Blasting agent and blasting method

一种物料、喷砂的技术,应用在磨料、用过的磨料的处理装置、金属加工设备等方向,能够解决杂质集聚、损害人体健康和环境、喷砂设备和喷砂物料清理费用增高等问题,达到便于清理、抑制火灾危险和/或爆炸危险的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

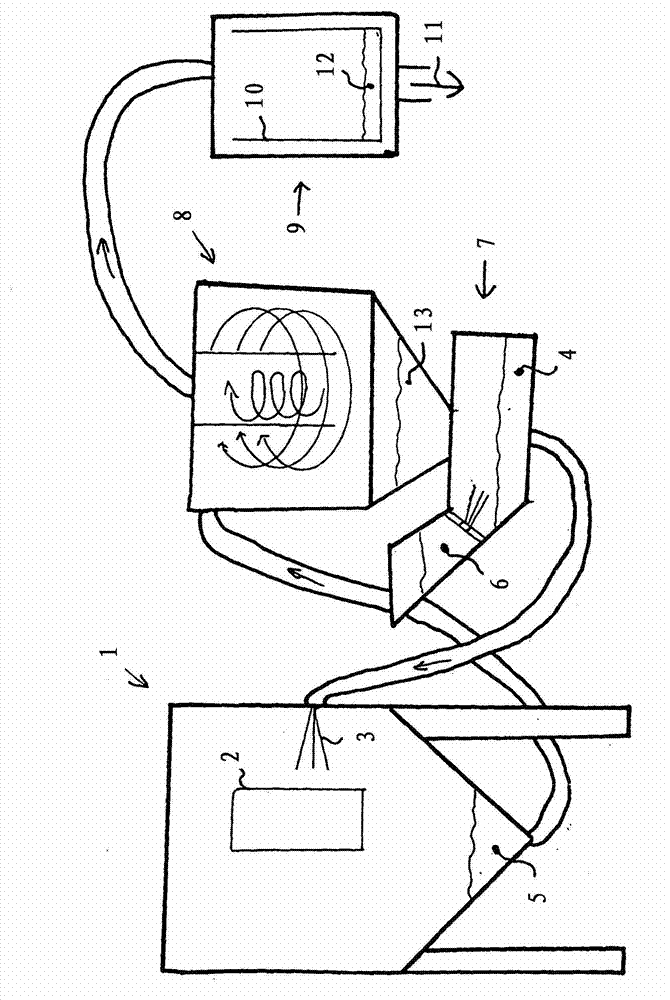

[0018] The exemplary device proposed by the invention has a sandblasting device 1 in which a sandblasting jet 3 is sprayed onto a workpiece 2 . The blasting material 5 used is collected and conveyed to a treatment device 8 in which a first fraction 13 (which essentially comprises the original blasting material and unfragmented additive fraction) and is separated from a second portion 12, which is preferably discharged by a carrier air flow, and which contains the fragmented additive fraction and the wear of the workpiece and / or blasting material substances and impurities to be removed from the process. This second part 12 can be removed from the carrier air flow by means of a filter, so that only waste gas free from impurities remains in the carrier air flow.

[0019] According to the invention, a device 7 is provided for the metering of granular additives 6, the function of which is to add the additives to the circulated blasting material 5, the added additives are preferabl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com