Patents

Literature

36results about How to "Leakproof" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-molecular hot-melt adhesive for preventing air leakage of automobile tyre, and manufacturing method of high-molecular hot-melt adhesive

The invention relates to a high-molecular hot-melt adhesive for security upgrade of an automobile tyre. The high-molecular hot-melt adhesive comprises the following components in percentage by weight: 40%-60% of thermoplastic elastomers, 34%-51% of thickening agents, 5%-8% of plasticizing agents, 0.5%-1.5% of anti-aging agents, 0.2%-1% of cross-linking agents and 3%-5% of filling agents. By using a glue sprayer of the automobile tyre, the high-molecular hot-melt adhesive is sprayed to the inner wall of a tyre after being hot-melted, the inner wall of the tyre is only subjected to mould release agent removal washing and drying treatment without being subjected to any damaging processing; the tyre can be upgraded to normally operate between low temperature of -40 DEG C and high temperature of +120 DEG C by spraying a layer of the high-molecular hot-melt adhesive with the thickness more than 3.5 mm on the integral part or crown type body part of the inner wall of the tyre, and the tyre has bullet-proof, leakage-proof and anti-puncturing properties. The invention also discloses a manufacturing method of the high-molecular hot-melt adhesive.

Owner:LUOYANG JUNTENG ENERGY TECH

Macromolecule self-glue rubber for preventing automobile tire flat and manufacturing method thereof

InactiveCN103849284AWidely used valueReduce the amount of vibrationRosin coatingsFoaming agentThermoplastic elastomer

The invention relates to macromolecule self-glue rubber for preventing automobile tire flat, comprises the following components in parts by mass (using 100 part by mass of thermoplastic elastomer as the standard): 100 parts of thermoplastic elastomer, 130-140 parts of tackifier, 100-110 parts of plasticizer, 5-5.5 parts of antiaging agent and / or antioxidant, 2-3 parts of foaming agent and 10-12 parts of filler. The macromolecule self-seal rubber after hot-melting is sprayed on the inner wall of the tire by using the automobile tire rubber sprayer, a layer of macromolecule self-seal rubber with thickness of more than 3.5mm is sprayed on all of the inner wall or partial crown type body of the tire by using the automobile tire rubber sprayer without performing any traumatic processing on the inner wall of the tire and only performing cleaning and drying treatment on the inner wall of the tire to remove the release agent, that is, the normal automobile tire is upgraded to realize that the tire can normally work within low temperature of minus 40 DEG C to high temperature 120 DEG C, and has the bullet-proof, leak-proof and puncture-proof performances; and the invention further discloses a manufacturing method of the macromolecule self-seal rubber.

Owner:LUOYANG JUNTENG ENERGY TECH

Temperature-resistant macromolecule self-seal rubber and manufacturing method thereof

InactiveCN103849283ANo change in dynamic balanceIncrease elasticityRosin coatingsFoaming agentThermoplastic elastomer

The invention discloses temperature-resistant macromolecule self-seal rubber and a manufacturing method thereof, and the self-seal rubber is composed of the following components in parts by mass: 100 parts of thermoplastic elastomer, 75-86.5 parts of tackifier, 6-11.7 parts of plasticizer, 1-3 parts of antiaging agent and / or antioxidant and 4-19 parts of foaming agent. The temperature-resistant macromolecule self-seal rubber is sprayed on the inner wall of a tire by using an automobile tire rubber sprayer without performing any traumatic processing on the inner wall of the tire and only performing cleaning and drying treatment on the inner wall of the tire to remove the release agent, a layer of temperature-resistant macromolecule self-seal rubber with thickness of more than 3.5mm is sprayed on all of the inner wall or partial crown type body of the tire, and then the tire is upgraded that the tire can normally work within low temperature of minus 40 DEG C to high temperature 120 DEG C, and has the bullet-proof, leak-proof and puncture-proof performances. The invention further discloses a manufacturing method of the temperature resistant macromolecule self-seal rubber.

Owner:LUOYANG JUNTENG ENERGY TECH

Isolation type paper diaper and production method thereof

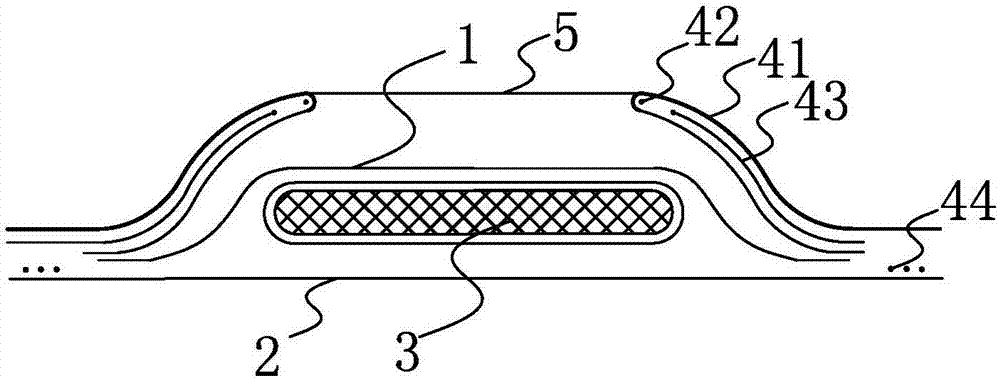

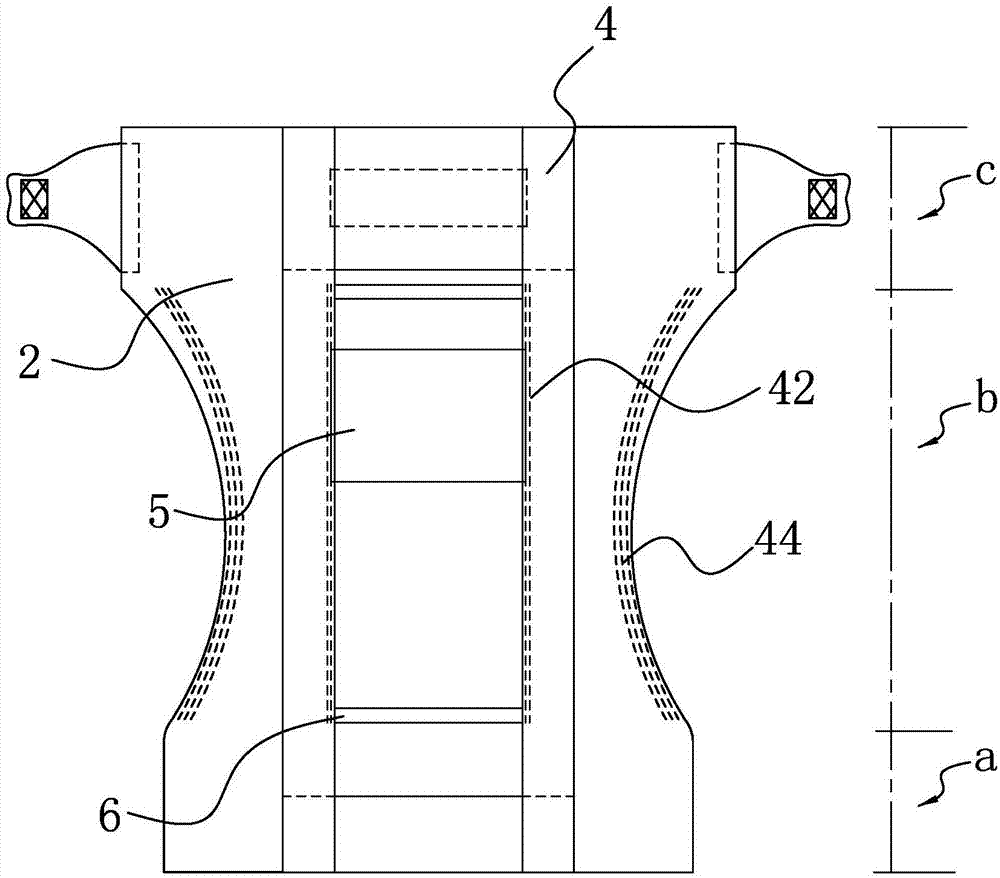

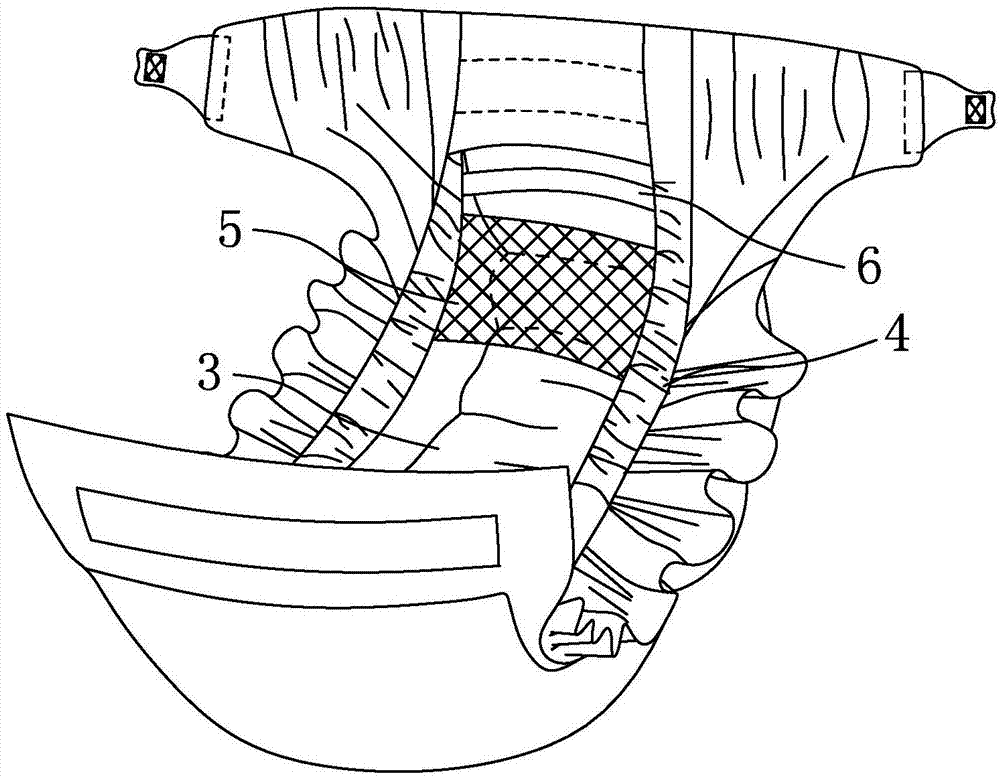

ActiveCN107981986AAvoid direct contactAvoid contactAbsorbent padsBaby linensSurface layerIsolation layer

The invention relates to the field of disposable sanitary products, and in particular to an isolation type paper diaper. The paper diaper includes a paper diaper body. The paper diaper body includes aliquid-permeable surface layer, a liquid-impermeable bottom layer and an absorber disposed between the surface layer and the bottom layer, and is defined to have a transverse direction in the width direction and a longitudinal direction in the longitudinal direction; the paper diaper body is provided with a front waist region, a crotch region and a back waist region in the longitudinal direction,leak-proof partitioning edges are arranged on the liquid-permeable surface layer at both lateral sides of the absorber, an isolation layer is arranged above the liquid-permeable surface layer betweenthe crotch region and the back waist region of the paper diaper body, both lateral sides of the isolation layer are fixedly connected with the leak-proof partitioning edges or the liquid-permeable surface layer respectively, and the length of the isolation layer is 1 / 4 to 1 / 3 of the length of the absorber. The paper diaper is used for isolating excretions of infants, especially for loose stools,and the paper diaper can keep the skin dry and has good antibacterial effects.

Owner:GUANGDONG YINYIN CO LTD

Macromolecular hot melt adhesive with self-repair function and manufacturing method thereof

InactiveCN103805021ANo change in dynamic balanceIncrease elasticityRosin coatingsPlasticizerThermoplastic elastomer

The invention relates to a macromolecular hot melt adhesive used for safety upgrade of automobile tires and having a self-repair function. The macromolecular hot melt adhesive consists of the following components in percentage by weight: 40 to 60 percent of thermoplastic elastomer, 34 to 51 percent of tackifier, 5 to 8 percent of plasticizer, 0.5 to 1.5 percent of anti-aging agent and / or antioxidant, and 0.2 to 1 percent of cross linker. The macromolecular hot melt adhesive is sprayed on the inner wall of a tire by using an automobile tire adhesive sprayer, any destructive processing is not needed for the inner wall of the tire, the inner wall of the tire is only subjected to release agent removal cleaning and drying treatment, the whole or crown part of the inner wall of the tire is coated with a layer of macromolecular hot melt adhesive of which the thickness is more than 3.5mm, and then the tire can be upgraded to run normally at the temperature of between -40 DEG C and 120 DEG C and has bullet-proof, leak-proof and prick-resistant performance. The invention also discloses a manufacturing method for the macromolecular hot melt adhesive.

Owner:LUOYANG JUNTENG ENERGY TECH

Application and preparation method of macromolecule self-sealing glue

InactiveCN103849289AWidely used valueNo change in dynamic balanceRosin coatingsElastomerPolymer science

The invention provides application and a preparation method of macromolecule self-sealing glue. The macromolecule self-sealing glue is applicable to auto tires. The macromolecule self-sealing hot melt glue is coated on the whole surface of the inner wall of the auto tire or coated on a crown-shaped body part in the upper surface of the inner wall by virtue of the hot melting and spraying technology so as to form an uniform coating being 3.5mm in thickness; the macromolecule self-sealing glue comprises the following components in parts by mass: 100 parts of thermoplastic elastomer, 80 to 100 parts of thickening agent, 10 to 25 parts of plasticizer, and 2 to 4.5 parts of anti-aging agent and / or antioxidant. According to the application, the macromolecule self-sealing glue is coated on the inner wall of the tire without any destructive processing for the inner wall of the tire, the inner wall of the tire is simply treated by washing with a release agent and drying, and then the tire can be upgraded to be able to run normally at the temperature ranging from minus 40 DEG C to +120 DEG C and has the shot-proof, leakproof and puncturing resistant performances.

Owner:LUOYANG JUNTENG ENERGY TECH

Polymer self-sealing hot melt adhesive capable of providing leakproof safety performance to vehicle tire and preparation method and application thereof

InactiveCN103849341ANo change in dynamic balanceReduce the amount of vibrationMineral oil hydrocarbon copolymer adhesivesNon-macromolecular adhesive additivesPolymer scienceSprayer

The invention relates to a polymer self-sealing hot melt adhesive capable of providing leakproof safety performance to a vehicle tire and a preparation method and application thereof. The polymer self-sealing hot melt adhesive comprises the following components in parts by weight: 100 parts of thermoplastic elastomer, 100-150 parts of tackifiers, 80-110 parts of plasticizers, and 4 parts of anti-aging agents and / or antioxidants. By using a rubber tire glue sprayer, the polymer self-sealing hot melt adhesive disclosed by the invention is sprayed on the inner wall of the tire, and is free of traumatic processing on the inner wall of the tire, just the inner wall of the tire is subjected to cleaning and drying treatment to remove a release agent, a layer of polymer self-sealing hot melt adhesive of which the thickness is greater than 3.5mm is sprayed on the whole inner wall or the crown body part of the tire, so that the tire can be upgraded to normally run within the range from the low temperature of -40 DEG C to the high temperature of +120 DEG C. The polymer self-sealing hot melt adhesive has bulletproof property, leakproof performance and punctured resistance. A method for manufacturing the polymer self-sealing hot melt adhesive is also disclosed by the invention.

Owner:LUOYANG JUNTENG ENERGY TECH

Application and preparing method of macromolecular self-sealing hot melt adhesive

The invention discloses application and preparing method of a macromolecular self-sealing hot melt adhesive which is used for an automobile tire. The macromolecular self-sealing hot melt adhesive is sprayed on the whole or the crown part of the inner wall surface of the automobile tire through a hot melt spray technology, and a uniform coating which is more than 3.5 mm in thickness is formed, wherein the macromolecular self-sealing hot melt adhesive consists of the following ingredients according to ratio by weight: 40-60% of thermoplastic elastomer, 34-51% of a tackifier, 5-8% of a plasticizer and 0.5-1.5% of an anti-ageing agent / antioxidant. The macromolecular self-sealing hot melt adhesive is sprayed on the inner wall of the tire, any destructive processing is not required to be carried out on the inner wall of the tire, and the removal washing of a mold release agent and drying processing are carried out on the inner wall of the tire only, the tire can be updated into a such tire capable of normally working in a range from the low temperature of -40 DEG C to the high temperature of 120 DEG C, and the tire has bullet-proof, leakage-proof and stab-proof performance.

