Method for upgrading common tyre to explosion-proof leakproof tyre and explosion-proof leakproof tyre

A tire and anti-leakage technology, applied to tire parts, transportation and packaging, vehicle parts, etc., can solve the problems of changing tires and easy flow of rubber, and achieve the effect of ensuring uniformity, high viscosity, and high stretchability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

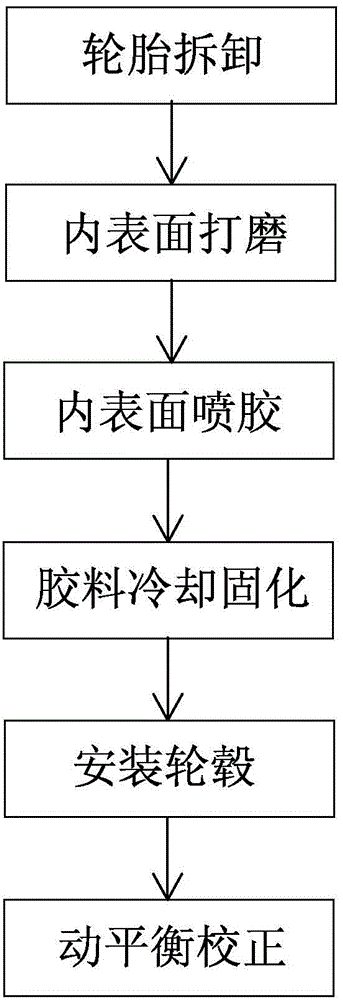

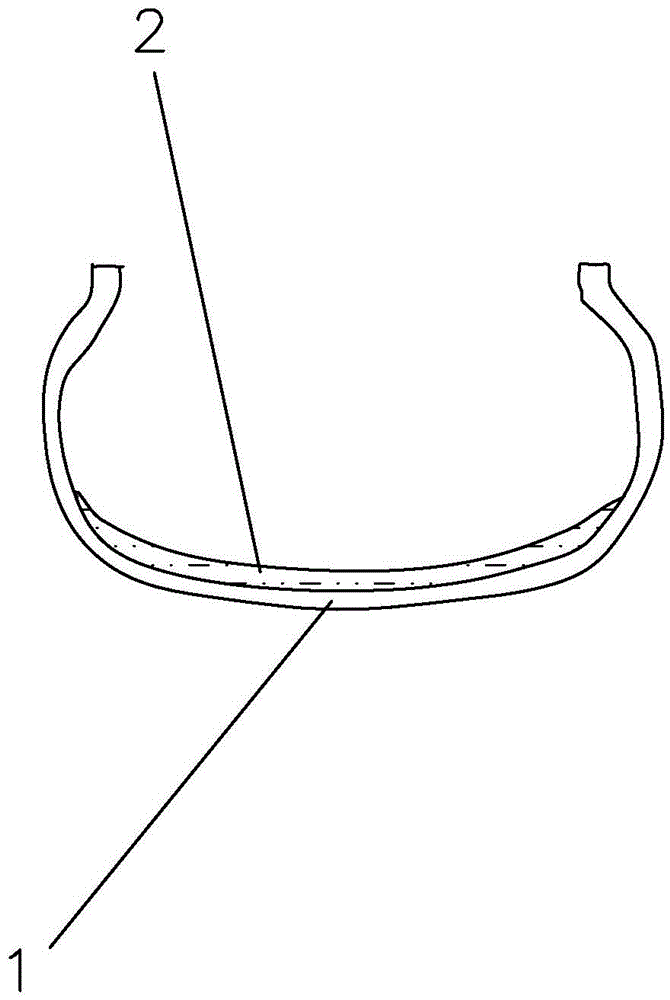

[0029] like figure 1 As shown, a method for upgrading common tires to explosion-proof and leak-proof tires comprises the following steps:

[0030] A1. First remove the tire that needs to be upgraded from the car, and remove the tire from the wheel hub;

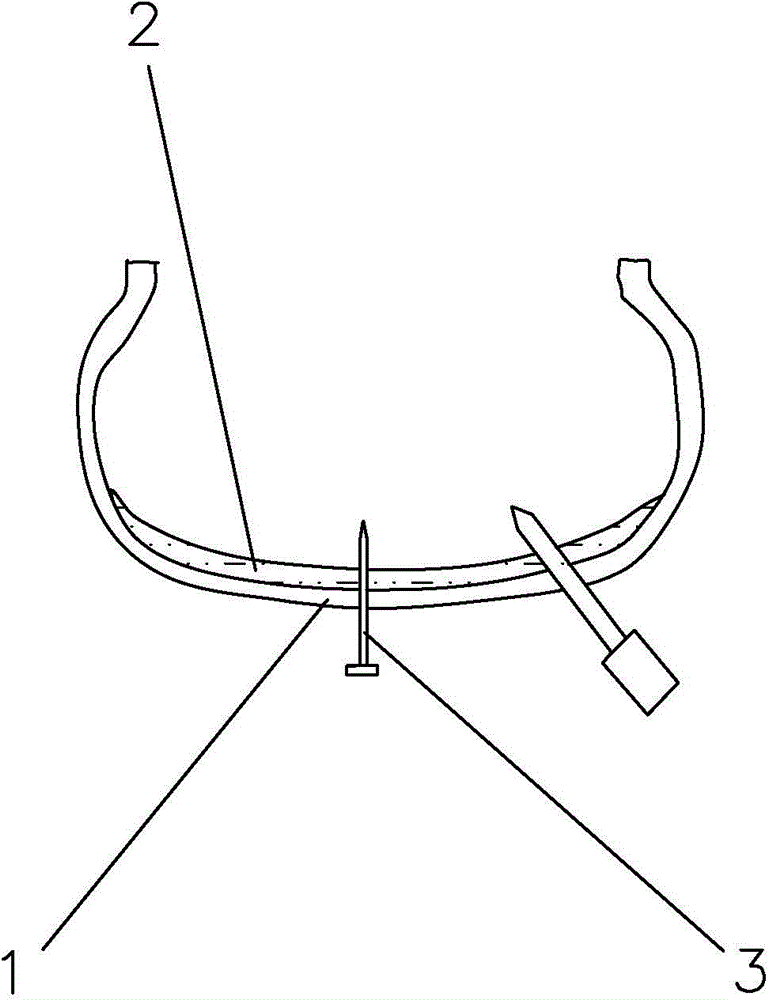

[0031] A2. Then use a steel brush to grind on the inner surface of the tire to remove impurities and burrs on the inner surface of the tire;

[0032] A3, then melt the polymer synthetic memory rubber block, and evenly spray the melted polymer synthetic memory rubber on the bottom of the inner surface of the tire;

[0033] A4. Then, the tire whose inner surface is sprayed with polymer synthetic memory compound is cooled to make it cool and solidify;

[0034] A5. Then reinstall the removed wheel hub to the tire sprayed with polymer synthetic memory rubber;

[0035] A6. Finally, perform a dynamic balance test and correction on the tire with the hub installed.

[0036] Wherein, in the fourth step, the cooling of the tires spra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com