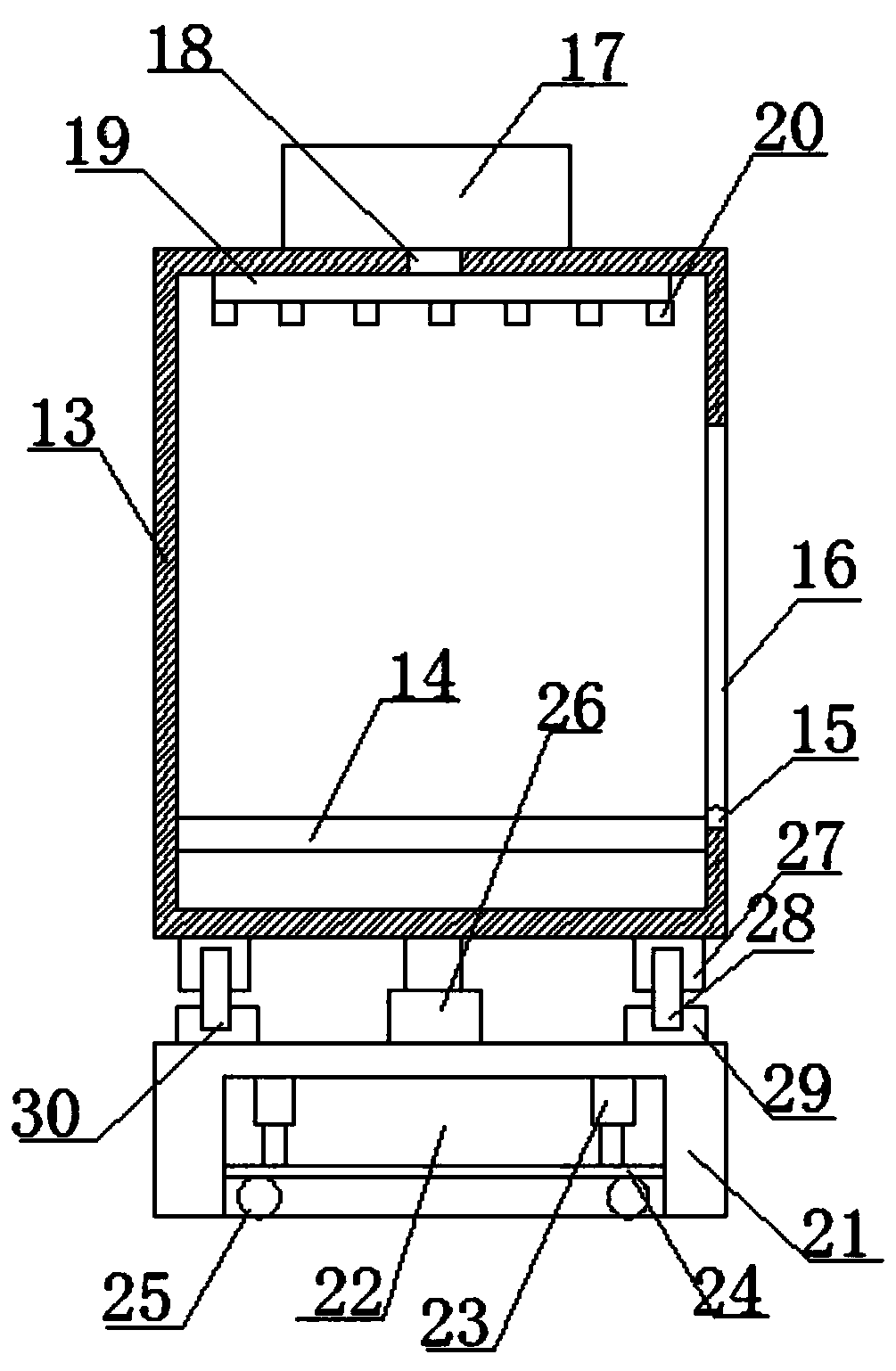

Efficient indoor environment-friendly air filter

An efficient indoor environment-friendly air filter comprises an air inlet frame, an air suction device, a first frame body device, a water tank device, a water spraying device, a second frame body device, a rotating device, a connecting device and a third frame body device; wherein the air inlet frame is provided with first through holes, a second through hole, first springs, a first filter screen, a first sponge block and a second filter screen; the air suction device comprises an air suction pipe, a fan, a first support and first fixing rods; the first frame body device comprises a first frame body, a sealing ring, a third filter screen, a fourth filter screen, a first inclined plate, a first pipeline and a first valve; the water tank device comprises a water tank, a fifth filter screen, a water inlet hopper, a second fixing rod, a second pipeline, a second valve, a second support and a third fixing rod; the water spraying device comprises a third support, a first fixing block, a rotating plate, a first transverse rod, a second spring and a first connection ring. The indoor air can be effectively purified, the purification efficiency is high and the purification effect is good.