Owner:LUOYANG JUNTENG ENERGY TECH

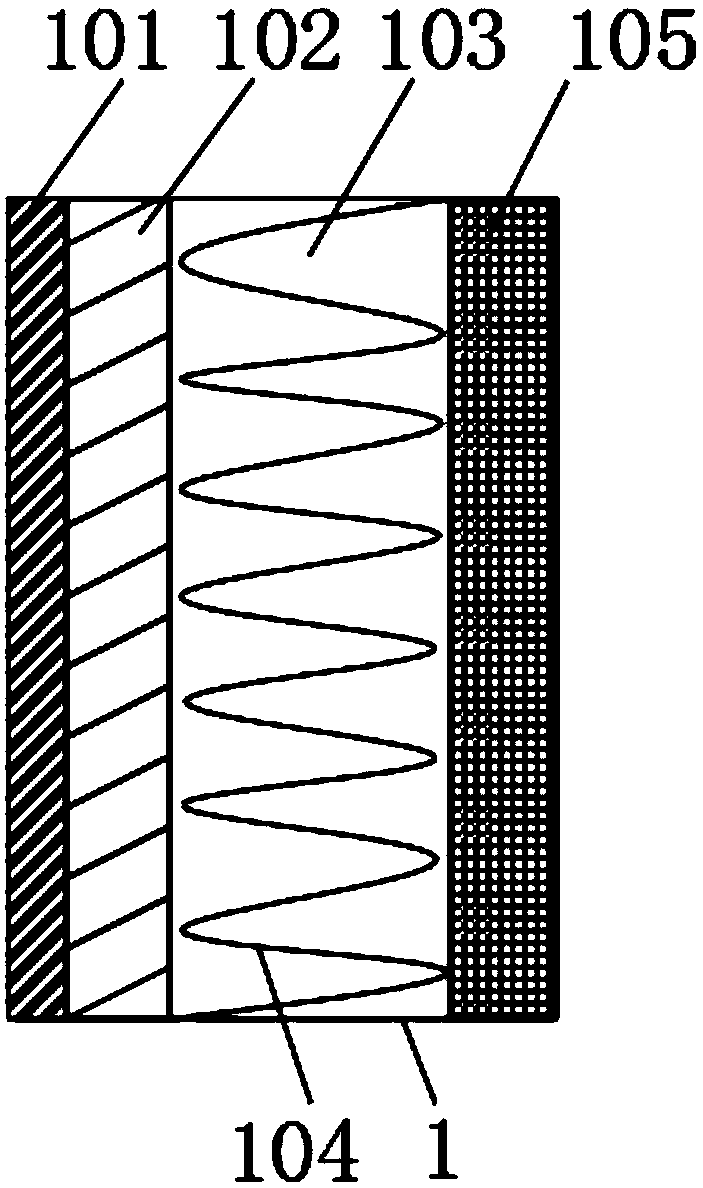

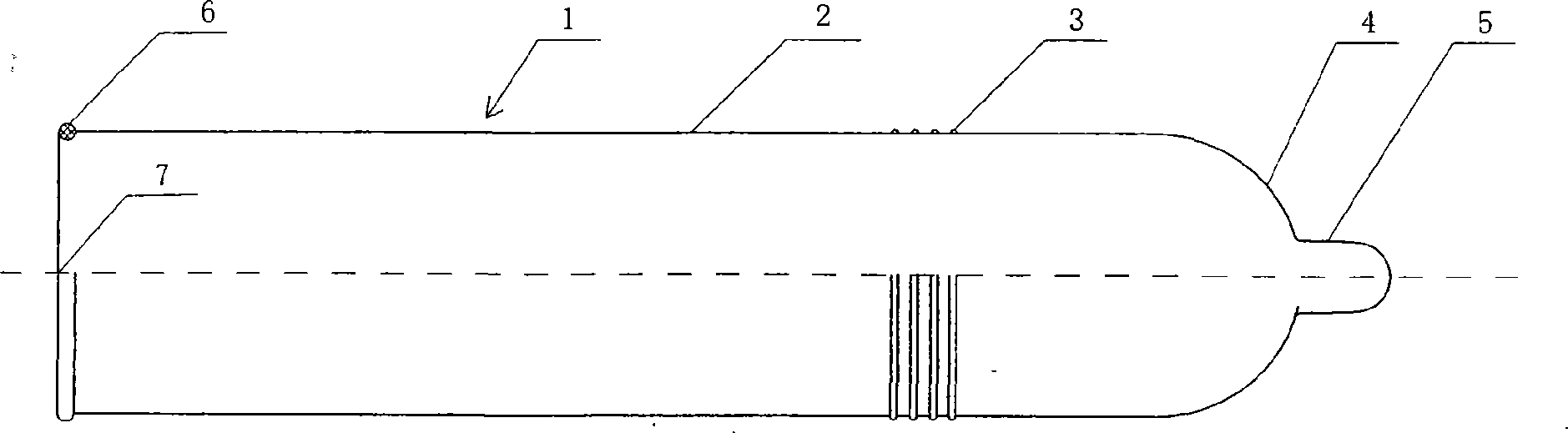

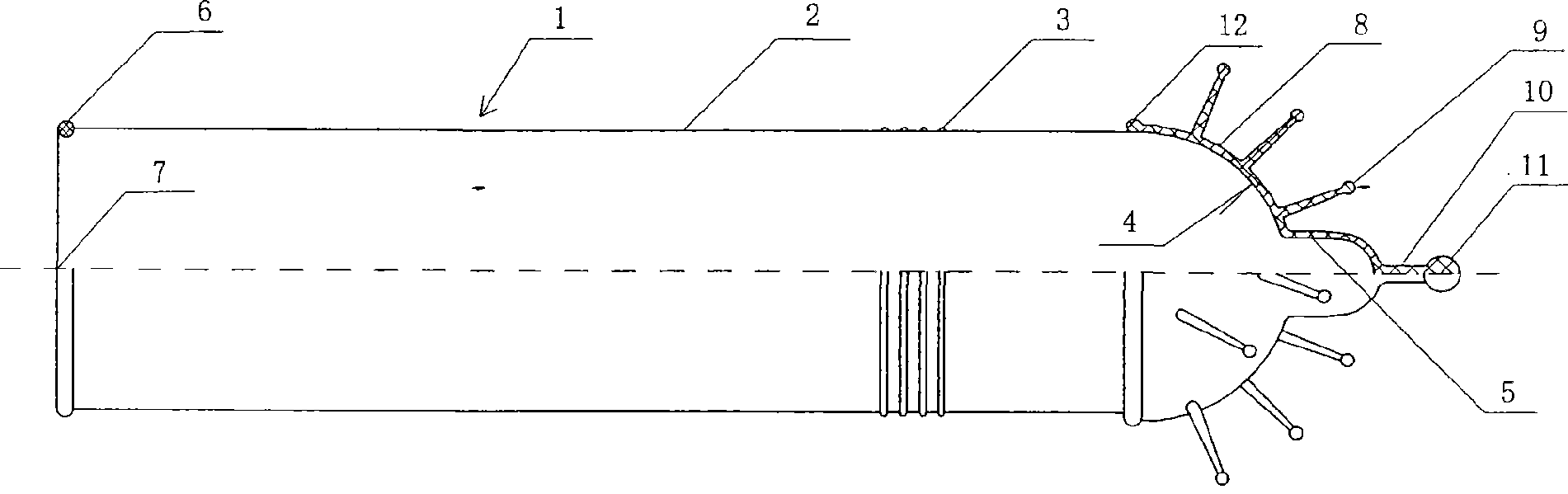

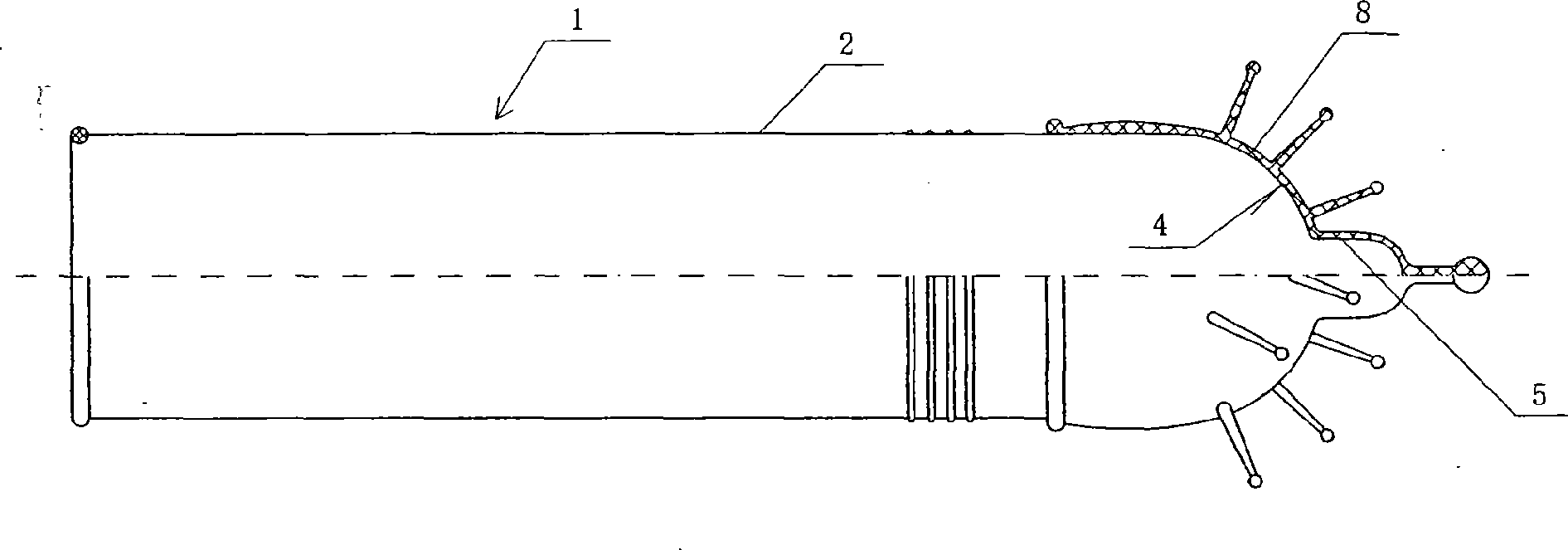

Bullet-proof security tire and manufacturing method of self-sealing polymer material used in bullet-proof security tire

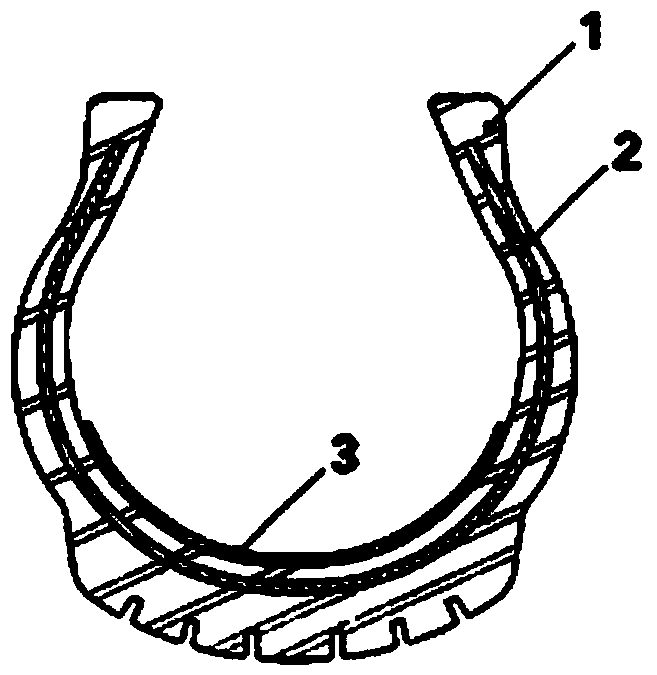

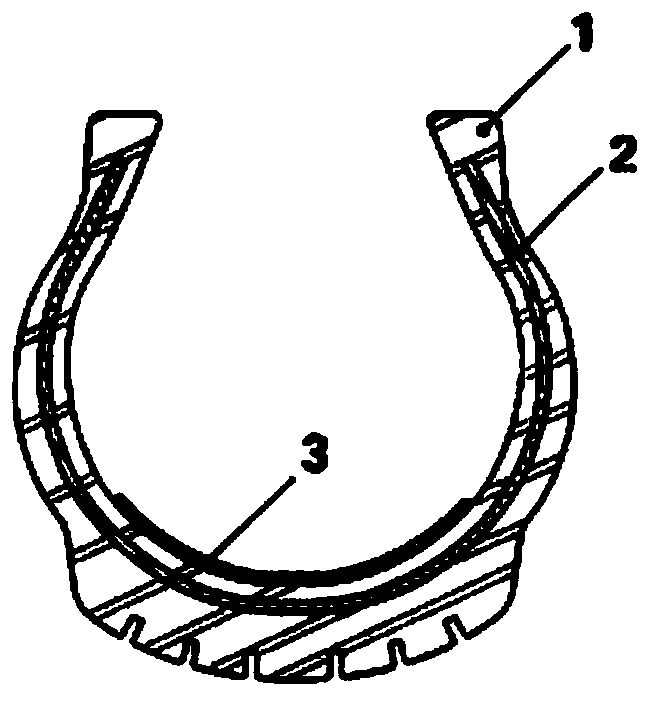

The invention relates to a bullet-proof security tire and a manufacturing method of a self-sealing polymer material used in the bullet-proof security tire. The bullet-proof security tire is characterized in that damaging or destructive processing is not required to be carried out on the surface of the inner wall of an automobile tire, and an elastic self-sealing layer made of the self-sealing polymer material and an organic protective layer with the thickness of 2.5-5mm are only sprayed onto the surface of the inner wall of the tire; the automobile tire has the safety performances such as bullet resistance, leakage resistance and pricking resistance within the temperature range of -45 to 120 DEG C; the invention also discloses the self-complement self-sealing polymer material and a manufacturing method of the bullet-proof security tire. The technical scheme provided by the invention is suitable for the production of the automobile tire and the security upgrade of the common automobile tire.

Owner:LUOYANG JUNTENG ENERGY TECH

Self-sealed tire adhesive and preparation method thereof

InactiveCN103849292ASuperior elasticity and extensibilityPrevent leakageCoatingsAutomotive engineeringPlasticizer

The invention discloses a self-sealed tire adhesive for security upgrading of an automobile tire. The adhesive comprises the following components in parts by mass (taking 100 parts by mass of thermoplastic elastomer as the standard): 100 parts of thermoplastic elastomer, 140-160 parts of tackifier, 100-120 parts of plasticizer, 4 parts of anti-aging agent and / or antioxidant 4 and 6-8 parts of filling agent. The self-sealed tire adhesive disclosed by the invention is sprayed onto the inner wall of the tire by using an automobile tire adhesive spraying machine, the inner wall of the automobile tire is prevented from generating any damage processing but is only subjected to washing by a demolding agent and drying treatment, the self-sealed tire adhesive that the thickness is greater than 3.5mm is sprayed on the whole inner wall or the crown-shaped part of the automobile tire, thus the ordinary automobile tire can be upgraded into a bulletproof, anti-leakage and pricking-resisting automobile tire which can work normally within a temperature range from a low temperature of minus 40 DEG C to a high temperature +120 DEG C. The invention further discloses a preparation method of the self-sealed tire adhesive.

Owner:LUOYANG JUNTENG ENERGY TECH

Self-sealed tyre leak-repairing glue and preparation method thereof

InactiveCN103805113AIncrease elasticityImprove ductilityMineral oil hydrocarbon copolymer adhesivesPlasticizerThermoplastic elastomer

The invention relates to self-sealed tyre leak-repairing glue for security upgrade of an automobile tyre. The self-sealed tyre leak-repairing glue comprises the following components in percentage by weight: 40-60% of a thermoplastic elastomer, 34-51% of a tackifier, 5-8% of a plasticizer, and / or 0.5-1.5% of an antiaging agent and 2-5% of filler. The self-sealed tyre leak-repairing glue is sprayed on the inner wall of the tyre by an automobile tyre glue sprayer, the inner wall of the tyre is not destructively processed, and the release agent is just removed to clean and dry the inner wall of the tyre. The self-sealed tyre leak-repairing glue which is thicker than 3.5mm is sprayed on the whole or the crown part of the inner wall of the tyre, so that the tyre is upgraded to the tyre which can normally work from a low temperature of -40 DEG C to a high temperature of 120 DEG C. The tyre has the performances of elasticity resistance, leak prevention and prick resistance. The invention further discloses a preparation method of the self-sealed tyre leak-repairing glue.

