Patents

Literature

34results about How to "Meet the requirements of rapid construction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

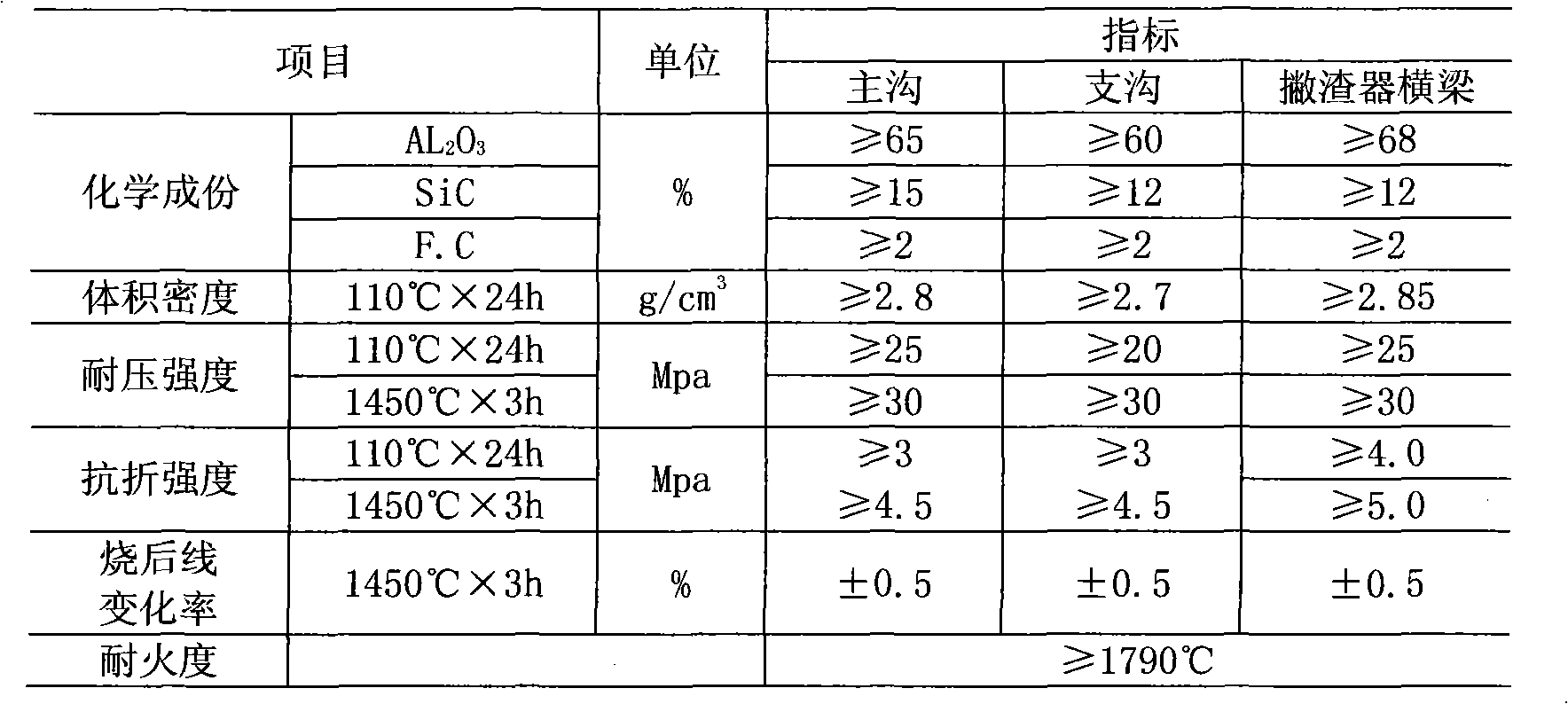

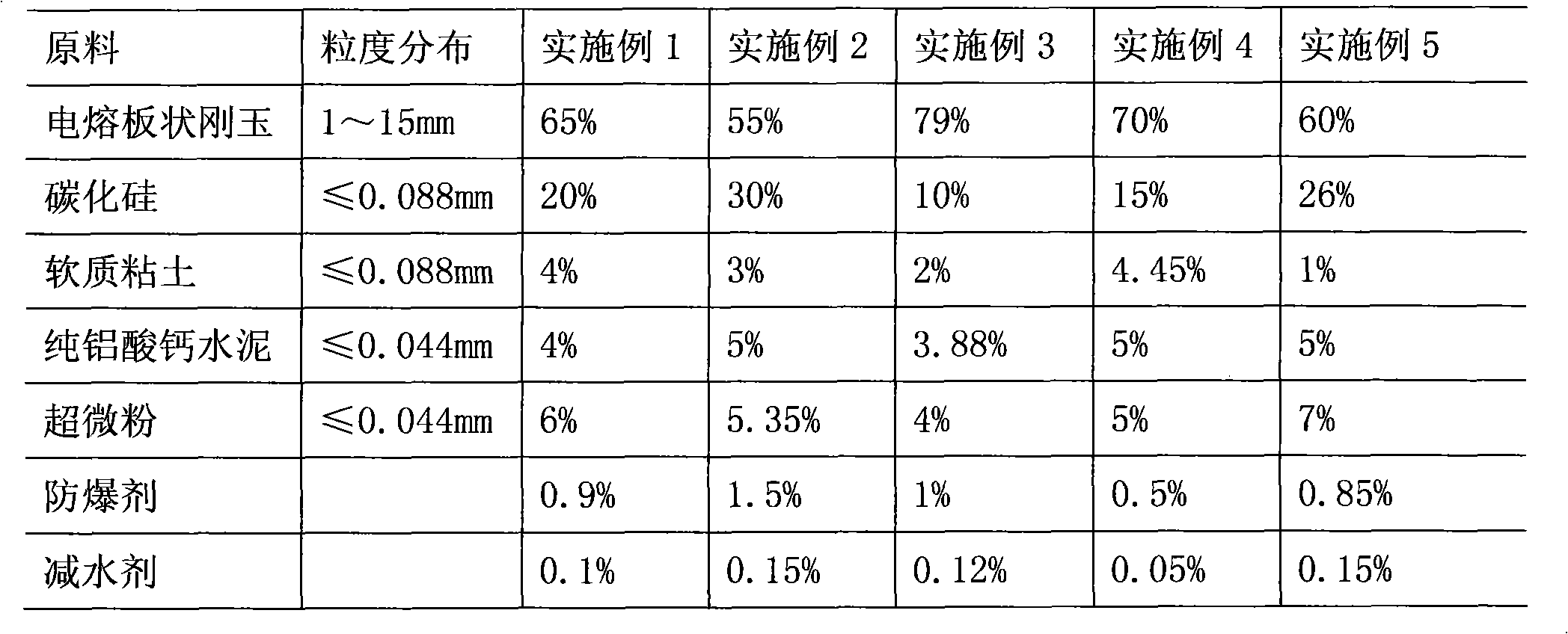

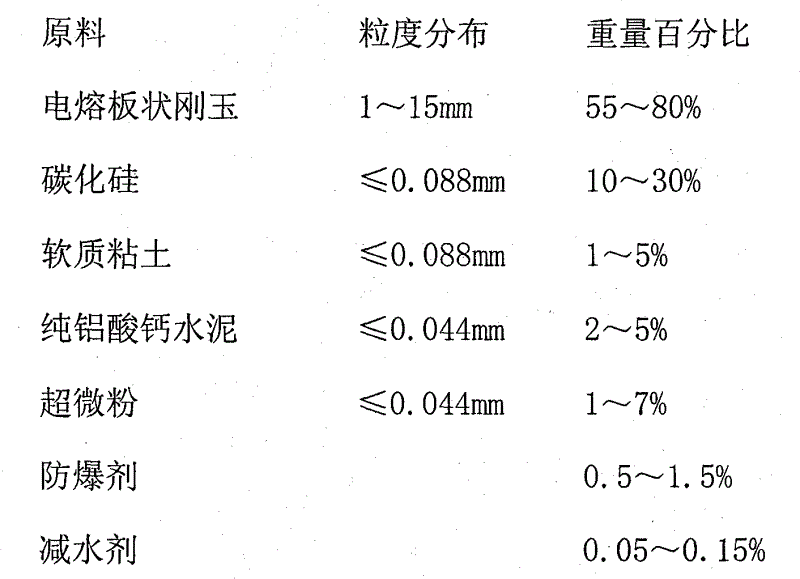

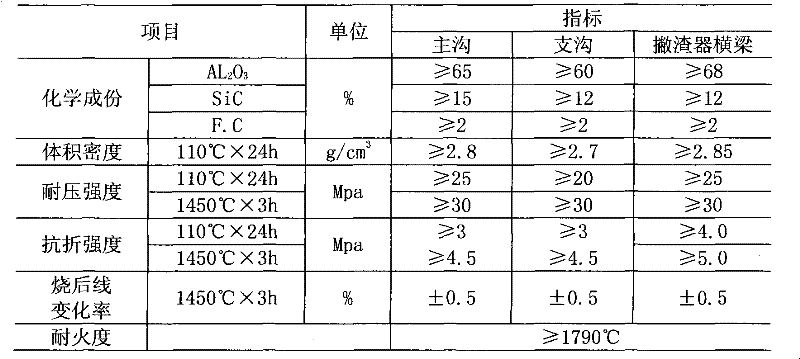

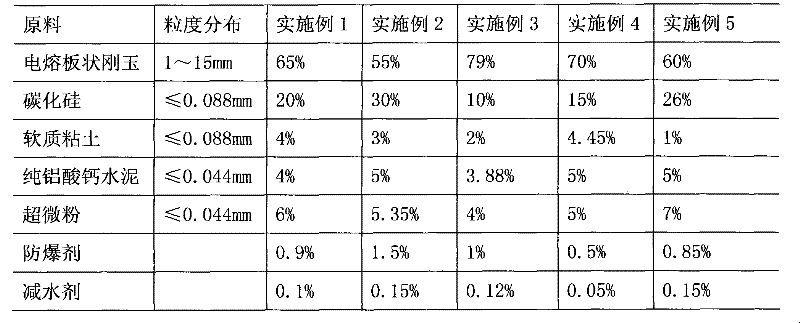

Explosion-proof iron runner castable

The invention relates to an explosion-proof iron runner castable which comprises the following raw materials in percentage by weight: 55-80 percent of fusion tabular corundum, 10-30 percent of silicon carbide, 1-5 percent of soft clay, 2-5 percent of pure calcium aluminate cement, 1-7 percent of submicron powder, 0.5-1.5 percent of explosion-proof agent and 0.05-0.15 percent of water reducing agent, wherein the explosion-proof agent is a mixture of aluminum powder, aluminum lactate, explosion-proof fiber and boron carbide powder with the weight ratio of 1-2:2.5-4:1-2.5:2-4. The castable of the invention has no cracks after demoulding and drying and no spalling during baking, has the safe explosion-proof temperature of 800 DEG C increased from 500 DEG C, can be subjected to construction under heat state and rapid temperature rise without spalling and can meet the operating requirements of rapid construction of middle and small size blast furnace iron runner. The castable has long service life, can improve the environment of a casting house, greatly reduces the labor intensity of the workers, improves the quality of molten iron and enhances the application safety factor of the iron runner.

Owner:HENAN HUAXI FURNACE REFRACTORY

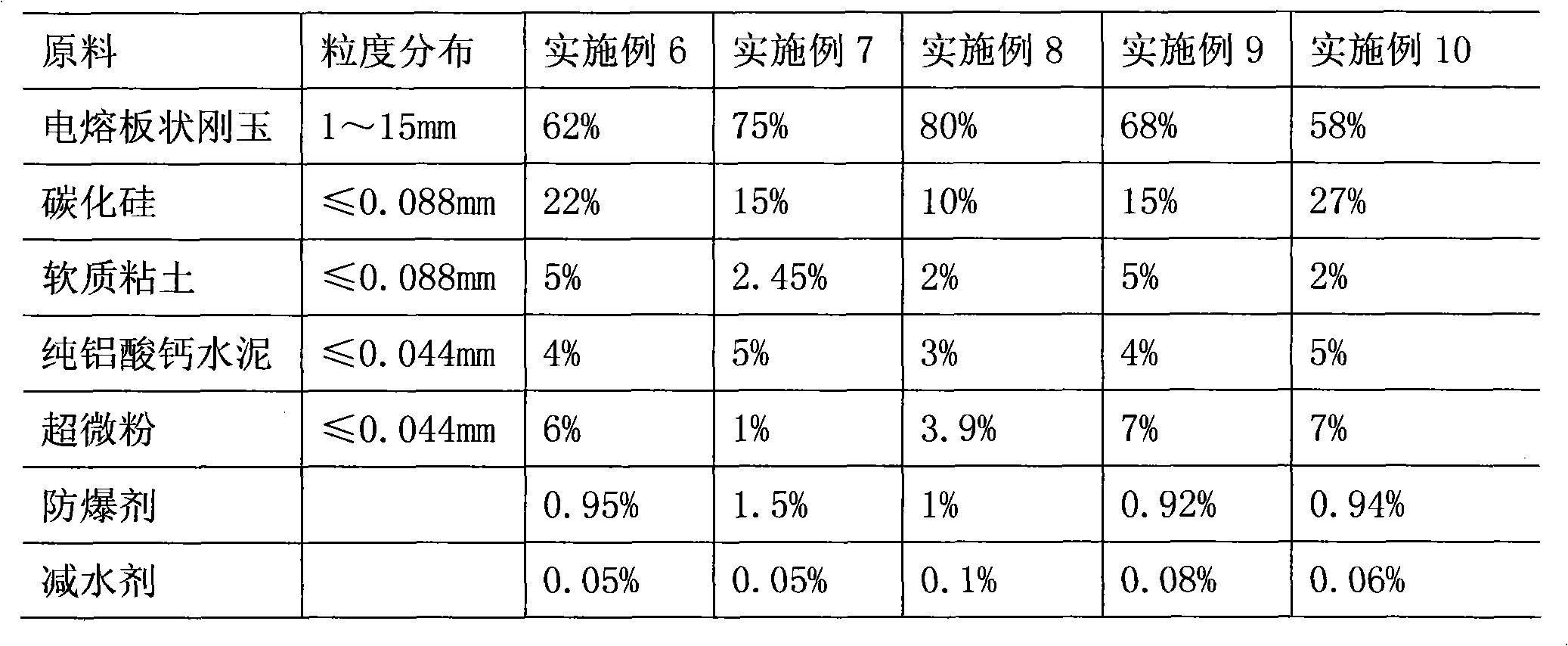

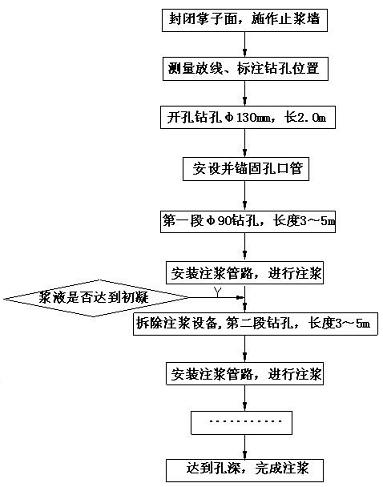

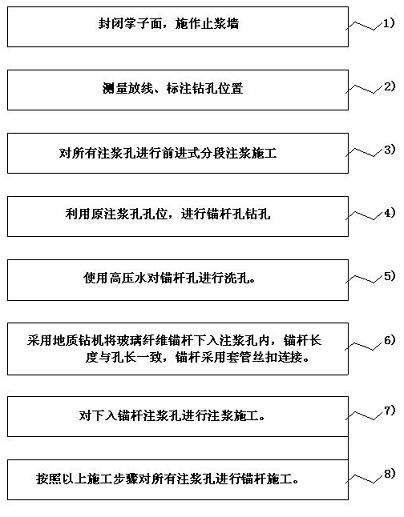

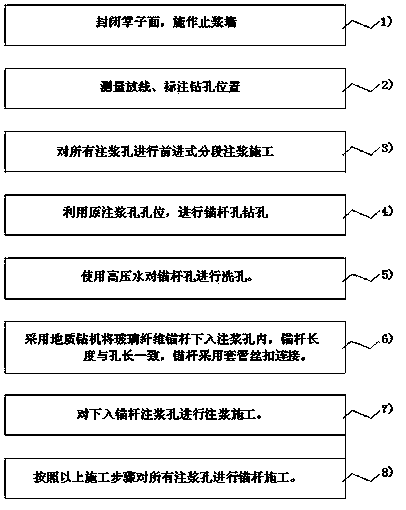

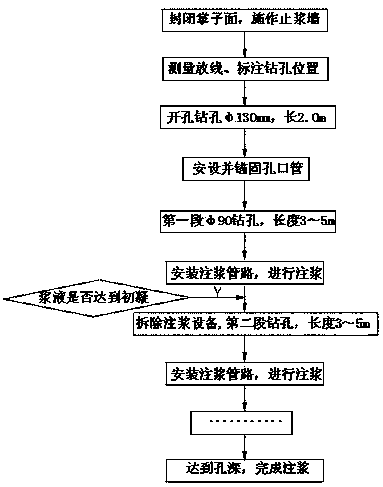

Technology method of reinforced grouting in high-pressure water-rich solution cavity of tunnel