Owner:江苏汇贤环保设备有限公司

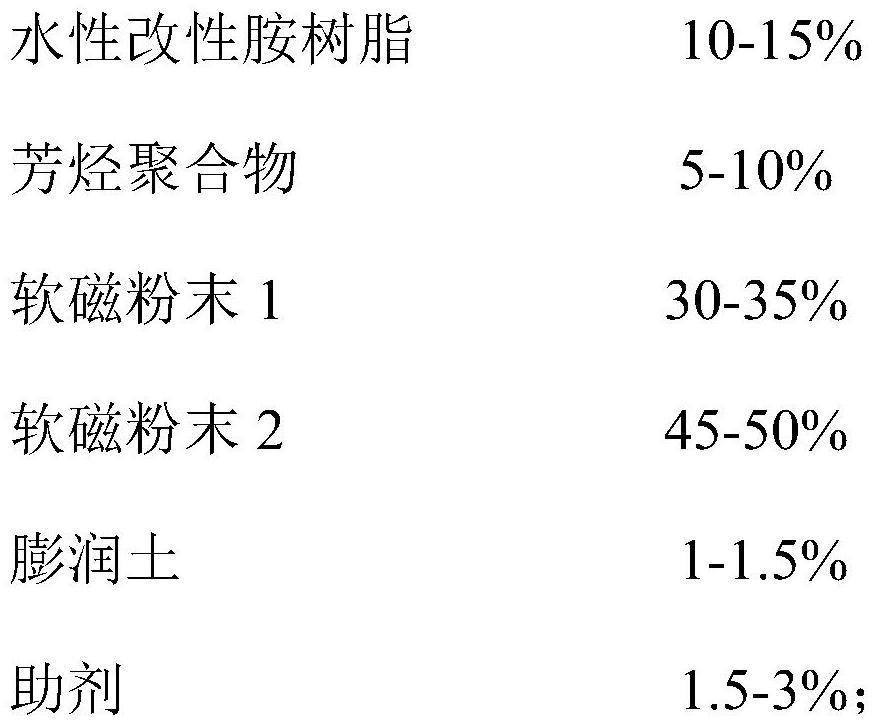

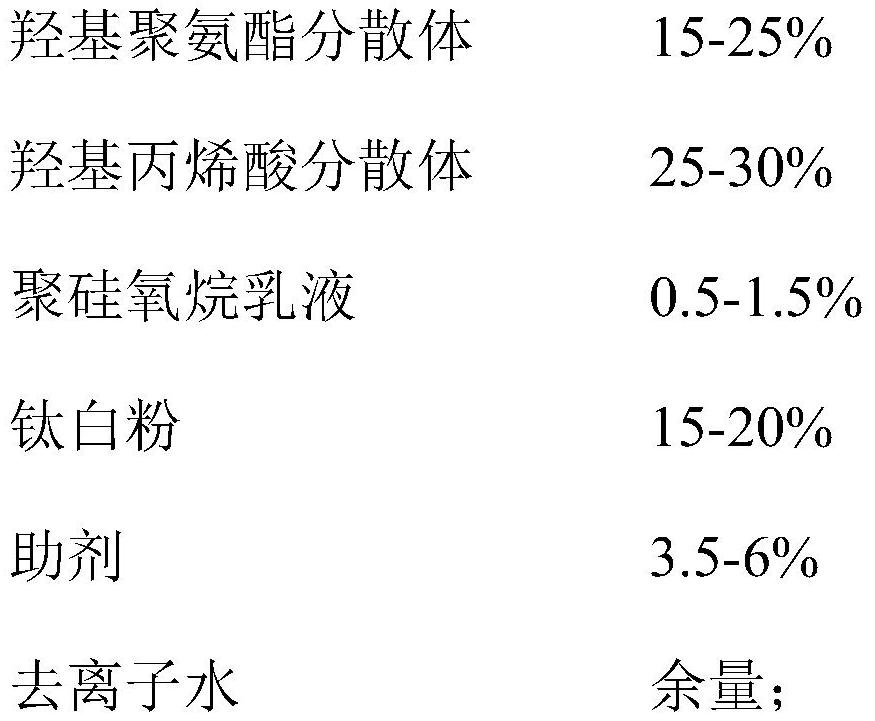

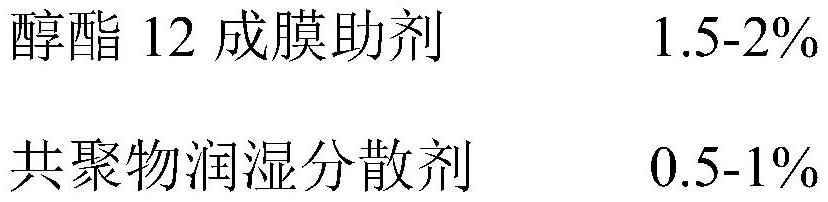

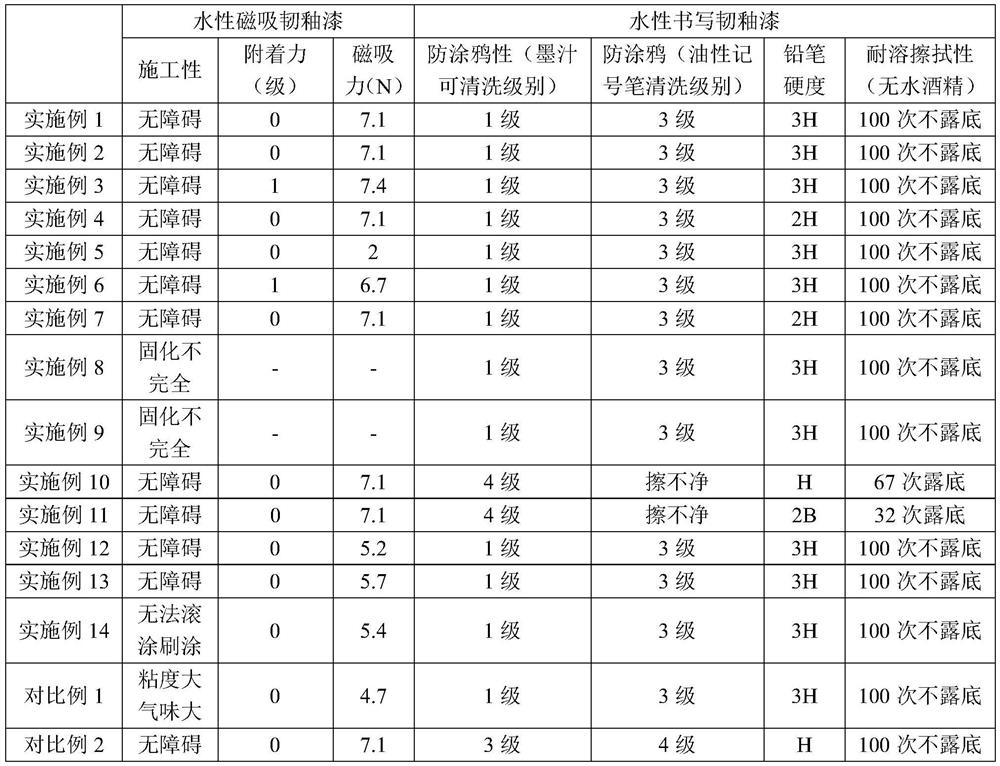

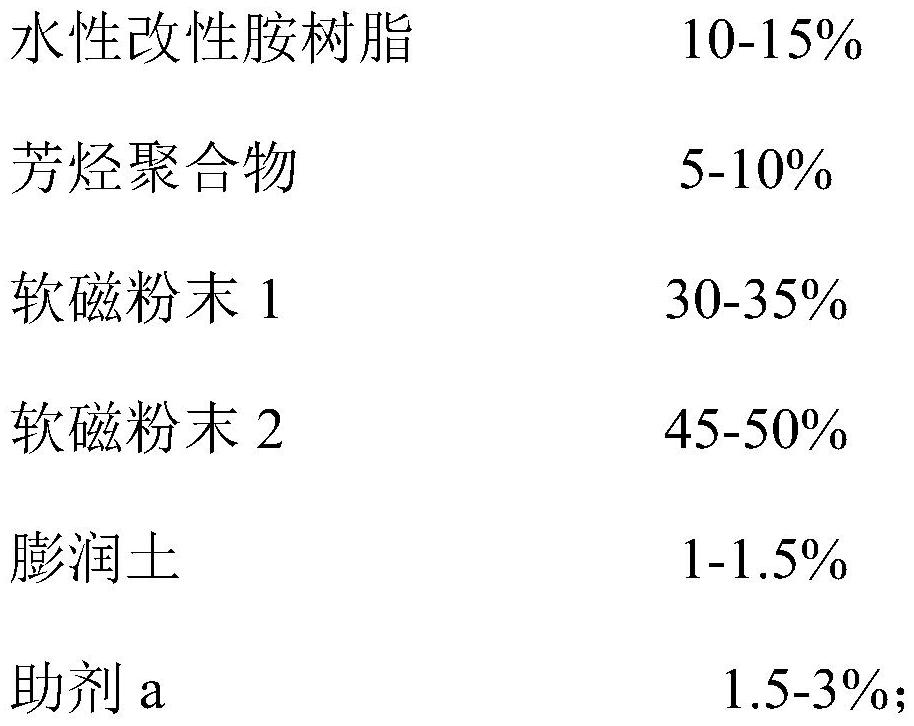

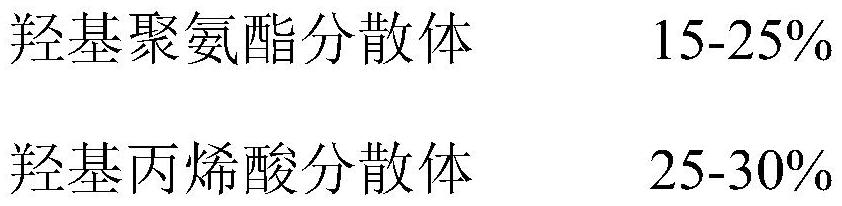

Magnetic writing wall and preparation process thereof

ActiveCN112724731AExcellent writing and erasabilityHigh scratch resistance hardnessCovering/liningsMagnetic paintsWhiteboardSocial benefits

The invention discloses a magnetic writing wall and a preparation process thereof. The magnetic attraction writing wall is prepared from water-based magnetic attraction tough glaze paint and water-based writing tough glaze paint. The magnetic attraction writing wall is easy to coat and construct, firm in adhesion to various base materials, strong in coating ferromagnetism, high in surface drying speed, excellent in writing erasability, high in scratch resistance and hardness, free of damage during solvent wiping, capable of completely meeting various requirements for whiteboard performance in actual use, capable of completely replacing metal whiteboards and glass whiteboards, reduces waste of financial resources and material resources, reduces unnecessary space occupation, and brings good economic benefits and social benefits into play.

Owner:SUZHOU DEODAR SPECIAL BUILDING MATERIALS

Strong cleaning compound used for equipment

The invention discloses a strong cleaning compound used for equipment, which comprises the following raw materials by weight part: 1.2-3.4 parts of nonylphenol ethoxylate sodium silicate, 1.5-3.2 parts of polyether modified silicone, 2.3-5.7 parts of valine, 3.2-5.5 parts of cypermethrin, 6.5-8.7 parts of lemon oil, 6.3-8.4 parts of alcohol polyoxyethylene ether phosphate, 1.2-2.5 parts of adsorbent, and 3.5-5.5 parts of emulsifier. The strong cleaning compound has strong decontamination capability, can rapidly and thoroughly remove the impurities such as oil stain, dust and copper cuttings on the surface of the copper pipe; has moderate volatilization speed, can satisfy twining requirement, and can prevent waste due to fast volatilization of the cleaning compound; the cleaning compound can be thoroughly volatilized without residues, thoroughly volatilization can be ensured in time from cleaning step to annealing step, and damage of the external surface of the copper pipe and equipment due to annealing can be avoided.

Owner:王璐

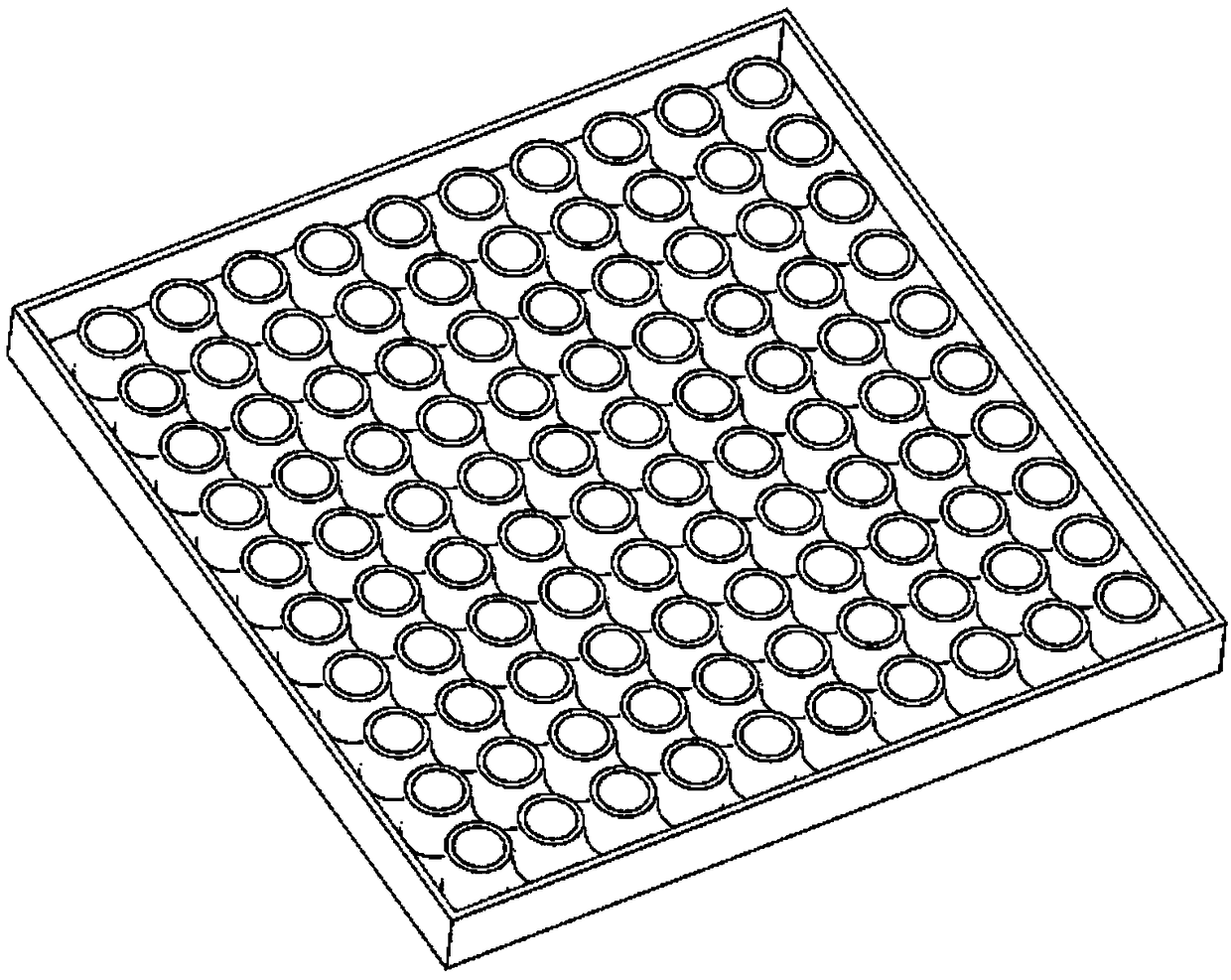

Biomass honeycomb paperboard, and preparation method and application thereof

The invention belongs to the technical field of packaging materials, and particularly relates to a biomass honeycomb paperboard, and a preparation method and application thereof. The biomass honeycombpaperboard comprises wheat straw, rice husks, cotton seed hulls, corncobs, wheat bran, corn flour, quick lime and gypsum, or comprises corn straw, the wheat straw, the wheat bran, the corn flour, thequick lime and the gypsum, or comprises the corncobs, the cotton seed hulls, the wheat bran, the quick lime and the gypsum. The biomass honeycomb paperboard has the advantages that use of conventional paper is reduced, and damage of papermaking to the environment is lowered; excessive crop waste is utilized, and a crop waste treatment method is provided; material density is reduced through the honeycomb structure, production cost is saved, and transport cost is reduced; the biomass honeycomb paperboard is formed integrally, has lower production and transport costs than honeycomb paperboards,and has broad market prospect and high economic value.

