Biomass honeycomb paperboard, and preparation method and application thereof

A honeycomb cardboard and biomass technology, applied in cardboard articles, wrapping paper, flexible coverings, etc., can solve the problem of excess crop waste residue, achieve a large market prospect and economic value, reduce transportation costs, and reduce production costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

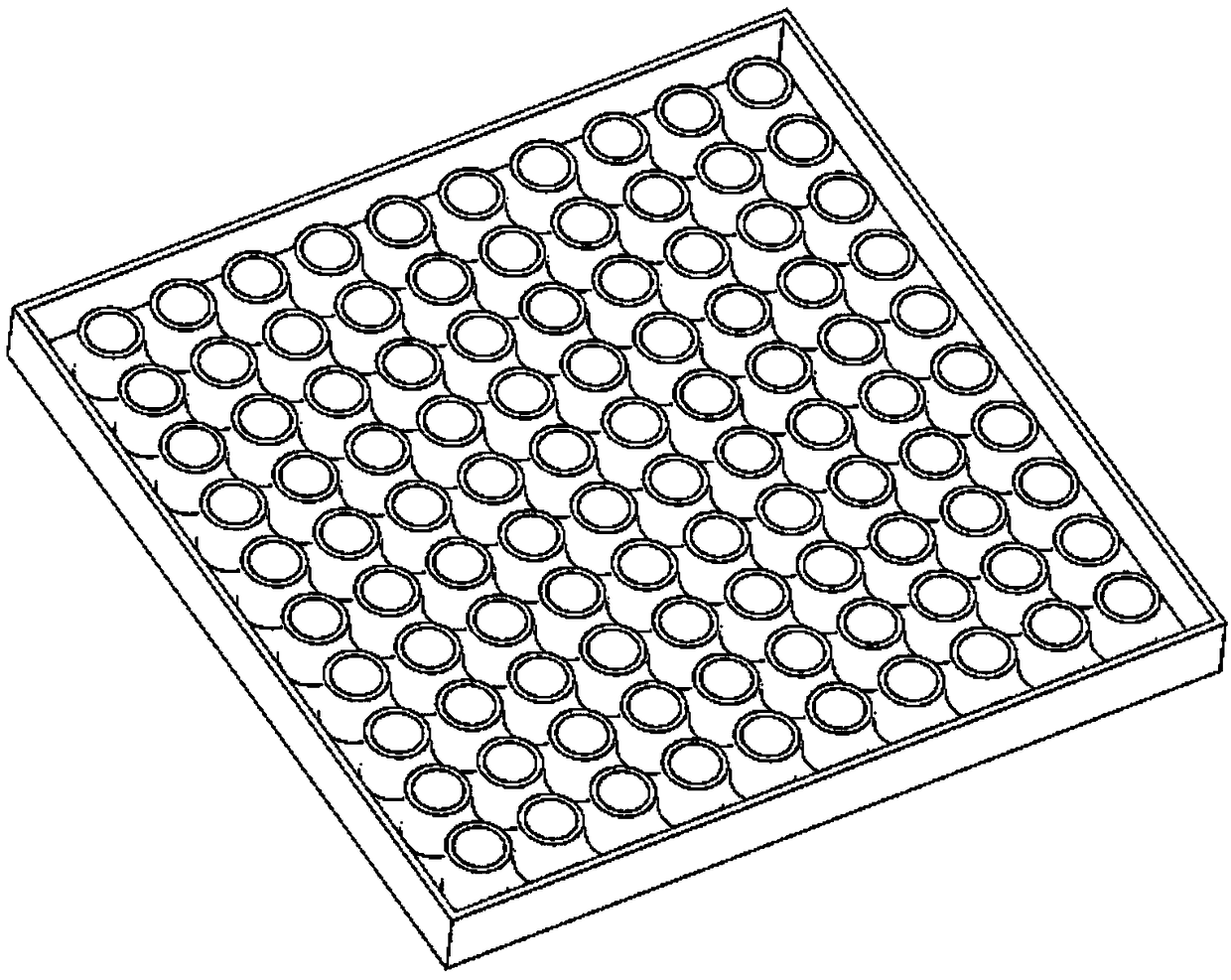

Image

Examples

Embodiment 1

[0031] Example 1 This example discloses a biomass honeycomb paperboard, the specific components are as follows:

[0032] 30-40 parts by weight of 12mm wheat straw, 20-30 parts by weight of rice husks, 0-15 parts by weight of cottonseed hulls, 0-10 parts by weight of 4mm corn cobs, 10-20 parts by weight of wheat bran, 0-10 parts by weight Corn flour in parts by weight, quicklime in 0-3 parts by weight, and gypsum in 0-3 parts by weight.

[0033] Biomass honeycomb paperboard made of raw materials with this ratio has fire-proof and heat-retaining properties, and at the same time has high tensile strength.

Embodiment 2

[0034] Example 2 This example discloses a biomass honeycomb paperboard, the specific components are as follows:

[0035] 50-60 parts by weight of 4mm corn stalks, 20-30 parts by weight of 12mm wheat straw, 10-20 parts by weight of wheat bran, 0-10 parts by weight of corn flour, 0-3 parts by weight of quicklime, 0-3 parts by weight parts of plaster.

[0036] The biomass honeycomb paperboard made of raw materials with this proportion has the characteristics of light density and fine material surface.

Embodiment 3

[0037] Example 3 This example discloses a biomass honeycomb paperboard, the specific components are as follows:

[0038] 50-70 parts by weight of corncobs, 20-30 parts by weight of cottonseed hulls, 0-10 parts by weight of wheat bran, 0-3 parts by weight of quicklime, and 0-3 parts by weight of gypsum.

[0039] Biomass honeycomb paperboard made of this ratio of raw materials has the characteristics of high compressive strength and can withstand higher strength pressure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com