Owner:LUOYANG JUNTENG ENERGY TECH

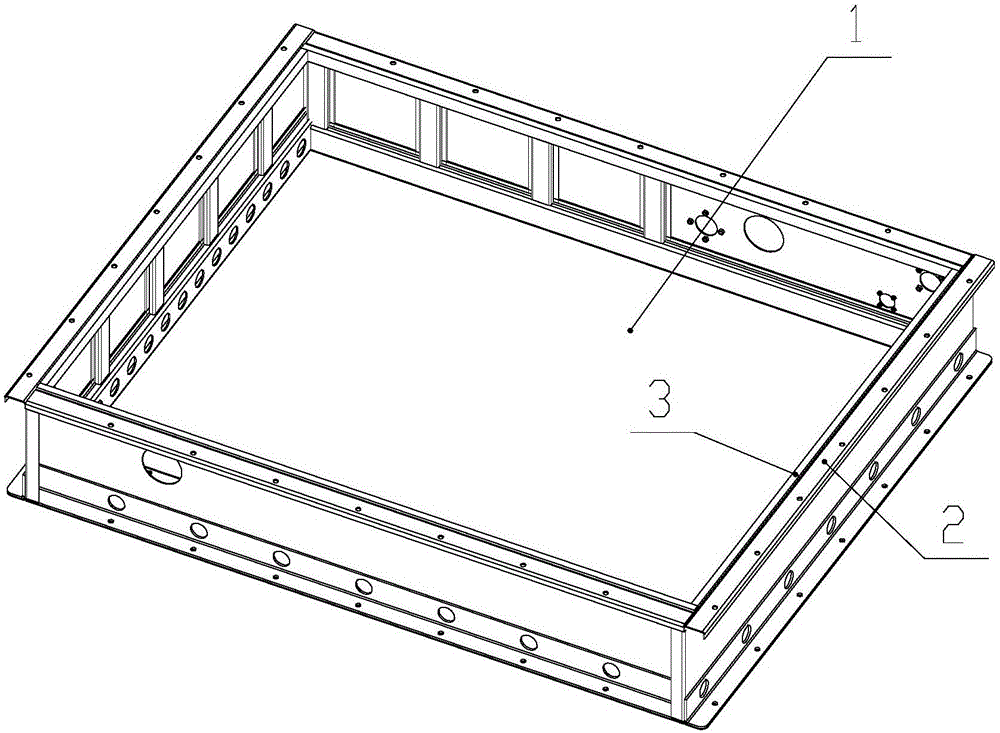

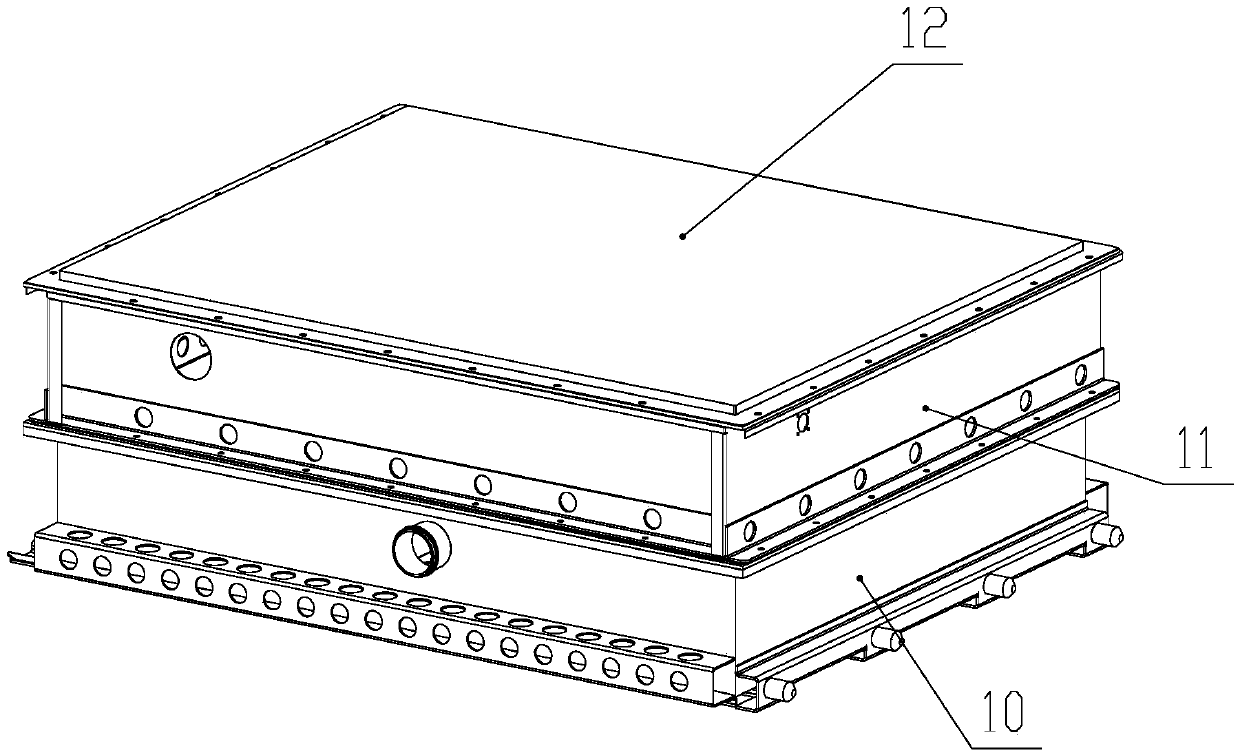

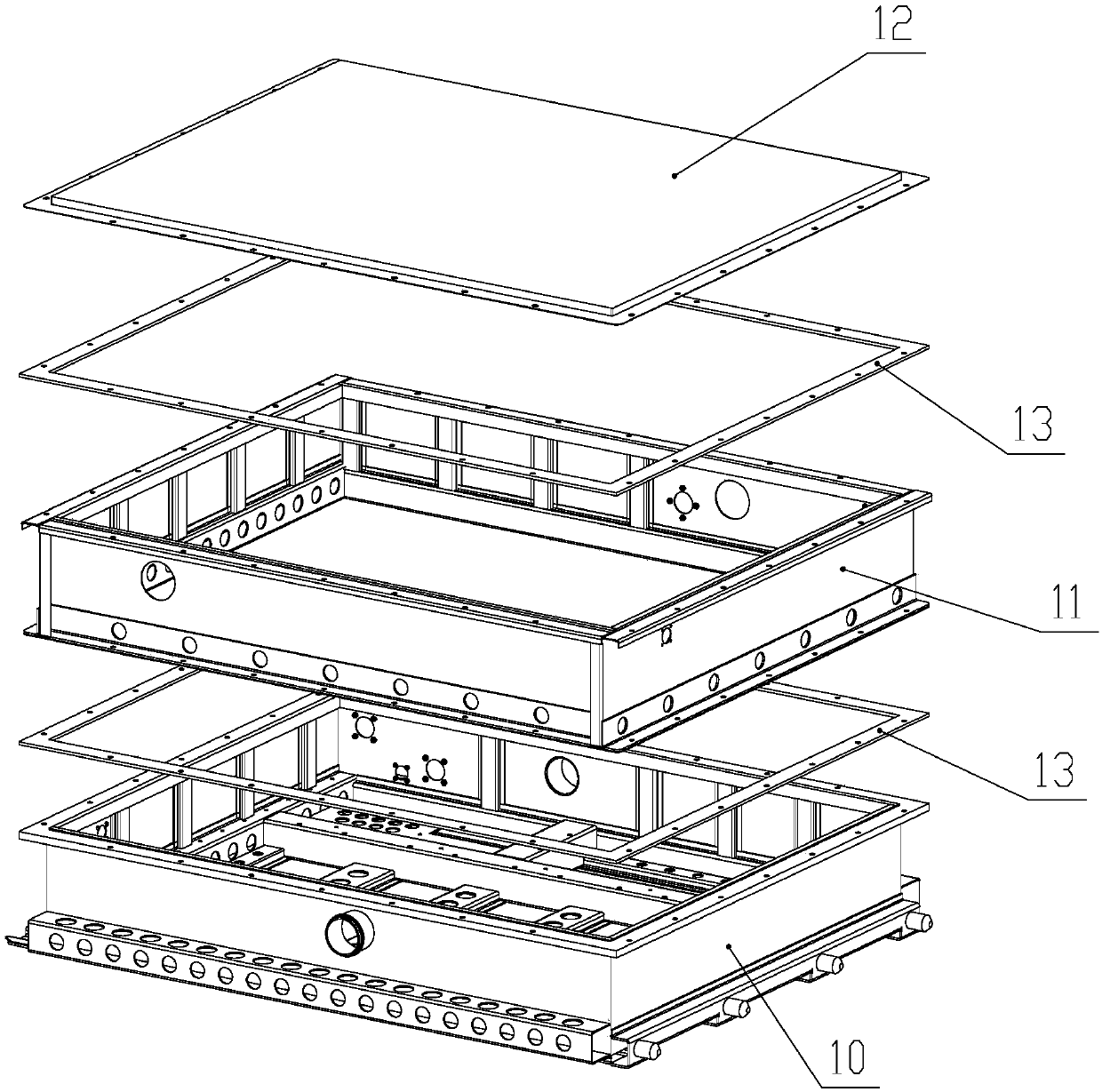

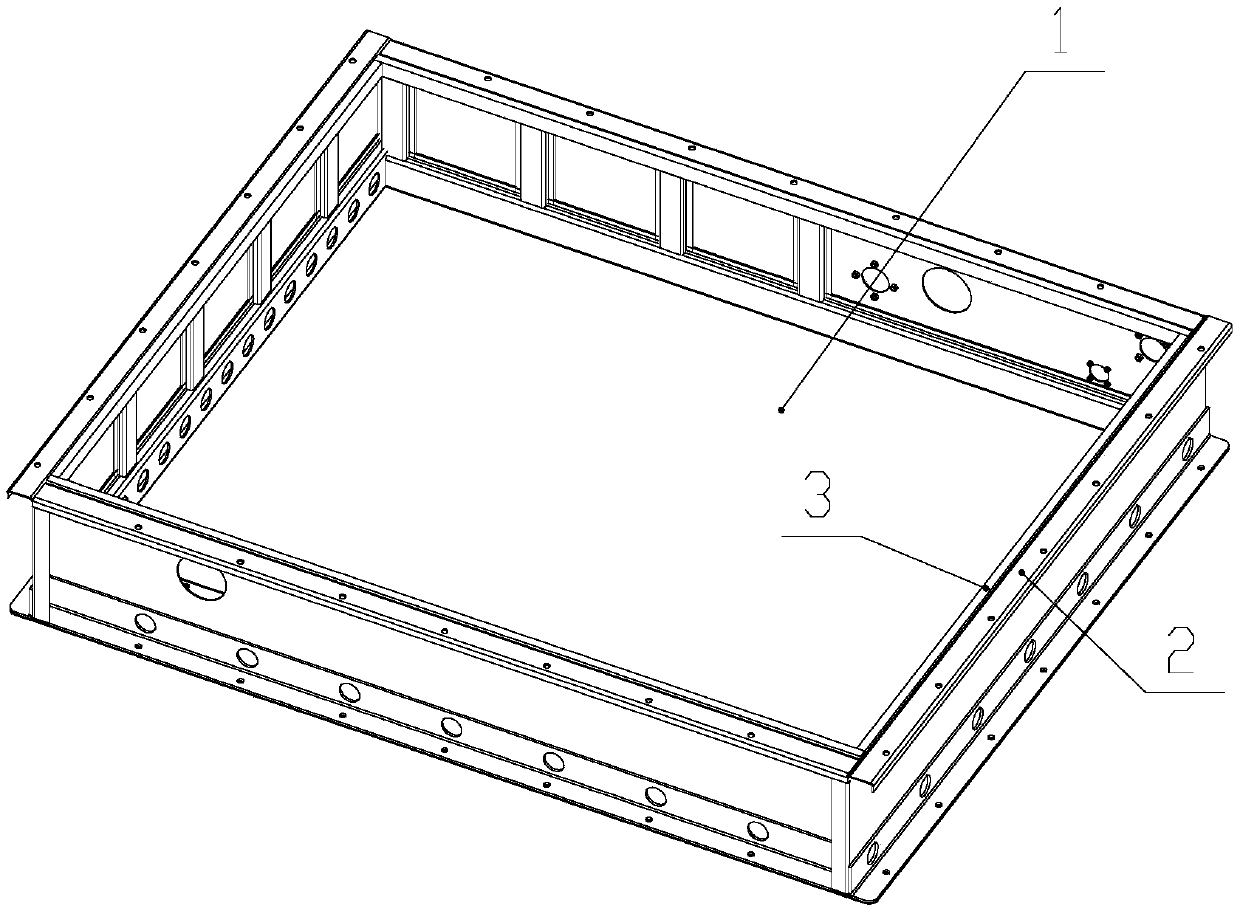

Stacked power battery pack box body

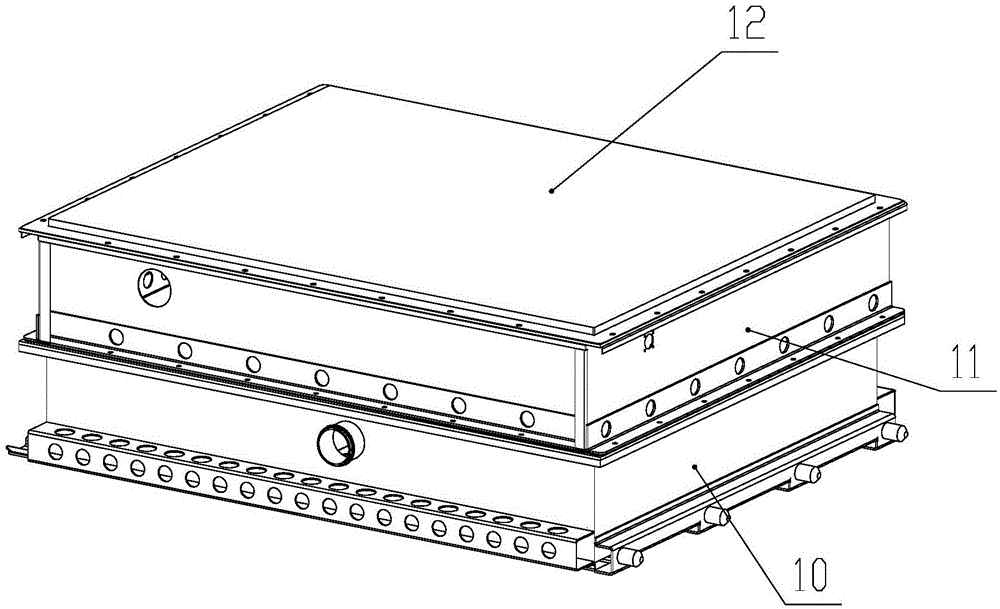

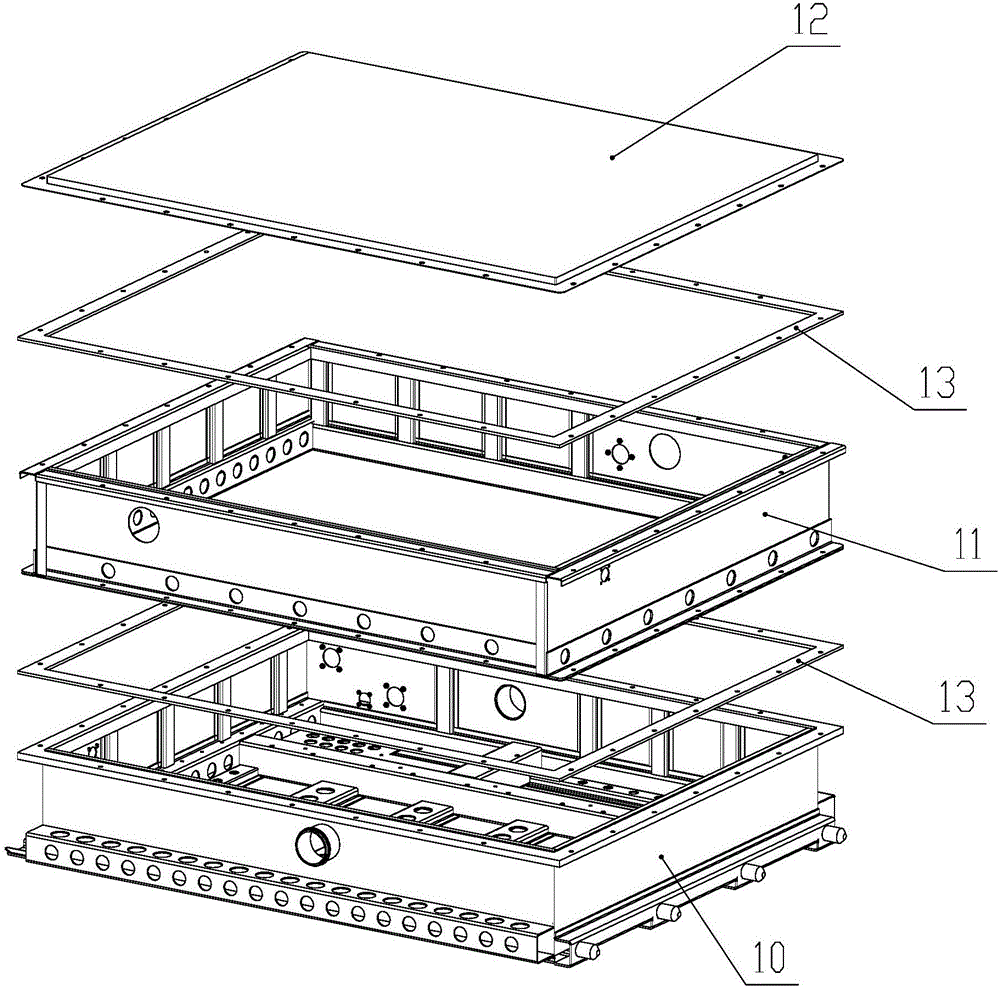

The invention relates to a stacked power battery pack box body. The box body comprises a lower-layer box body located on the bottommost layer and an upper-layer box body located on two or more layers, wherein the box bodies of all the layers are connected through flanges; the upper-layer box body comprises a bottom box, four side plates and four locating pipes; the bottom box adopts a cuboid box body structure with an upper open end and consists of a bottom plate and four fences vertically connected on the edges of the bottom plate; the four side plates are same in height; flange sides extending outwards are arranged at the top and bottom of each side plate; the four side plates are fixedly connected to the outer sides of the fences respectively; the lower surfaces of the side plates are flush with the lower surface of the bottom box; the four locating pipes are transversely fixed on the inner sides of the four side plates respectively; the upper surfaces of the four locating pipes are flush; and the upper surfaces of the four locating pipes are higher than the upper surfaces of the side plates. The box body is no need of a bracket due to multilayer direct installation and arrangement, and is reasonable in structure, higher in strength and better in seal property.

Owner:BEIJING PRIDE NEW ENERGY BATTERY

Elasticity-proof, leakage-proof and prick-resistant macromolecular material for automobile tyres

InactiveCN103804836AReduce viscosityAdjust heat resistance temperatureSpecial tyresPlasticizerThermoplastic elastomer

The invention relates to an elasticity-proof, leakage-proof and prick-resistant macromolecular material for automobile tyres. The elasticity-proof, leakage-proof and prick-resistant macromolecular material for automobile tyres comprises the following components in percentage by weight: 42-62% of a thermoplastic elastomer, 34-54% of a tackifier, 3-8% of a plasticizer, 0.5-1.5% of an antioxidant and 0-3% of a curing agent. According to the technical scheme provided by the invention, a common automobile tyre can be upgraded to into a high-temperature-resistant, low-temperature-resistant, elasticity-proof, leakage-proof and prick-resistant automobile tyre.

Owner:LUOYANG JUNTENG ENERGY TECH

Preparation method of adhesive for architectural engineering

InactiveCN104592902AFully curedAnti-vibrationNon-macromolecular adhesive additivesOrganic non-macromolecular adhesiveMethacrylateMass ratio

The invention discloses a preparation method of an adhesive for architectural engineering. The preparation method is characterized in that the adhesive comprises triuret ethylene glycol bis-methyl acrylate, cumyl hydroperoxide, 1,2,3,4-tetrahydroquinoline, p-benzoquinone, p-toluene sulfonic acid, saccharin, polystyrene, polyacetal ethylene glycol dioctyl phthalate and colloidal silicon dioxide in a mass ratio of 110:3.4:0.5:(0.06-0.08):0.2:0.3:15:14:11. In a metal adhesion process, the curing within 30 minutes is complete; moreover, the adhesive has functions of preventing vibration, leakage, corrosion and the like, and has very strong practicability.

Owner:中扬电力科技有限公司

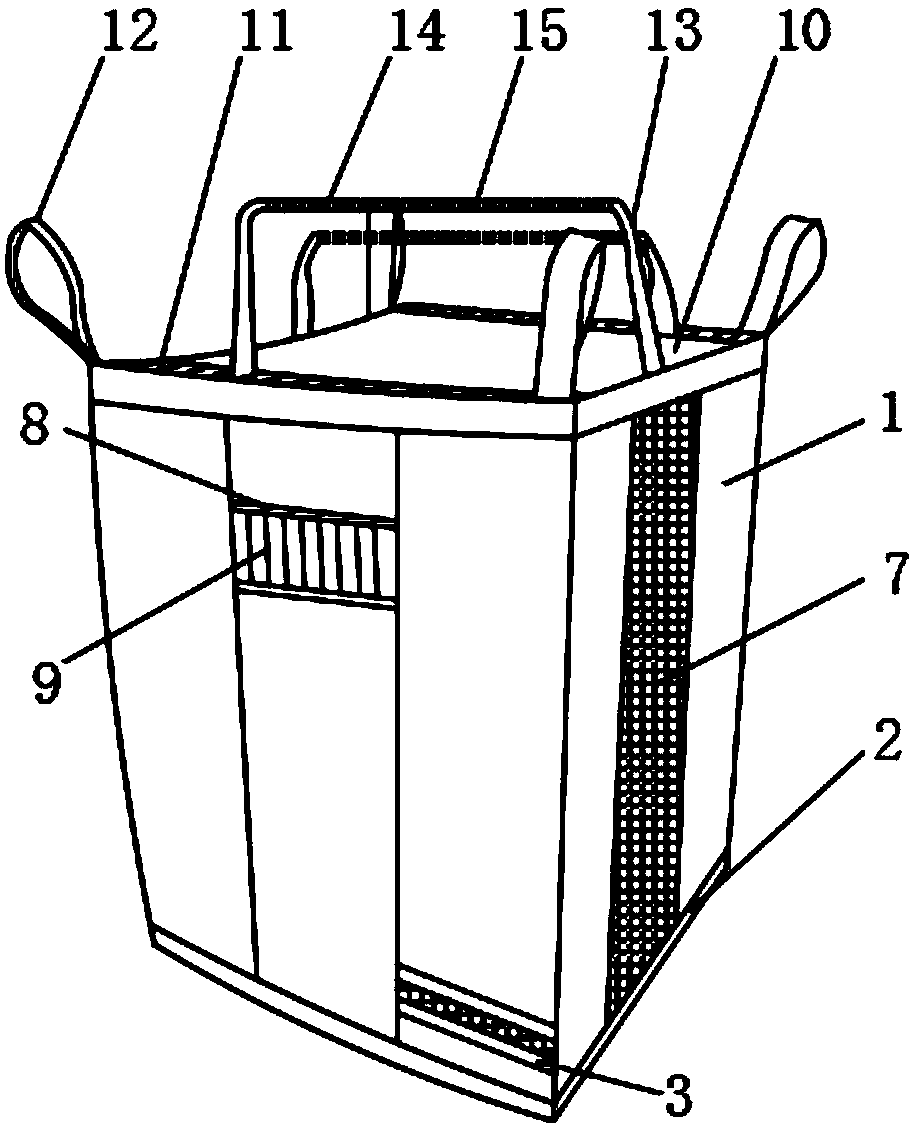

Dampproof leakage-proof compound container bag

The invention discloses a dampproof leakage-proof compound container bag. The dampproof leakage-proof compound container bag comprises a container bag body, a wear-resisting base, a standby storage chamber, a first zipper and a waterproof seal ring, wherein the wear-resisting base is arranged at the bottom end of the container bag body; the standby storage chamber is arranged in the position, positioned above the wear-resisting base, of the lower part of the container bag body; the first zipper is arranged on the outer side of the standby storage chamber; and the waterproof seal ring is arranged at the connection part of the first zipper and the standby storage chamber. According to the dampproof leakage-proof compound container bag, integral wear resistance is improved, integral service life is prolonged, the integral material storage function is improved, scattered objects are conveniently stored, a user better knows objects in the container bag, conveniently locates the objects at night, conveniently searches the objects, and better tightens and carries the container bag, the objects are classified and stored, integral classification storage capacity is improved, and the integral dampproof leakage-proof compound container bag has certain dampproof, leakage-proof and fireproof properties.