Owner:SHENZHEN ZEQINGYUAN TECH DEV SERVICE CO LTD

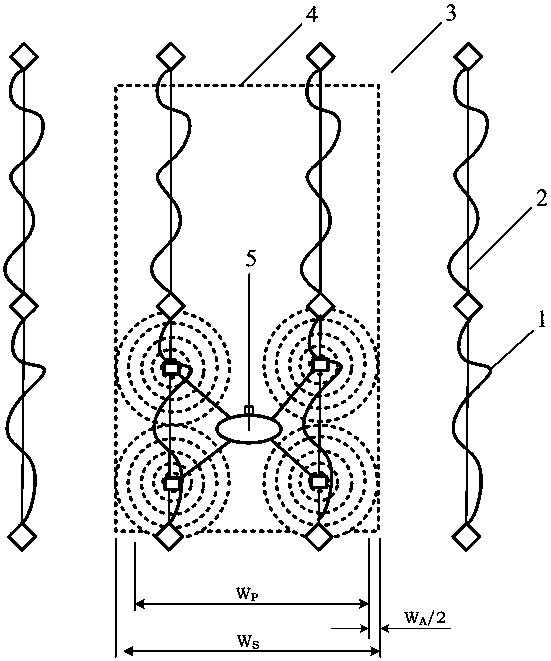

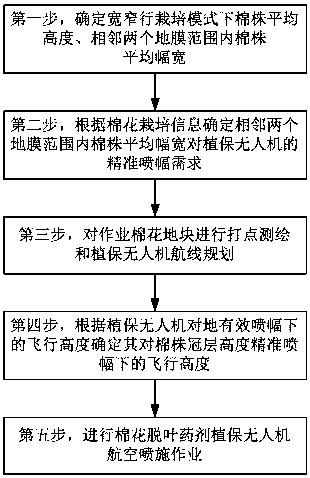

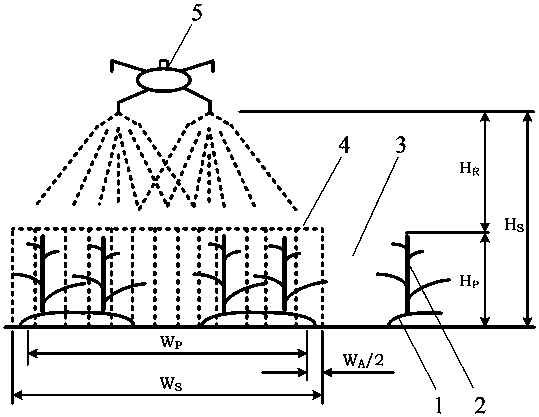

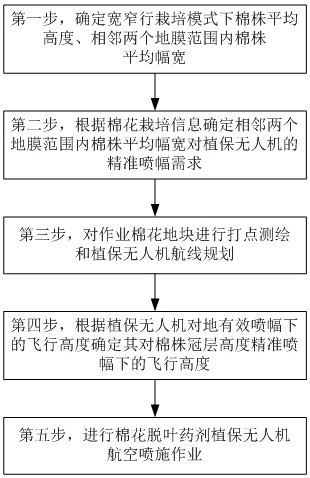

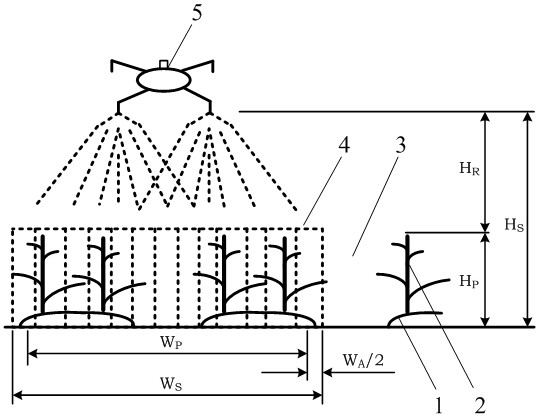

Aerial spraying operation method of cotton leaf-removing medicament in wide-narrow row cultivation mode

ActiveCN109328718ARealize the integration of agricultural machinery and agronomyIntegration of precision agricultural machinery and agronomyAircraft componentsData processing applicationsAviationPlastic mulch

The invention provides an aerial spraying operation method of a cotton leaf-removing medicament in a wide-narrow row cultivation mode. Compared with the prior art, (1) the aerial spraying operation method of the cotton leaf-removing medicament in the wide-narrow row cultivation mode ensures that the effective sprinkling width of a plant protection unmanned aerial vehicle exactly covers or slightlyexceeds the average width of cotton plants formed by four rows of cotton plants and one connecting row on two adjacent mulching films in the single-line operation flight process from the technical point of view, thereby meeting the practical requirement of a planter who does not want to spray the liquid medicine too much in the connecting line, namely a wide line, for not leading to liquid medicine waste and soil pollution; (2) the effective sprinkling width of the plant protection unmanned aerial vehicle under different operation heights cooperates with a cotton cultivation mode 'wide-narrowrow' which is widely popularized and adopted in many places in China, so that the integration of agricultural machinery and agronomy in the pesticide spraying process of the plant protection unmannedaerial vehicle is achieved, and the overall national requirement of the integration of agricultural machinery and agronomy is met; (3) the aerial spraying operation method of the cotton leaf-removingmedicament in the wide-narrow row cultivation mode provides a reference operation standard for the accurate aerial spraying of other pest control agents in the cotton field management process.