ActiveCN102278130AControl deformationAvoid deformationUnderground chambersTunnel liningGlass fiberGeomorphology

The invention relates to the technical fields of tunnel and underground engineering, providing a process method for reinforcing and grouting of a high-pressure water-rich solution cavity of a tunnel. The process method comprises the following steps of: carrying out drilling, grouting and reinforcing within a range required to be reinforced in front of a tunnel work face by adopting an advanced segmented grouting mode; after the grouting is ended, carrying out drilling and flushing on a anchor rod hole at the original grouting hole site by using a geological drilling rig; and feeding a glass fiber anchor rod into the anchor rod hole and carrying out grouting construction. According to the process method disclosed by the invention, the glass fiber anchor rod is additionally arranged in a grouting solidified body to form a space meshy structure body with soil (sand) body, thus the action of the glass fiber anchor rod for resisting shearing, cutting and tensioning in the system is fully exerted. In addition, according to the process method disclosed by the invention, the deformability of digging a hole body is effectively controlled while water from karst can be blocked and the soft ground stratum is reinforced; and the capability of resisting high water pressure can be born and the construction requirement for quick digging and coupling of the karst hole body is met.

Owner:CHINA RAILWAY TUNNEL GROUP CO LTD

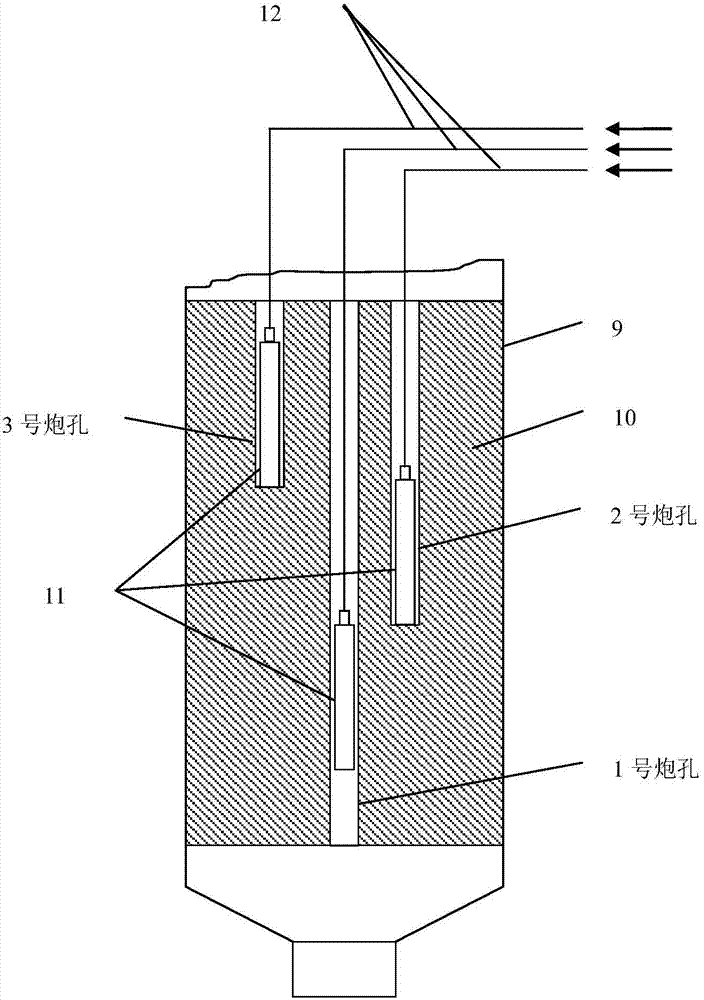

Dry ice blasting method and dry ice blasting device

InactiveCN104500068AOvercome potentially dangerous drawbacksWill not cause an explosionDisloding machinesUnderground miningToxic gasWater source

The invention relates to a dry ice blasting method and a dry ice blasting device, and belongs to the field of engineering blasting. The dry ice blasting device comprises a spray head, a cylinder body, a tail cover and a one-way valve, wherein the spray head is provided with an exhaust hole; the tail cover is provided with a water inlet hole; a sealing gasket is arranged between the cylinder body and the tail cover; a blasting sheet is arranged between the cylinder body and the spray head; and the tail cover is communicated with the one-way valve through the water inlet hole. The dry ice blasting method comprises the following steps: drilling in a coal bed; assembling the dry ice blasting device, and filling the dry ice blasting device with dry ice and a heating bag; connecting the dry ice blasting device with a water pipe, and placing into a blast hole; and communicating with a water source, and injecting water into the dry ice blasting device, wherein the heating bag inside the cylinder body fast releases heat when encountering water so as to urge the dry ice to be fast sublimated into carbon dioxide gas, when gas pressure exceeds the design pressure of the blasting sheet, the instant blasting of the blasting sheet is caused, and the carbon dioxide gas is fast discharged through the exhaust hole formed in the spray head to form impaction and expansion extrusion on the wall of the blast hole, so that the blasting is realized. The dry ice blasting method and the dry ice blasting device which are disclosed by the invention have the advantages of achieving the bursting at normal temperature, generating no flame or toxic gas and being suitable for a coal mine with gas and coal dust explosion risks.

