A magnetic writing wall and its preparation process

A preparation process and magnetic absorption technology, applied in the field of building decoration materials, can solve the problems of poor surface writing and erasing performance, restricting the application of magnetic whiteboards, leaving residual glue on the surface, etc., and achieves excellent writing erasability, Good economic and social benefits, and the effect of fast surface drying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

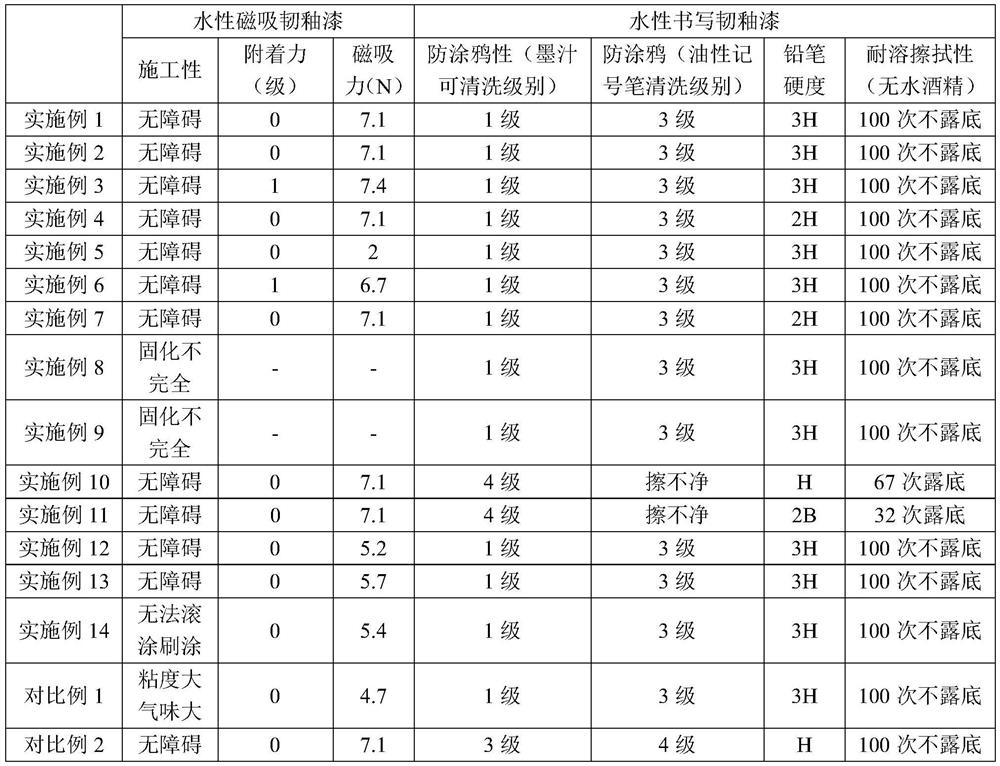

Examples

Embodiment 1

[0068] The preparation process of the magnetic writing wall of the present embodiment includes the following process steps:

[0069] 1) Leveling of the base layer of the wall surface: plastering with high-strength putty to repair and level the base layer of the wall surface;

[0070] 2) Apply the water-based reinforcing sealant to the leveled wall surface in step 1), penetrate and reinforce and seal the base layer, and after the surface is dry, lightly sand the surface to remove the burrs;

[0071] 3) Apply the water-based magnetic tough glaze paint evenly on the surface of the base layer that has been sealed in step 2) with a roller, and apply 3 coats evenly. Under the temperature condition of 23°C, the time between two coats is 2h;

[0072] 4) Evenly apply the water-based writing tough glaze paint on the surface of the water-based magnetic suction tough glaze coating formed in step 3) with a roller, and apply 2 coats evenly. After 4 hours, a magnetic writing wall is obtaine...

Embodiment 2

[0083] The preparation process of the magnetic writing wall of the present embodiment includes the following process steps:

[0084] 1) Leveling of the base layer of the wall surface: plastering with high-strength putty to repair and level the base layer of the wall surface;

[0085] 2) Apply the water-based reinforcing sealant to the leveled wall surface in step 1), penetrate and reinforce and seal the base layer, and after the surface is dry, lightly sand the surface to remove the burrs;

[0086] 3) Apply the water-based magnetic tough glaze paint evenly on the surface of the base layer that has been sealed in step 2) with a roller, and apply 3 coats evenly. Under the temperature condition of 23°C, the time between two coats is 2h;

[0087] 4) Evenly apply the water-based writing tough glaze paint on the surface of the water-based magnetic suction tough glaze coating formed in step 3) with a roller, and apply 2 coats evenly. After 4 hours, a magnetic writing wall is obtaine...

Embodiment 3

[0098] The difference between this embodiment and embodiment 1 is that, in the water-based magnetically attractive tough glaze paint, the mass ratio of component A to component B is 1:11, and the others are the same as in embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com