A kind of polymer adhesive and preparation method thereof

An adhesive and polymer technology, applied in the direction of adhesives, polyether adhesives, adhesive types, etc., can solve the problems of few adhesives, etc., and achieve the effect of good inorganic acid resistance and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

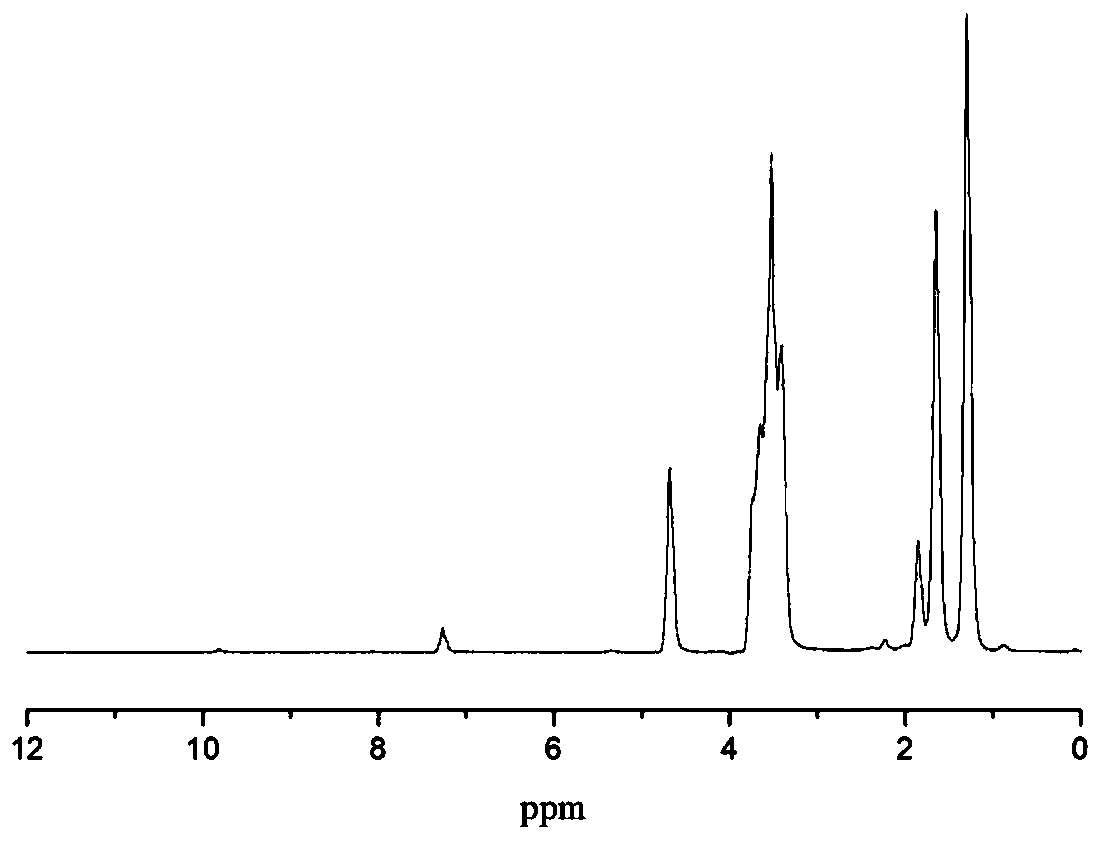

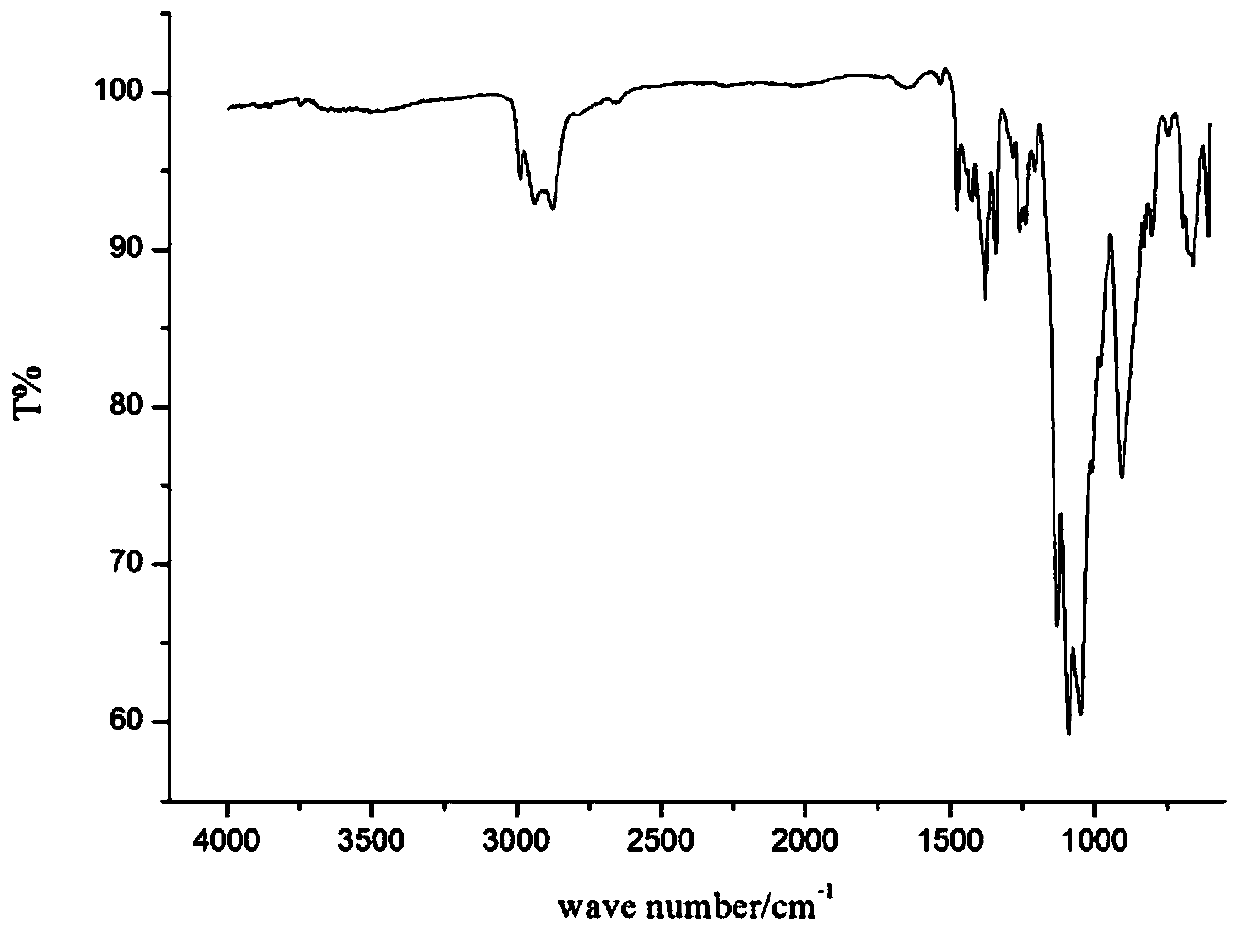

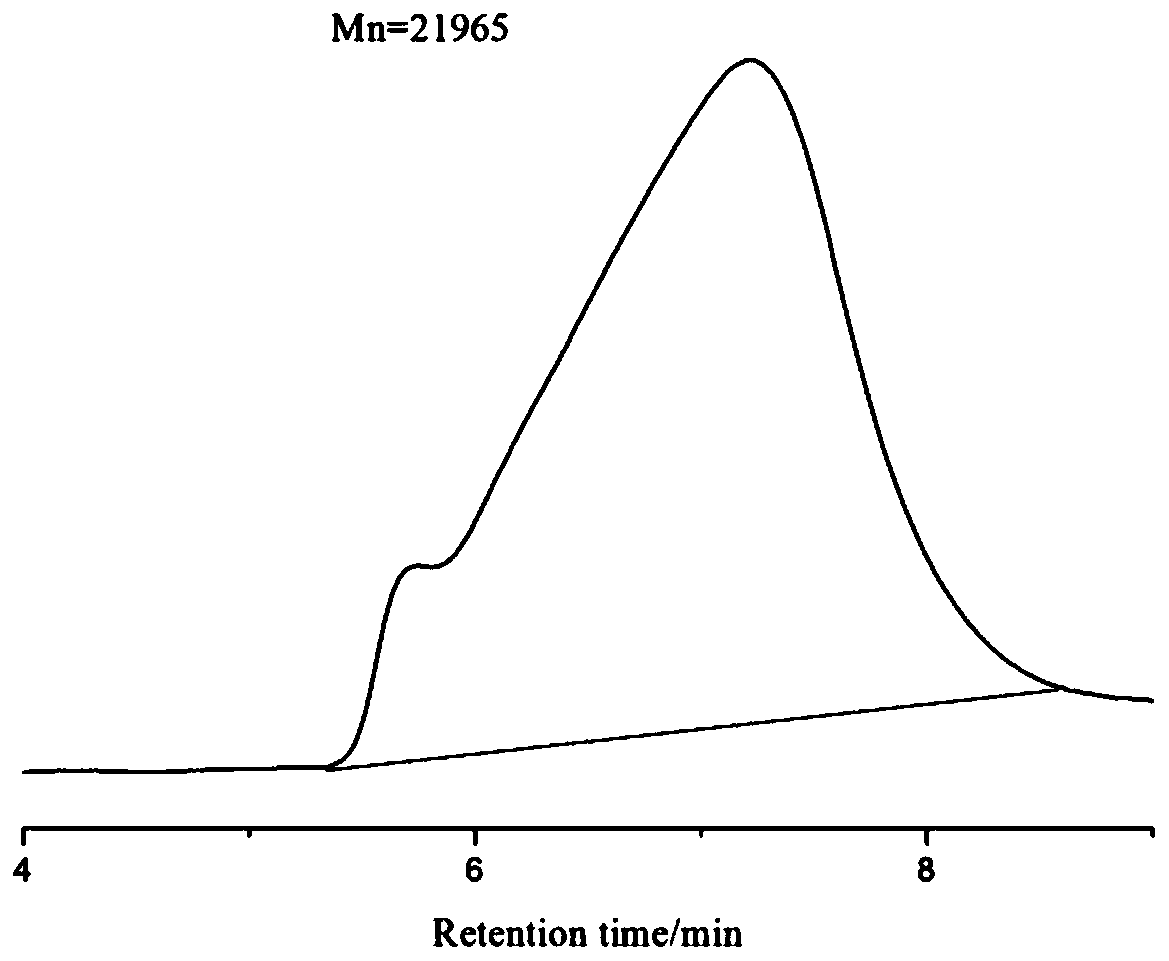

[0034] Such as Figure 1 to Figure 3 As shown, Embodiment 1 of the present invention includes the following steps:

[0035] (1) Mix 2.62g (0.01mol) of dibromoneopentyl glycol (CSA No. 3296-90-0) and 8mL of tetrahydrofuran at 15-30°C and stir at 200-600r / min for 10min to dissolve the reactants completely ;

[0036] (2) Add 20mg of p-toluenesulfonic acid and stir until completely dissolved;