Owner:NANTONG LIANRONG GRP

Condom

InactiveCN101543439ACost advantage Comfortable to wearIncrease the lengthMale contraceptivesEngineeringPenis

The invention provides a condom which comprises a closed end, an opened end, a tubular condom body and an elastic ring, wherein the tubular condom body is positioned between the closed end and the opened end, and the elastic ring is arranged on the opened end. The condom is characterized in that an end cap device made of nontoxic elastic material is fixedly sleeved on the external end of the closed end. The invention has the advantages of preventing premature ejaculation, strengthening, preventing leakage, aiding to increase the length, strengthening the physical stimulation action, and the like.

Owner:宁小静

Swimming safety paste

PendingCN106880438AImprove adhesionImprove breathabilityBathroom accessoriesBodily discharge devicesAnimal scienceMedicine

The invention discloses swimming safety paste, and belongs to the field of swimming and sports equipment facilities. The swimming safety paste is mainly composed of a main part, an opening and a pipeline, wherein the position, at female genitalia, of the main part is provided with the opening, the vertical axis of the opening coincides with that of the main part, the lower portion of the opening is provided with the pipeline, the pipeline is connected to the main part in a sealed mode, and the inner wall of the pipeline is provided with a drainage pipeline. The swimming safety paste solves the problem that contaminated water has a negative impact on genitals when female people swim. The swimming safety paste is mainly made from silica gel, is pasted outside the genitals so that the genitals can be safely isolated from water, and thus the swimming safety paste is a female hygienic supply which is convenient for urinate and menstrual blood to discharge. The swimming safety paste guarantees that female people can freely swim whenever at ordinary times or during menstruation, breeding of inflammation caused by invasion of bacteria is avoided, and thus the swimming safety paste is the safe hygienic supply for protecting the reproductive health of the female people.

Owner:孙秋云

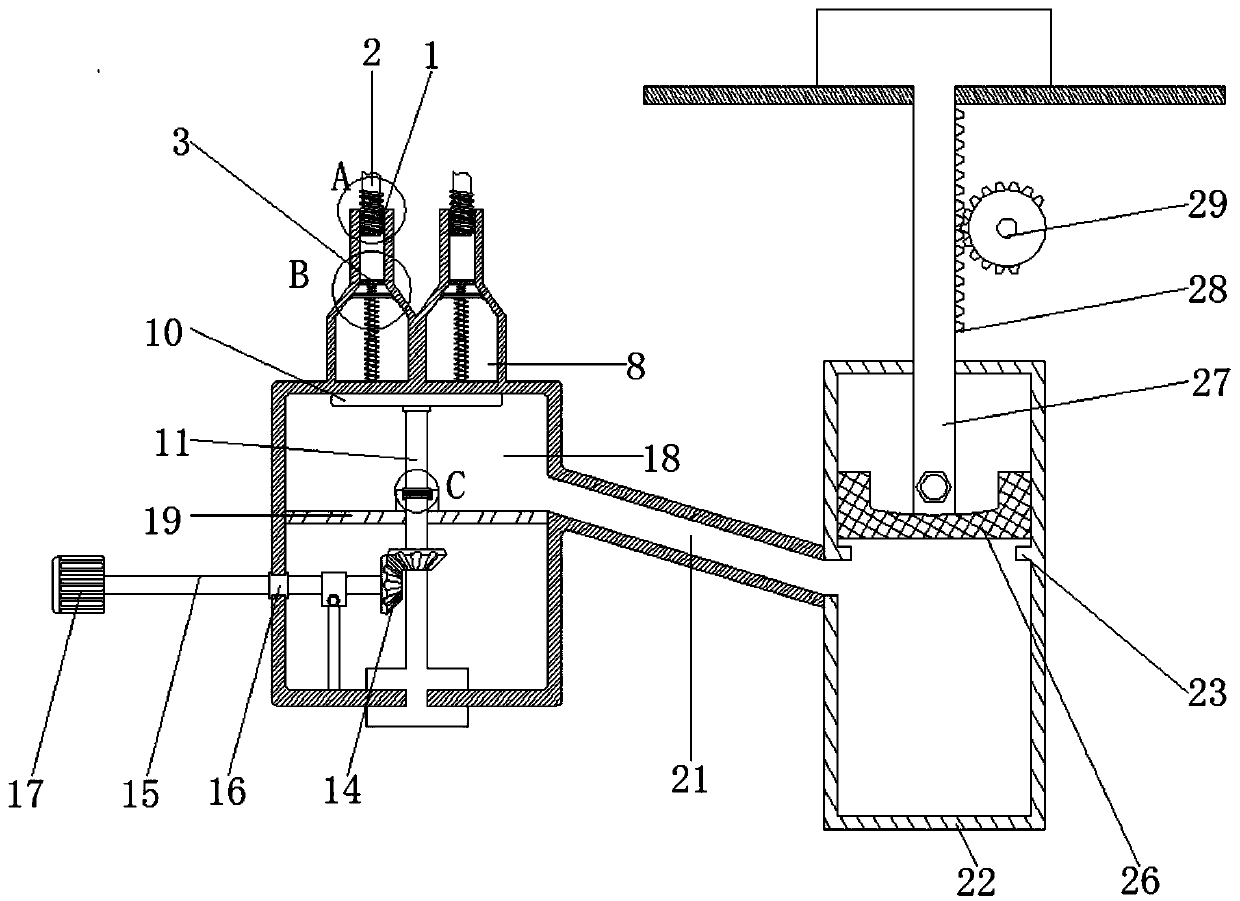

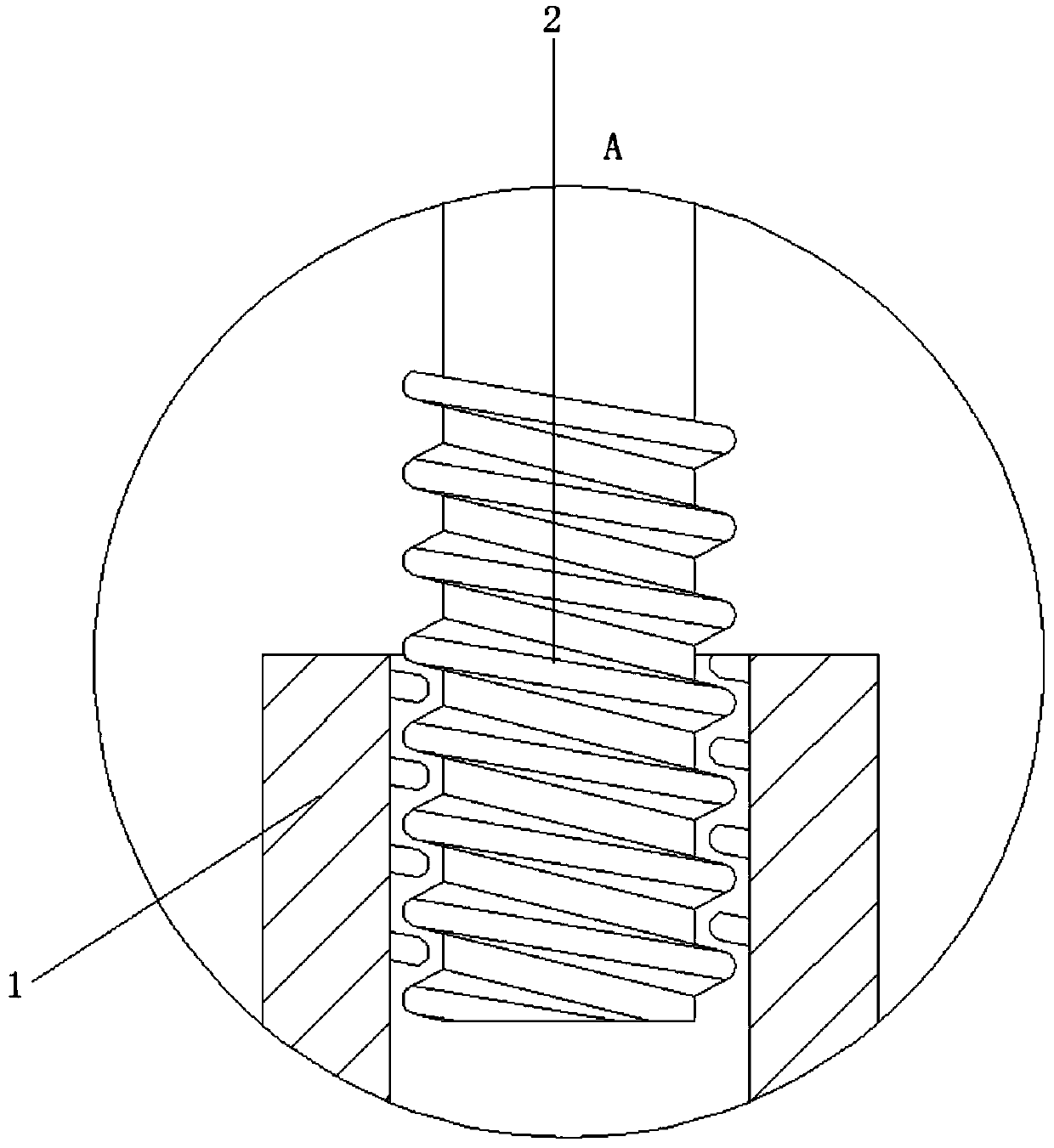

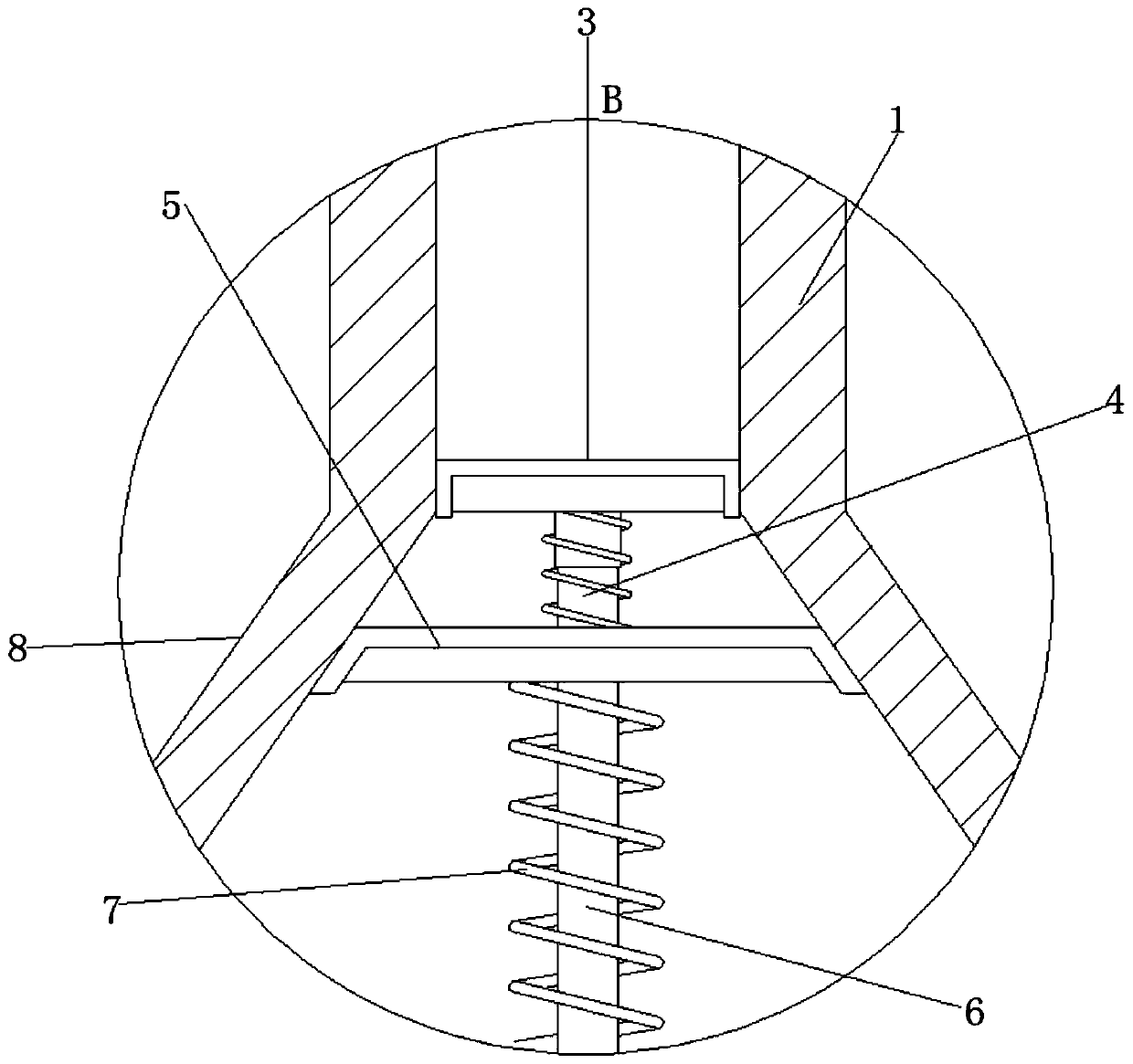

Environment-friendly water valve with adjustable temperature and more water saving

InactiveCN111503347AEasy to adjustLeakproofOperating means/releasing devices for valvesMultiple way valvesWater leakagePiston

The invention relates to the technical field of environmental protection, and discloses an environment-friendly water valve with an adjustable temperature and more water saving. The environment-friendly water valve with the adjustable temperature and more water saving comprises a water inlet. A water pipe is movably connected into the water inlet, the end, away from the water pipe, of the water inlet is movably connected with a first-level water-leakage prevention platform, the bottom of the first-level water-leakage prevention platform is movably connected with a first-level telescopic rod, the bottom of a water inlet container is movably connected with a rotary valve, and the inner wall of a mixing container is movably connected with a water-stop sheet. According to the environment-friendly water valve with the adjustable temperature and more water saving, through the expansion and contraction of the first-level telescopic rod and a second-level telescopic rod, water leakage is prevented or waste of water resources is prevented under the condition that people forget to close a faucet, the end, away from a sword gear, of a transmission shaft is movably connected with a regulatingtable, cold water and hot water can be adjusted at the same time, the problem that water temperature is not adjusted well is solved, the inner wall of a water outlet container is movably connected with a pneumatic piston, the water pressure of the water flow is improved through the air pressure, the stains are effectively cleaned, and the problem of waste of the water resources is solved.

Owner:杭州秦夜商贸有限公司

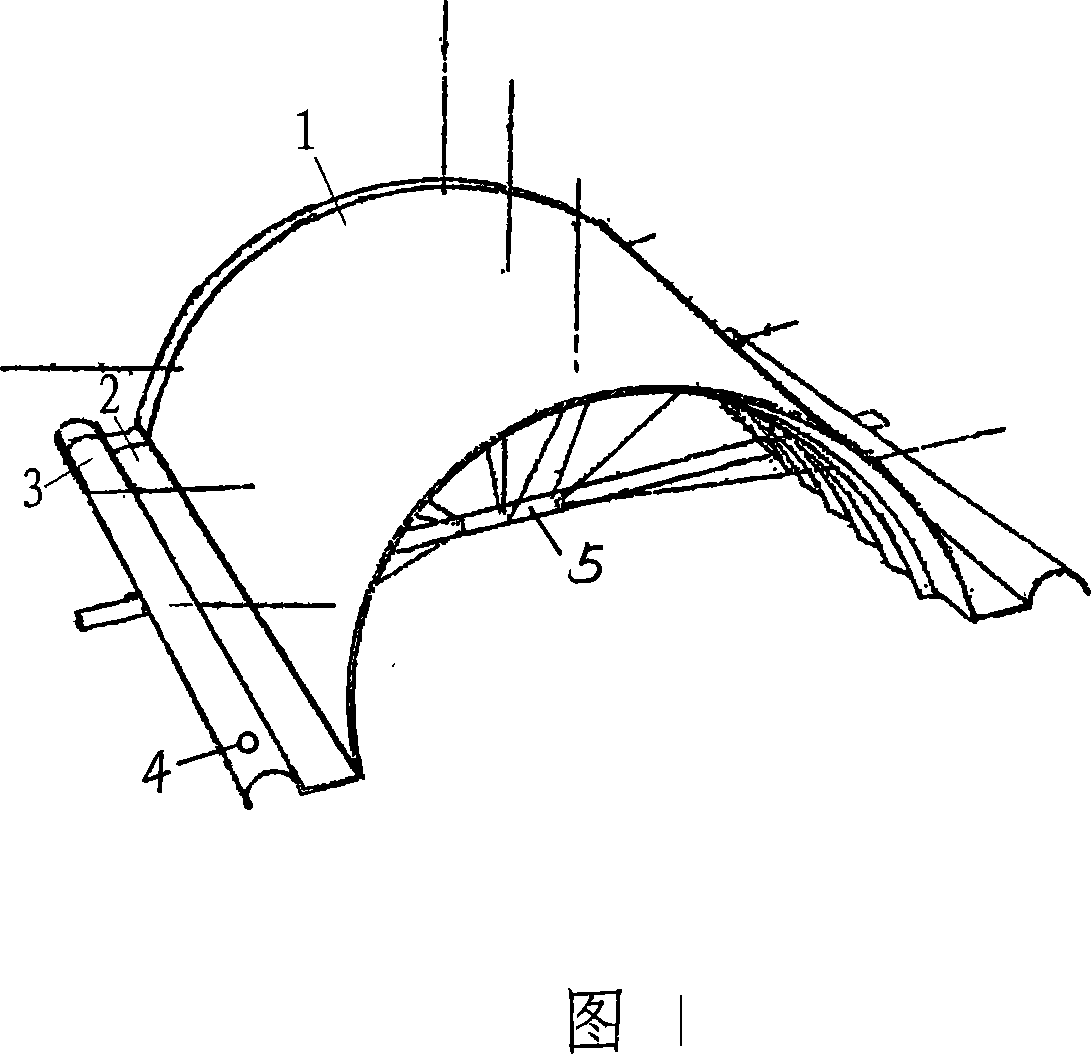

Sunlight tile

InactiveCN101046121AAchieve positioning and focusIncrease heat absorption areaSolar heating energyRoof covering using slabs/sheetsFresnel lensEngineering

The sunlight tile capable of absorbing solar energy effectively for utilization consists of two parts, including one light gathering tile and one heat exchange tube. The light gathering tile has outer arched or plate lighting surface and Fresnel lens in the inner side; and the heat exchange tube is set below the light gathering tile. The sunlight tile can absorb solar energy effectively and can realize adaptive tracking focusing without tracking unit except the traditional functions of keeping rain and hail out.