Owner:CHINA UNIV OF MINING & TECH

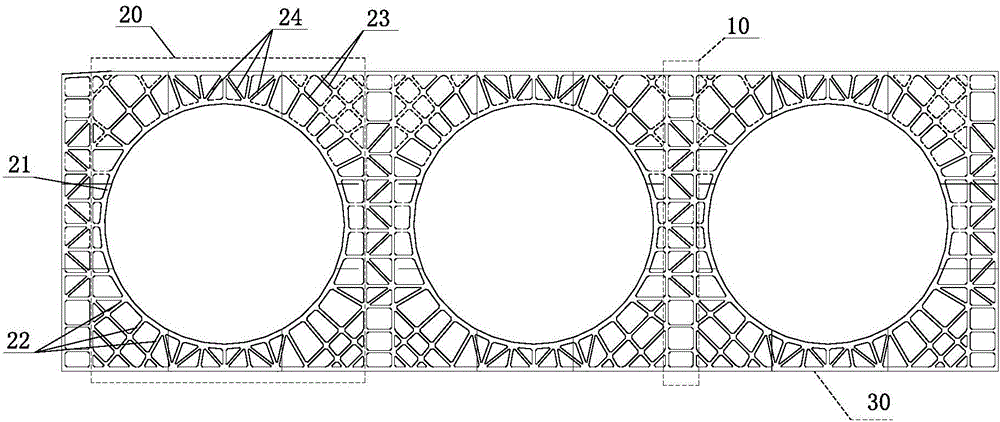

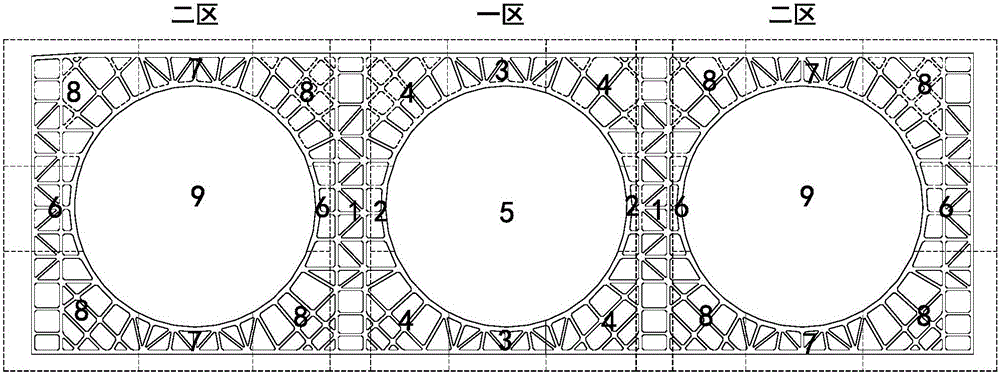

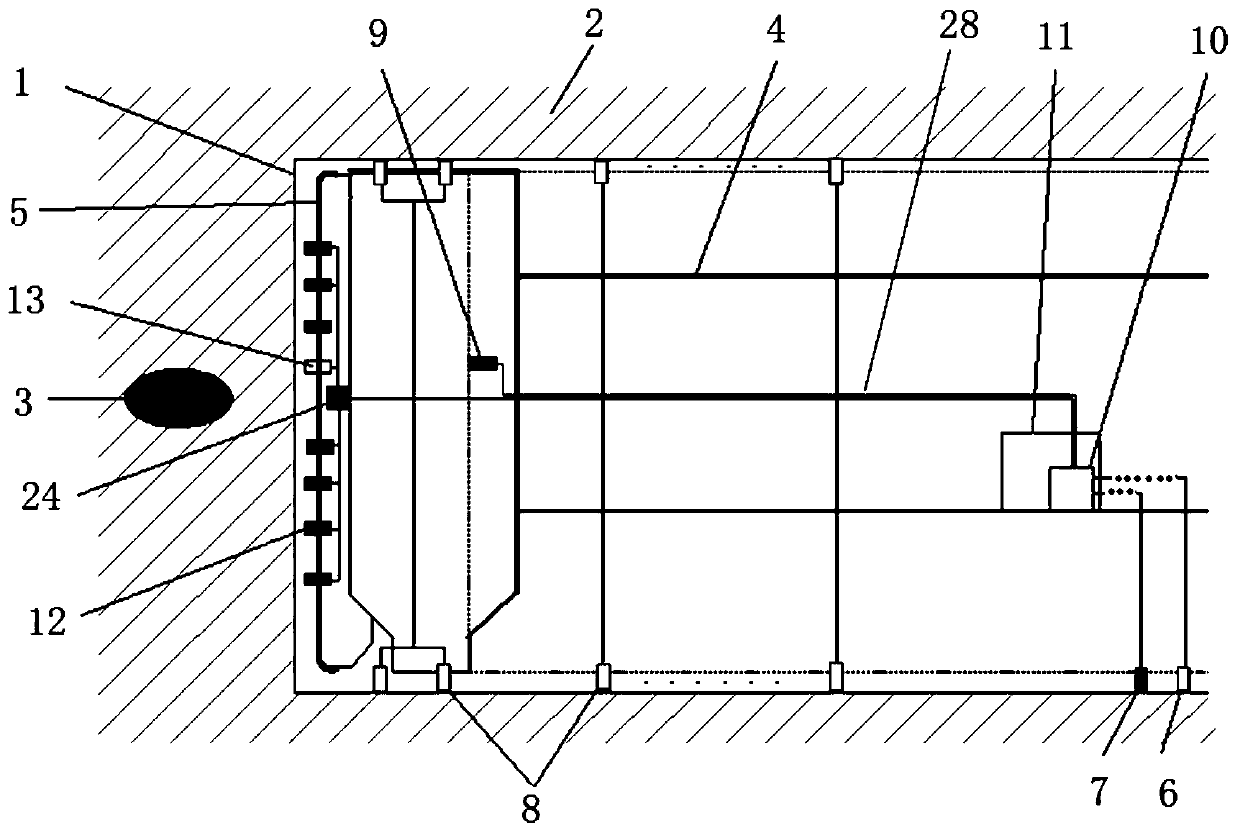

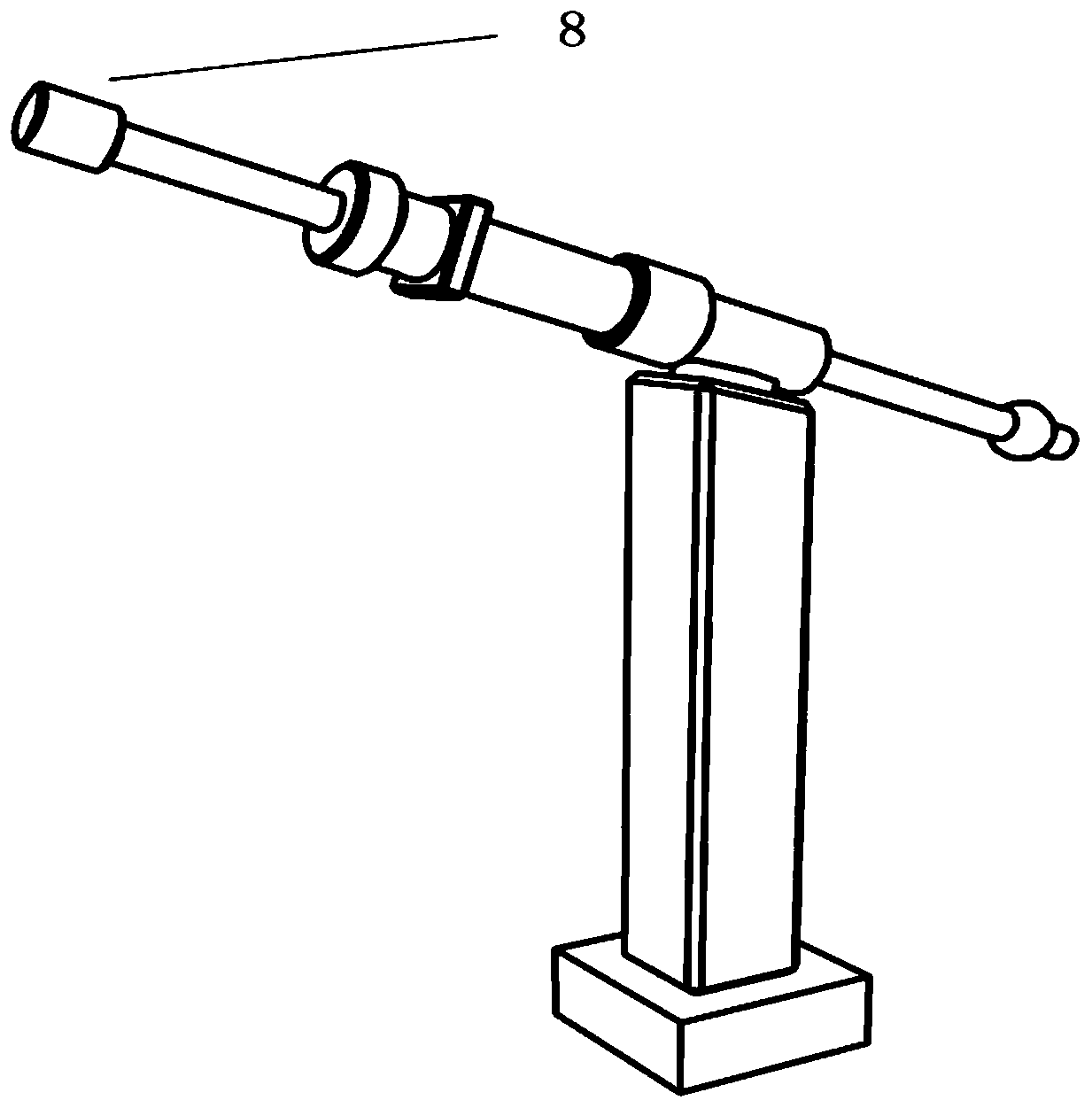

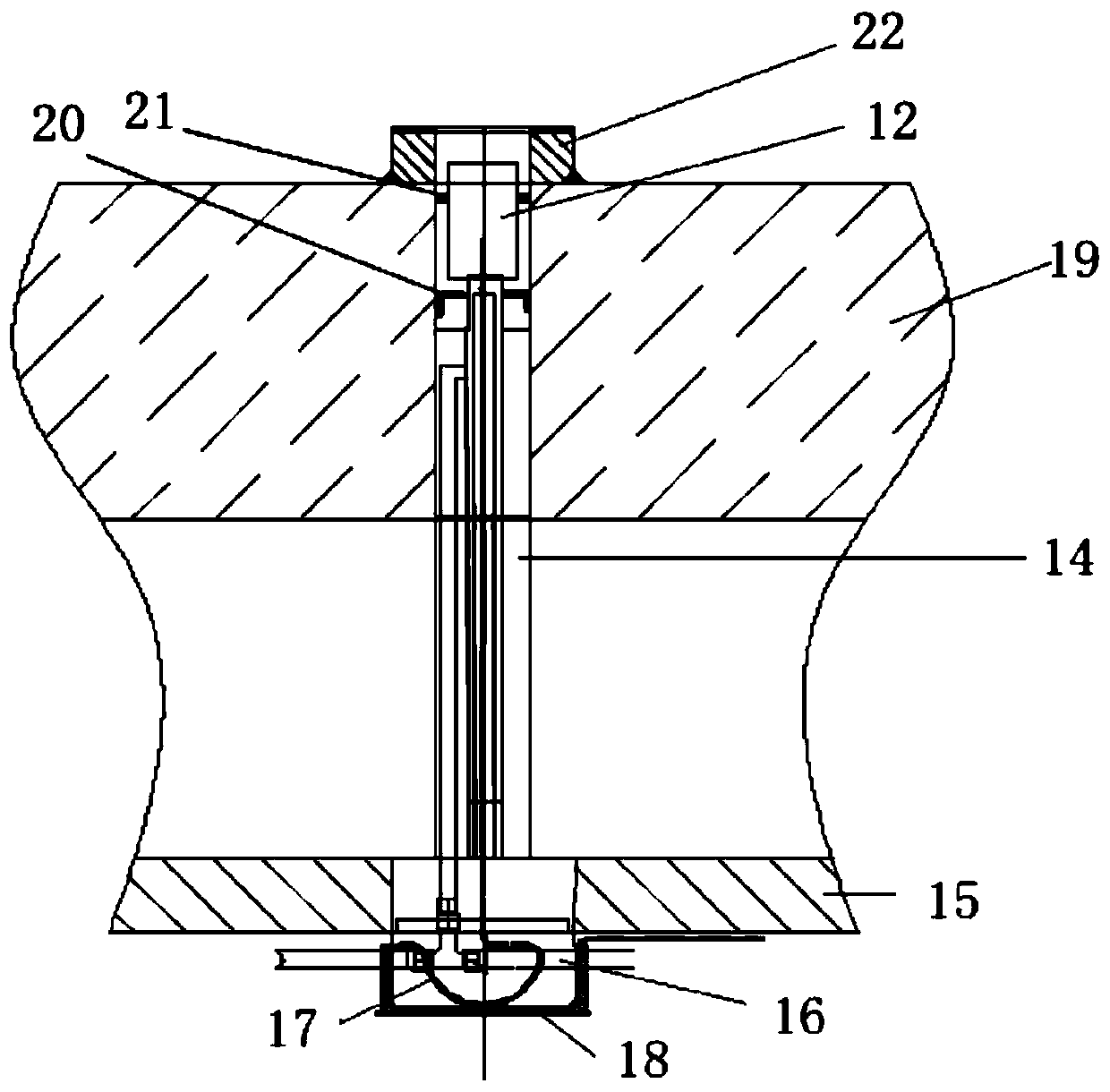

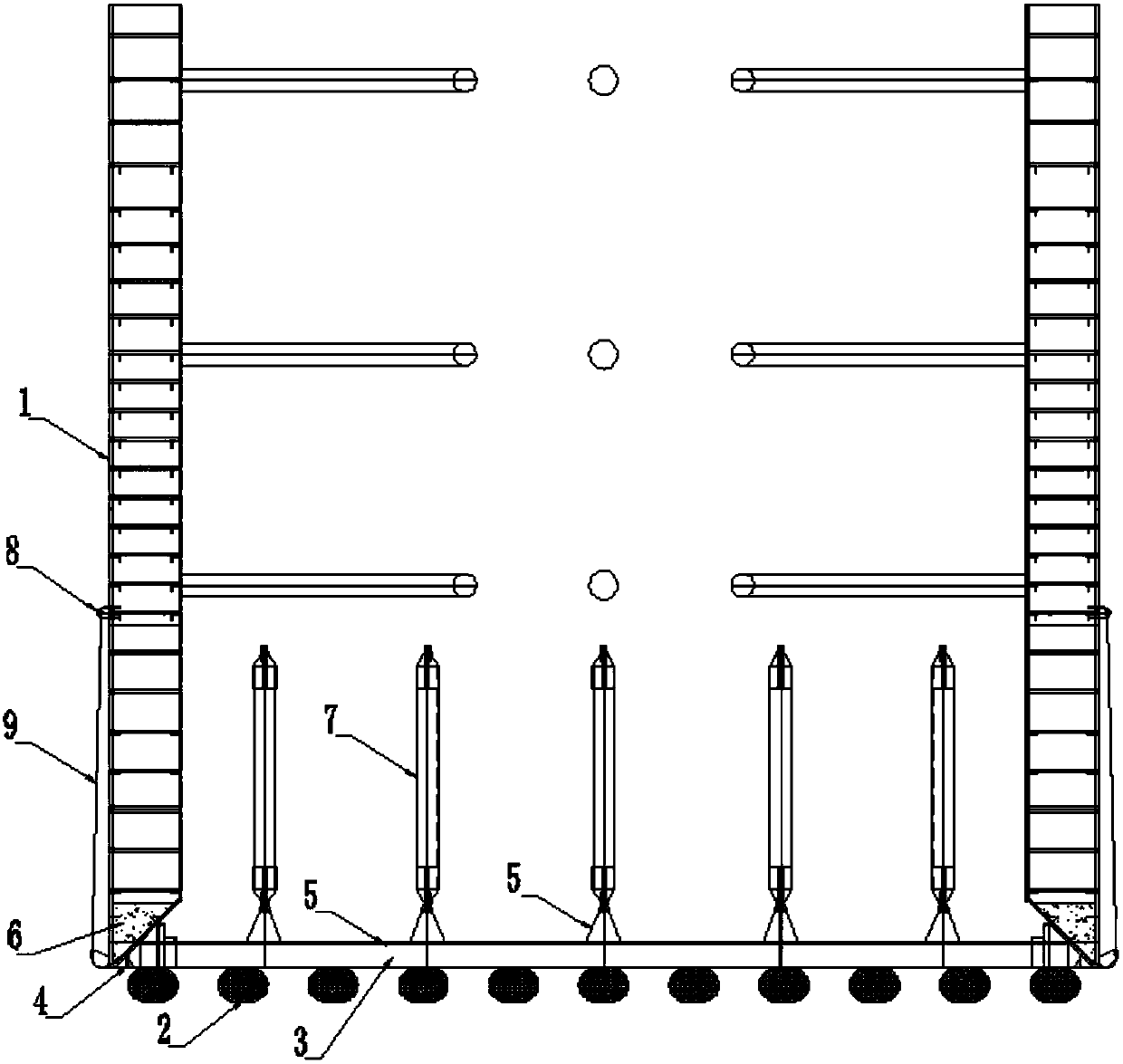

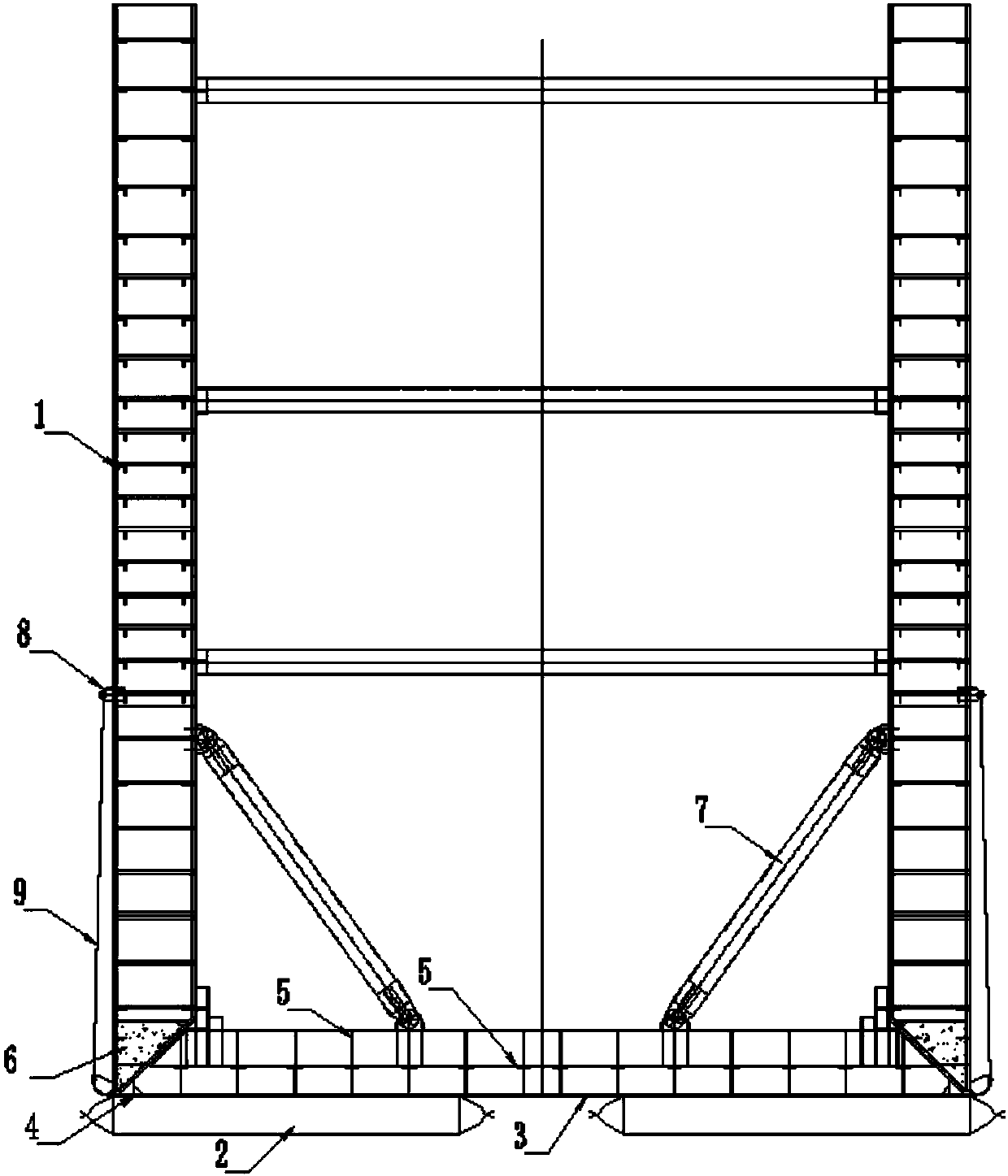

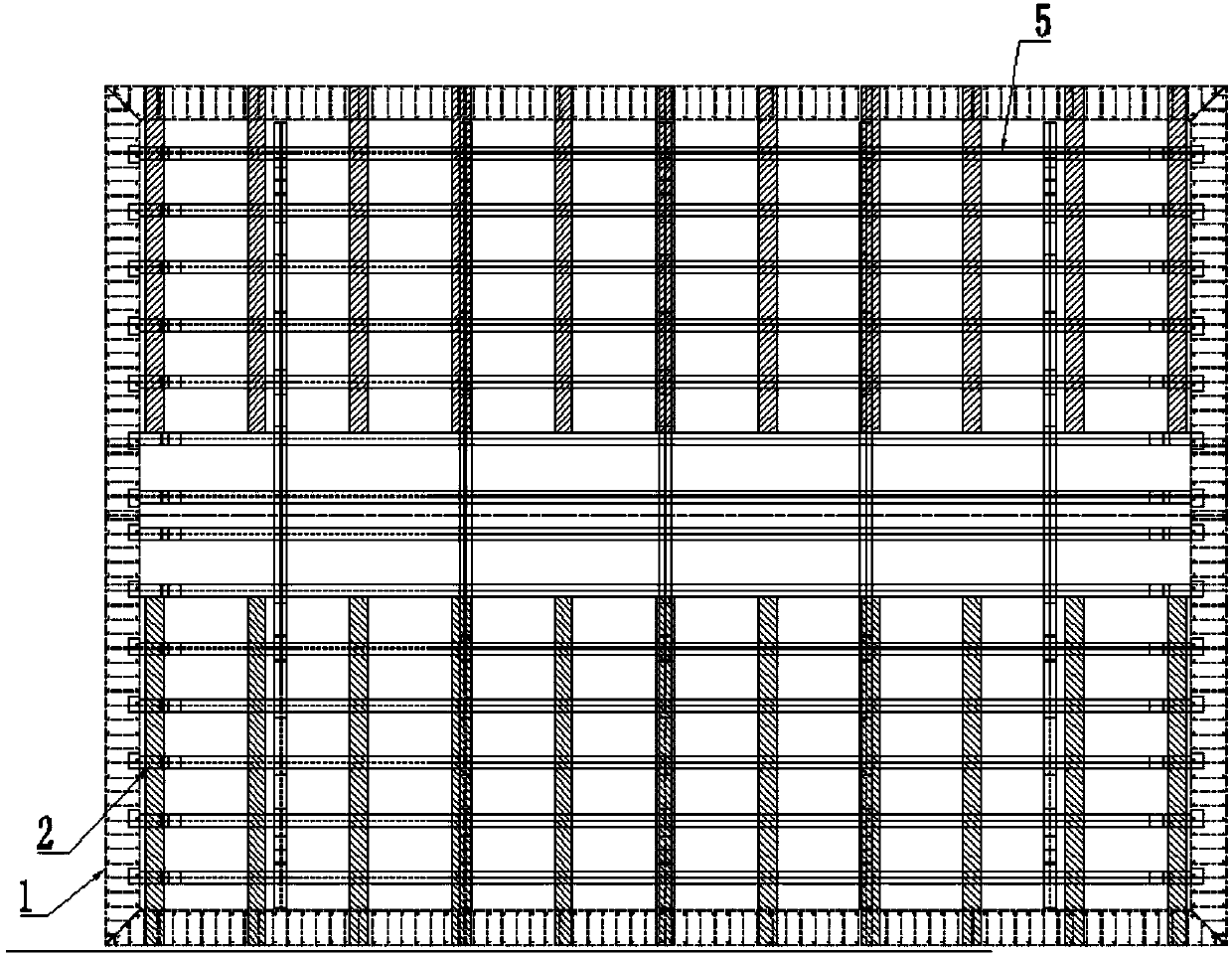

Partitioning supporting structure and method for large, long and deep foundation pit

InactiveCN106013167AImprove construction progressAvoid Staging Wall DemolitionExcavationsTowerBasement floor

The invention discloses a segmented support structure and a support method for long and deep foundation pits. The structure includes a plurality of partition supports that divide the foundation pit into several partitions, and a ring brace is fixed in each partition, and the ring The inner edge of the brace is rounded, and the outer edge of the ring brace matches the edge of the partition in which it is placed. It can realize the one-time excavation of super long and super large foundation pits, which greatly speeds up the construction speed, reduces the waste of labor, materials and time, and meets the development requirements of green construction. And it can effectively reduce the number of internal supports, so that the tower can avoid the construction of the supporting structure. When the basement floor is completed, the tower can be constructed, which speeds up the overall construction progress. Different construction sequences will have an important impact on the deformation of the ring brace and the distribution of internal forces, and the poor control of the roundness of the ring brace will affect the safety of the foundation pit project. , effectively controlling the roundness of the ring brace, thereby improving the safety of the foundation pit project.

