Oxygen feeding device, and corresponding methane tri-reforming reaction device and method

A reforming reaction and feeding device technology, applied in feeding devices, chemical instruments and methods, hydrogen/synthesis gas production, etc., can solve the problems of small ratio, too fast temperature rise of catalyst bed, large amount of catalyst, etc., to achieve Solve the effects of rapid temperature rise, not easy to crush, and eliminate carbon deposits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

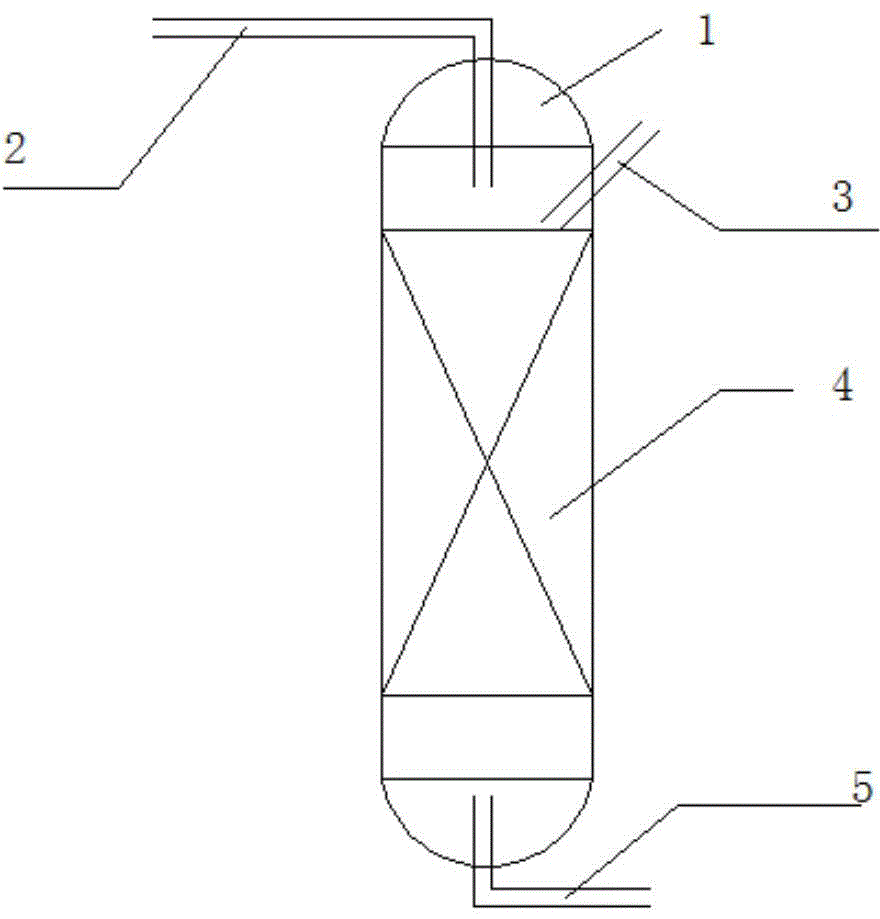

[0043] According to the present invention, a device for preparing synthesis gas by methane triple reforming using subsonic oxygen comprises a fixed bed shell 1, an oxygen feed device 3, a catalyst bed 4, a mixed gas inlet 2 and a synthesis gas outlet 5, wherein the The mixed gas inlet 2 is set on one side of the fixed bed shell 1, the synthesis gas outlet 5 is set on the other side of the fixed bed shell 1, and the catalyst bed 4 is set in the middle of the fixed bed shell 1 , the oxygen feeding device 3 is arranged on the fixed bed shell 1 at a position close to the catalyst bed 4 .

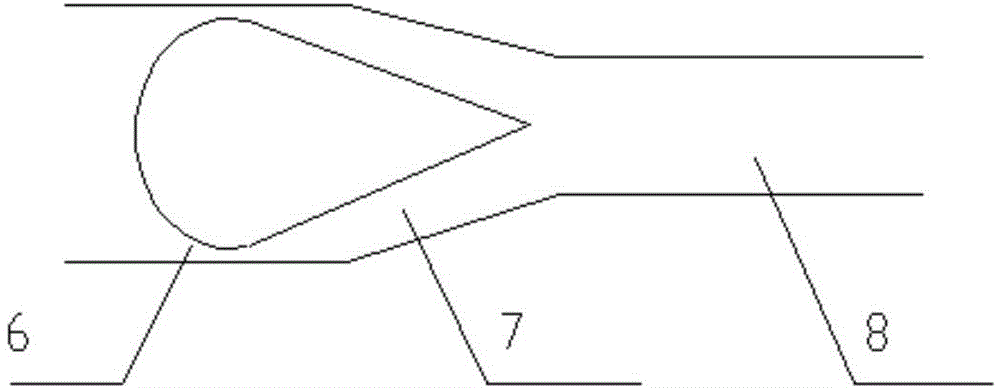

[0044] Preferably, the oxygen feeding device 3 adopts a special structure, and the whole oxygen feeding device includes a conical core with a hemispherical bottom and an outer tube, and the two ends of the outer tube are two tubes with different diameters , the middle part of the outer tube is a conical tube connecting the two ends of the tube, the conical core is fixed in the outer tube, includ...

Embodiment 2

[0052] Preferably, the reaction bed layer used in the above-mentioned triple methane reforming reaction device is a fixed bed shell 1 . The design dimensions of the oxygen feeding device 3 are as follows: the ratio of the spherical bottom diameter of the conical core to the inner diameter of the tube in the compression zone is 0.8:1; the apex angle of the cone body is 50°; the angle between the conical tube and the straight pipe is 135°; The ratio of the inner diameter of the pipeline in the working area to the inner diameter of the pipeline in the compression area is: 1:3; the ratio of the length of the working area to the inner diameter of the working area is: 8:1; the angle between the oxygen outlet end and the catalyst bed is 60o; the distance between the oxygen outlet end and the catalyst bed is 80mm.

[0053] Utilize above-mentioned reaction device, according to a kind of method that utilizes the methane triple reforming of subsonic speed oxygen of the present invention ...

Embodiment 3

[0064] Preferably, the reaction bed used in the above-mentioned triple methane reforming reaction device is a fixed bed shell 1 . The design dimensions of the oxygen feeding device 3 are as follows: the ratio of the spherical bottom diameter of the conical core to the inner diameter of the tube in the compression zone is 0.8:1; the apex angle of the conical body is: 50 o ; The angle between the tapered pipe and the straight pipe is: 135 o ;The inner diameter ratio of the pipeline in the working area and the inner diameter of the pipeline in the compression area is: 1:3; the ratio of the length of the working area to the inner diameter of the working area is: 8:1; the angle between the oxygen outlet end and the catalyst bed is 60° o ; The distance between the oxygen outlet port and the catalyst bed is 80mm. The difference from the second embodiment is that the feeding method of oxygen is continuous air intake.

[0065] Utilize above-mentioned reaction device, according to ano...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com