Owner:滕启林

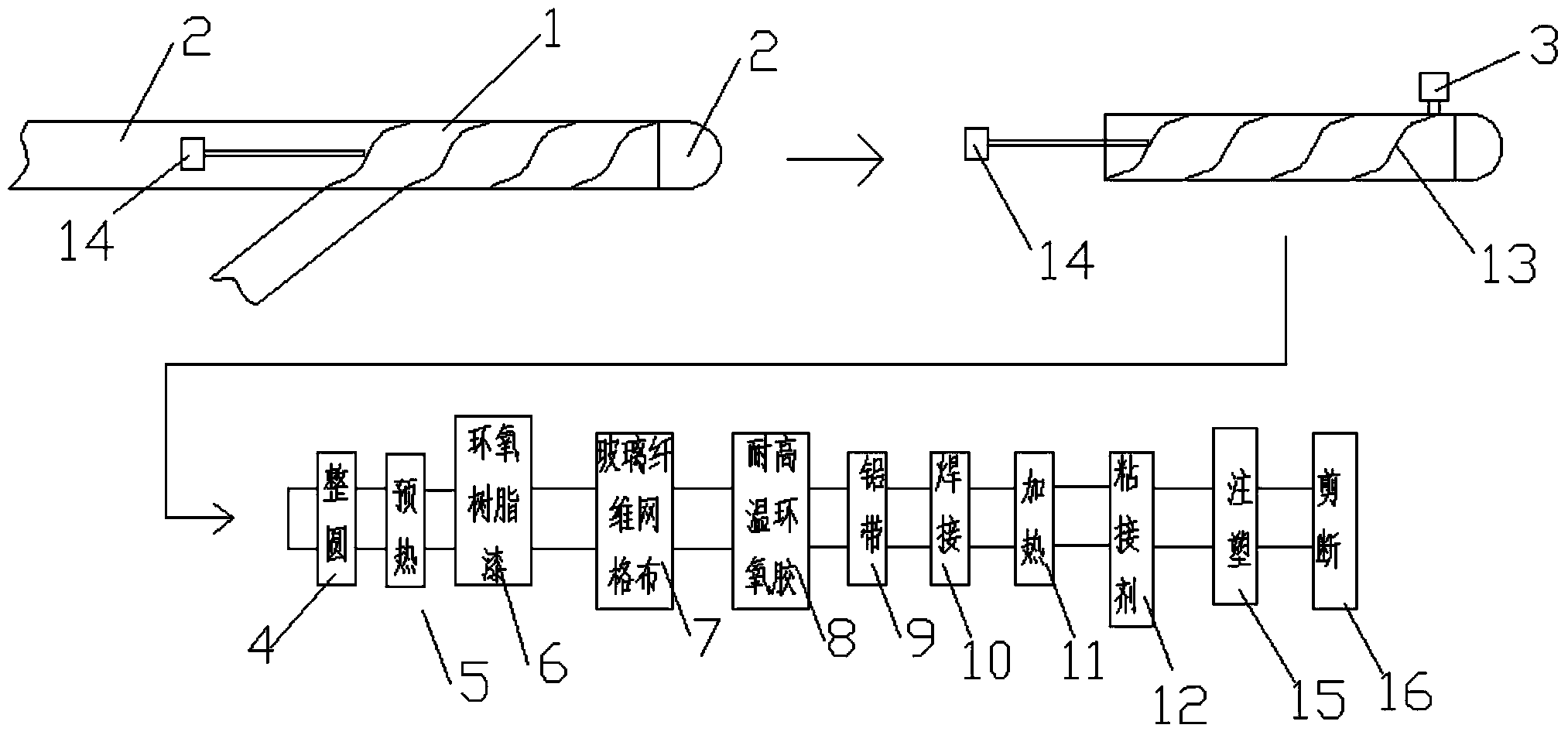

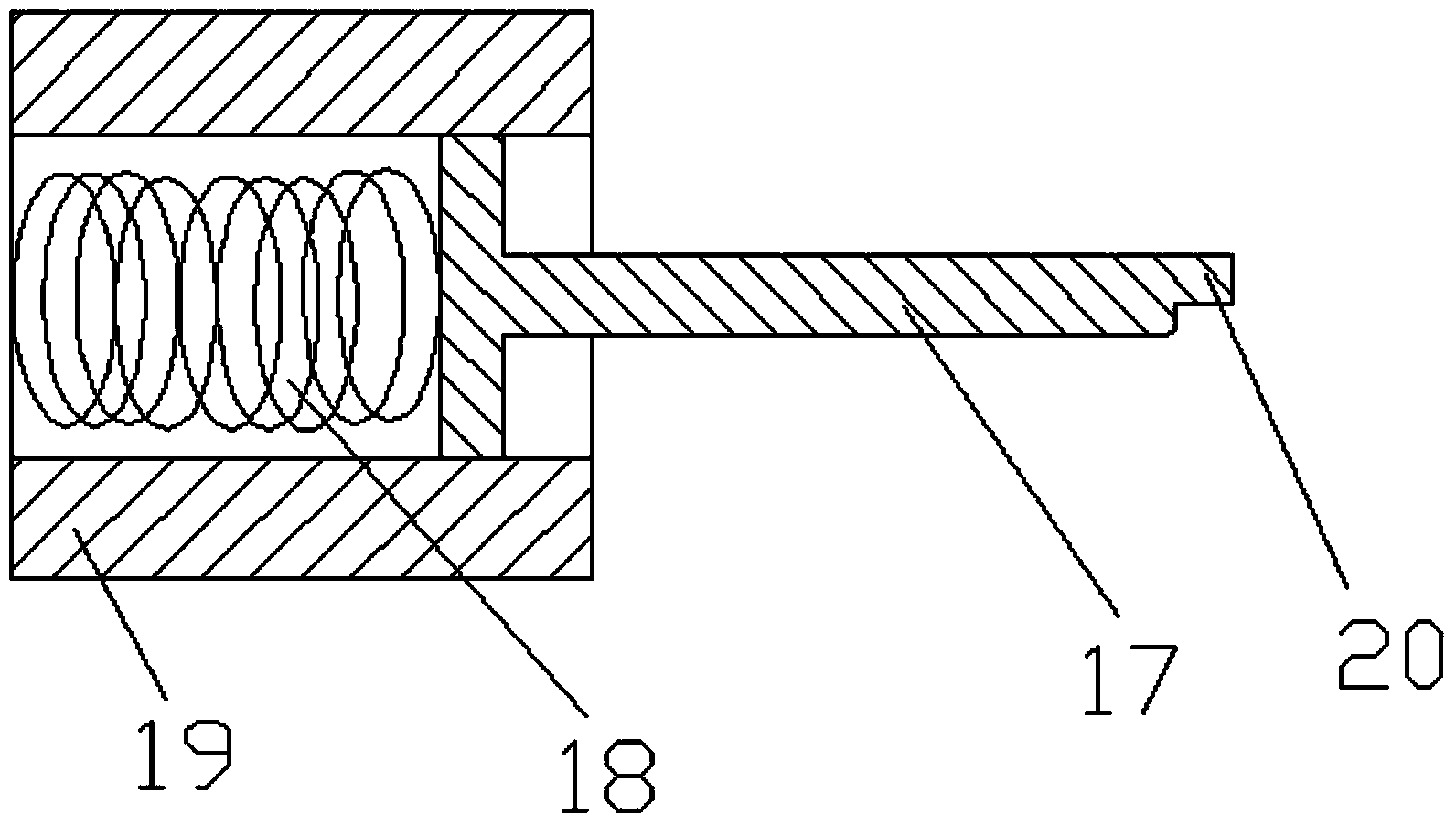

Manufacturing method of copper plastic pipe

The invention discloses a manufacturing method of a copper plastic pipe. The copper plastic pipe comprises a copper pipe; the copper pipe is coated with a fiberglass mesh; the outside of the fiberglass mesh is sprayed with high-temperature-resistant epoxy glue; a layer of aluminum tube is arranged outside the copper pipe sprayed with the high-temperature-resistant epoxy glue; a PPR material is formed outside the aluminum tube by injection molding. Thus, the manufacturing method of the copper plastic pipe, which has the advantages of smooth circumferential surface, complete smooth weld joints, heat preservation, large bearing capacity and high injection efficiency, is provided.

Owner:NINGBO YONGXIANG COPPER PIPELINE

Building material

InactiveCN104961430AImprove stress resistanceNo qualitative change will be foundChlorideSodium nitrite

The invention belongs to the field of mixing and preparation of a building material, specifically relates to a building material, and particularly relates to a building material. The building material is characterized by comprising the following components: magnesium oxide, magnesium chloride, catalyst sulfuric acid, sodium nitrite, quartz sand, silicon carbide and calcium oxide.

Owner:SINOMA CHENGDU ENERGY TECH

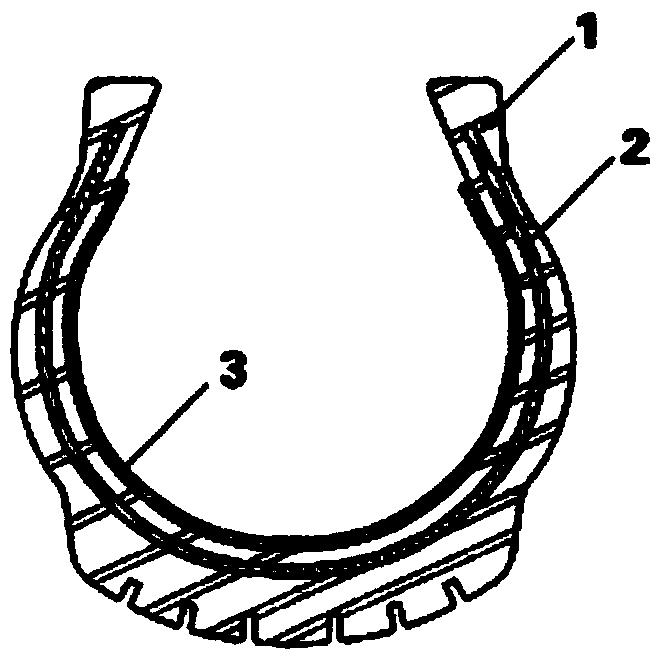

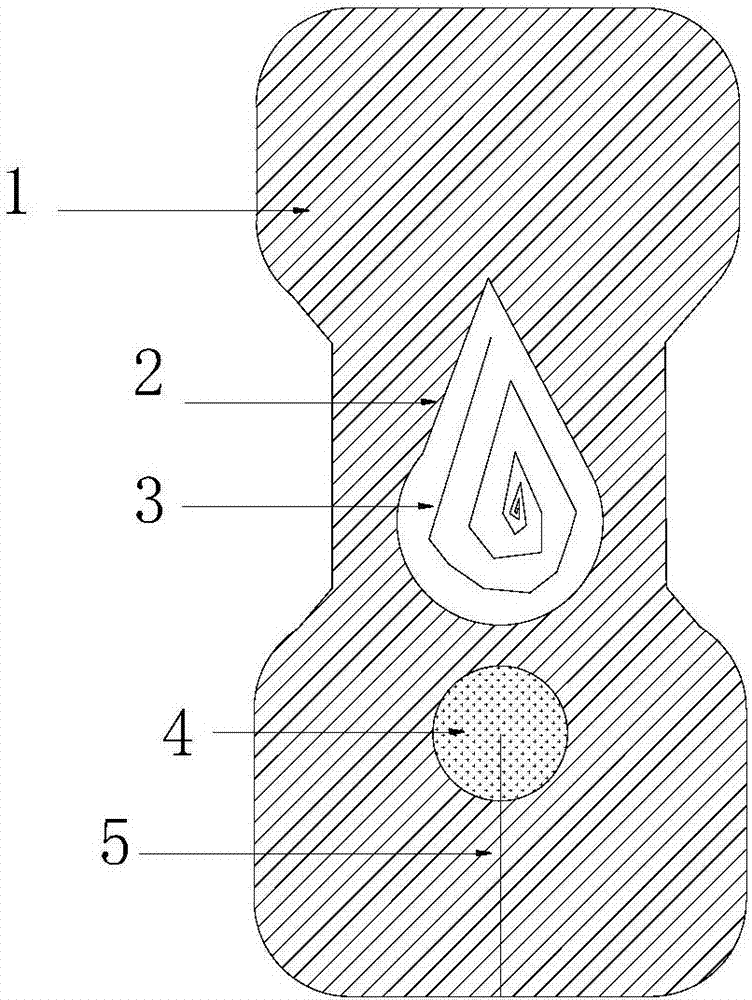

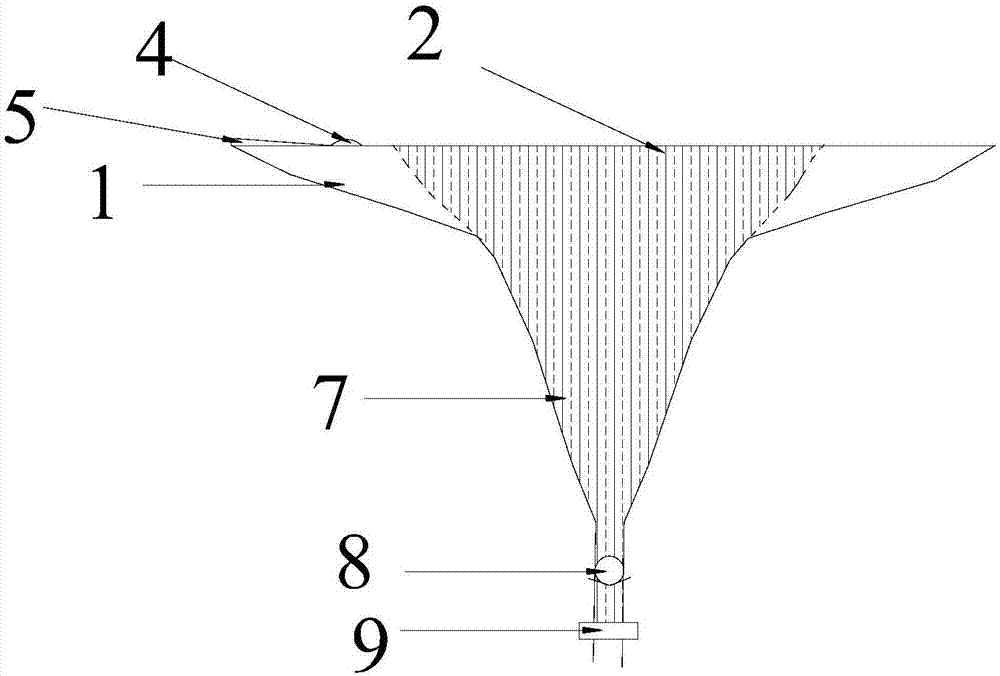

Rubber methane-generating pit

InactiveCN100478433CWaterproofLeakproofGas production bioreactorsWaste based fuelGlass fiberPolymer science

the invention discloses a glue powder of waste rubber, which is characterized by the following: removing sulfur under high temperature; melting through masticator; adding each mating agent within softener, accelerator, activator, antiager, reinforcing filler and vulcanizator; paving steel filament and glass fiber or canvas on the metal mould as frame; moulding the melted rubber; vulcanizing; preparing assembly part of rubber methane pool; finishing; assembling in-site; coating adhesive on the seam of each assembly part; sealing through rubber belt.

Owner:卢正伦

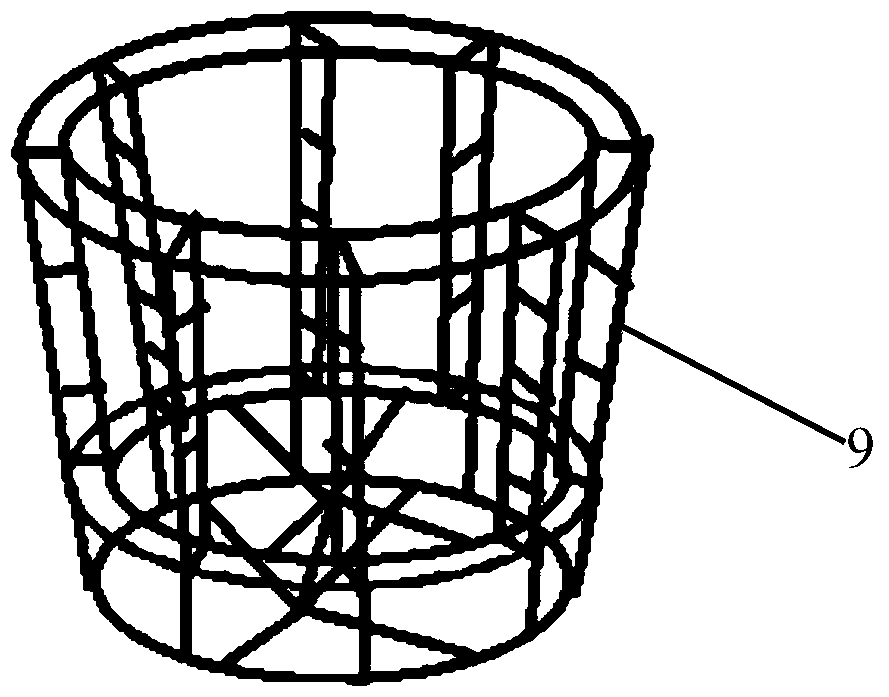

A laminated power battery pack box

The invention relates to a stacked power battery pack box body, which includes a lower box body located at the bottom and an upper box body located on the second floor or above, and the boxes of each layer are connected by flanges. The upper box includes a bottom box, side plates and positioning pipes; the bottom box is a cuboid box structure with an open upper end, consisting of a bottom plate and four enclosures vertically connected to the edge of the bottom plate; the side plates are four and the height is the same, the top and the bottom all have outwardly extending flange edges, the four side plates are respectively fixedly connected to the outer sides of the enclosure, the lower surface of the side plates is connected to the lower side of the bottom box The surface is even; there are four positioning tubes, which are respectively fixed laterally on the inner sides of the four side plates, the upper surfaces of the four positioning tubes are flush, and the upper surfaces of the four positioning tubes are higher than the side plates of the upper surface. The cabinet is multi-layered and directly installed without brackets; the structure is reasonable, the strength is higher, and the sealing performance is better.

