Pitched roof structure of prefabricated floor slab, construction method and prefabricated floor slab

A technology for sloping roofs and floor slabs, which is applied to roofs, roofs, and roof coverings using flat/curved panels, can solve problems such as difficulty in pouring compactness control, concrete slippage or segregation, and high labor intensity for workers, so as to reduce moisture content. Work workload and formwork workload, reduce construction difficulty and labor intensity of workers, and simplify the effect of construction difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

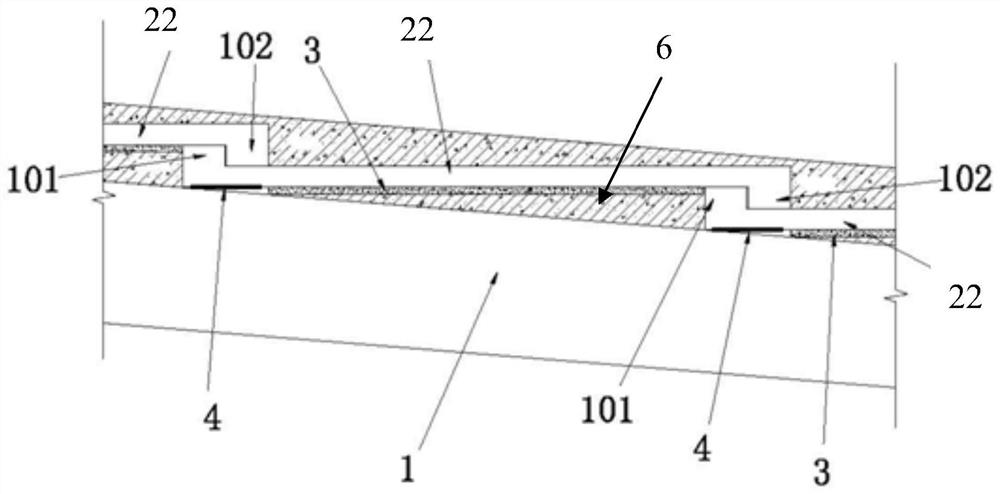

[0043] like figure 1 and figure 2 As shown, it is a prefabricated floor sloping roof structure of the present invention, which includes a frame beam 1 and several prefabricated floor slabs 22 laid on the frame beam 1. It should be noted that the cross section of the frame beam 1 is generally rectangular or T-shaped. , In the assembled monolithic frame structure, the frame beam 1 is often made into a rectangular section, the prefabricated floor slabs 22 are continuously arranged in rows along the slope direction of the sloping roof, and several rows of prefabricated floor slabs 22 are arranged at intervals along the direction perpendicular to the slope. It can be understood that Therefore, a plurality of prefabricated floor slabs 22 are laid on a plurality of frame beams 1 arranged at intervals in a matrix manner, two adjacent prefabricated floor slabs 22 in each column are connected by a snap structure, and the prefabricated floor slabs 22 in each horizontal row are arranged ...