Owner:SHANDONG UNIV OF TECH

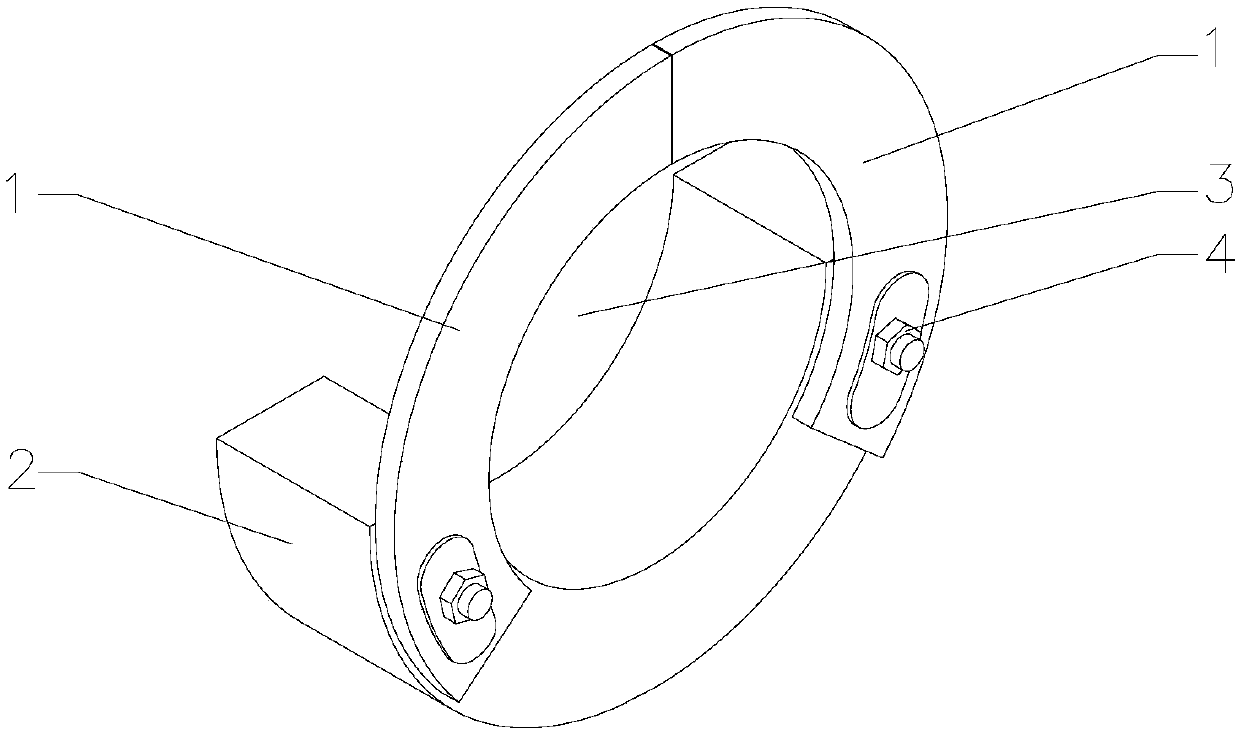

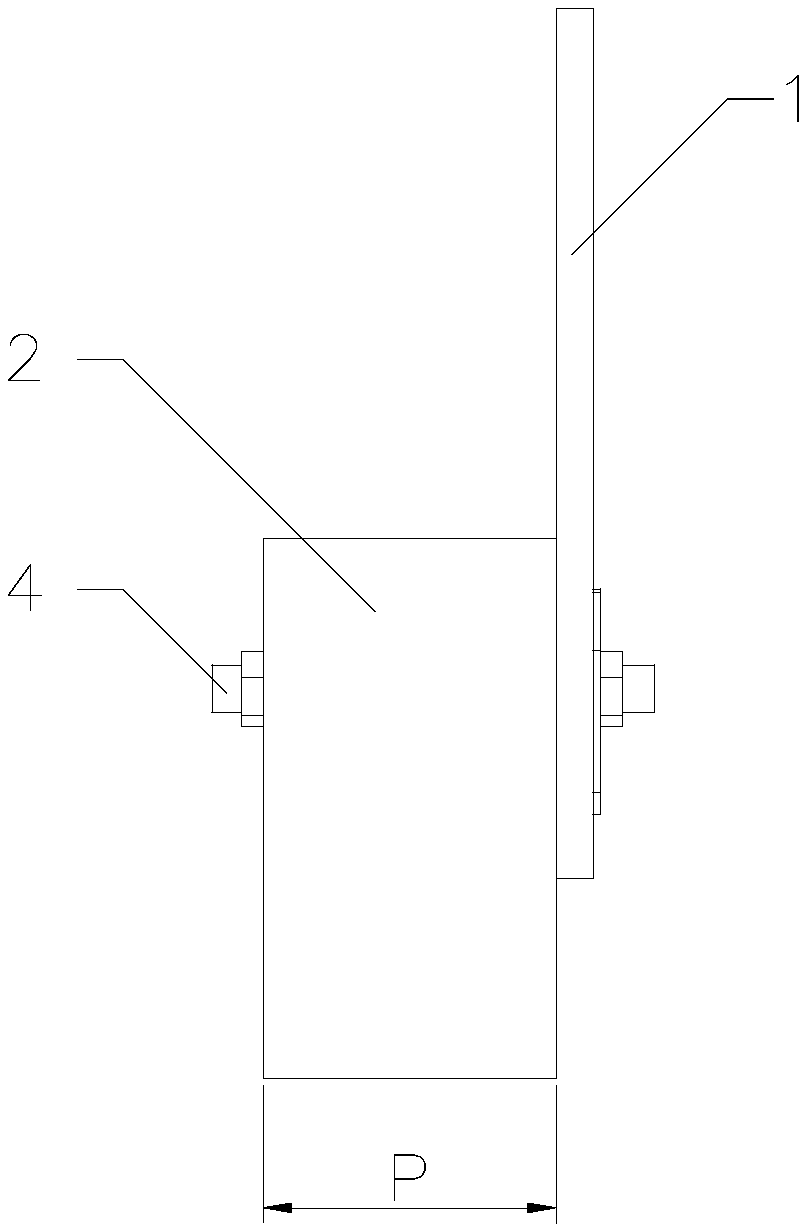

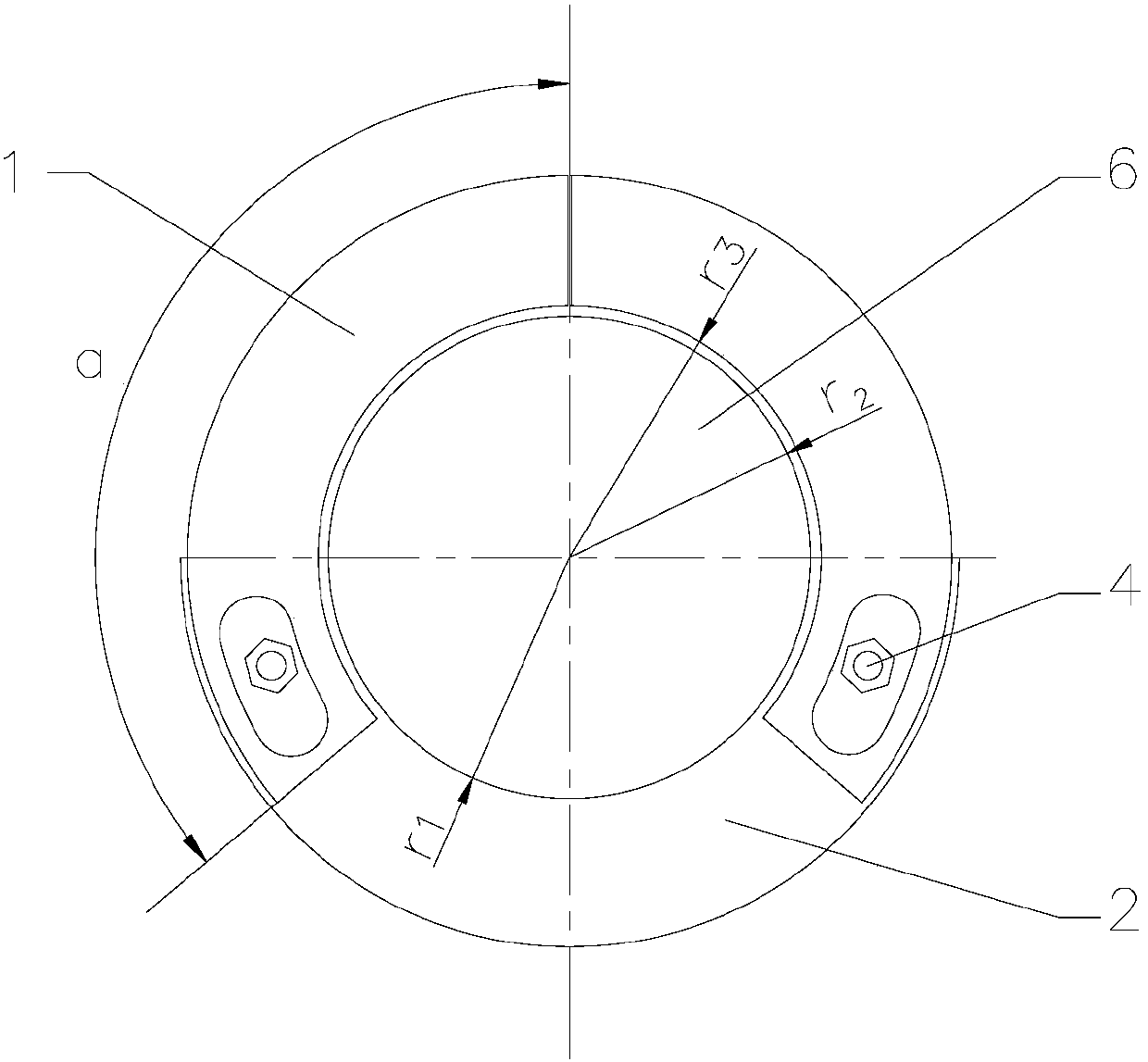

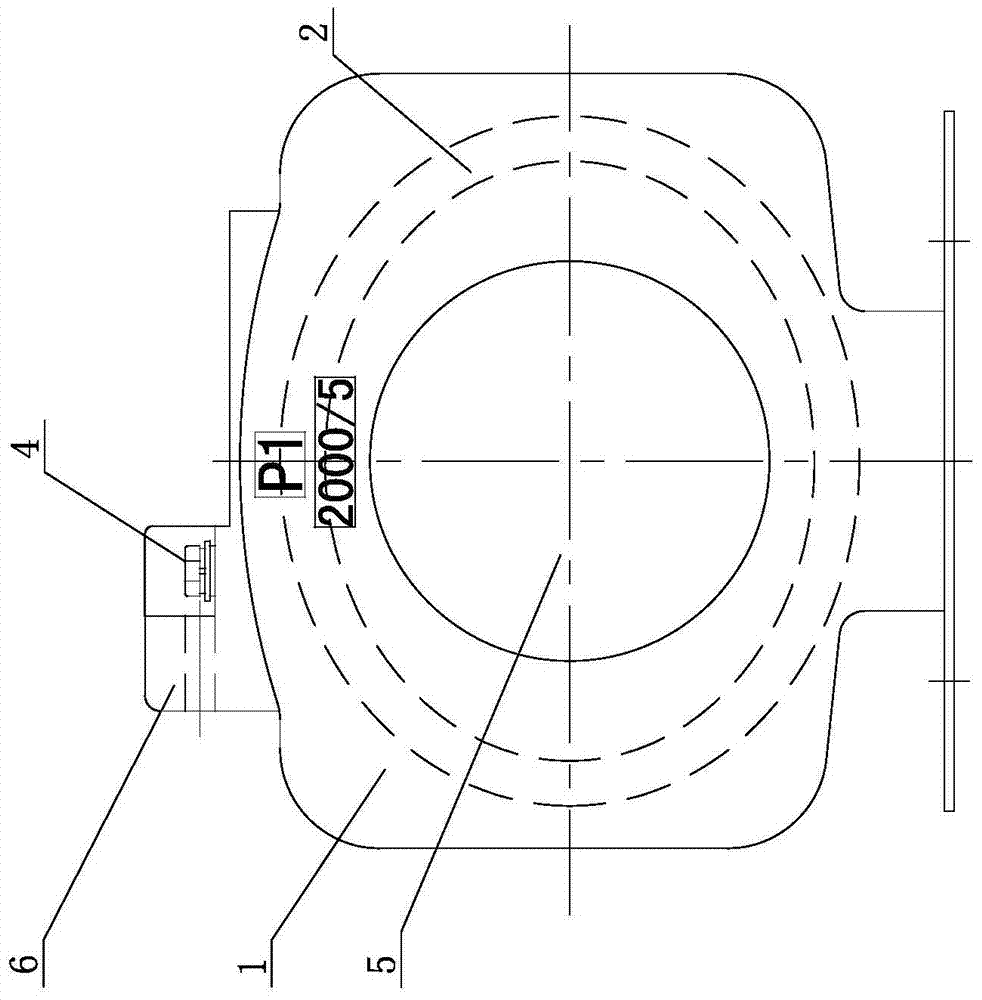

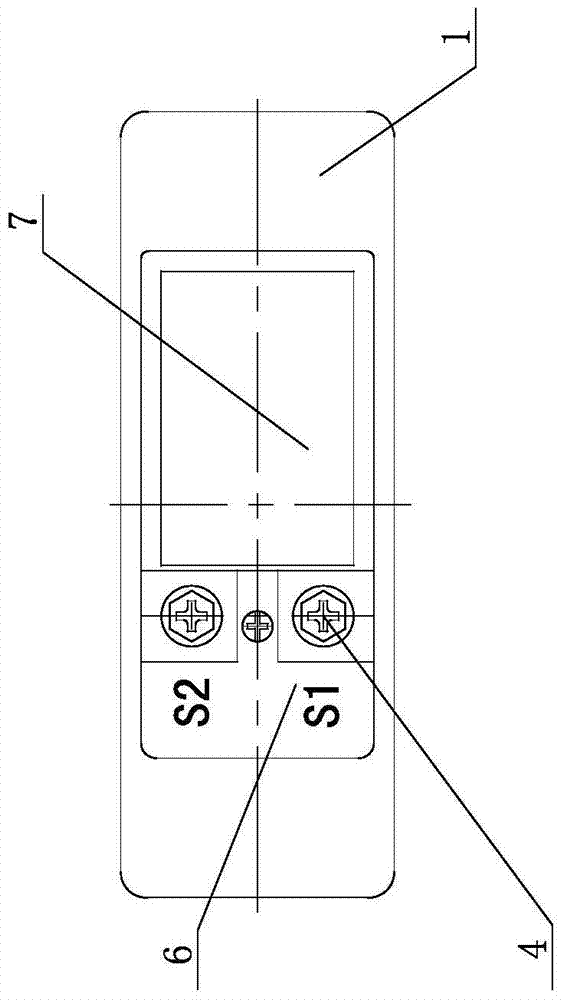

Automatic detecting type outdoor low-voltage metering current transformer

ActiveCN104715914AGuaranteed anti-theft effectGuarantee the rainproof requirements for outdoor useTransformersTransformers/inductances coils/windings/connectionsEpoxyLow voltage

The invention provides an automatic detecting type outdoor low-voltage metering current transformer. The automatic detecting type outdoor low-voltage metering current transformer comprises an epoxy resin main body and an annular iron core, wherein the iron core is provided with a secondary winding in a coiled manner; two ends of the secondary winding are connected with secondary wiring terminals; the iron core and the secondary winding are integrally poured through the epoxy resin main body; a terminal seat is arranged on the epoxy resin main body; the secondary wiring terminals are arranged on the terminal seat; an antitheft electric cover is arranged on the terminal seat; the annular iron core is an elliptic ultracrystalline iron core; the secondary winding is coiled at the left side and the right side of the elliptic ultracrystalline iron core; the diameter of a primary bus through hole is 75mm to 85mm. According to the automatic detecting type outdoor low-voltage metering current transformer, a cable equipped with a wiring copper nose can pass through the primary bus through hole, so that the mounting and replacing efficiency can be increased, and the material waste can be reduced; the secondary wiring terminals are positioned on the epoxy resin main body, and the elliptic ultracrystalline iron core structure is adopted, so that the automatic detecting requirement of an automatic detecting system of the low-voltage current transformer can be met, the labor intensity can be reduced, and the detecting efficiency can be increased.