Owner:SHANGHAI CONSTR NO 1 GRP

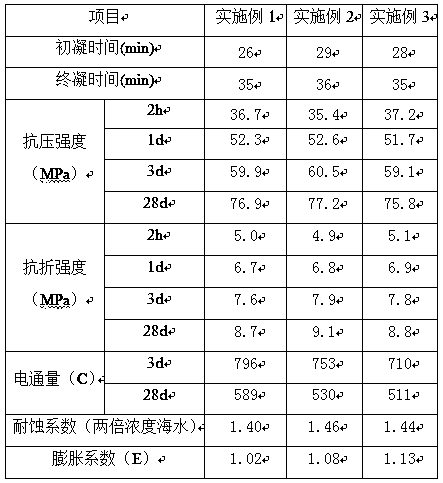

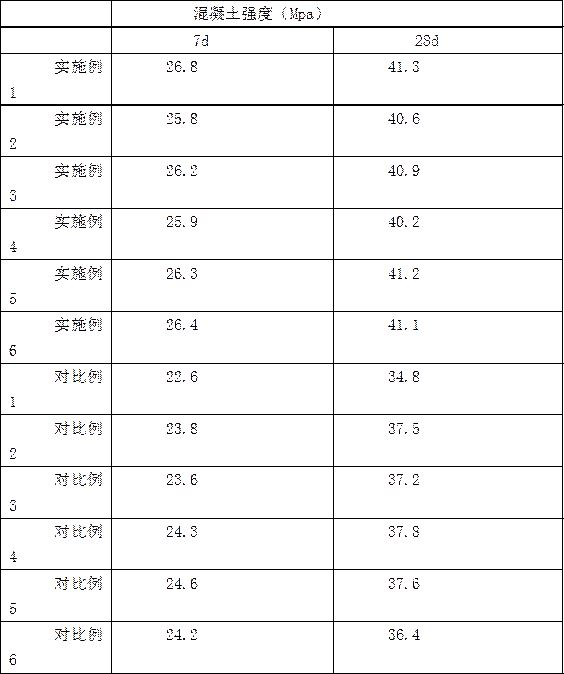

Marine sulphoaluminate cement for rapid construction and preparation method thereof

The invention discloses marine sulphoaluminate cement for rapid construction and a preparation method thereof. The marine sulphoaluminate cement is prepared from the following raw materials in parts by weight: 40-60 parts of sulphoaluminate cement clinker, 5-10 parts of modified nano calcium carbonate, 0.05-0.2 part of an efficient water reducing agent, 0-4 parts of a setting accelerator, 6-8 parts of an anti-cracking waterproof expanding agent, 3-5 parts of redispersible latex powder, 10-15 parts of clinker sea sand, 2-5 parts of silica fume, 6-10 parts of granulated blast furnace slag powderand 0.01-0.1 part of modified graphene. Concrete prepared from the marine sulphoaluminate cement can be quickly cured, has high early strength, can reach the demolding strength earlier, can be widelyapplied to ocean engineering buildings, and meets the requirement of quick construction in an ocean environment.

Owner:广西云燕特种水泥建材有限公司

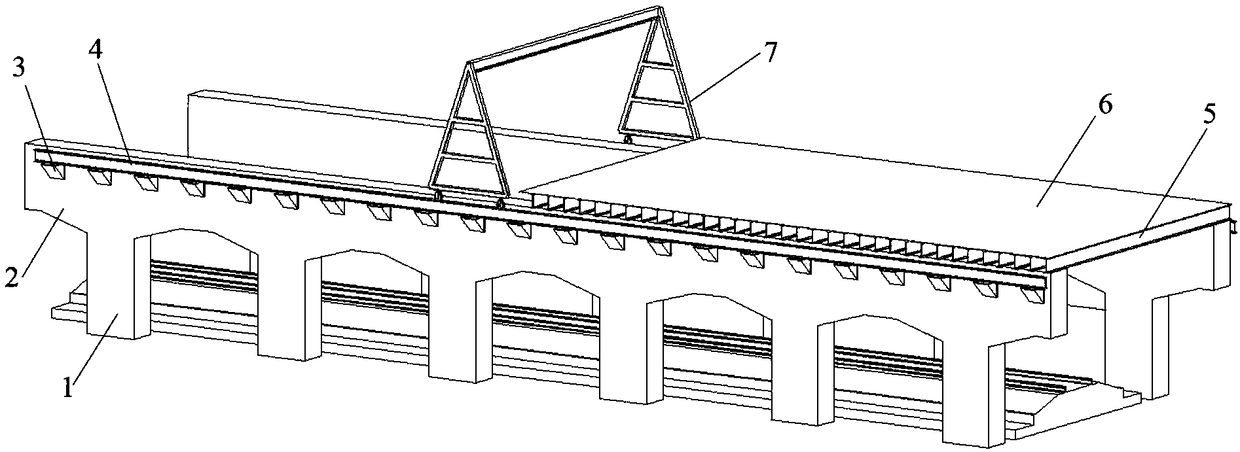

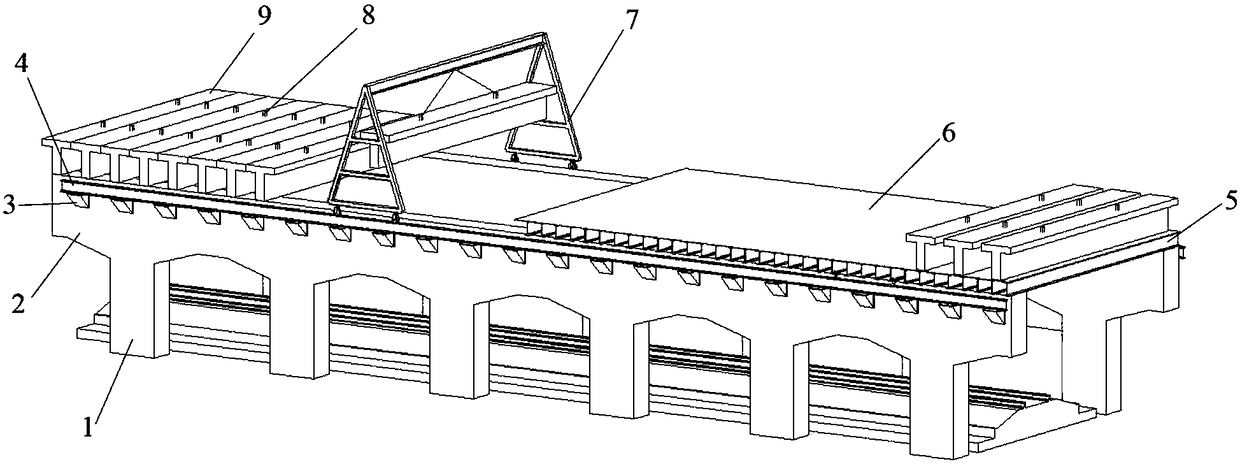

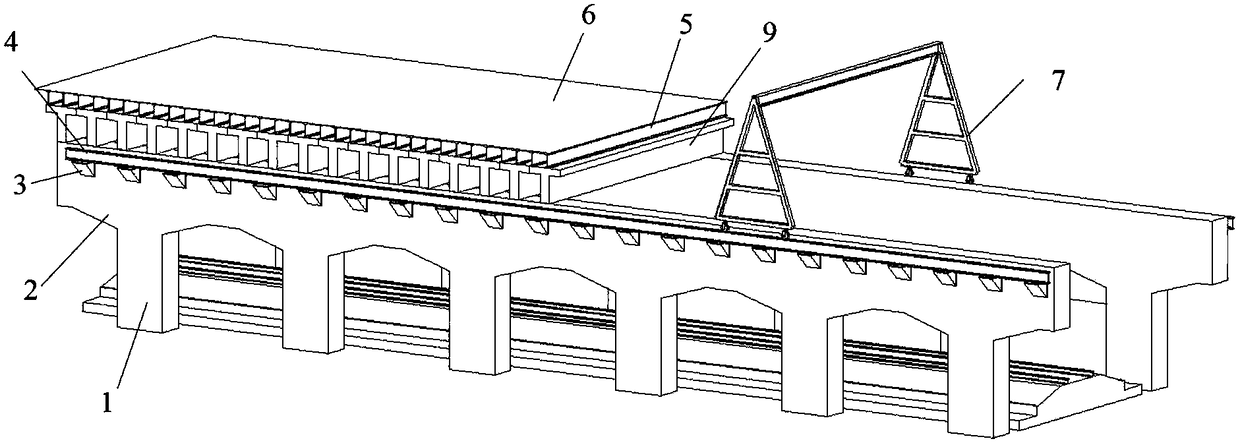

Quick construction method for over-crossing business line hangar tunnel T-shaped girder in narrow space

The invention discloses a quick construction method for an over-crossing business line hangar tunnel T-shaped girder in narrow space. The quick construction method includes the following steps that ahangar tunnel foundation pit is dug according to a designed location and a hangar tunnel stand column is constructed; a hangar tunnel vertical girder is constructed, a bracket support is pre-buried and a gantry crane walking railway is set up on the bracket support; a distributive girder and a form board are laid on the top of the hangar tunnel vertical girder to be used as a T-shaped girder primary prefabricating platform, and a gantry crane is arranged on the gantry crane walking railway; a T-shaped girder is poured on the T-shaped girder primary prefabricating platform and hoisted to a vacant zone; if the vacant zone can not be laid fully, then the step is conducted repeatedly; the T-shaped girder primary prefabricating platform is demolished, and the form board is laid on the T-shapedgirder to be used as a T-shaped girder secondary prefabricating platform; a T-shaped girder is poured on the T-shaped girder secondary prefabricating platform and hoisted to a vacant zone and erectingof the T-shaped girder is completed; the T-shaped girder secondary prefabricating platform is demolished and auxiliary facilities are exerted; and other unnecessary facilities are demolished. The problem of insufficient prefabricating places can be solved and the risk of the hoisting operation near the business line is avoided.

