Aerial spraying operation method of cotton leaf-removing medicament in wide-narrow row cultivation mode

A cultivation mode, wide and narrow row technology, applied in the field of aerial spraying of cotton defoliants under the wide and narrow row cultivation mode, to achieve the effect of green operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

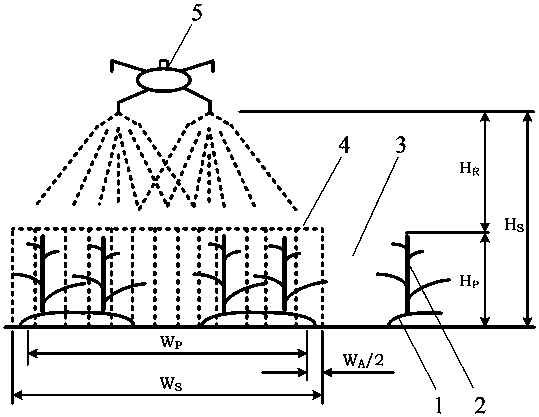

[0030] The present invention will be further described in detail with reference to the accompanying drawings and embodiments.

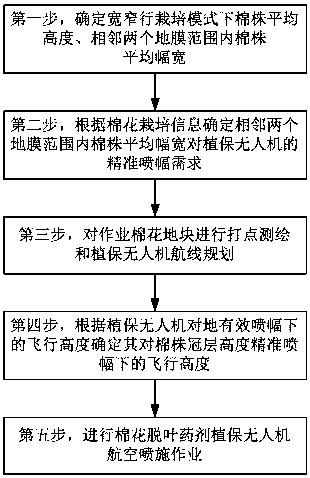

[0031] see figure 1 , figure 2 As shown, the present invention is an aerial spraying operation method of cotton defoliation agent under the wide and narrow row cultivation mode, including the following steps.

[0032] Step 1: Determine the average height of cotton plants and the average width of cotton plants within the range of two adjacent mulch films under the wide and narrow row cultivation mode

[0033](A) The cotton variety planted in a certain plot is Lumian 532. The plot adopts the "wide and narrow row" cultivation mode. The specific specification is to sow 2 rows of cotton plants with a row spacing of 50cm on the plastic film. The 2 rows of cotton plants A "narrow row" is formed, and a "wide row" is formed by the handover row formed between two adjacent mulch films because there is no sowing cotton plant, and the width of the "wide row" is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com