Owner:BEIJING PRIDE NEW ENERGY BATTERY

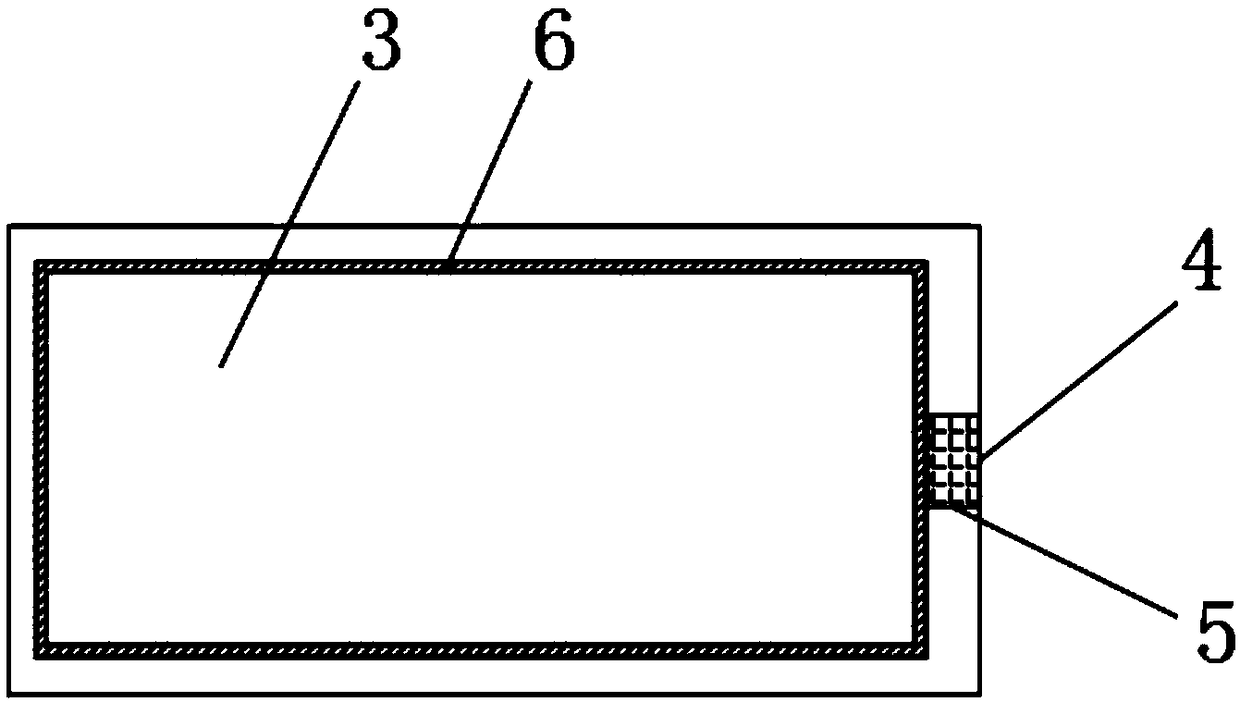

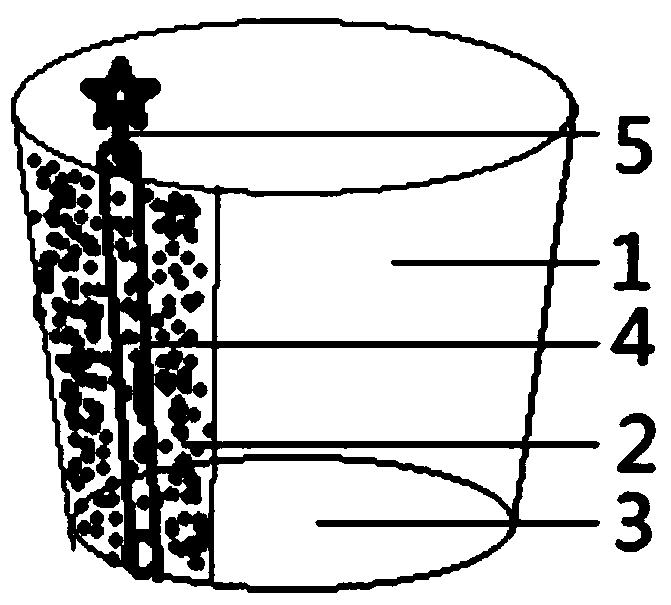

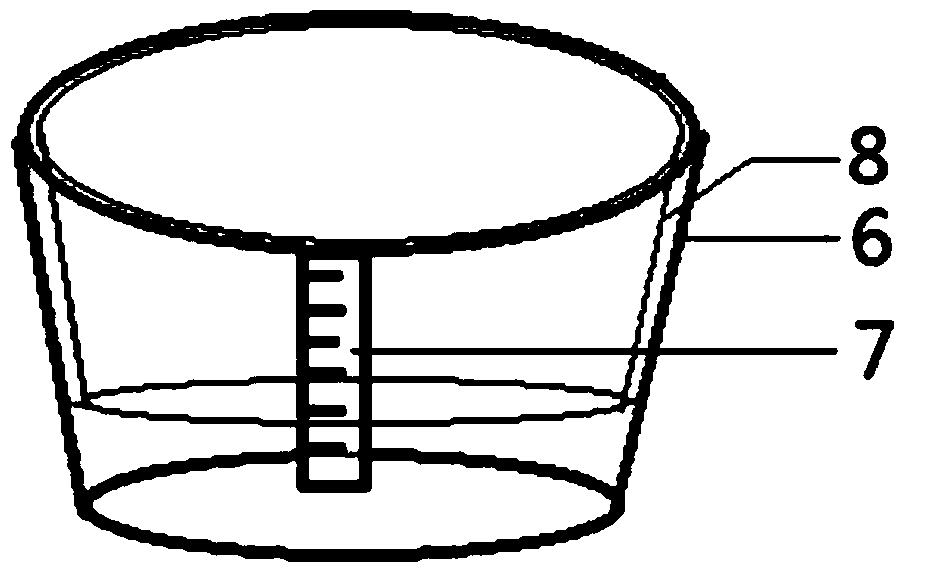

A multifunctional potted container

ActiveCN105052593BIncrease oxygen contentLeakproofDirect liquid fertiliser deliveryCultivating equipmentsWater leakageEngineering

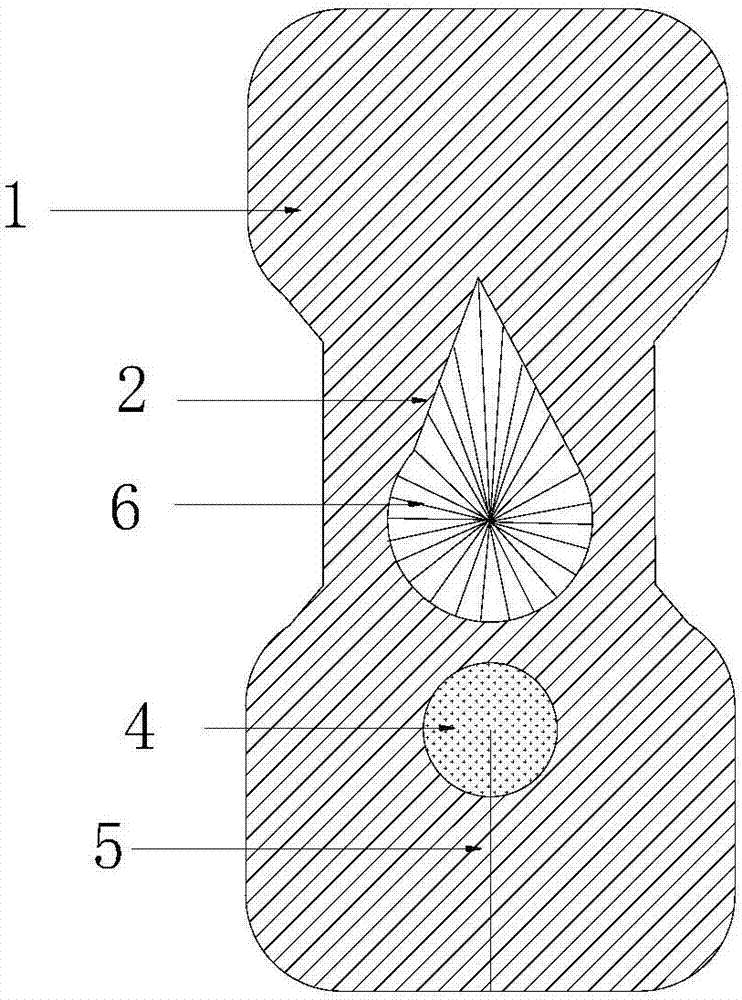

The invention discloses a multifunctional pot culture container which comprises an inner pot body I and an outer pot body II. A vertical airtight region on an inner pot wall (1) is a soil humidity indicating region (2) and the rest of the inner pot wall and an inner pot bottom (3) are ventilating regions. A slot (4) of a soil humidity indicating rod (5) which is attached to the inner side of the inner pot body I is arranged in the middle of the soil humidity indicating region (2). The hollow slot (4) is matched with the humidity indicating rod (5) which just can be tightly inserted. The multifunctional pot culture container disclosed by the invention has the benefits that the container various functions of storing water, preventing water leakage, not watering from the surface of soil, controlling the water amount, ventilating in an omnibearing manner, indicating the soil humidity, automatically adding fertilizers and the like. The multifunctional pot culture container improves the oxygen content near the root system and some plants with strict requirements on permeability of soil can be cultured by conventional soil.

