New SRC rubber material and manufacturing process thereof, and sticking-resistant and anti-explosion tire

A manufacturing process and new material technology, applied in the direction of special tires, tire parts, rolling resistance optimization, etc., can solve problems such as products are easy to fall off, edge off, can not achieve puncture resistance, air leakage and explosion protection, tires have no dynamic balance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

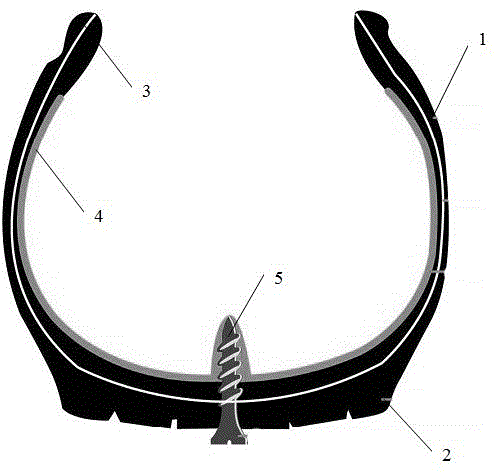

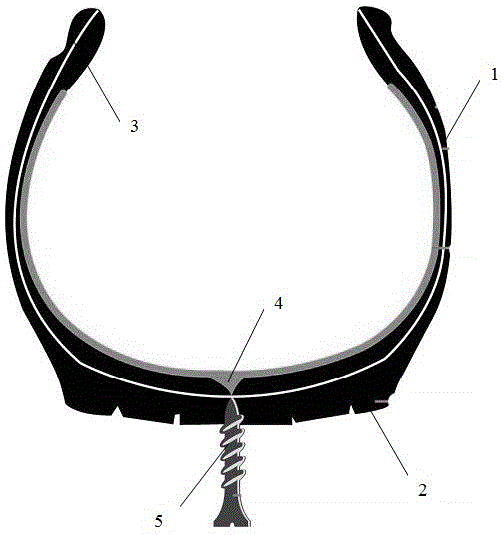

[0052] SRC rubber new material, such as Figure 1 to Figure 2 Shown, the weight percentage ratio is:

[0053] Polymer rubber elastomer: 30%~60%;

[0054] Tackifier: 25%~55%;

[0055] Phase solvent: 5%~15%;

[0056] Antiaging agent: 0.5%~1%;

[0057] Filler: 1%~4%;

[0058] Active agent: 0.5%~6%.

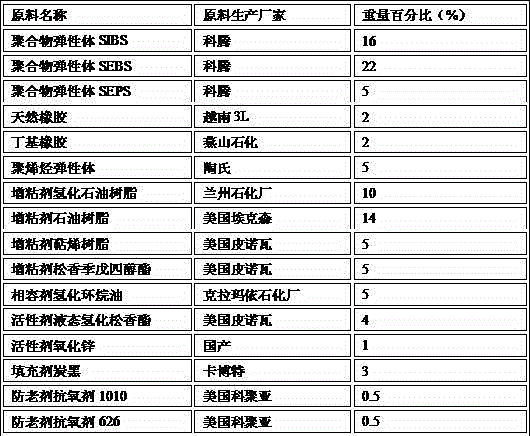

[0059] The present embodiment is an automobile tire, which is puncture-resistant, air-leakage-proof, explosion-proof, and bullet-proof tire containing SRC rubber new material. The composition and weight percentage ratio of SRC rubber new material is as follows in Table 1. It melts completely at a high temperature of 200 ° C. , the new SRC rubber material is sprayed on the inner wall of the tire (thickness 2.5mm) through the spraying equipment, and after cooling and solidification treatment, the safety upgraded safety tire is obtained.

[0060] Table I

[0061]

[0062] In the new SRC rubber material in the embodiment, the weight percentage ratio is: polymer rubber e...

Embodiment 2

[0074] SRC rubber new material, such as Figure 1 to Figure 2 Shown, the weight percentage ratio is:

[0075] Polymer rubber elastomer: 30%~60%;

[0076] Tackifier: 25%~55%;

[0077] Phase solvent: 10%~15%;

[0078] Antiaging agent: 0.5%~1%;

[0079] Filler: 1%~2%;

[0080] Active agent: 0.5%~1%.

[0081] This embodiment is an automobile tire, which is a puncture-resistant, air-leakage-proof, explosion-proof, and bullet-proof tire containing SRC rubber new material. The composition and weight percentage ratio of the SRC rubber new material is shown in Table 2 below. It melts completely at a high temperature of 200 ° C. , the new SRC rubber material is sprayed on the inner wall of the tire (thickness 2.5mm) through the spraying equipment, and after cooling and solidification treatment, the safety upgraded safety tire is obtained.

[0082] Table II

[0083] raw material name Raw material manufacturer Weight percentage (%) polymer elastomer SIBS Kraton...

Embodiment 3

[0088] The present embodiment is the tire of light and small storage battery car, motorcycle, the tire that contains SRC rubber new material to be resistant to pricking, leak-proof, explosion-proof, bulletproof, SRC rubber new material, its composition and weight percentage proportioning are as following table three, in The melting is complete at a high temperature of 200°C. The new material is sprayed on the inner wall of the tire (thickness 2.0mm) by special spraying equipment, and after cooling and solidification treatment, a safety upgraded safety tire is obtained.

[0089] Table three

[0090] raw material name Raw material manufacturer Weight percentage (%) polymer elastomer SIBS Kraton 15 Polymer Elastomer SEBS Kraton 15 Butyl rubber Yanshan Petrochemical 2 fluororubber American GE 1 polyolefin elastomer Dow 1 Tackifier hydrogenated petroleum resin Lanzhou Petrochemical Plant 26 tackifier petroleum resin ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com