Owner:THE SECOND CONSTR OF CTCE GROUP +1

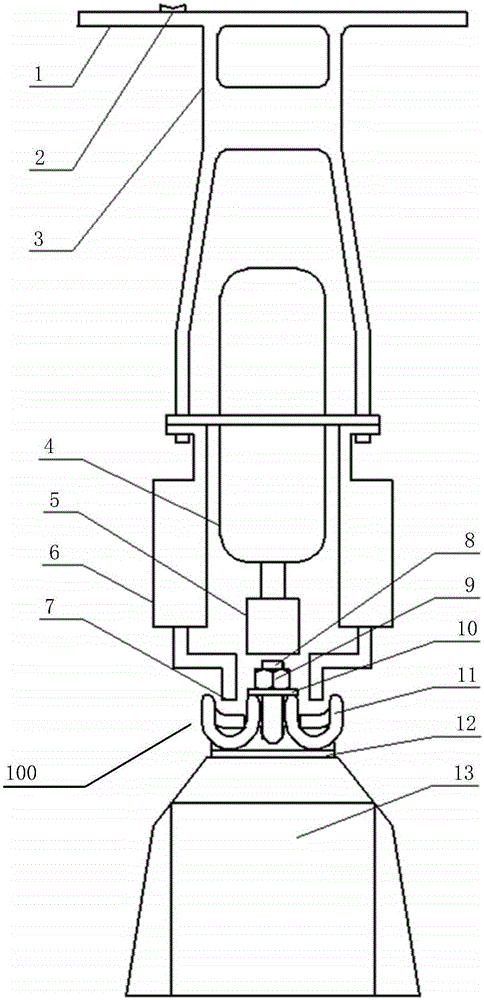

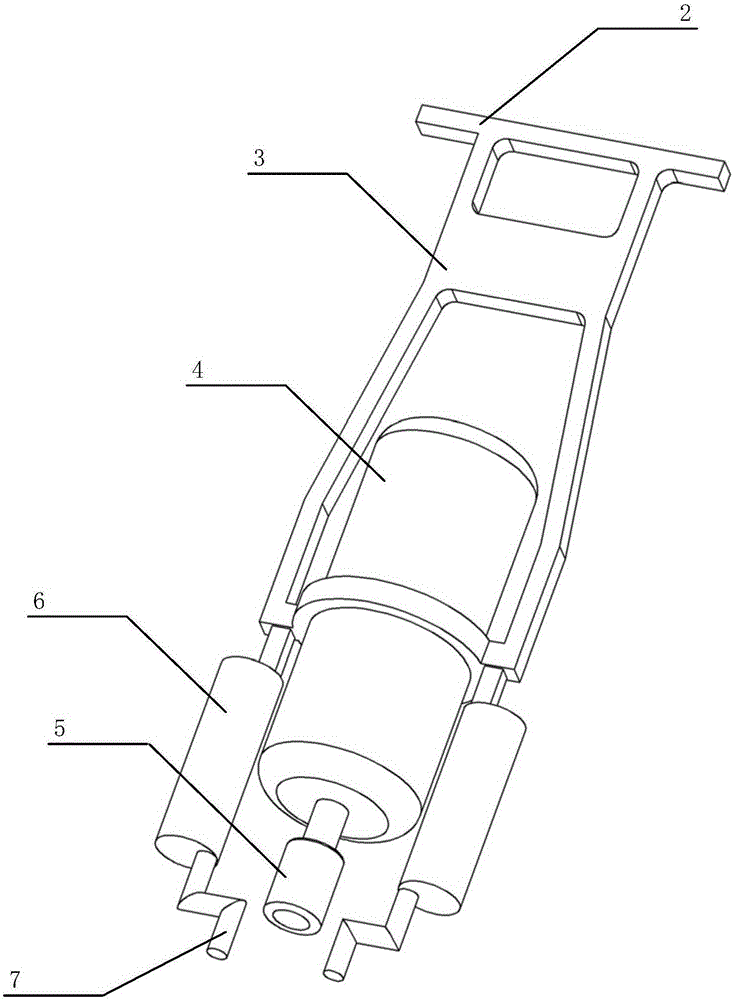

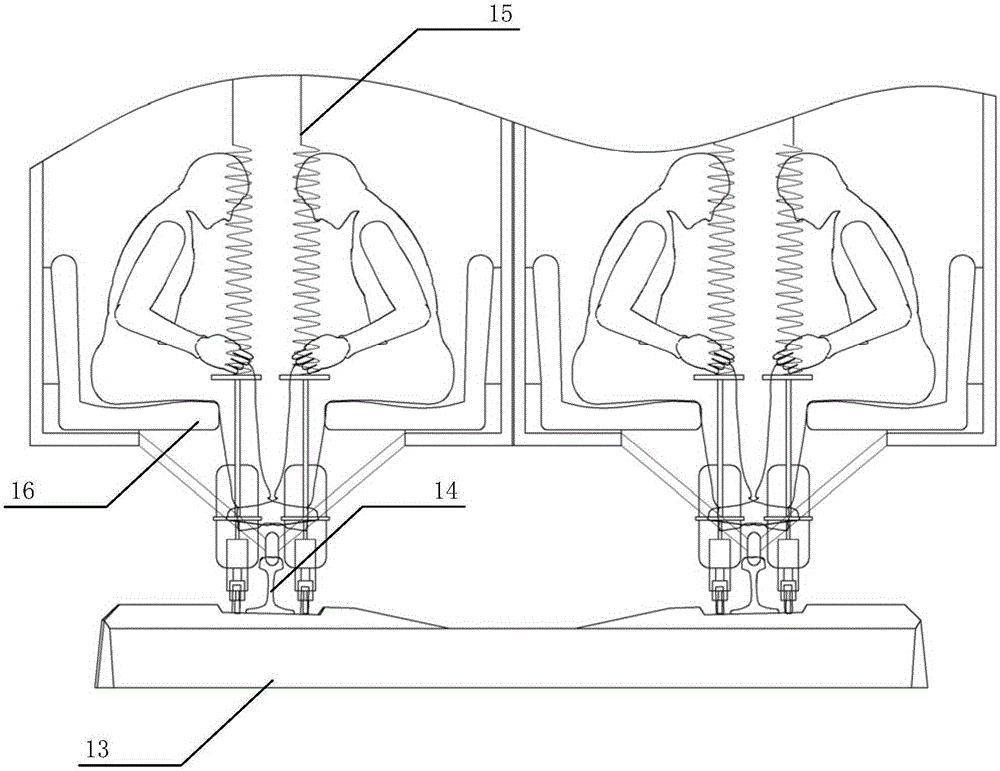

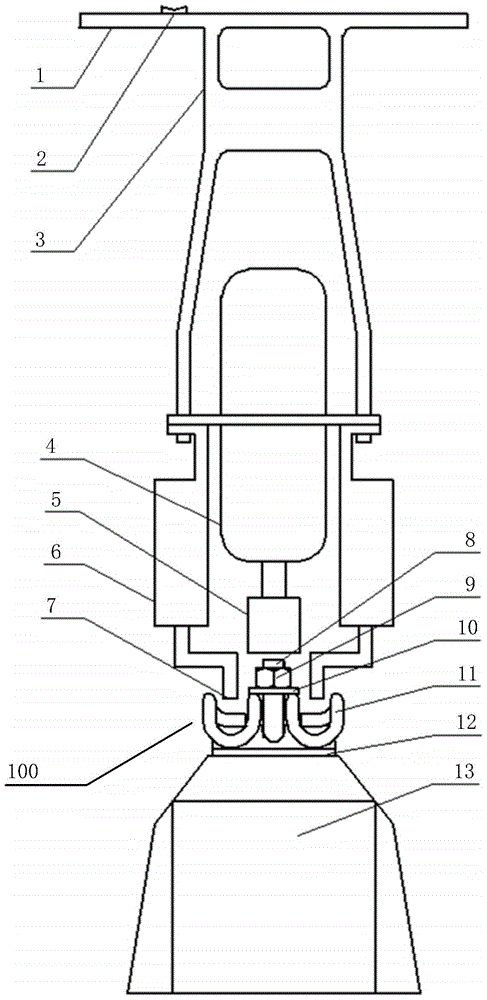

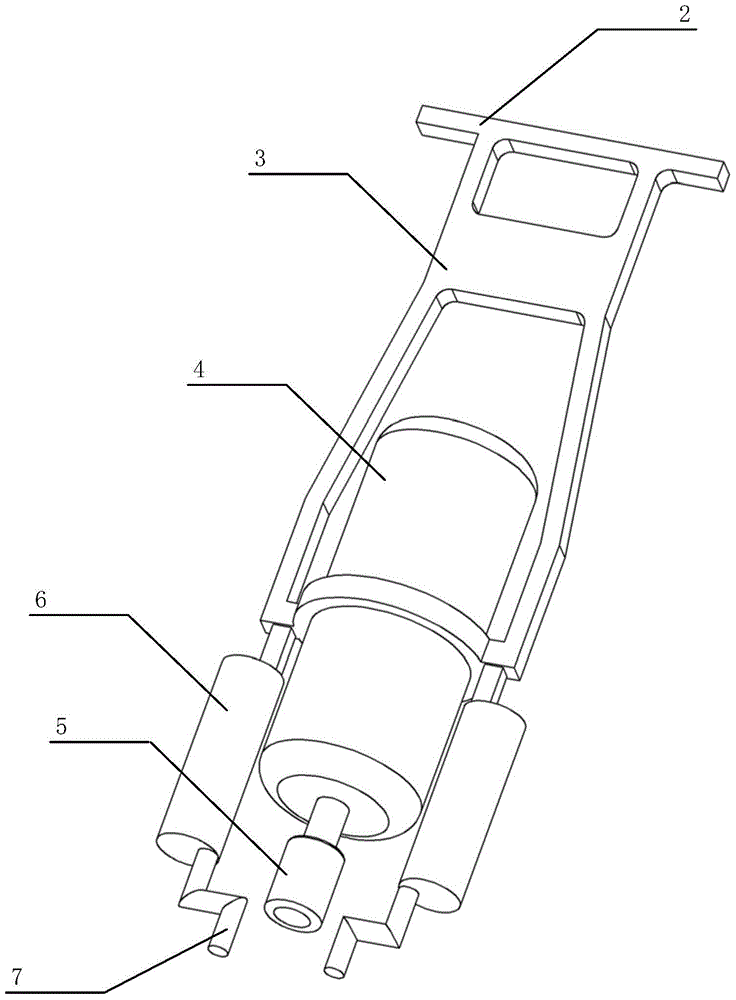

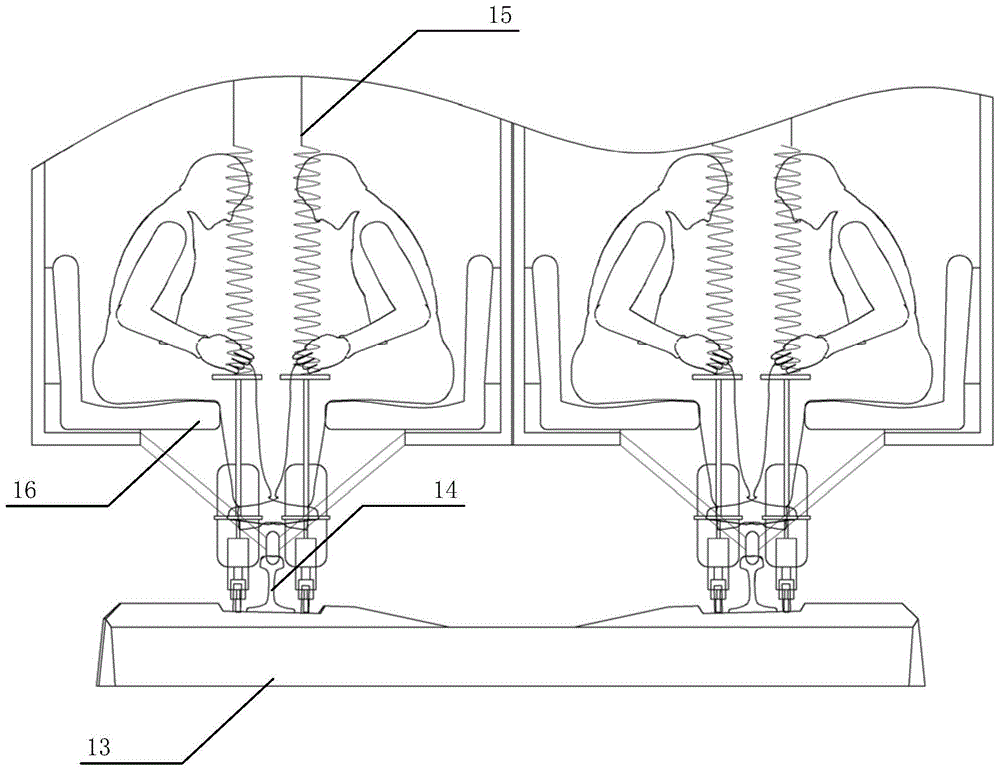

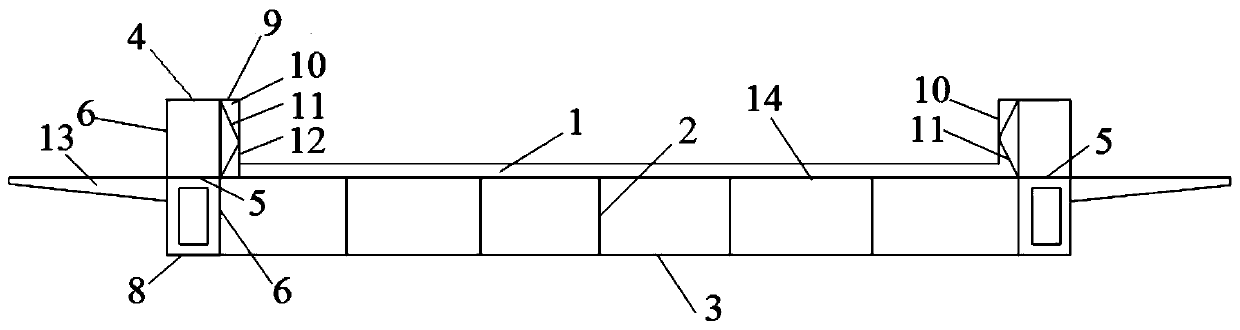

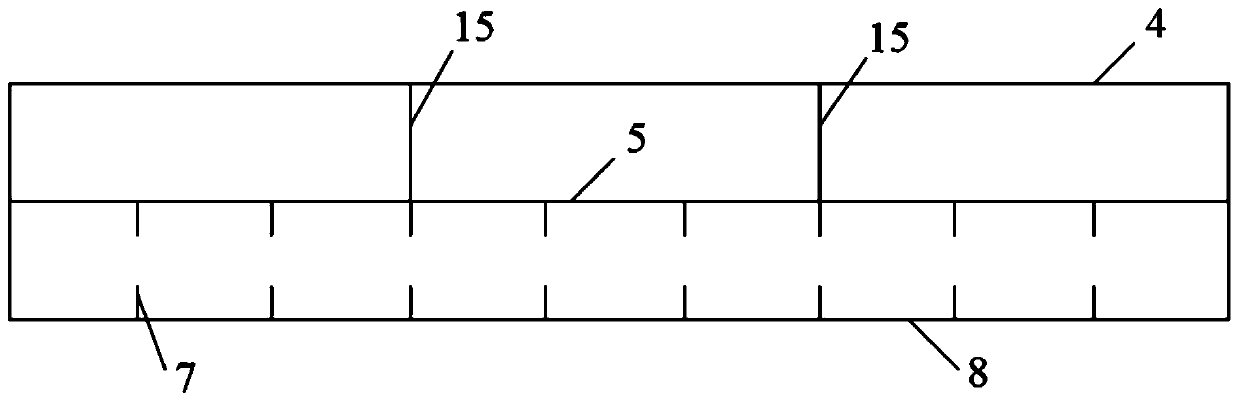

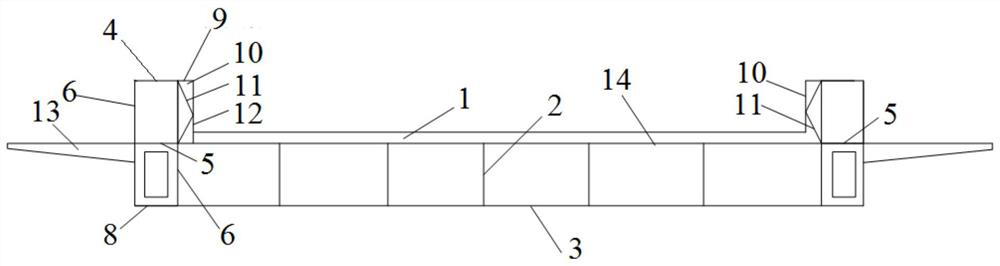

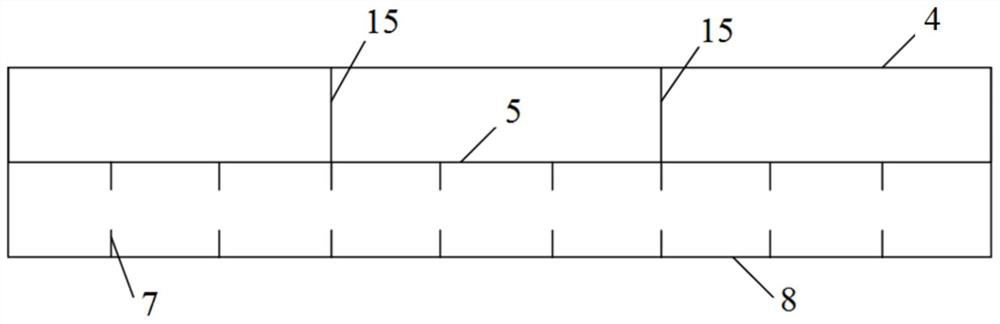

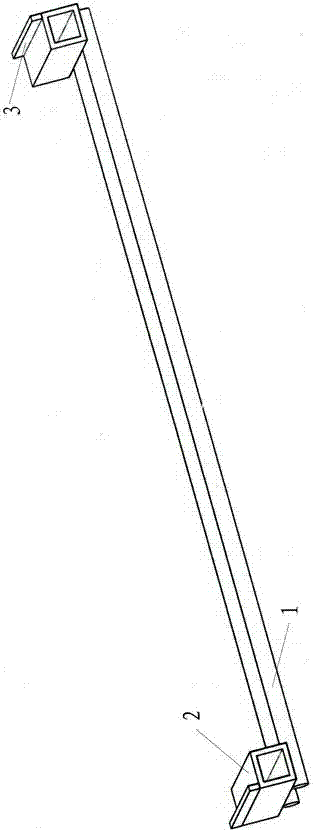

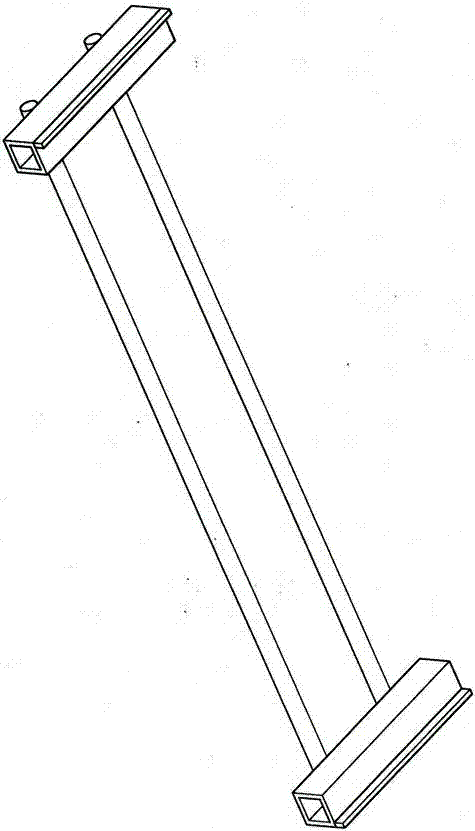

Railway fastener dismantling device and operating method thereof

ActiveCN105200874AMeet the requirements of rapid constructionAdapt quicklyRailway track constructionMagnetic polesEngineering

The invention discloses a railway fastener dismantling device and an operating method thereof. The device is used for dismantling a fastener on a railway line, and comprises a support, an electric wrench, a sleeve and electromagnets, wherein handles are arranged on two sides of the upper part of the support, the electric wrench is fixed at the lower part of the support, the sleeve is connected with the lower part of the electric wrench, and the electromagnets are arranged on two sides of the support. A nut on the fastener is loosened by the electric wrench, the whole fastener is sucked up by magnetic poles at the bottoms of the electromagnets, and the fastener is enabled to automatically fall off after the electromagnets are powered off and demagnetized. According to the device and the operating method thereof, not only can the nut be dismantled, but also the whole fastener can be dismantled; not only is the labor cost reduced, but also the operation efficiency is improved at the same time.