Owner:山东分秒智能装备有限公司

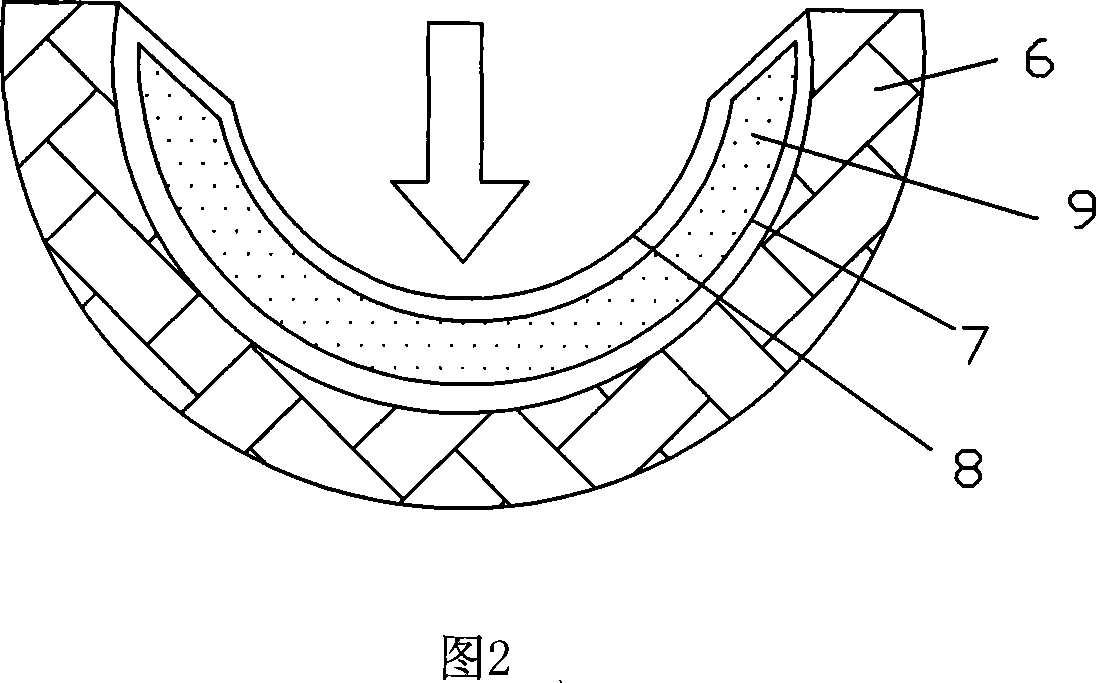

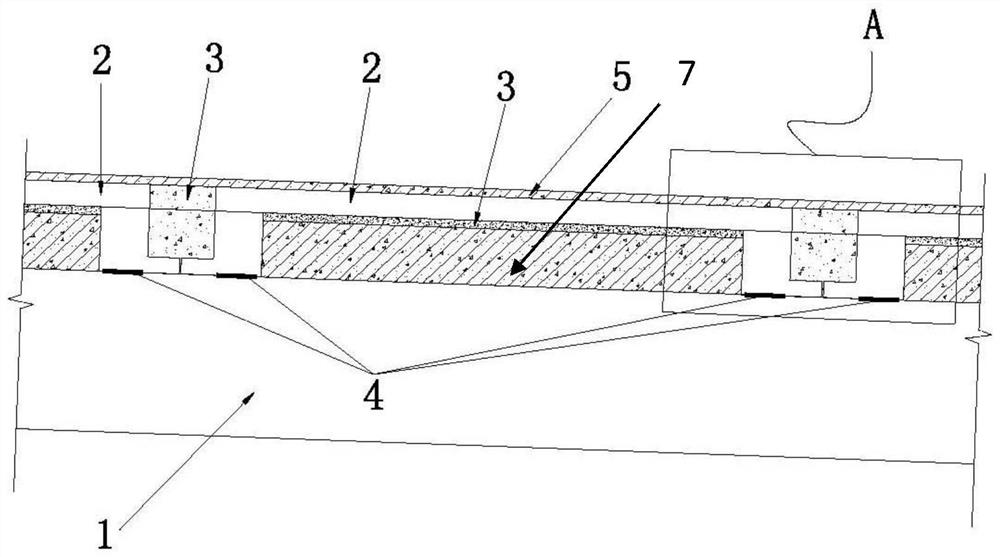

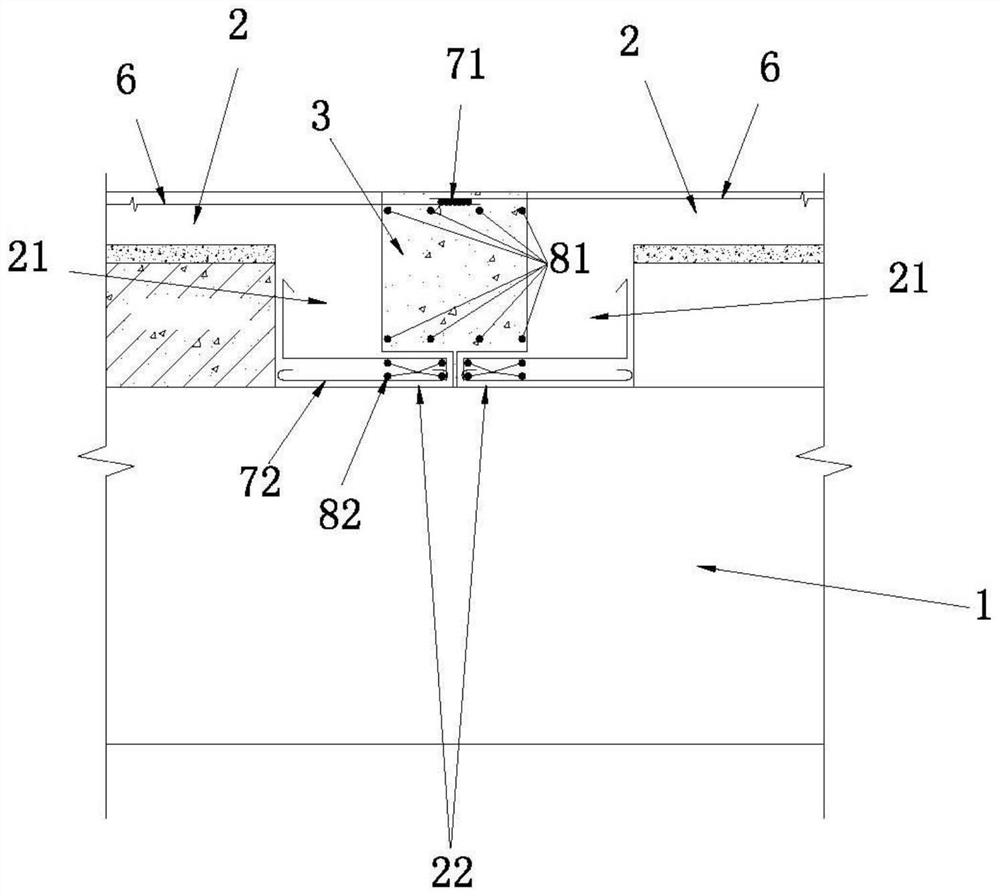

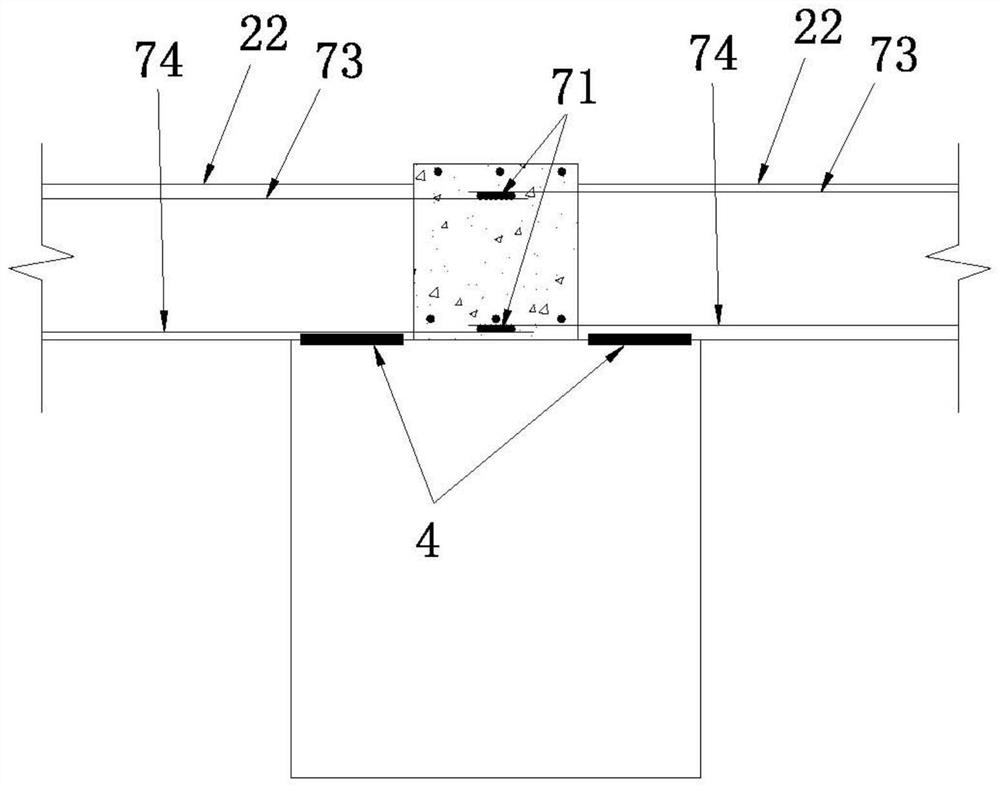

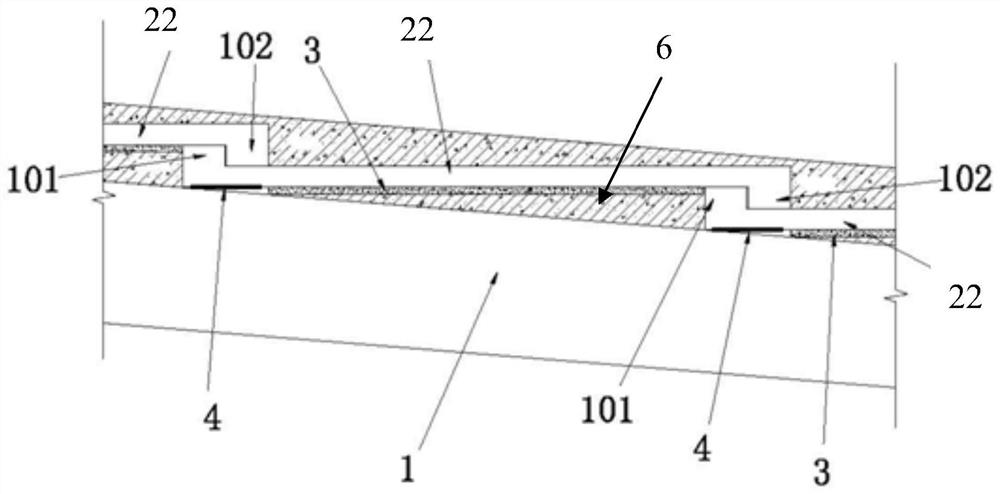

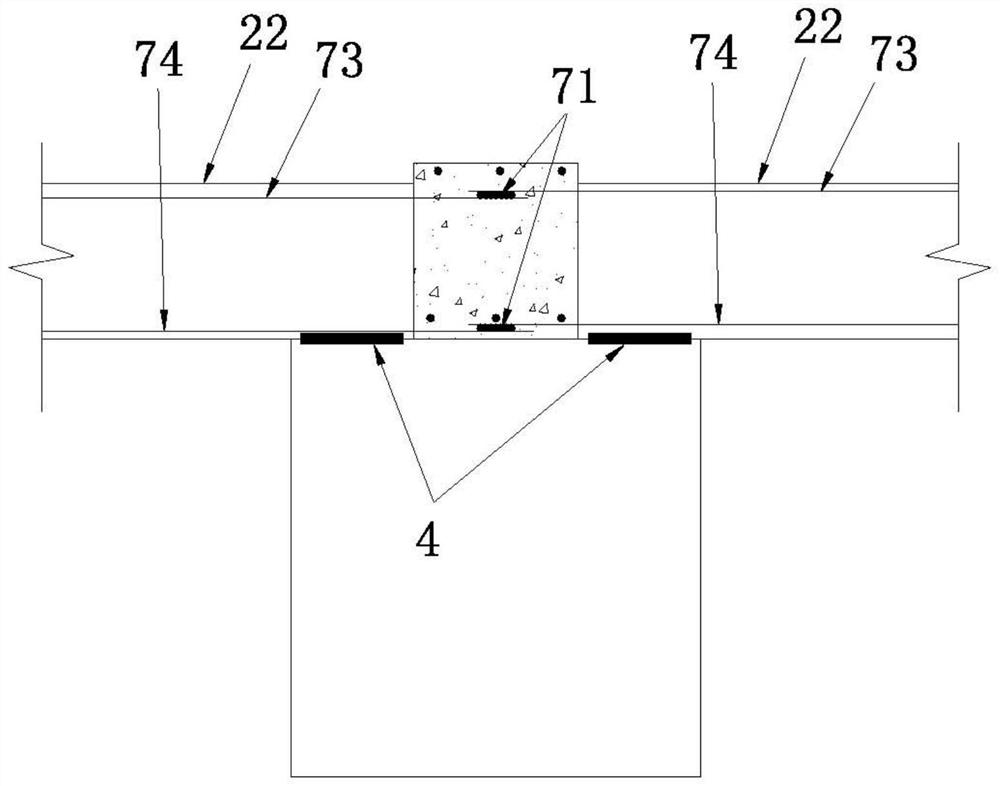

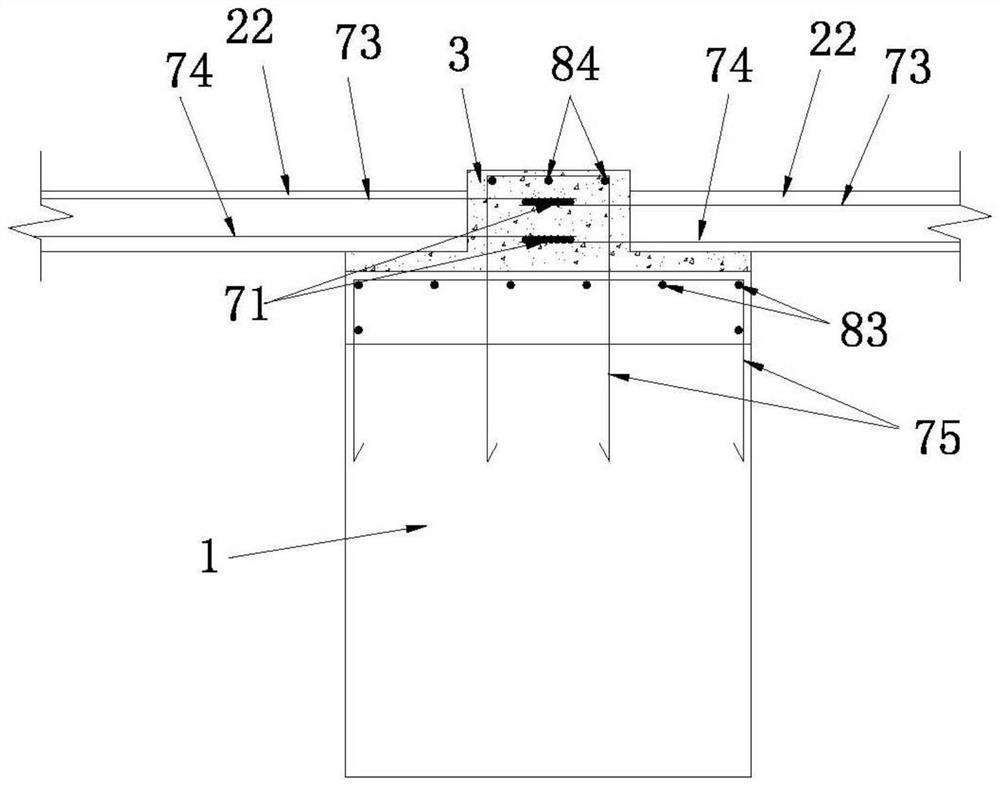

Prefabricated floor slab small-slope roof structure, construction method and prefabricated floor slab

PendingCN114809411AGood effectReduce labor intensityRoof covering using slabs/sheetsBuilding roofsFloor slabArchitectural engineering

The invention discloses a prefabricated floor slab small-slope roof structure, a construction method and prefabricated floor slabs, the prefabricated floor slab small-slope roof structure comprises a frame beam and a plurality of prefabricated floor slabs laid on the frame beam, the prefabricated floor slabs are continuously arranged in rows in the slope direction of a slope roof, the multiple rows of prefabricated floor slabs are arranged at intervals in the direction perpendicular to the slope, and each prefabricated floor slab comprises a slab body; the front end and the tail end of each slab body extend downwards to form longitudinal sections and then are bent outwards to form butt joint parts, the butt joint parts of every two adjacent prefabricated floor slabs in each row are oppositely combined to form a filling area defined by the longitudinal sections and the butt joint parts, and gaps are formed between the prefabricated floor slabs and the frame beams. Gaps communicated with the gaps and the filling areas are formed in the two sides of each row of prefabricated floor slabs, and the gaps, the gaps and the filling areas are filled with concrete, so that all the prefabricated floor slabs and the frame beam are fixedly connected through the concrete, and every two adjacent prefabricated floor slabs are fixedly connected through the concrete. The device is simple and compact in structure, meets the safety requirement, is simple and convenient to assemble on site, reduces the construction difficulty and labor intensity, and improves the working efficiency.