Owner:ZHEJIANG HORIZON INSTR TRANSFORMERS

A magnetic writing wall and its preparation process

ActiveCN112724731BExcellent writing and erasabilityHigh scratch resistance hardnessCovering/liningsMagnetic paintsWhiteboardSocial benefits

Owner:SUZHOU DEODAR SPECIAL BUILDING MATERIALS

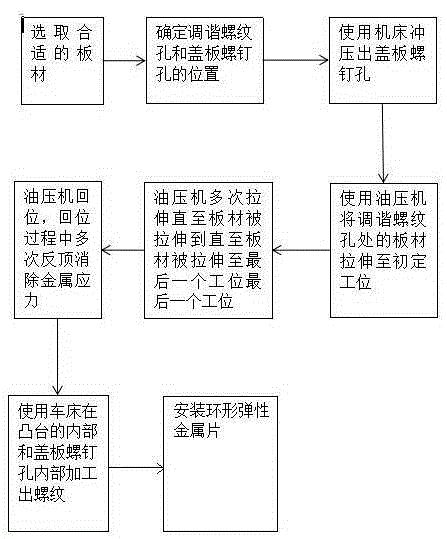

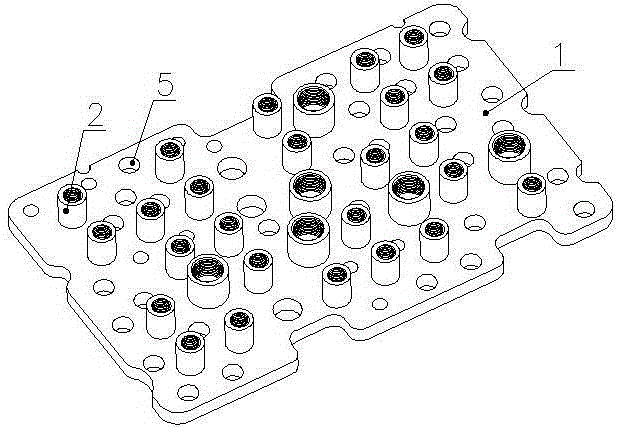

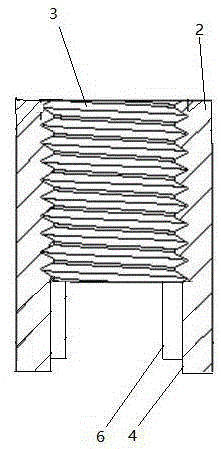

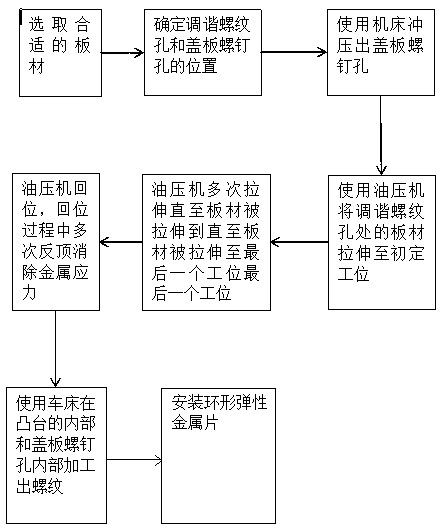

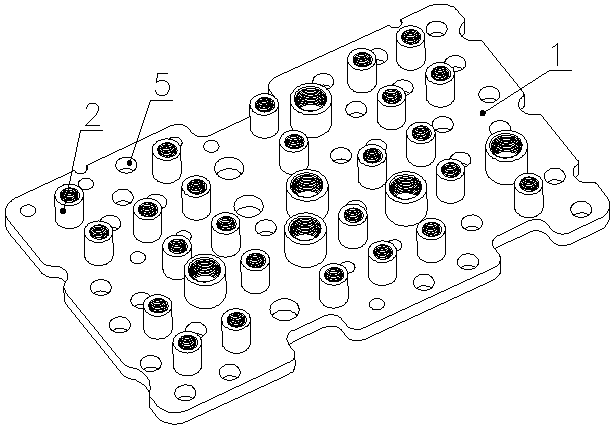

Manufacturing method of cover board of cavity filter

The invention discloses a manufacturing method of a cover board of a cavity filter. The method comprises the following steps: selecting materials, carrying out positioning and processing a tuning threaded hole; stretching a board through a hydraulic stretching machine, stretching a copper surface of the cover board to an aluminum surface in the stretching process, and arranging a plurality of stations on a stretching die according to the thickness of the board and the requirements of materials; quickly stretching the board with the determined tuning threaded hole position on the cover board to the initial station after stretching is started, stretching the board from fast to slow for a plurality of times, and stretching the board to the final station by the hydraulic stretching machine; enabling the stretching machine to begin to slowly return to the normal position, reversely jacking a processing head of the stretching machine quickly in the return process for a plurality of times, and enabling the stretching machine to return to the normal position after reverse jacking is ended; and processing a lug boss which is integrated with the cover board in the position of the tuning threaded hole by the hydraulic stretching machine, wherein the middle part of the lug boss is hollow. The stretching problem is handled by an oil press; and compared with a conventional punching mode employing a punching machine, the manufacturing method is higher in yield and better in manufacturing effect.

Owner:JOHNSON PRECISION ENG SUZHOU

A kind of manufacturing method of cavity filter cover

ActiveCN105322270BPerformance is not affectedSoft textureWaveguide type devicesPunch pressEngineering

A method for manufacturing a cavity filter cover plate, including material selection, positioning, and processing tuning threaded holes, stretching the plate through a hydraulic stretching machine, stretching the copper side of the cover plate facing the aluminum side during stretching, According to the thickness of the plate and the material requirements, the stretching mold is equipped with multiple stations. After the stretching starts, the plate at the position of the tuning threaded hole on the cover plate is quickly stretched to the initial station, and then from fast to slow. Multiple times of stretching, after the hydraulic stretching machine stretches the sheet to the final position, the stretching machine slowly returns to its original position, and the processing head of the stretching machine quickly reverses several times during the process of returning to its position. The stretching machine returns to its original position after being reversed for many times. At this time, the hydraulic stretching machine processes a boss integrated with the cover plate at the position of the tuning threaded hole. The middle part of the boss is hollow. The present invention uses a hydraulic machine to process For the stretching problem, compared with the traditional method of punching holes with a punching machine, the present invention has a higher yield and a better manufacturing effect.

Owner:JOHNSON PRECISION ENG SUZHOU

Preparation method of aluminum alloy semi solid-state slurry

The present invention discloses process of preparing semi-solid aluminum alloy slurry. The process includes the following steps: 1. preparing aluminum alloy powder through high pressure inert gas atomizing or jet molding; 2. heating partial aluminum alloy into melt and maintaining in semi-solidifying temperature region; and 3. mixing the aluminum alloy powder and the aluminum alloy melt through stirring to obtain semi-solid aluminum alloy slurry. The process of the present invention can produce semi-solid aluminum alloy slurry with fine structure in short period, simple apparatus and low cost.

Owner:临沂高新城乡发展有限公司

Method for producing large thickness and high intensity steel plate for boiler drum

InactiveCN101451213BImprove mechanical propertiesImprove performance qualityMolten metal pouring equipmentsRoll mill control devicesSteam drumAustenite

The invention discloses a production method for a high tensile steel plate used for a high thickness boiler drum. The production method comprises the following steps: (1) smelting: smelting molten steel in an electric furnace, the refining the molten steel in an LF finer, adding 300 to 500 meters of Al thread, and carrying out vacuum treatment in a bale VD furnace when the temperature of the baleis more than or equal to 1600 DEG C; (2) casting: keeping the temperature between 1,545 and 1,555 DEG C after damaging the vacuum; (3) heating: realizing the sending, clearing and filling of a steel ingot at a moderate temperature, cooling down the furnace for over 30 minutes before steel filling, and stewing the steel for one hour; (4) rolling: adopting II type rolling control technology, and setting a first stage as an austenite recrystallization stage and a second stage as an austenite non-recrystallization stage; (5) water cooling: cooling down the rolled steel plate on line, and keeping the red temperature between 700 and 750 DEG C; (6) heat treatment: carrying out the normalizing plus tempering treatment of the steel plate; and (7) shot blasting: carrying out shot blasting before storing the steel plate in a warehouse so as to completely remove the iron sheet produced during heating. The method shortens the steel rolling and heating time, reduces the consumption of production energy, and meets the requirements of a plurality of heat cycles during the boiler manufacturing process. The steel plate has good welding performance.

Owner:WUYANG IRON & STEEL

Layered shearing type sealing filler material used for rotary pump and preparation method thereof

ActiveCN102433100BNo pollution in the processFood gradeOther chemical processesOperational costsRotary pump

The invention relates to a filler material for braided packing and especially to a layered shearing type sealing filler material used for a rotary pump and a preparation method thereof. The invention mainly aims to overcome technical problems in the prior art, e.g., a conventional sealing mode consumes considerable power, a shaft is severely abraded, a pump body is frequently examined and repaired, a set of cooling device needs to be designed on a stuffing box to realize heat dissipation, which makes broadly defined zero leakage difficult to achieve, a rotary pump has to be shut down for repair, and braided packing of different specification has to be stocked, which increases operational cost and wastes resources. According to the invention, vegetable fibers are put in a fluff carding machine for fluff carding so as to allow the vegetable fibers to become fluffy floccules; grease and an inorganic filler material are subjected to anhydration and then to mixing and then are put in a mixer for fully stirring; the vegetable fibers are put in the mixer and are mixed with the grease and the inorganic filler material, and after uniform mixing, a finished product of the layered shearing type sealing filler material used for a rotary pump is obtained.