Owner:ZHUZHOU TIMES ELECTRONICS TECH CO LTD

A railway fastener removal device and its working method

ActiveCN105200874BMeet the requirements of rapid constructionImprove construction work efficiencyRailway track constructionMagnetic polesEngineering

The invention discloses a railway fastener dismantling device and an operating method thereof. The device is used for dismantling a fastener on a railway line, and comprises a support, an electric wrench, a sleeve and electromagnets, wherein handles are arranged on two sides of the upper part of the support, the electric wrench is fixed at the lower part of the support, the sleeve is connected with the lower part of the electric wrench, and the electromagnets are arranged on two sides of the support. A nut on the fastener is loosened by the electric wrench, the whole fastener is sucked up by magnetic poles at the bottoms of the electromagnets, and the fastener is enabled to automatically fall off after the electromagnets are powered off and demagnetized. According to the device and the operating method thereof, not only can the nut be dismantled, but also the whole fastener can be dismantled; not only is the labor cost reduced, but also the operation efficiency is improved at the same time.

Owner:ZHUZHOU TIMES ELECTRONICS TECH CO LTD

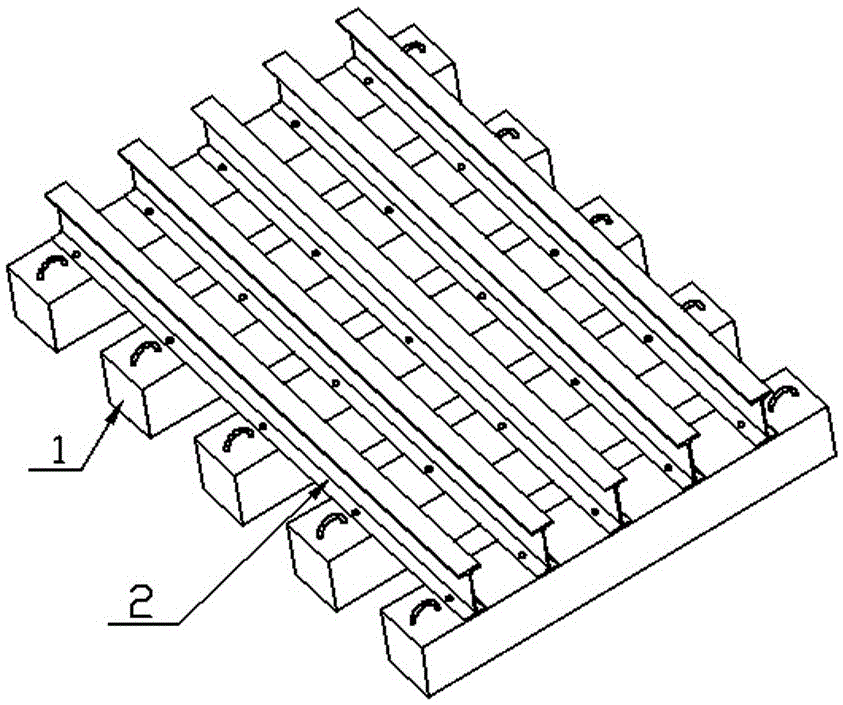

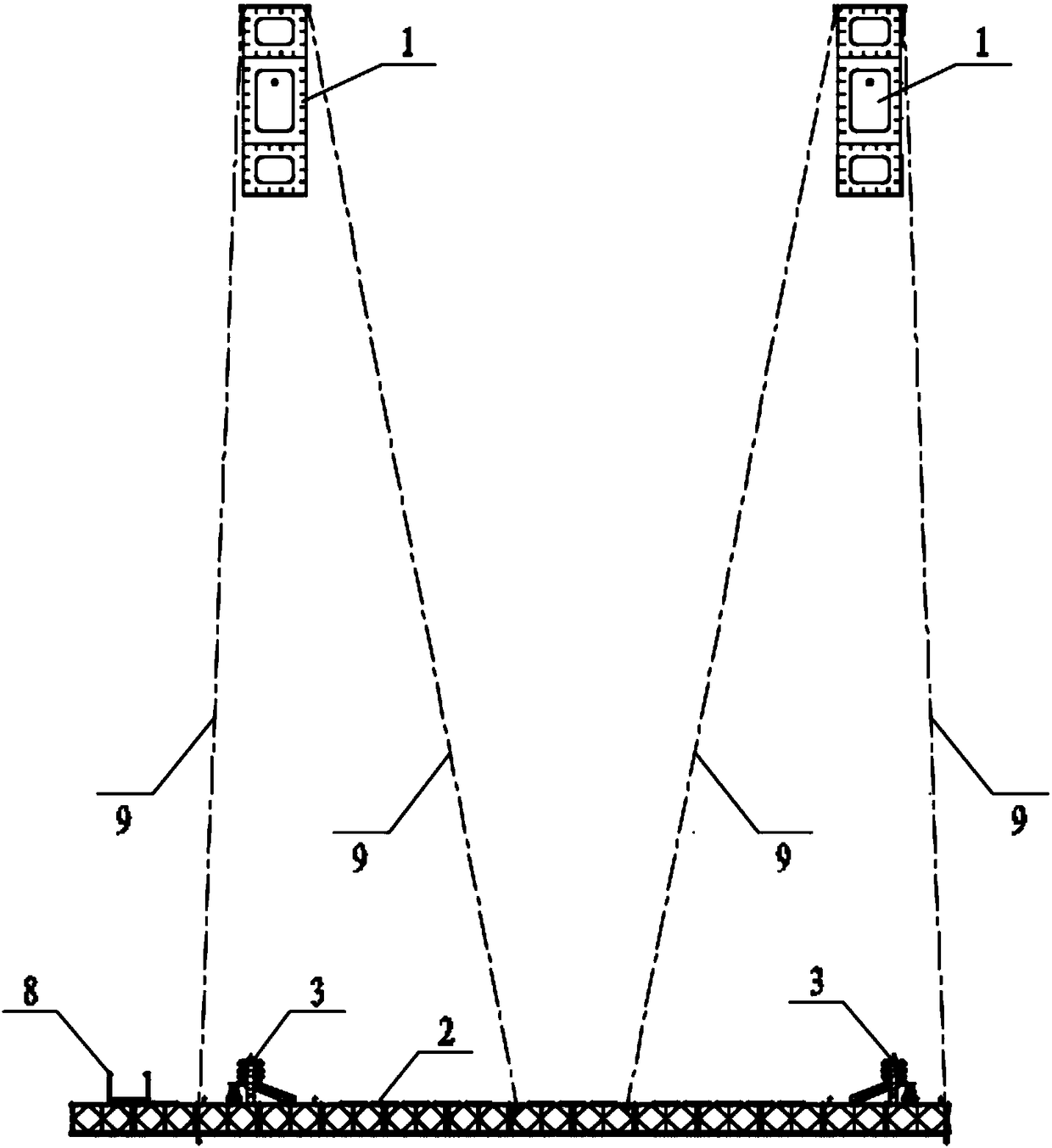

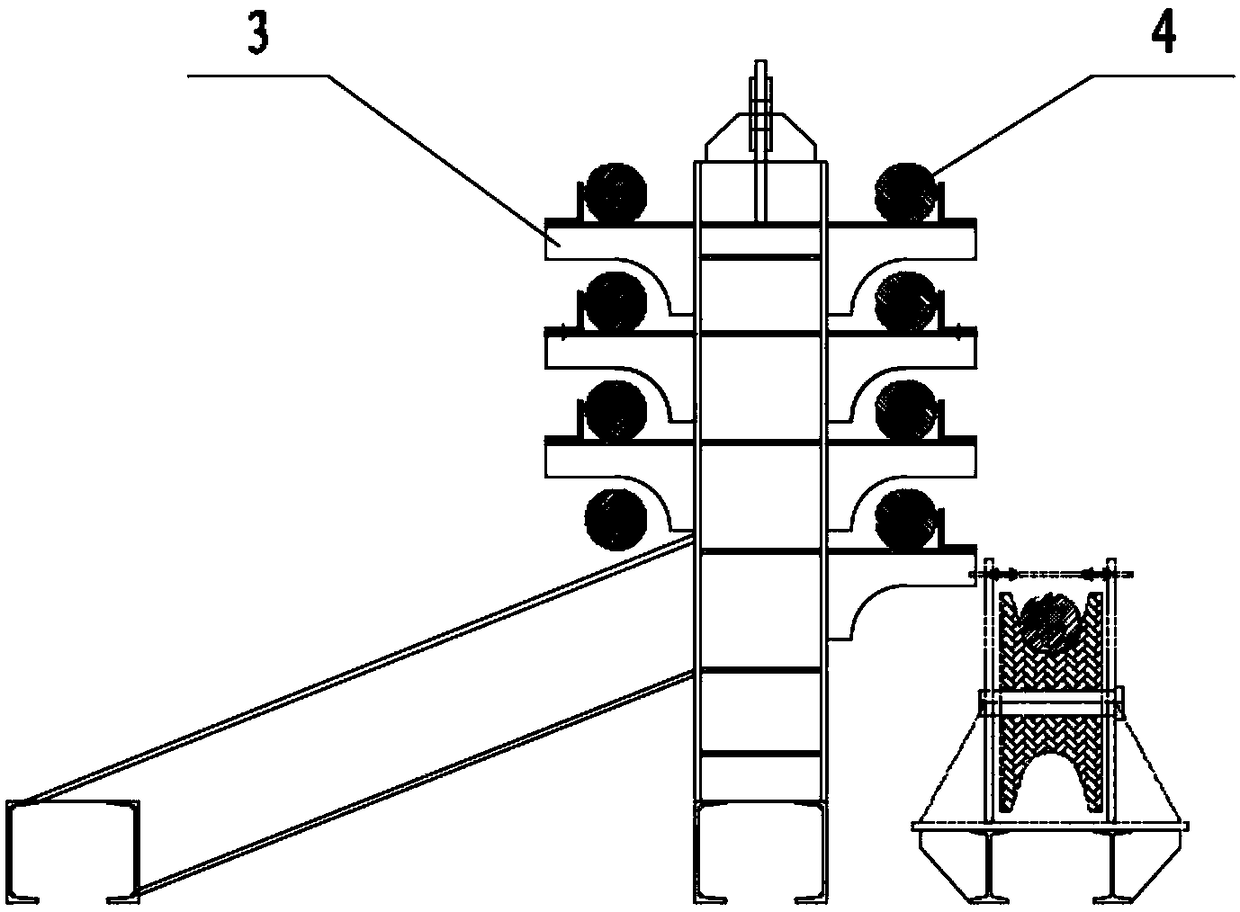

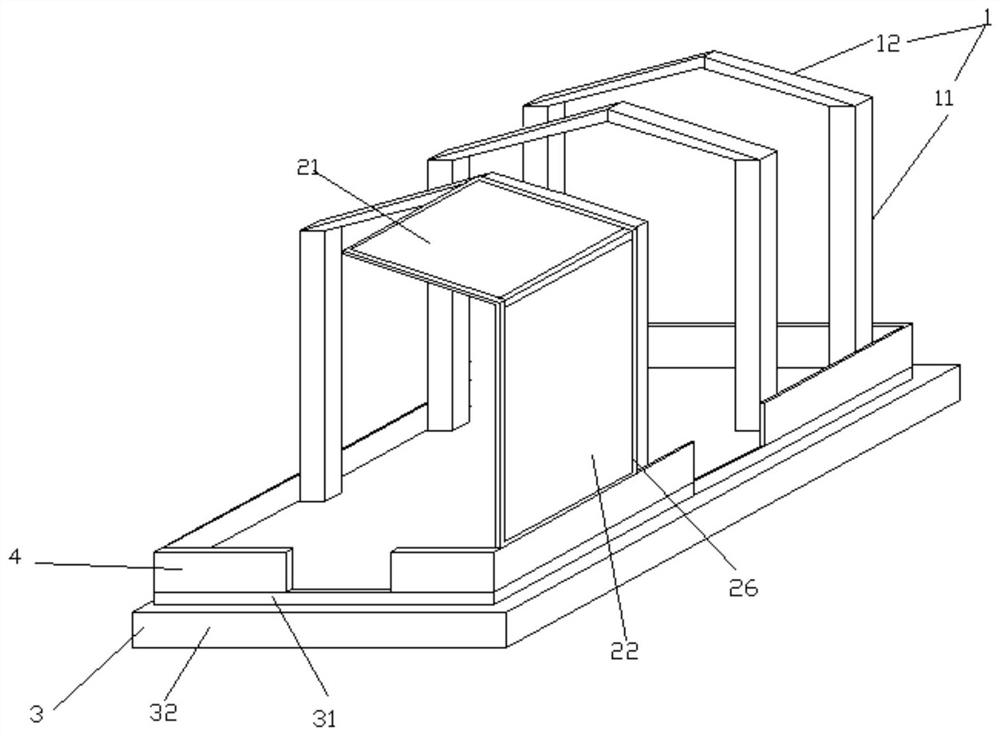

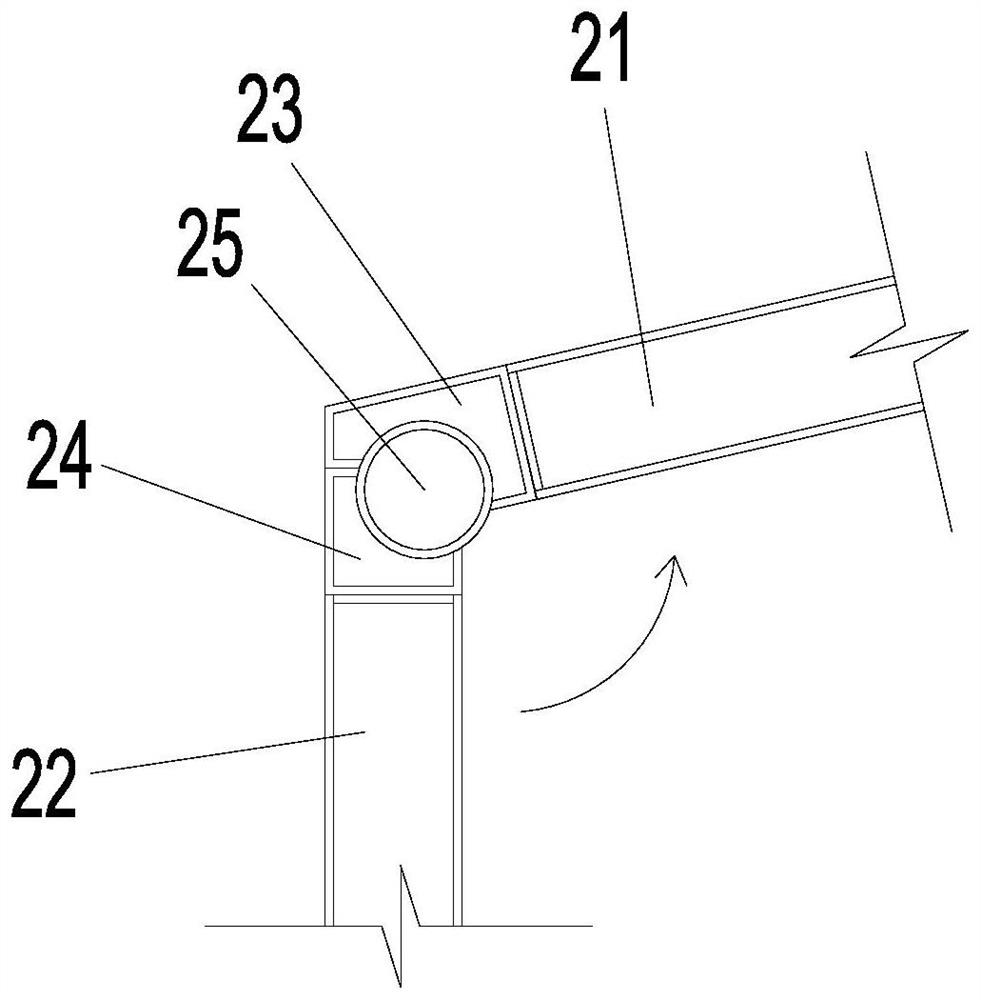

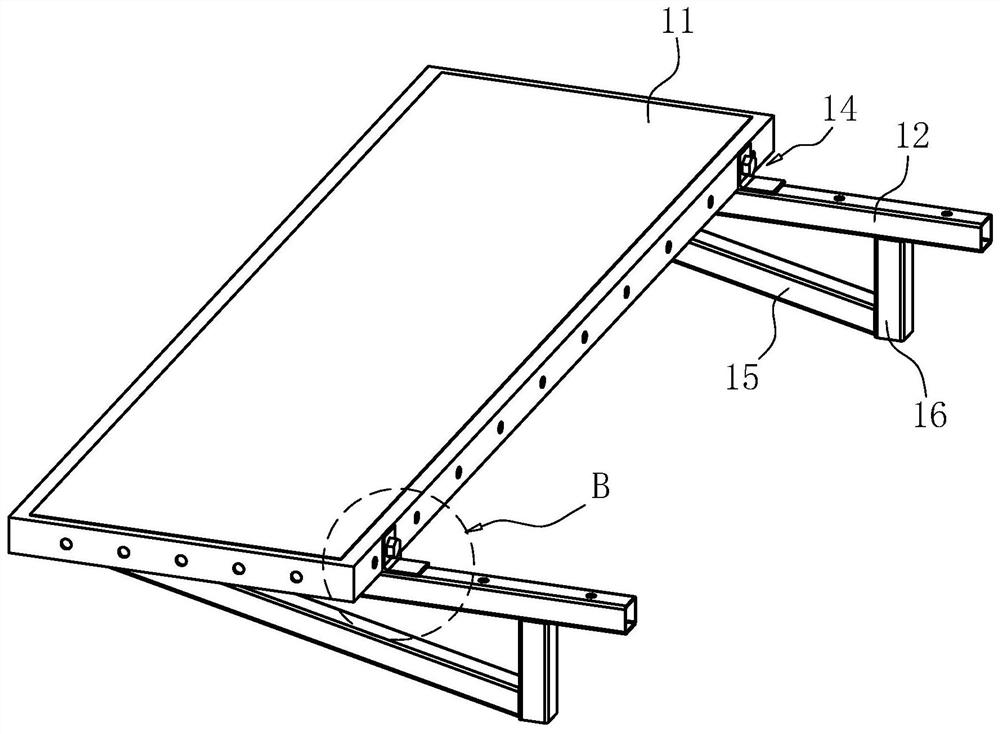

Ground prefabricated foundation of communication tower and mounting method of ground prefabricated foundation

InactiveCN106436738AShort cycleGuaranteed to be completed on scheduleFoundation engineeringReinforced concreteEngineering

The invention provides a ground prefabricated foundation of a communication tower and a mounting method of the ground prefabricated foundation. The ground prefabricated foundation of the communication tower comprises a plurality of strip-shaped foundation bodies which are distributed at equal intervals in parallel and a plurality of foundation steel frame beams which are distributed at equal intervals in parallel. The foundation steel frame beams are perpendicular to the strip-shaped foundation bodies. Each foundation steel frame beam is fixed to all the strip-shaped foundation bodies through prearranged bolts on the strip-shaped foundation bodies. By adoption of the ground prefabricated foundation of the communication tower and the mounting method of the ground prefabricated foundation, the problem that in the prior art, the cycle of field pouring of reinforced concrete is long is solved, the cycle is greatly shortened; and meanwhile, the transportation workload is reduced, and labor and cost are saved.

Owner:江苏铭远杆塔有限公司

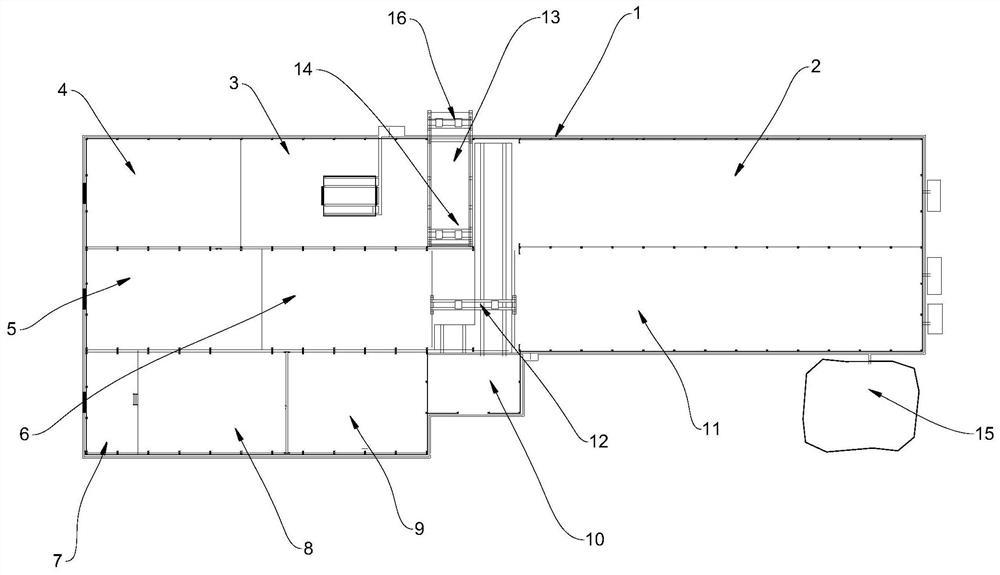

Detachable movable assembly line factory

PendingCN112140324AImprove qualityHigh dimensional accuracyCeramic shaping plantsProduction lineAssembly line

The invention relates to the technical field of assembly type concrete tower drum production, in particular to a detachable movable assembly line factory which comprises a movable detachable factory building, a matched full-automatic steel bar machining production line, a split type high-precision mold and a concrete component secondary finish machining center. The movable detachable workshop comprises an incoming material storage area, a reinforcement cage machining area, a reinforcement cage stacking area, a reinforcement cage mold entering area, a concrete distributing area, a mold closingarea, a heating curing area, a mold removal area, a grinding machine machining area, a high-pressure steam curing area and a finished product stacking area. A reinforcing steel bar machining area comprises a top hoisting system, an automatic ring sheet reinforcing steel bar stacking system and a conveying system; the reinforcement cage mold entering area comprises a mold cleaning mechanism and a lifting mechanism; and the mold removal area is provided with an independent cleaning area. The detachable movable assembly line factory provided by the invention has the advantages of being controllable in quality precision, high in component quality, efficient in production, capable of meeting the requirement for rapid construction of a wind field, standardized in component and convenient and rapid to construct, assemble and move.

