Wood bleaching device

A technology of wood products and bleaching agent, which is applied in the direction of wood treatment, manufacturing tools, wood processing appliances, etc., can solve the problems of insufficient safety, etc., and achieve the effect of uniform painting, simple structure, cost saving and maintenance of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

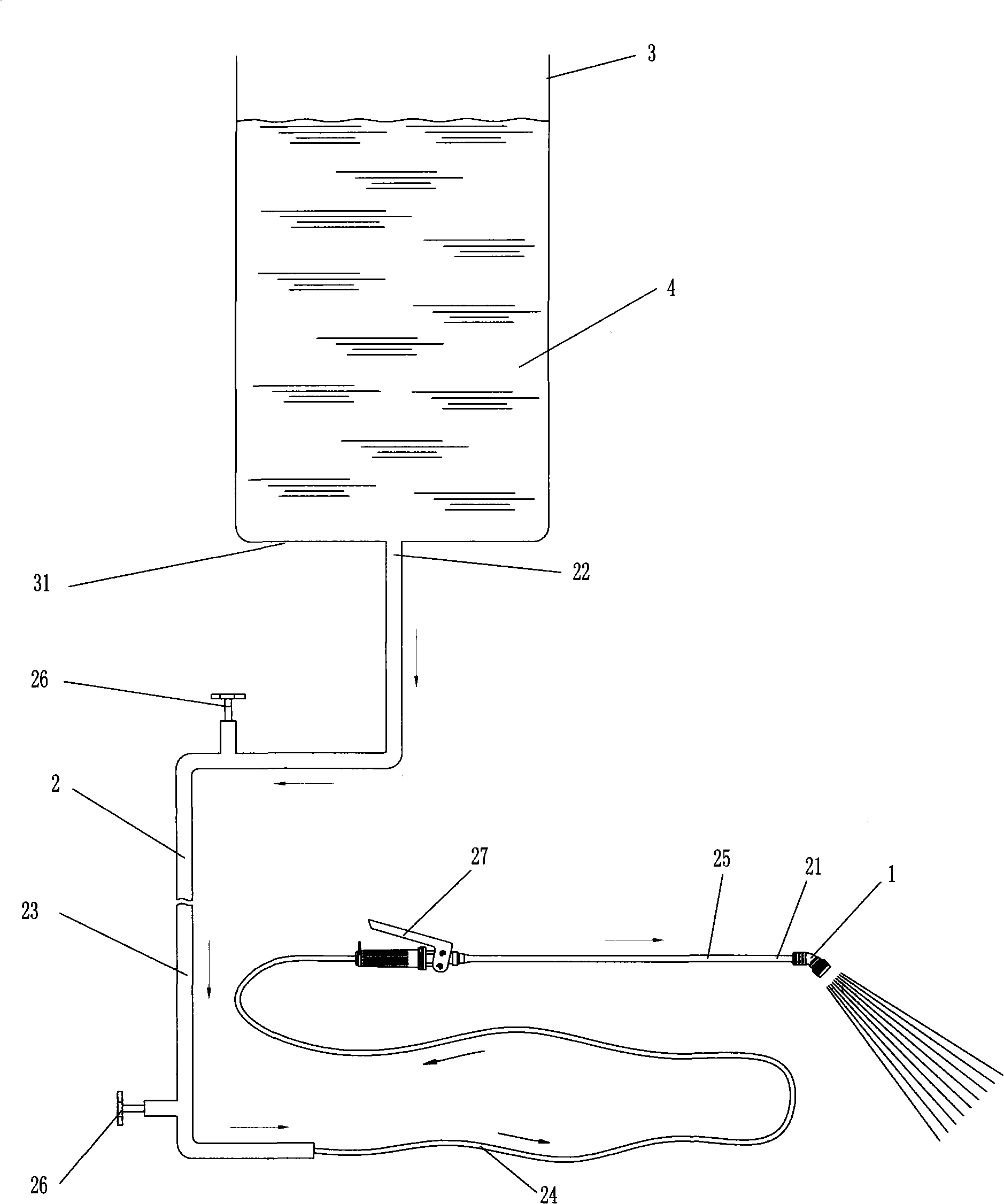

[0017] The present invention comprises a nozzle 1, the nozzle is connected to the bottom 21 of the ascending pipe 2, and the top 22 of the ascending pipe is connected to a reaction tank 3 which is higher than the nozzle 1 and has a certain height and enables the nozzle to generate sufficient injection pressure; the position of the reaction tank bottom 31 is higher than that of the nozzle 1. high. The reaction tank is open, and bleaching agent 4 is contained in the reaction tank.

[0018] The position of the bottom 31 of the reaction tank is higher than that of the nozzle 1, so that the gravity of the bleaching solution in the reaction tank and the height difference between the bottom of the reaction tank and the nozzle are used to generate a certain pressure on the bleaching solution sprayed from the nozzle to the surface of the wooden product. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com