Automatic detecting type outdoor low-voltage metering current transformer

An automatic verification and current transformer technology, applied in the field of transformers, can solve the problems of huge waste of materials, time-consuming and laborious, and long time for replacement, and achieve the effect of improving installation efficiency, reducing labor intensity and reducing external dimensions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

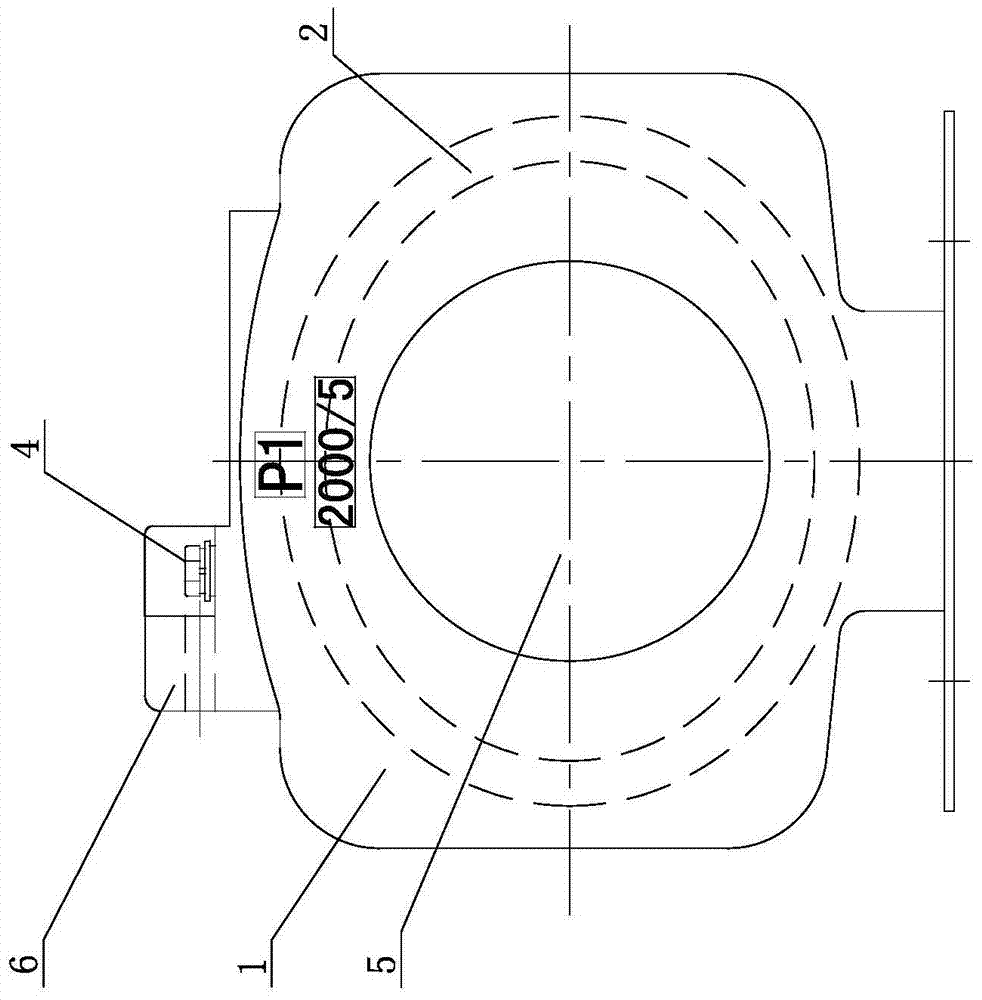

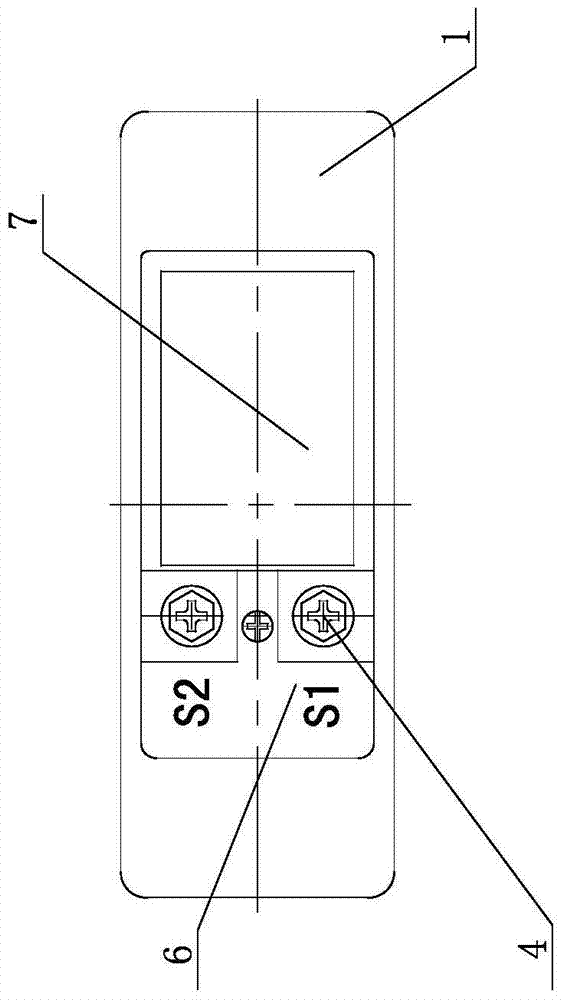

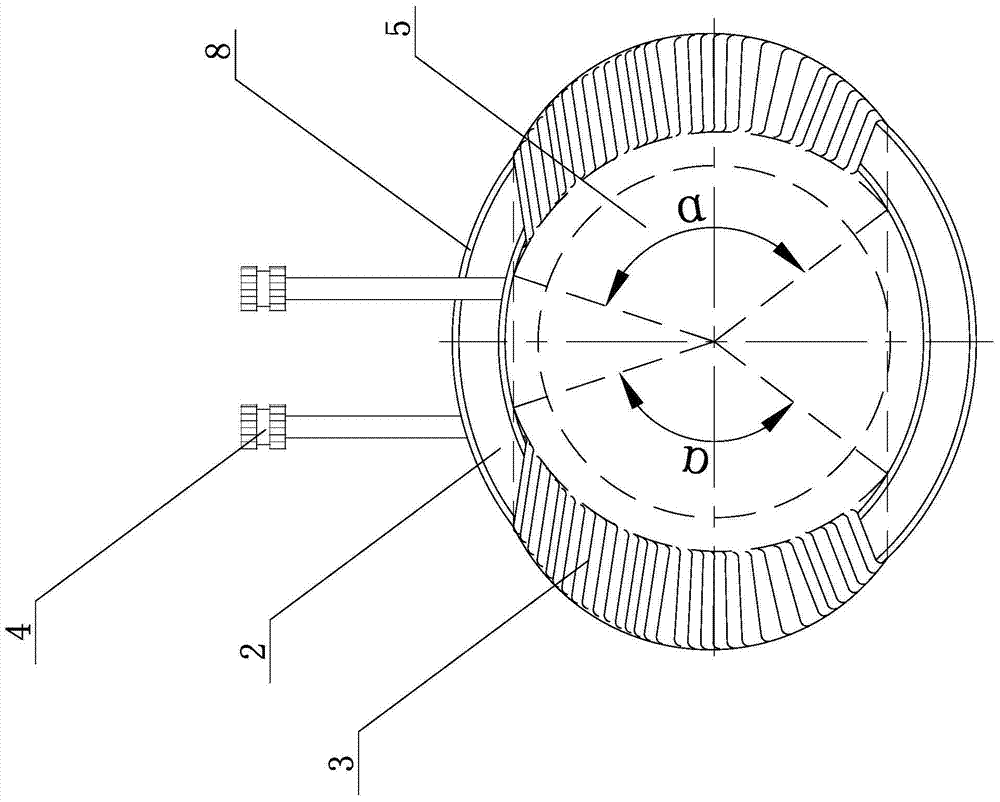

[0022] exist Figure 1 to Figure 3Among them, the structure of a low-voltage bus-type current transformer, taking the model LMZW-0.66 current transformer as an example, includes an epoxy resin main body 1, an annular iron core 2, and a secondary winding 3 wound on the iron core 2. The two ends of the secondary winding 3 are connected with the secondary terminal 4, the iron core 2 and the secondary winding 3 are integrally cast with the epoxy resin main body 1, the center of the epoxy resin main body 1 is the primary busbar through hole 5, and the primary busbar through hole 5 The diameter is 80m. The annular iron core 2 is an elliptical ultramicrocrystalline iron core. The long axis of the annular iron core 2 is located in the horizontal direction. The protective layer 8 and the secondary winding 3 are wound on the left and right sides of the elliptical ultramicrocrystalline iron core 2, and the secondary The included angle between the upper and lower ends of the winding 3 an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com