Owner:上海电气研砼(木垒)建筑科技有限公司

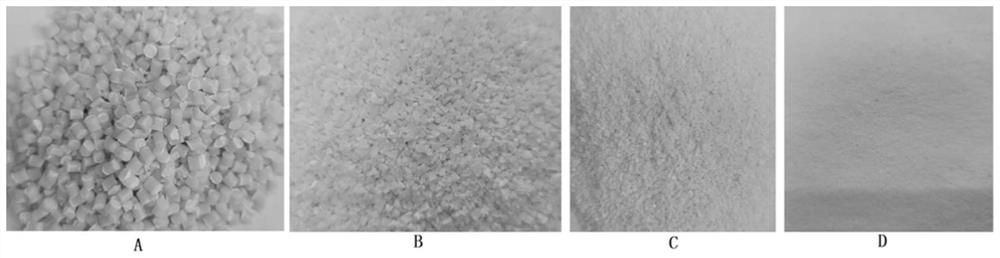

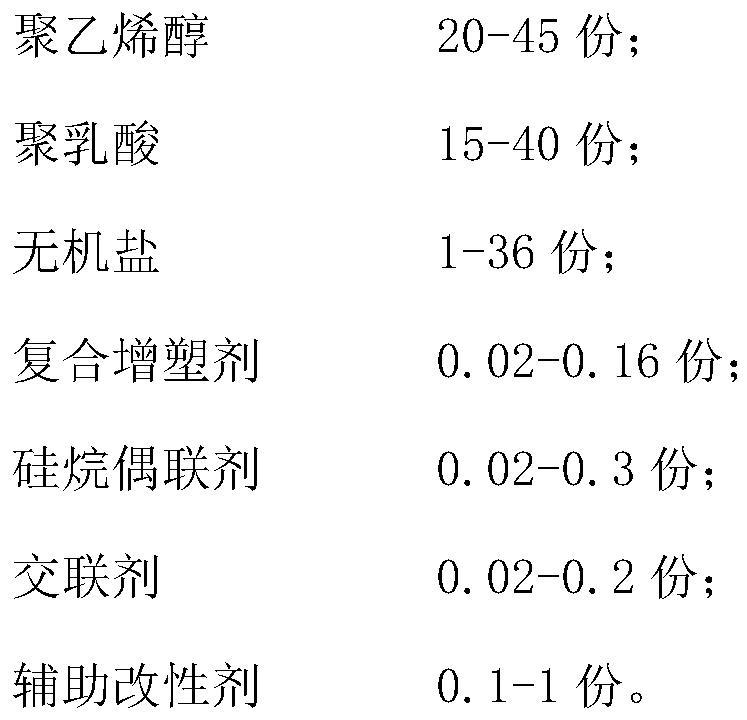

High-strength high-temperature acid fracturing temporary plugging agent and preparation method and application thereof

ActiveCN113372891AImprove solubilityEffective control of dissolution timeDrilling compositionPolyvinyl alcoholSilanes

The invention relates to the technical field of oil field water plugging agents, and discloses a high-strength high-temperature acid fracturing temporary plugging agent and a preparation method and application thereof. The high-strength high-temperature acid fracturing temporary plugging agent comprises the following components in parts by weight: 20-45 parts of polyvinyl alcohol; 15-40 parts of polylactic acid; 1-36 parts of an inorganic salt; 0.02-0.16 part of a composite plasticizer; 0.02-0.3 part of a silane coupling agent; 0.02-0.2 part of a cross-linking agent; and 0.1-1 part of an auxiliary modifier. The high-strength high-temperature acid fracturing temporary plugging agent is high in bearing strength; the dissolving time is controllable; the dispersibility in the dissolving process is good; high temperature resistance is realized; the compatibility is good; the raw materials are cheap and easily available; and the preparation process is simple and convenient for grinding.

Owner:CHENGDU LEARN PRACTICES TECH CO LTD

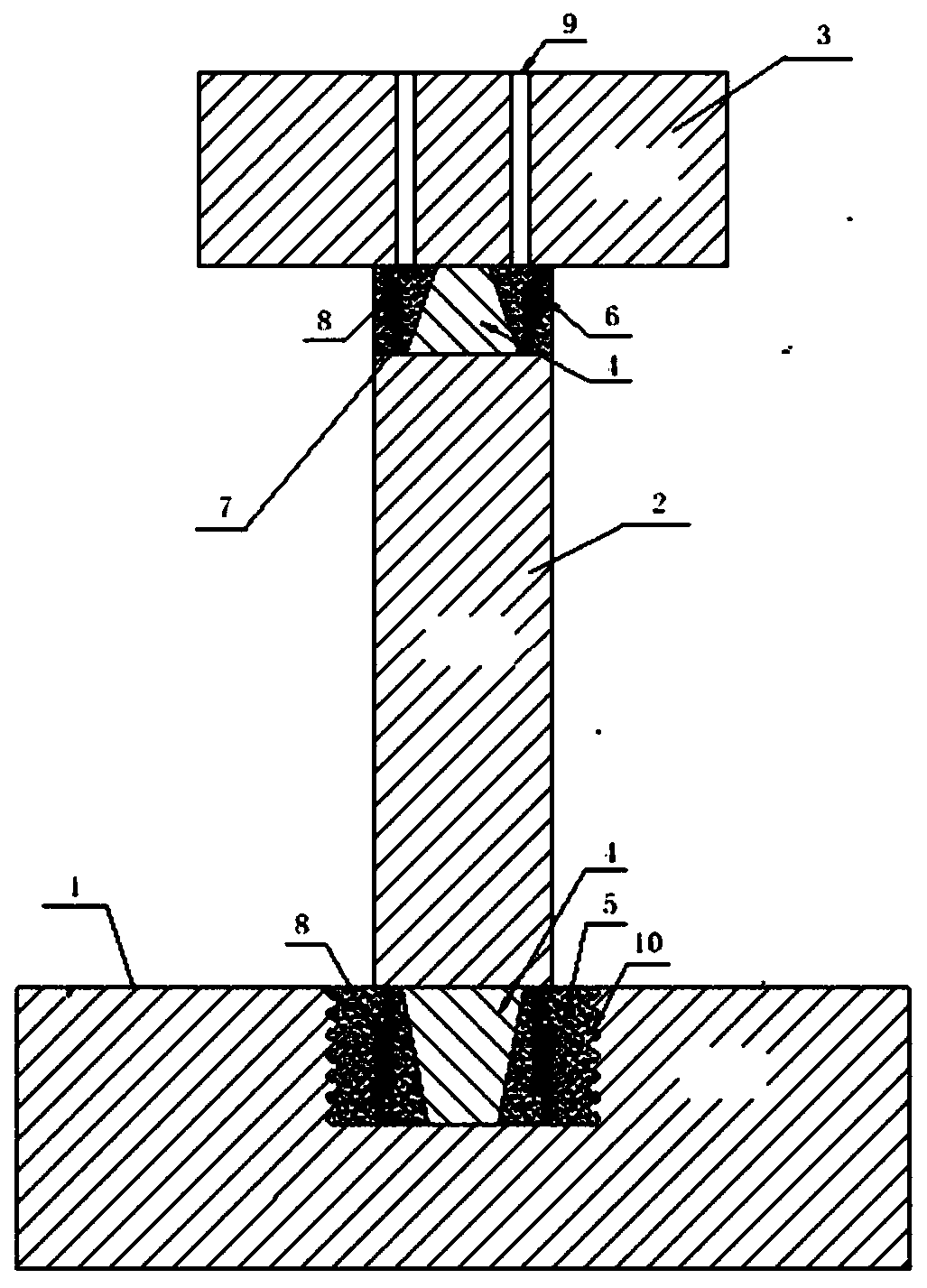

External structure suitable for prefabricated assembled pier stud connection and construction method thereof

PendingCN111485485AStable structureImprove seismic performanceBridge structural detailsFoundation engineeringArchitectural engineeringPier

The invention discloses an external structure suitable for prefabricated assembled pier stud connection and a construction method thereof. The external structure comprises a bearing platform, a pier body and a cover beam which are sequentially arranged from bottom to top; pouring spaces are formed between parts, corresponding to the cover beam and the bearing platform, of the upper end and the lower end of the pier body and are used for pouring concrete, and the cover beam, the pier body and the bearing platform form a fixed whole; the portions, correspondingly connected with the cover beam and the bearing platform, of the upper end and the lower end of the pier body are provided with reinforcing components respectively, and the reinforcing components arranged at the upper end and the lower end of the pier body are both located in the pouring spaces of the corresponding ends of the pier body. The external structure has the technical effects of being stable in structure, reliable in connection, convenient to adjust and capable of being rapidly installed, and can be widely applied to the field of building construction.

Owner:CCCC SECOND HARBOR ENG +1

Prefabricated assembled narrow-web combined box girder structure and construction method thereof

ActiveCN111501518ALower beam heightSolve the situation where the beam height is limitedBridge erection/assemblyArchitectural engineeringBridge deck

The invention discloses a prefabricated assembled narrow-web combined box girder structure which comprises a box girder body and two side longitudinal beams arranged at the two ends of the box girderbody respectively, and a bridge deck slab is arranged on the top face of the box girder body. An anti-collision area is arranged on the side, close to the bridge deck slab, of the upper portion of each side longitudinal beam. The anti-collision area comprises a sealing plate, an anti-collision panel and an anti-collision K support fixedly connected with a side plate of the edge longitudinal beam,the anti-collision panel is located on the side, away from the edge longitudinal beam, of the anti-collision K support, the sealing plate is located above the anti-collision K support, and the anti-collision panel and the edge longitudinal beam are fixedly connected with the sealing plate. According to the prefabricated assembled narrow-web combined box girder structure and the construction methodthereof, the structure is simple, assembling is convenient, and the requirement for rapid construction of urban bridges can be met.