[0037] (3) Mix 1.58 g (0.01 mol) of diethylene glycol divinyl ether and 12 mL of tetrahydrofuran in a constant pressure dropping funnel, and shake gently to completely dissolve;

[0038] (4) Stir the mixed solution obtained in step (1) and step (2) at a speed of 800-1000 r / min at 0°C;

[0039] (5) Slowly drip the mixed solution of diethylene glycol divinyl ether and tetrahydrofuran obtained in step (3) into the solution obtained in step (4) at a rate of 1 drop / 5s;

[0040] (6) After the dripping in step (5) is finished, slowly rise to room temperature within 1-2h, and continue to stir at 800-1000r / mi...

Embodiment 2

[0049] (1) Mix 5.24g (0.02mol) of dibromoneopentyl glycol (CSA No. 3296-90-0) and 16mL of tetrahydrofuran at 15-30°C and stir at 200-600r / min for 10min to dissolve the reactants completely ;

[0050] (2) Add 32mg of p-toluenesulfonic acid and stir until completely dissolved;

[0051] (3) Mix 3.12g (0.02mol) of diethylene glycol divinyl ether and 30mL of tetrahydrofuran in a constant pressure dropping funnel, and shake gently to completely dissolve;

[0052] (4) Stir the mixed solution obtained in step (1) and step (2) at a speed of 800-1000 r / min at 0°C;

[0053] (5) Slowly drip the mixed solution of diethylene glycol divinyl ether and tetrahydrofuran obtained in step (3) into the solution obtained in step (4) at a rate of 1 drop / 5s;

[0054] (6) After the dripping in step (5) is finished, slowly rise to room temperature within 1-2h, and continue to stir at 800-1000r / min for 6h;

[0055] (7) Slowly add the mixed solution obtained in step (6) to 400 mL of cyclohexane, stir at a speed of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com