Owner:GUANGDONG PROVINCE COMM PLANNING & DESIGN INST

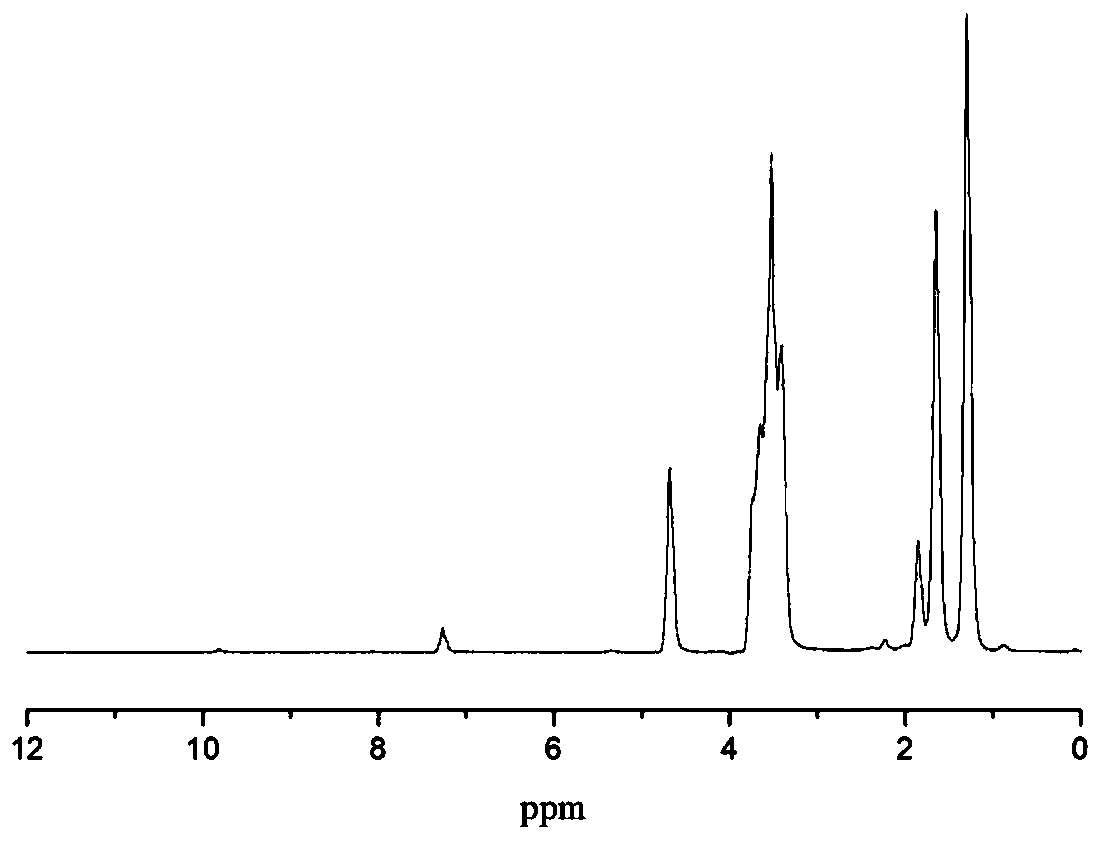

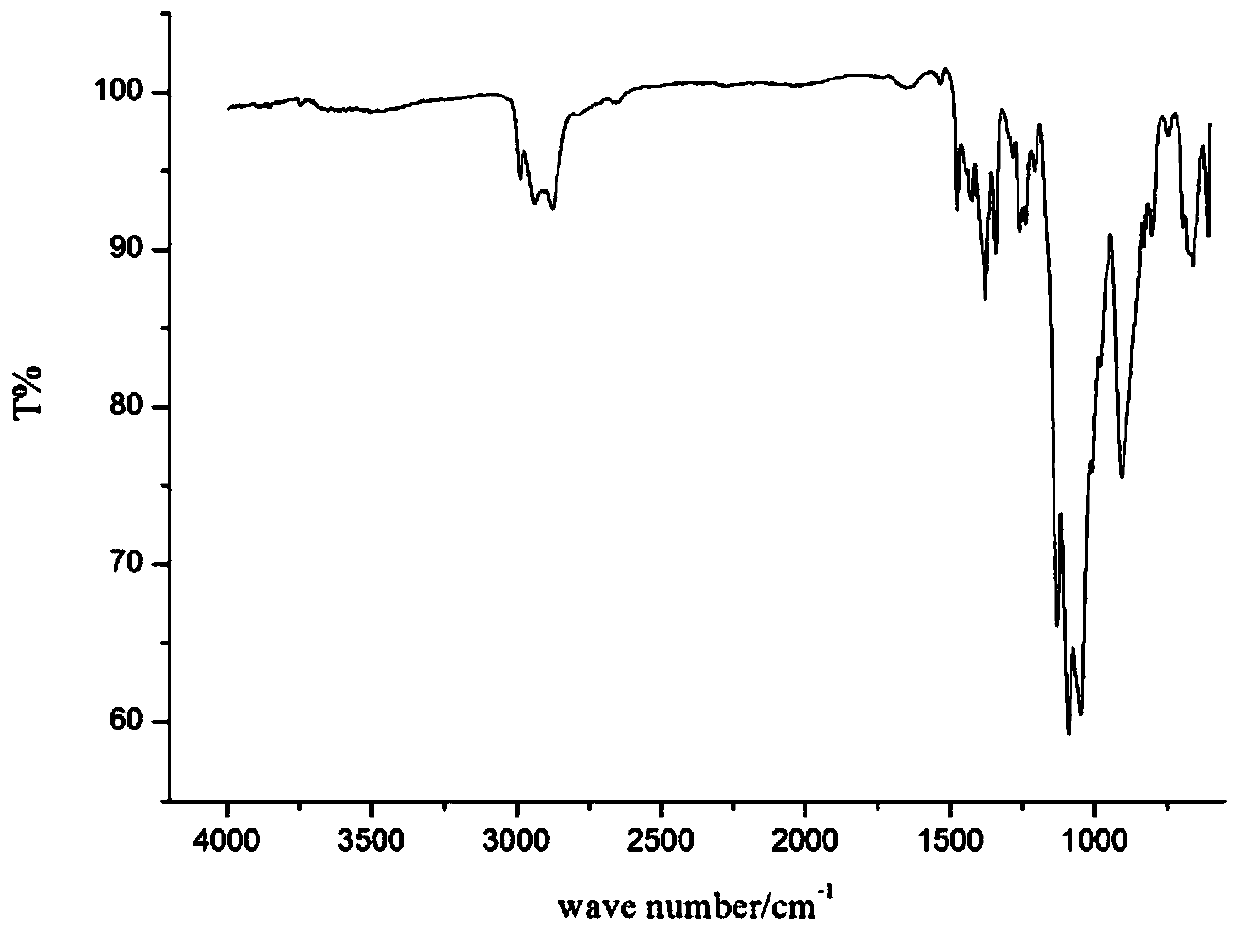

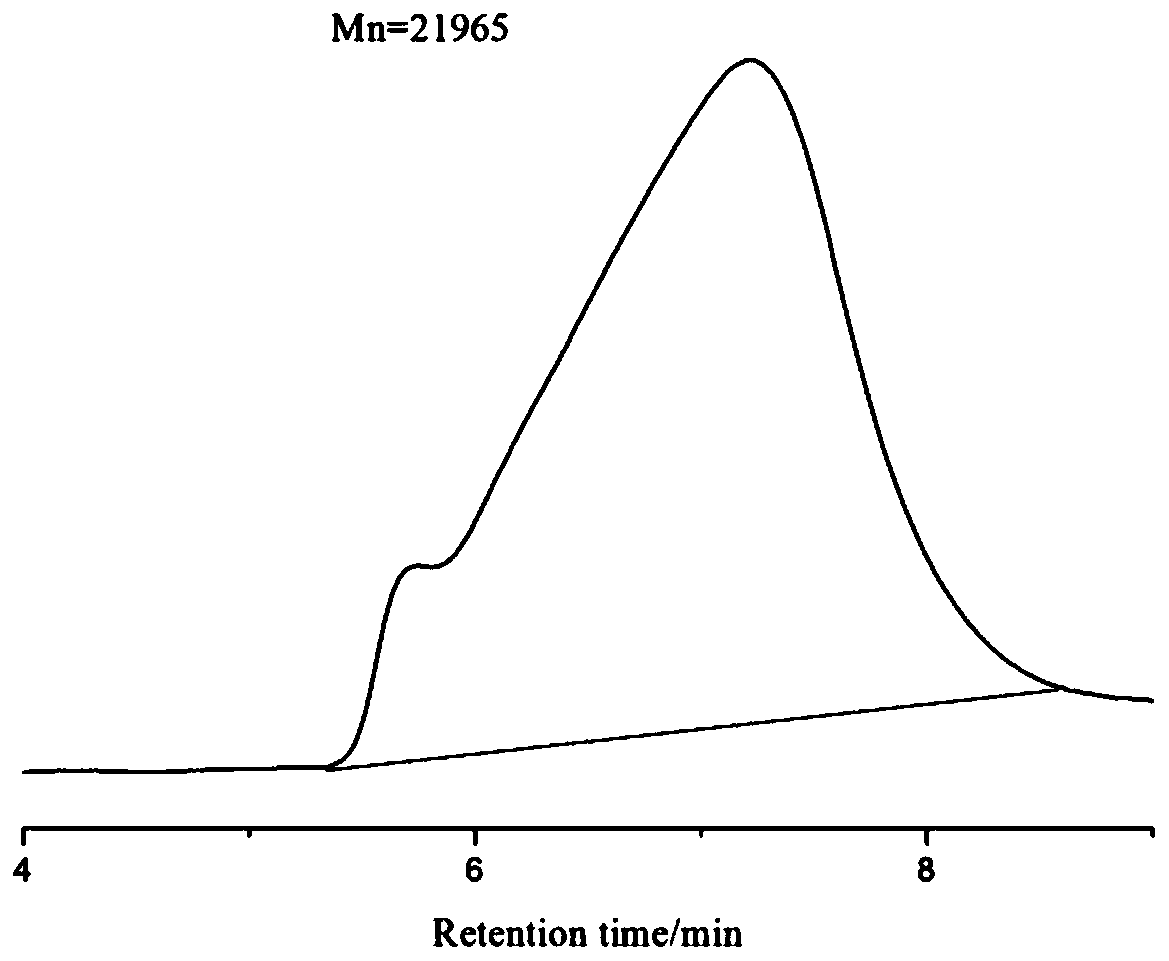

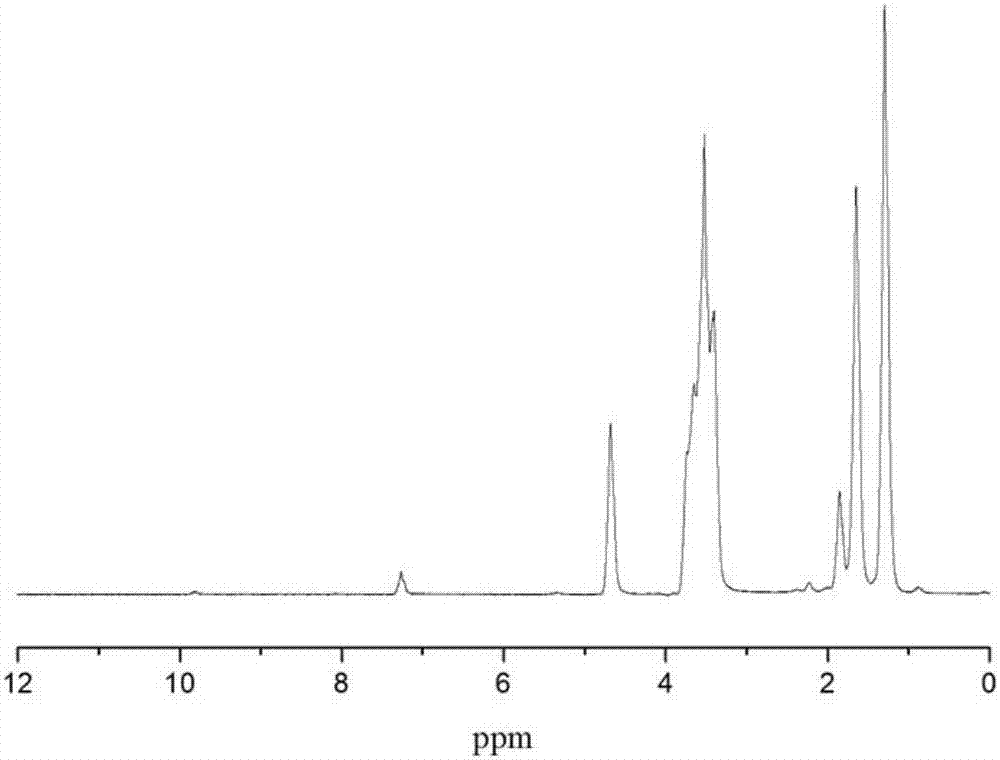

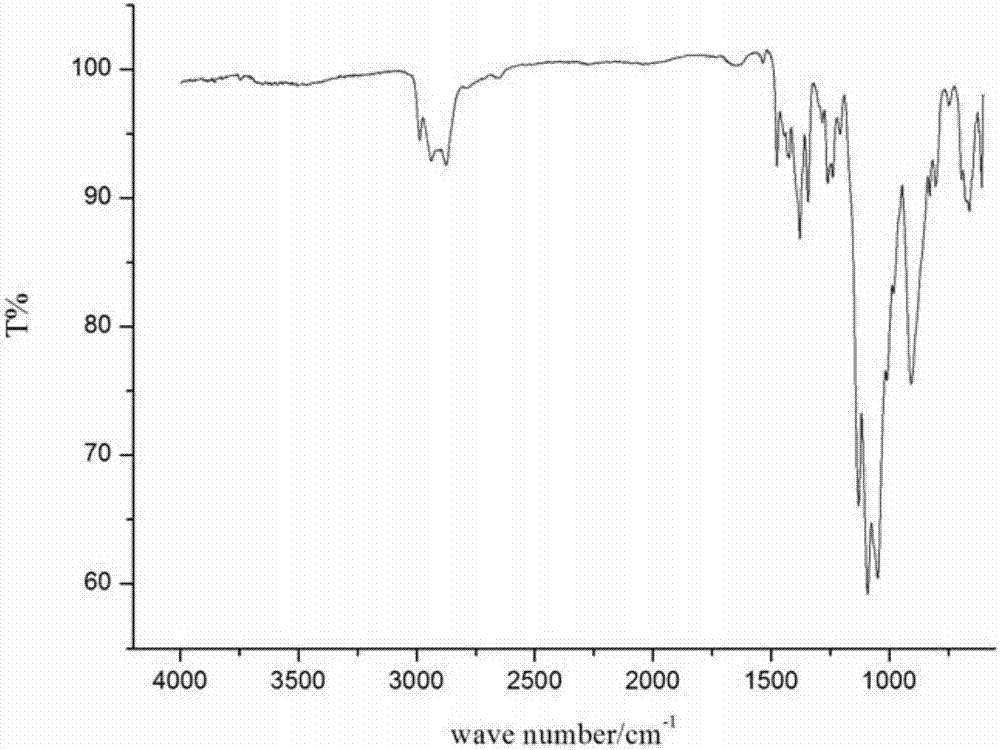

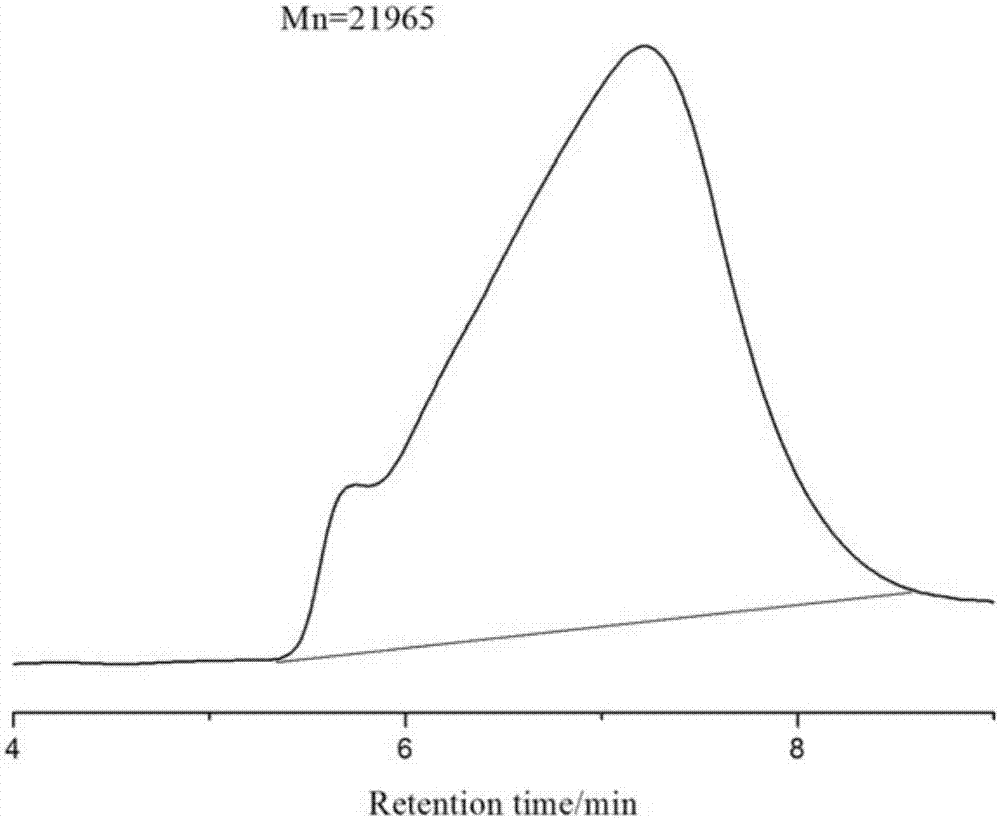

A kind of polymer adhesive and preparation method thereof

InactiveCN107254041BIncrease stickinessSticky implementationProductsReagentsPolymer adhesiveDiethylene glycol

The invention discloses a polymer adhesive and a preparation method thereof. The compound is obtained by taking diethylene glycol divinyl ether and dibromoneopentyl glycol as reactants, taking p-toluenesulfonic acid and tetrahydrofuran as catalysts and carrying out polymerization reaction at the temperature of 0 DEG C. The polymer adhesive has the advantages that plastics can be adhered well, metals can also be adhered well, adhesion can be implemented within 6 minutes, functions of preventing leakage, preventing water, resisting inorganic acid corrosion and the like are fulfilled, and the practicality is quite high.

Owner:WENZHOU UNIV

Polymer adhesive and preparation method thereof

InactiveCN107254041AIncrease stickinessSticky implementationProductsReagentsPolymer adhesiveDiethylene glycol

The invention discloses a polymer adhesive and a preparation method thereof. The compound is obtained by taking diethylene glycol divinyl ether and dibromoneopentyl glycol as reactants, taking p-toluenesulfonic acid and tetrahydrofuran as catalysts and carrying out polymerization reaction at the temperature of 0 DEG C. The polymer adhesive has the advantages that plastics can be adhered well, metals can also be adhered well, adhesion can be implemented within 6 minutes, functions of preventing leakage, preventing water, resisting inorganic acid corrosion and the like are fulfilled, and the practicality is quite high.

Owner:WENZHOU UNIVERSITY

Manufacturing method of copper-plastic pipe

The invention discloses a manufacturing method of a copper plastic pipe. The copper plastic pipe comprises a copper pipe; the copper pipe is coated with a fiberglass mesh; the outside of the fiberglass mesh is sprayed with high-temperature-resistant epoxy glue; a layer of aluminum tube is arranged outside the copper pipe sprayed with the high-temperature-resistant epoxy glue; a PPR material is formed outside the aluminum tube by injection molding. Thus, the manufacturing method of the copper plastic pipe, which has the advantages of smooth circumferential surface, complete smooth weld joints, heat preservation, large bearing capacity and high injection efficiency, is provided.

Owner:NINGBO YONGXIANG COPPER PIPELINE

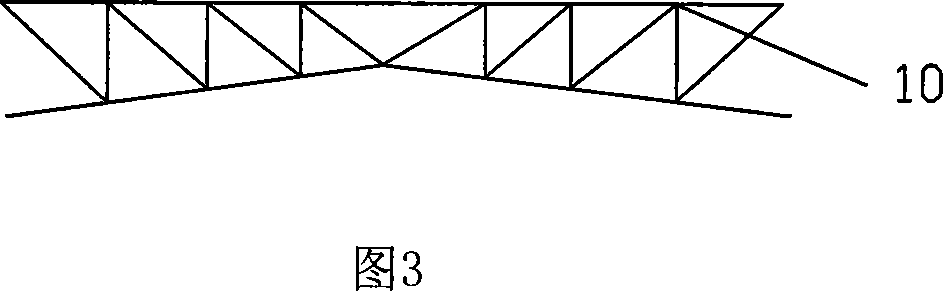

Pitched roof structure of prefabricated floor slab, construction method and prefabricated floor slab

PendingCN114837340AGood effectReduce labor intensityRoof covering using slabs/sheetsBuilding roofsFloor slabArchitectural engineering

The invention discloses a prefabricated floor pitched roof structure, a construction method and prefabricated floors, the prefabricated floor pitched roof structure comprises a frame beam and a plurality of prefabricated floors laid on the frame beam, the prefabricated floors are continuously arranged in rows in the gradient direction of a pitched roof, and the multiple rows of prefabricated floors are arranged at intervals in the direction perpendicular to the gradient. Every two adjacent prefabricated floor slabs in each row are connected through a buckle structure, gaps are formed between the prefabricated floor slabs and the frame beams, gaps communicated with the gaps are formed in the two sides of each row of prefabricated floor slabs, the gaps and the gaps are filled with concrete, all the prefabricated floor slabs and the frame beams are fixedly connected through the concrete, and every two adjacent prefabricated floor slabs are fixedly connected through the concrete. The prefabricated floor is simple and compact in structure, meets the safety requirement, is simple and convenient to assemble on site, reduces the construction difficulty and the labor intensity of workers, improves the working efficiency, has good drainage performance and rain leakage prevention, can select prefabricated floors of different specifications according to actual construction requirements, can be suitable for pitched roof structures with the gradient larger than 9 degrees, and is high in applicability.

Owner:GUANGDONG PROVINCE COMM PLANNING & DESIGN INST

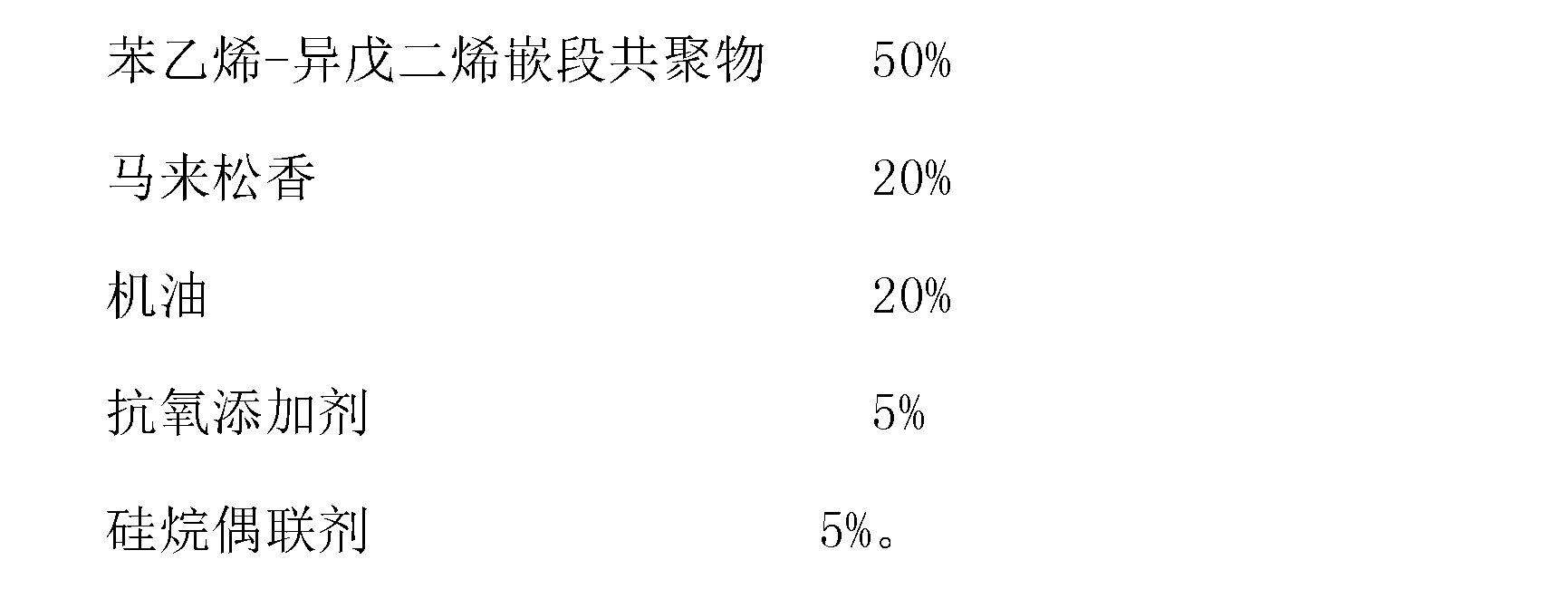

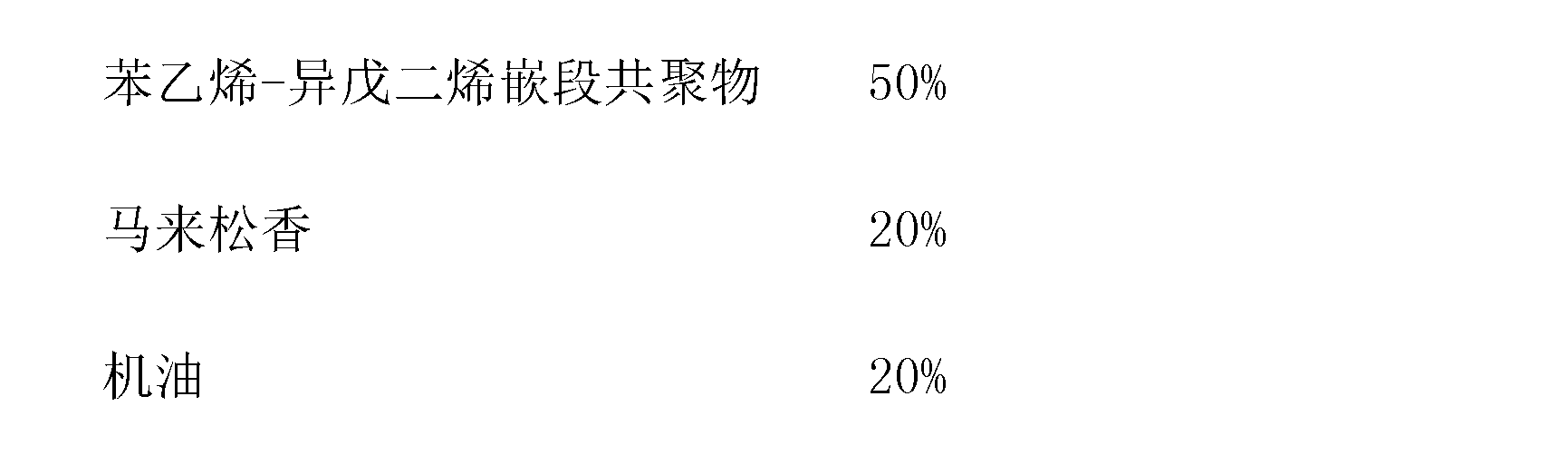

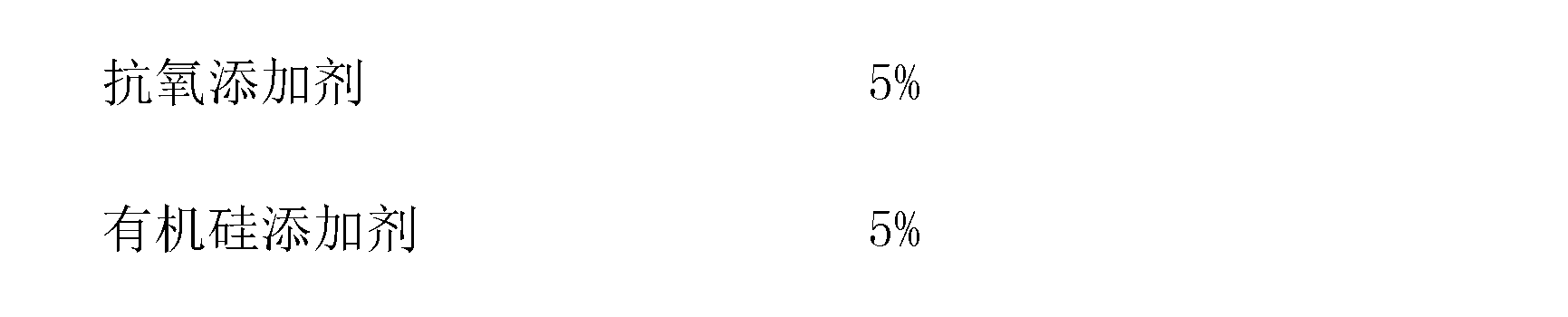

Bulk density (BD)-free radical silicon molecule polymeric material capable of adapting to tire self repair

InactiveCN102585426BPromotes self-healingWith noise reductionSpecial tyresMaterials preparationNoise reduction

The invention relates to the technical field of automobile tire protection material manufacture, in particular to a bulk density (BD)-free radical silicon molecule polymeric material capable of adapting to tire self repair and a production method of the BD-free radical silicon molecule polymeric material. The free radical silicon molecule polymeric material is characterized by comprising styrene-isoprene segmented copolymers, maleated rosin, engine oil, antioxidant additives and organic silicon additives. The material preparation process comprises the following steps that: raw materials are proportionally mixed and are then put into a reaction kettle, the temperature is raised, the pressurization is carried out, the materials are sufficiently stirred, the temperature is lowered, and the materials are discharged. Compared with the prior art, the free radical silicon molecule polymeric material provided by the invention can be used in a temperature range being 0 to 20 DEG C, the regional disparity does not exist in the use process, the physical and chemical properties are stable, after the free radical silicon molecule polymeric material is coated on the tire, the tire can realize the self repair after being pierced, the tire repair and the tire replacement are not needed, the tire also has the functions of noise reduction, shock absorption, energy saving, blasting prevention and leakage prevention, the temperature inside the temperature is reduced, and the service life of the tire is prolonged.

Owner:张兵 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com