Embodiment 2

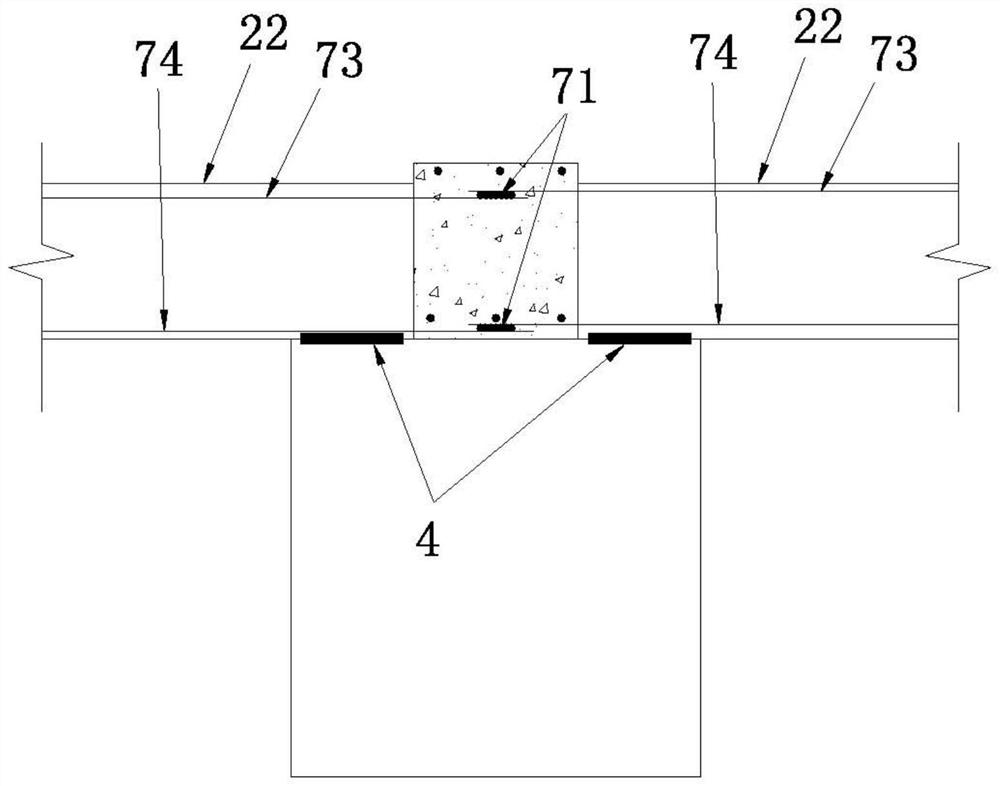

[0055] like image 3 As shown, the difference between the prefabricated floor slab sloping roof structure of this embodiment and Embodiment 1 is that the prefabricated floor slab 22 and the frame beam 1 are fixed in different ways, no neoprene pad is provided, and the top surface of the frame beam 1 is anchored into the insert reinforcement. 75. The anchored bar 75 is a closed stirrup. The closed stirrup is formed by cross-connecting two U-shaped stirrups. One of the U-shaped stirrups is embedded in the top of the frame beam 1, with a diameter of 12mm and a spacing of 200mm. The stirrups are bent, and the inner side is bound with a plurality of first longitudinal bars 83 with HRB600 diameter of 12mm arranged at intervals; the lower part of another U-shaped stirrup is located in the frame beam 1, and the upper part extends out of the frame beam 1 to enter The concrete part is also formed by bending stirrups with a diameter of 12mm and a spacing of 200mm, and a plurality of seco...

Embodiment 3

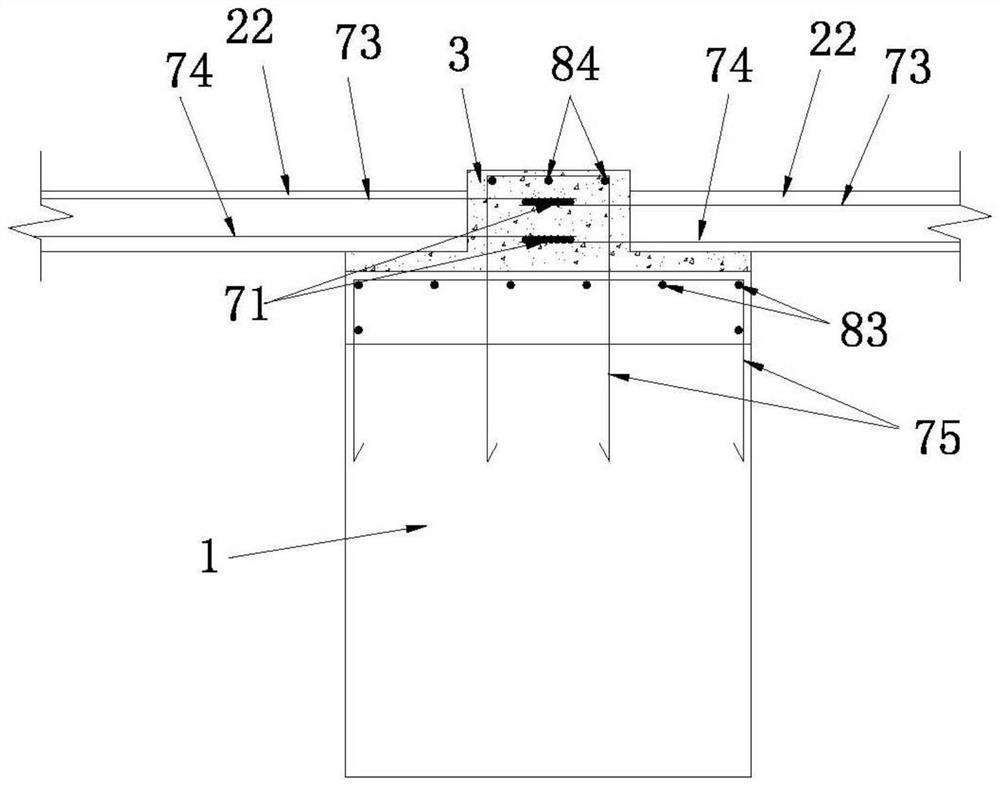

[0059] like Figure 4 As shown, the difference between the prefabricated floor slab sloping roof structure of this embodiment and Embodiment 2 is that the frame beam 1 of this embodiment is a single-sided frame beam, and the beam gluten 73 and the beam bottom rib 74 of the prefabricated floor slab 22 are respectively welded by welding The connecting bars 71 connect the supporting bars 76 arranged in the length direction. The length of the supporting bars 76 is preferably 400 mm, and the supporting bars 76 are located in the closed portion of the insert bars.

[0060] Anchoring bars are placed on the top surface of the frame beam 1. The anchor bars are closed stirrups. The closed stirrups are formed by cross-connecting two U-shaped stirrups. One of the U-shaped stirrups is embedded in the frame beam 1. The inner top is formed by bending stirrups with a diameter of 12mm and a spacing of 200mm, and the inner side is bound with a plurality of third longitudinal bars 85 with a diam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com