Owner:浙江国泰萧星密封材料股份有限公司

Aerial Spraying Method of Cotton Defoliant in Wide and Narrow Row Cultivation Mode

ActiveCN109328718BRealize the integration of agricultural machinery and agronomyIntegration of precision agricultural machinery and agronomyAircraft componentsData processing applicationsAgricultural engineeringPlastic mulch

The present invention provides an aerial spraying operation method of cotton defoliation agents under the wide and narrow row cultivation mode. The effective spray width just covers or slightly exceeds the average width of cotton plants formed by 4 rows of cotton plants and 1 transfer row on two adjacent mulch films, which satisfies the need for growers not to spray too much liquid on the transfer row, that is, " (2) The present invention coordinates the effective spray width of plant protection drones at different operating heights with the "wide and narrow row" cotton cultivation mode popularized and adopted in many places in China Correspondingly, the integration of agricultural machinery and agronomy in the spraying process of plant protection drones is realized, which meets the overall requirements of the country for the integration of agricultural machinery and agronomy; (3) The present invention provides a precise aerial spraying of other pest control agents in the cotton field management process. An operational norm that can be used for reference.

Owner:SHANDONG UNIV OF TECH

A high-efficiency indoor air filter for environmental protection

A high-efficiency indoor environment-friendly air filter, including an air intake frame, an air extraction device, a first frame device, a water tank device, a sprinkler device, a second frame device, a rotating device, a connecting device and a third frame device, The air intake frame is provided with a first through hole, a second through hole, a first spring, a first filter net, a first sponge block and a second filter net, and the air extraction device includes an air extraction pipe, a fan, a first bracket and a first The fixing bar, the first frame device includes the first frame, the sealing ring, the third filter net, the fourth filter net, the first inclined plate, the first pipeline and the first valve, the water tank device includes the water tank, the fifth filter net, The water inlet bucket, the second fixed rod, the second pipe, the second valve, the second bracket and the third fixed rod, the sprinkler device includes the third bracket, the first fixed block, the rotating plate, the first cross bar, the second spring, First connecting ring. The invention can effectively purify the indoor air, has high purification efficiency and ideal purification effect.

Owner:江苏汇贤环保设备有限公司

A modular animal husbandry house

Owner:丁文海

Layered shear-mode sealing filler for rotary pump and preparation method thereof

ActiveCN102410215BNo pollution in the processFood gradeProductsOther chemical processesFiberRotary pump

Owner:浙江国泰萧星密封材料股份有限公司

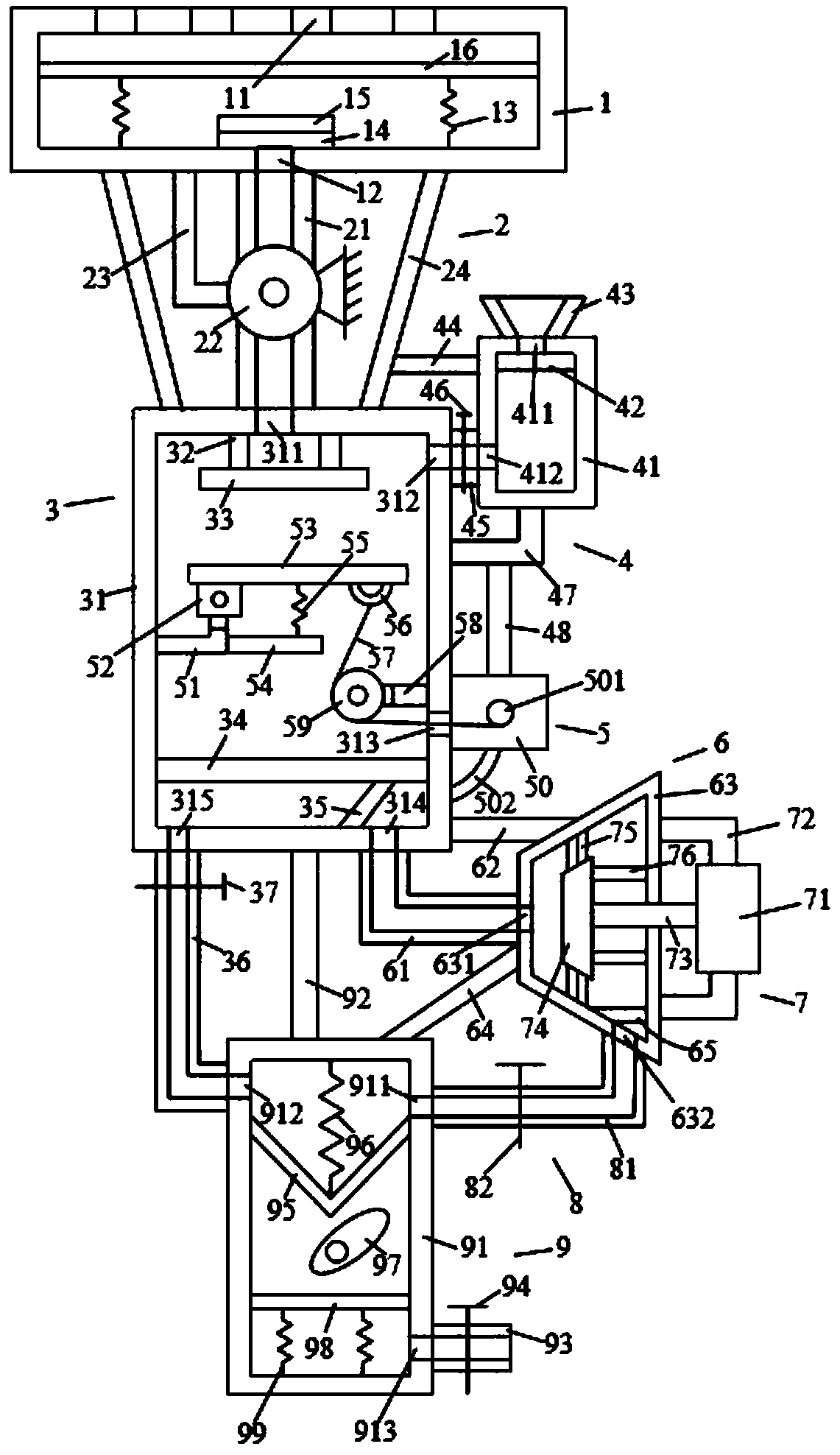

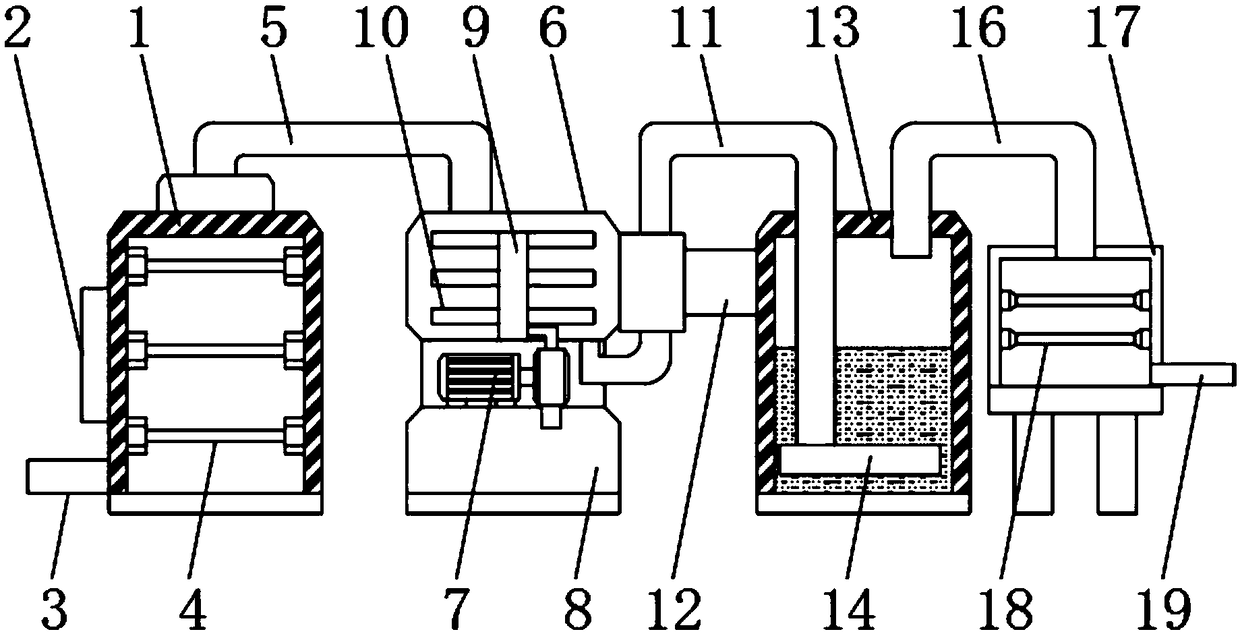

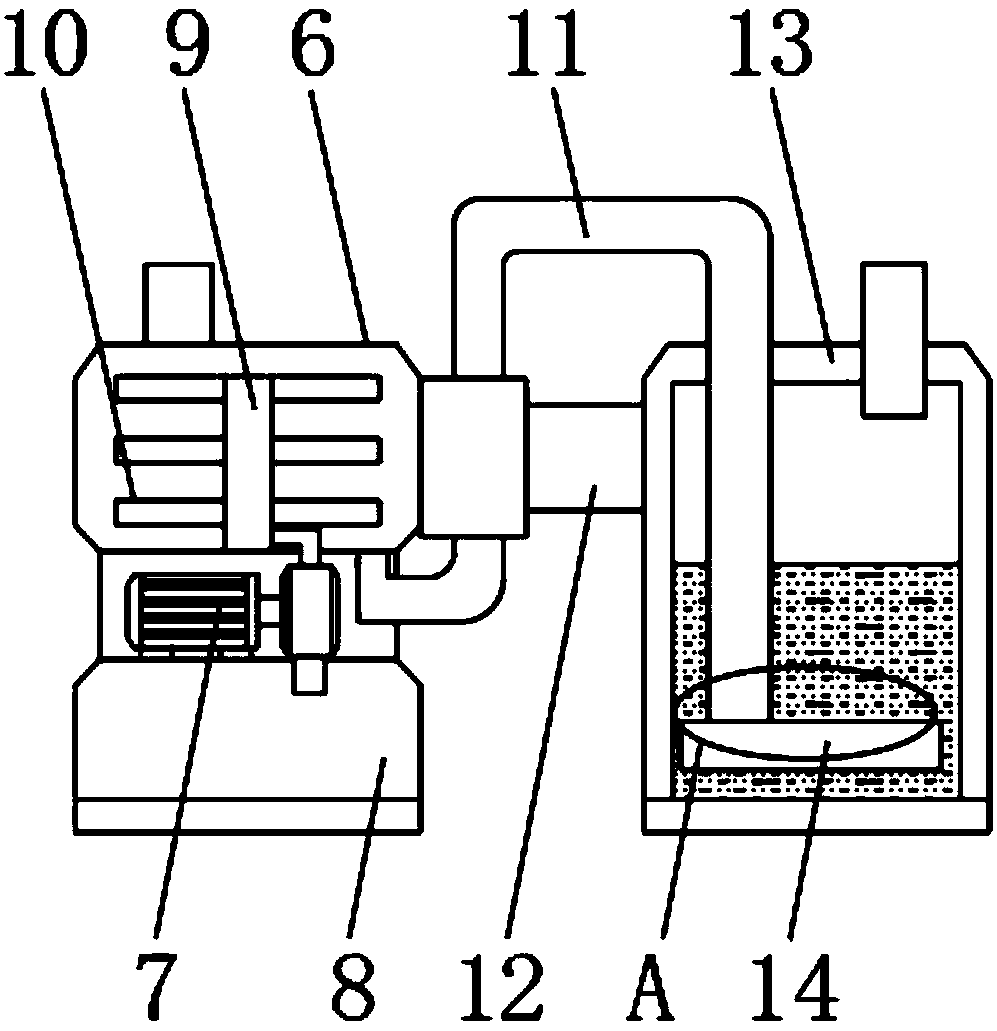

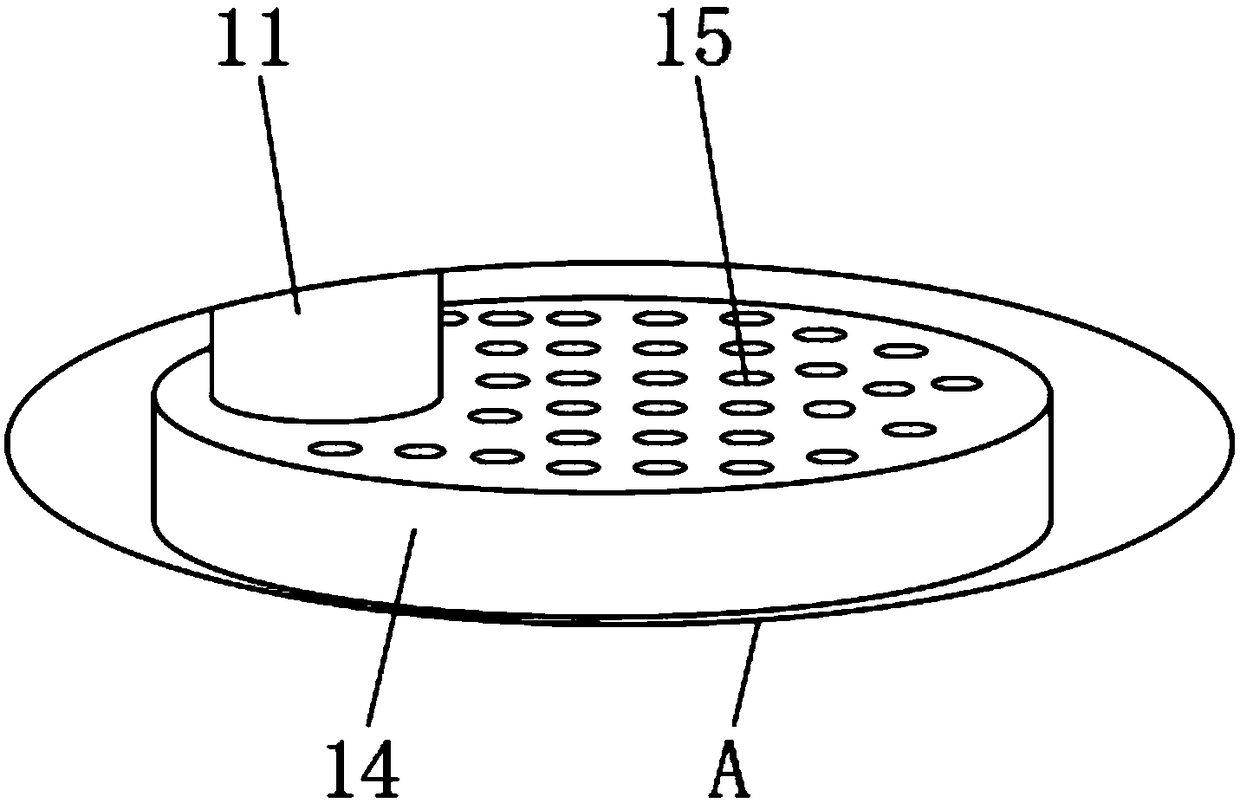

Energy-saving type tail gas pretreatment system for field of steel ingot refining

PendingCN108722147ASimple structureEasy to operateDispersed particle filtrationTransportation and packagingCells panelPhosphate

The invention discloses an energy-saving type tail gas pretreatment system for the field of steel ingot refining. The energy-saving type tail gas pretreatment system comprises a coarse filtering tank,wherein a control unit is fixedly arranged on the outer surface of one side of the coarse filtering tank; in addition, an air inlet is formed in one side of the bottom end of the coarse filtering tank; dust filtering cotton is arranged inside the coarse filtering tank; besides, a first air duct is fixedly connected to the outer surface of the upper end of the coarse filtering tank; a first treatment chamber is fixedly connected to the outer surface of one end of the first air duct; in addition, an exhaust fan is arranged on the outer surface of the lower end of the first treatment chamber; anammonia chamber is fixedly connected to the outer surface of the lower end of the exhaust fan. The energy-saving type tail gas pretreatment system for the field of steel ingot refining, disclosed bythe invention is provided with porous emission columns, a hollow disk and a photovoltaic cell panel; ammonia can be sufficiently emitted to the first treatment chamber, reaction speed is increased, the ammonia can be sufficiently mixed with a phosphate solution, light energy can be utilized for supplying power to the system, energy saving and environment friendliness are realized, and a better useprospect is brought.

Owner:华林特钢集团有限公司

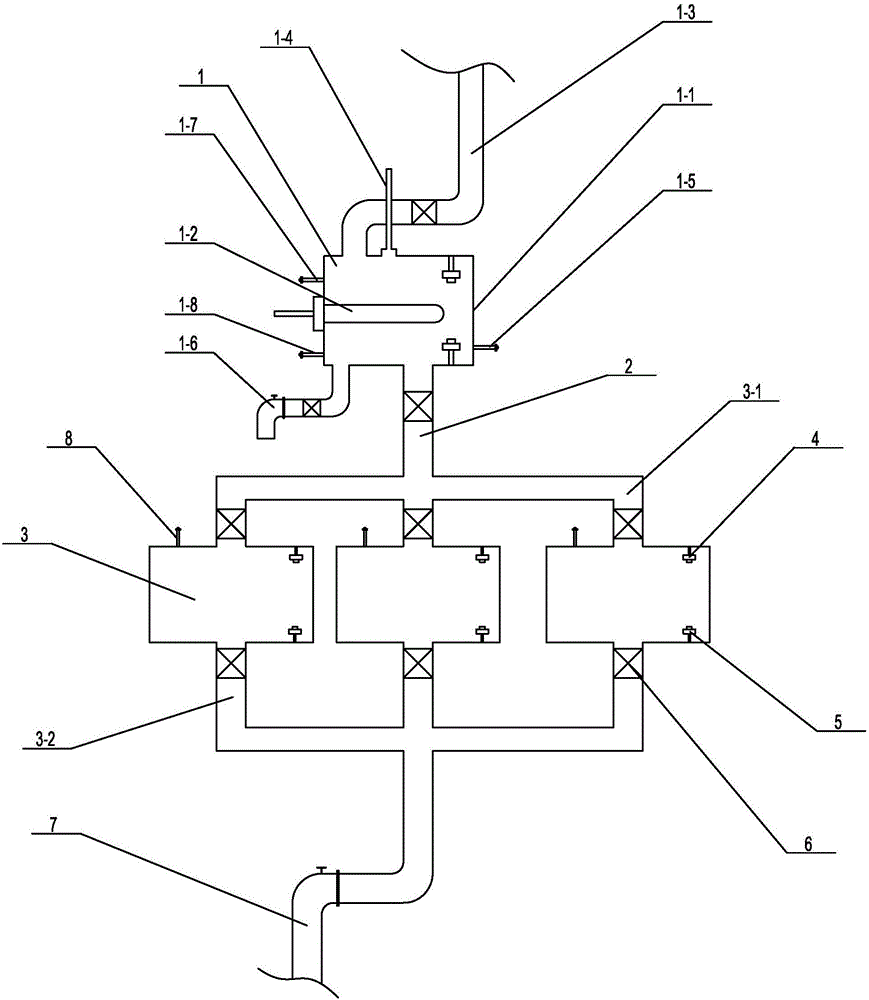

Multi-capacity healthy type water drinking device

InactiveCN105795924AAvoid getting lostAvoid wastingBeverage vesselsThermal insulationWater resources

The invention provides a multi-capacity healthy type water drinking device. The multi-capacity healthy type water drinking device comprises a heating system, wherein the heating system comprises a heating tank, the heating tank is provided with a water outlet header pipe, the tail end of the water outlet header pipe is provided with a plurality of heat preservation tank water inlet branch pipes, the tail ends of the heat preservation tank water inlet branch pipes are arranged on heat preservation tanks, an upper float switch and a lower float switch are arranged in each heat preservation tank, a heat preservation tank water outlet branch pipe is arranged on each heat preservation tank, a magnetic valve is arranged on each heat preservation tank water outlet branch pipe, the heat preservation tank water outlet branch pipes are connected with a water receiving pipe, the water receiving pipe is controlled by a switch component, and the switch component comprises switches for controlling the heat preservation tanks correspondingly. With the adoption of the multi-capacity healthy type water drinking device, the waste of drinking water can be avoided, and meanwhile, high-temperature pollution-free healthy drinking water with different temperatures can be simultaneously provided, thus the various demands can be satisfied; moreover, the application range is wide, the thermal insulation properties are good, the purpose of saving water resource, electric energy and the like is achieved, and thus the multi-capacity healthy type water drinking device is worth of wide popularization.

Owner:QINZHOU UNIV

A method for comprehensive utilization of tail gas in the production of nitromethane by nitrite replacement method

ActiveCN109796345BAchieve recyclingImprove absorption efficiencyOrganic chemistryOrganic compound preparationNitrosoNitroethane

Owner:QINGDAO UNIV OF SCI & TECH

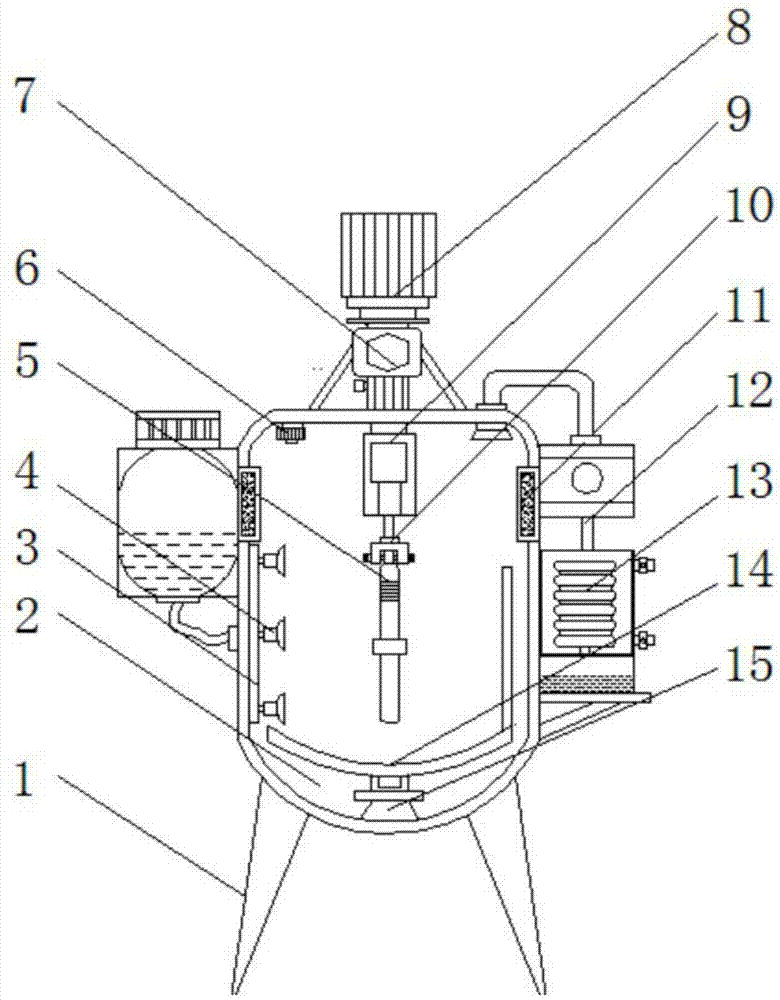

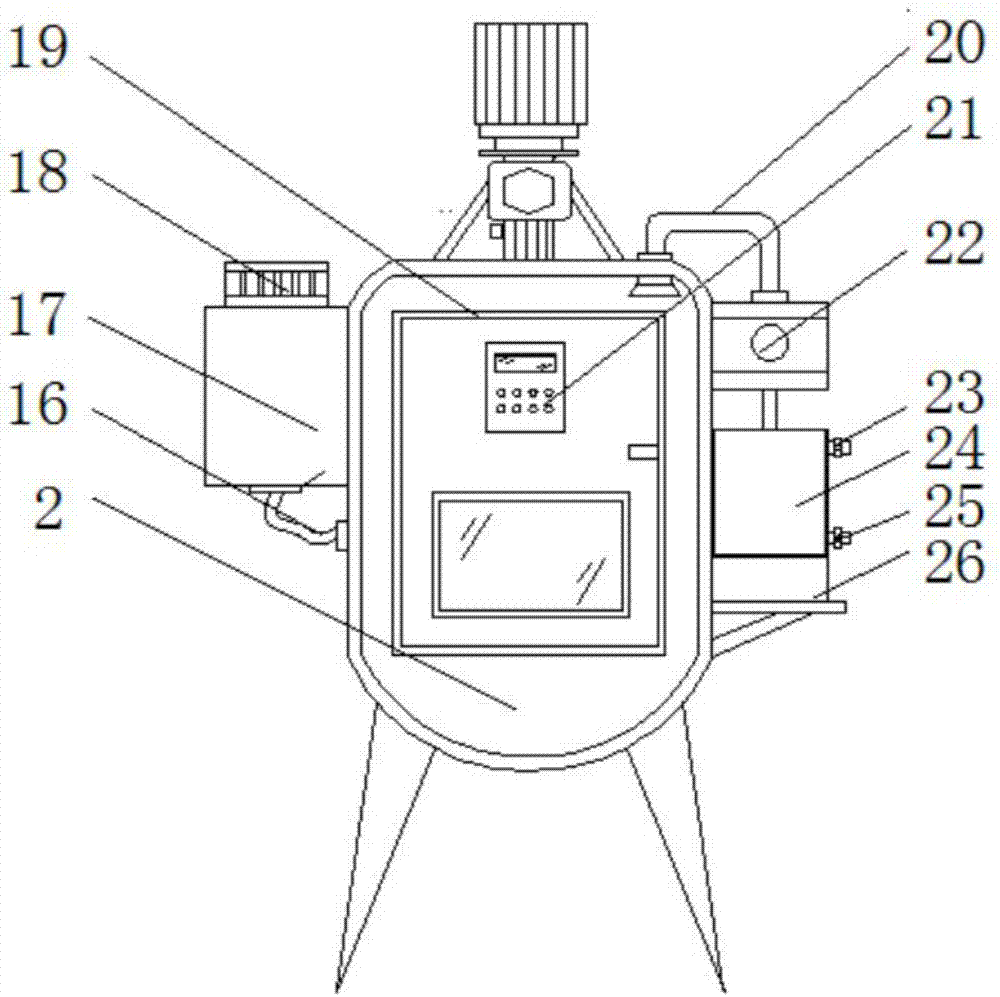

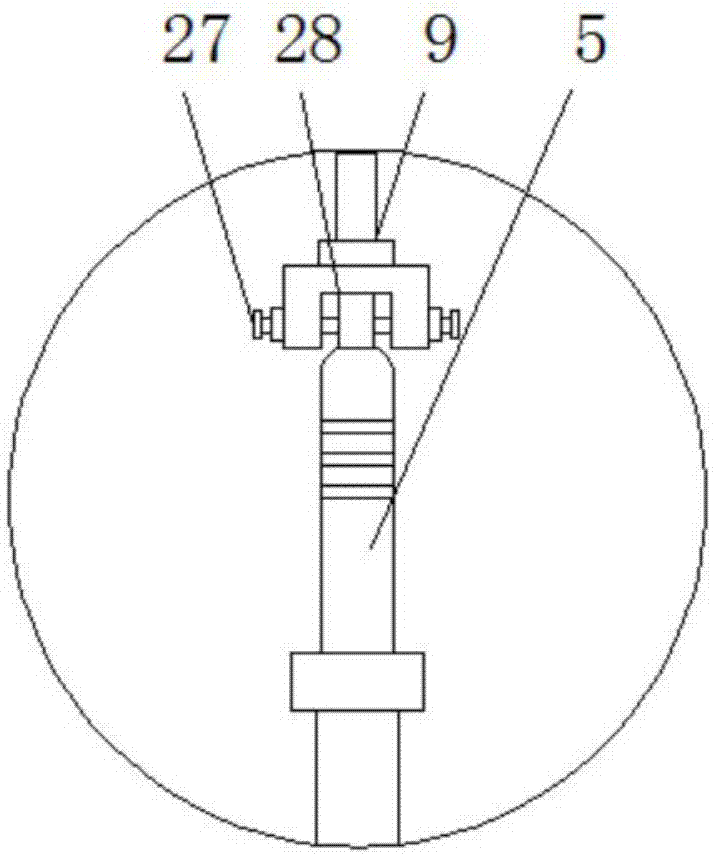

Processing device of ignition needle of gas stove as household appliance

InactiveCN107538604AEasy to replaceEasy to controlAuxillary shaping apparatusHydraulic motorSpray nozzle

The invention relates to an ignition needle processing device for a gas stove of a household appliance, which comprises a tank body, a spraying device, a glaze liquid storage tank and a door body. The two ends of the bottom of the tank body are fixed with supporting columns, and one side of the tank body is installed with a A door body, a control panel is installed on one side of the door body, a base is fixed at the bottom of the inside of the tank, and a card slot is arranged on the top of the base, a material trough is fixed above the base, and the bottom of the material trough The middle position is fixed with a block that cooperates with the card slot. Both ends of the inside of the tank are provided with heating blocks. The top of the glaze liquid storage tank is equipped with a pressurizing device, and the bottom of the glaze liquid storage tank The spraying device is connected with the spraying device through the material guide pipe, and the spraying device is evenly equipped with spraying heads. The invention is equipped with a motor, a reducer and a hydraulic telescopic rod, and the motor drives the hydraulic telescopic rod to rotate, so that the main body of the ignition needle fixed at the bottom end of the hydraulic telescopic rod rotates, which facilitates more uniform glazing and better glazing effect.

Owner:王彩英

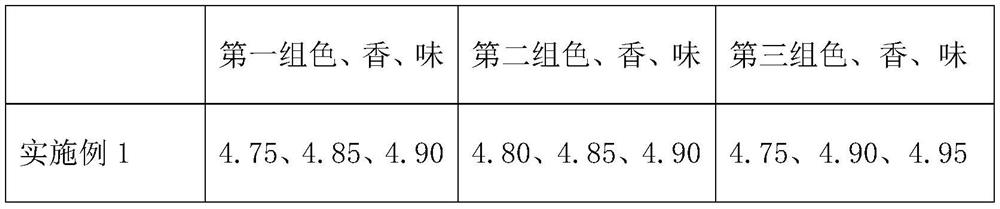

Production and processing technology for off-tree chilies

InactiveCN112425748ABreathableAdsorptiveFruit and vegetables preservationFood ingredient as flavour affecting agentProcess engineeringVANILLA FLAVORING

The invention discloses a production and processing technology for of off-tree chilies, and belongs to the technical field of chili food processing. The technology comprises the following steps: (1) carefully choosing off-tree chilies without impurities, disease spots and rot; (2) cutting off stems of carefully selected off-tree chilies, performing cleaning, draining, stir-frying and cooling, andtaking out the chilies for later use; (3) preparing a first seasoning liquid, a second seasoning liquid and a third seasoning liquid; (4) preparing a first mixture and a second mixture; (5) preparinga third mixture, and performing sealing, pickling and fermentation; and (6) after the fermentation is finished, chopping and bottling the chilies, and performing sterilizing, sealing and warehousing.The method makes use of a large amount of off-tree chilies on strike, improves the utilization ratio of the resources, thus avoids the waste of the production resources, and effectively solves the problems that: off-tree chilies in the prior art are not well recycled, and the resource waste is caused.

Owner:贵州苗幺娘食品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com