Owner:SHENZHEN MUNICIPAL DESIGN & RES INST

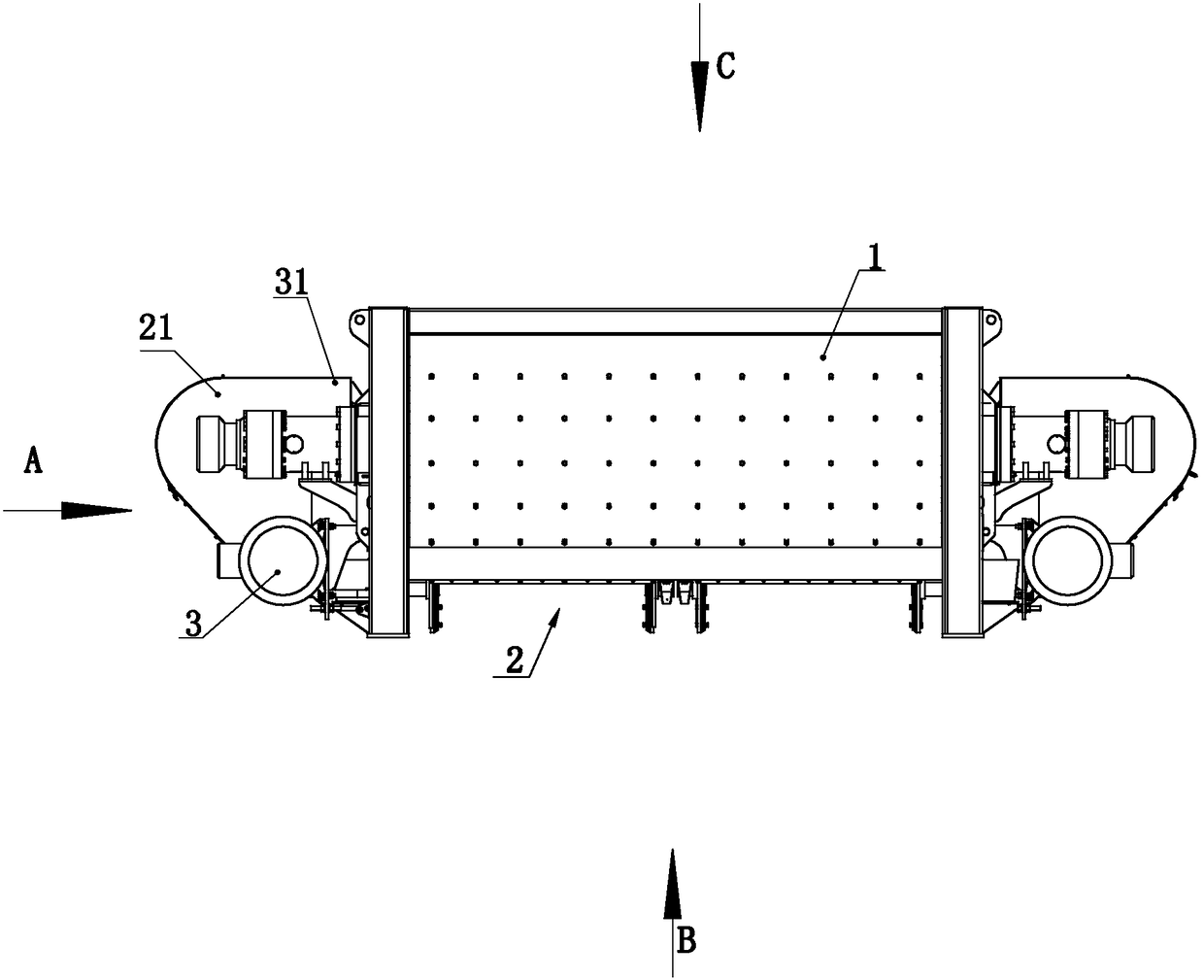

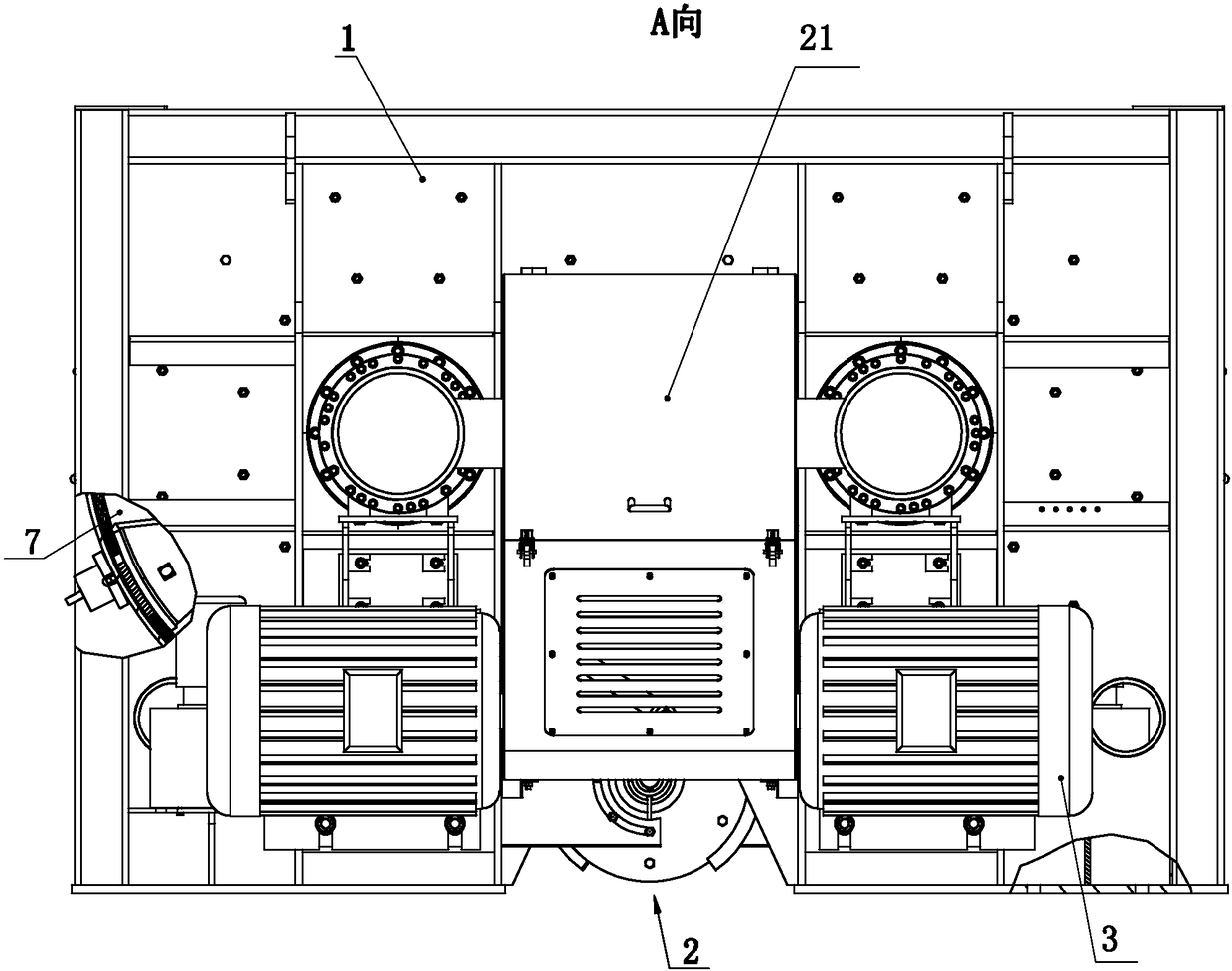

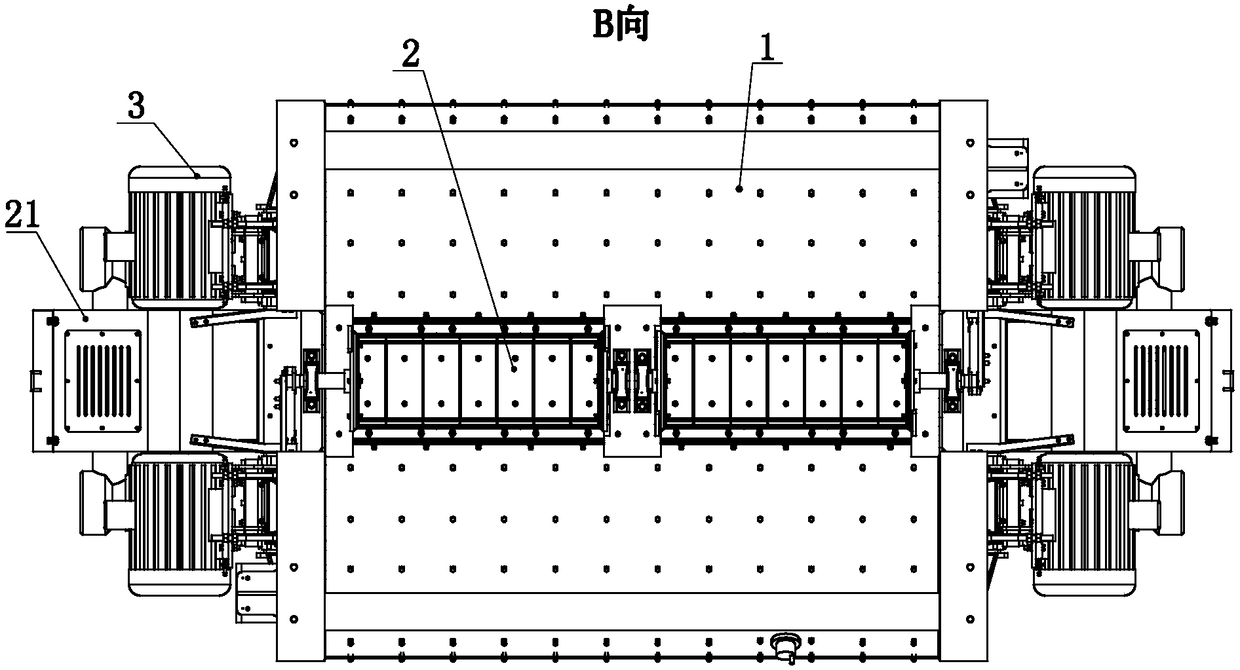

Large-scale concrete mixing engine for irrigation works

PendingCN108340490AQuality assuranceEasy to manage centrallyDischarging apparatusCement mixing apparatusRoller-compacted concreteMixing tank

The invention relates to the technical field of concrete mixing, in particular to a large-scale concrete mixing engine for irrigation works. The large-scale concrete mixing engine is used for solvingthe problem that in the prior art, the single-tank mixing amount is small. The large-scale concrete mixing engine for the irrigation works comprises a mixing tank, a mixing device and a driving system. Two unloading doors are arranged at the bottom of the mixing tank, and the unloading doors are rotationally connected to the mixing tank. Each unloading door is in transmission connection with a hydraulic driver for driving the unloading door to rotate, and the mixing device is arranged in the mixing tank. The mixing device is in transmission connection with the driving system, and the driving system achieves double-end driving on the mixing device. The large-scale concrete mixing engine has the beneficial effects that the single-tank mixing amount can reach 9,000 L, and the large-scale concrete mixing engine is especially suitable for mixing work of roller compacted concrete for the irrigation works.

Owner:SHANTUI JANEOO MACHINERY

Underwater concrete and preparation method thereof

The invention discloses underwater concrete, belonging to the technical field of concrete. According to a technical scheme in the invention, the underwater concrete is prepared from the following rawmaterials in parts by weight: 35-45 parts of gravel, 3-10 parts of fine aggregate, 20-25 parts of machine-made sand, 6-20 parts of cement, 0.1-0.6 part of a polycarboxylate superplasticizer, 0.05-0.2part of sodium fluosilicate, 0.01-0.05 part of aluminum fluoride, 0.03-0.1 part of diethanol amine and 0.05-0.1 part of xanthan gum. The invention also provides the preparation method of the underwater concrete. The underwater concrete prepared by using the preparation method has the properties of low loss rate and rapid solidification, and can meet the requirement of rapid construction in seawater.

Owner:湖州上建华煜混凝土有限公司

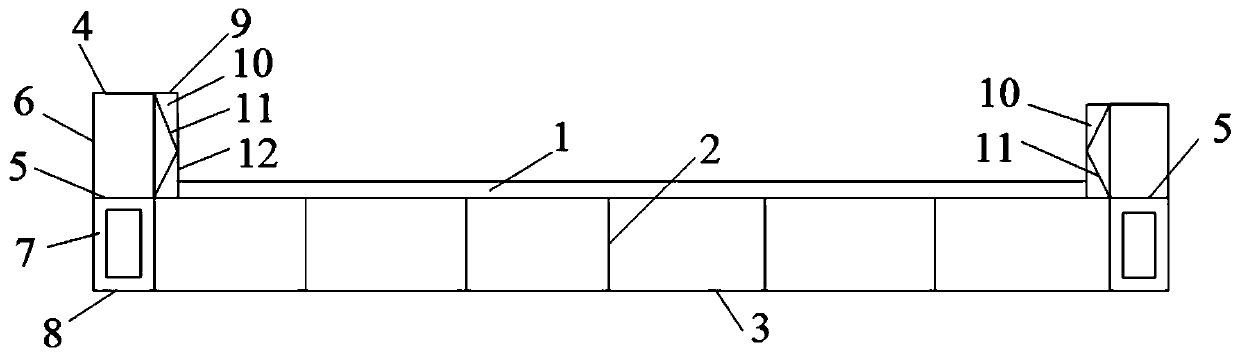

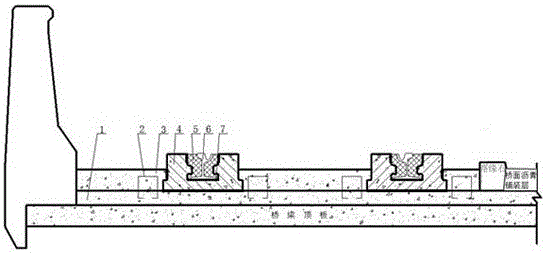

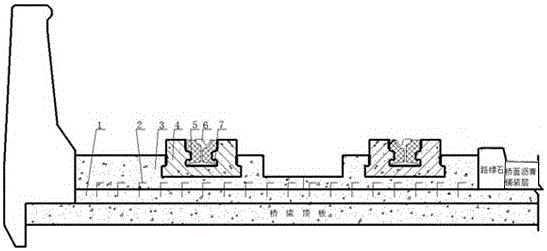

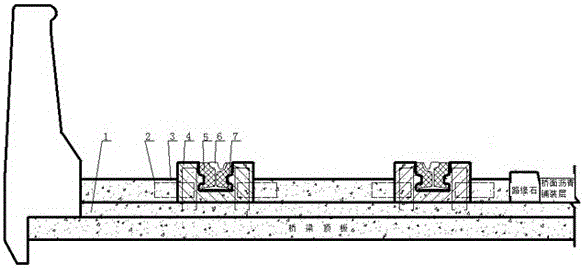

An embedded track structure suitable for medium and small span bridges and its construction method

ActiveCN105133493BGood vibration and noise reductionReduce peeling lossBridge structural detailsBridge erection/assemblyReinforced concreteBridge deck

The invention discloses an embedded track structure suitable for a middle-span and small-span bridge. The embedded track structure comprises a bridge top plate, a bridge deck cast-in-place layer, a connecting element, a reinforced concrete base, two track bearing grooves and two groove type tracks, wherein the bridge deck cast-in-place layer is cast on the bridge top plate; each groove type track is arranged in the corresponding track bearing groove in an embedded manner; the two track bearing grooves are embedded into the reinforced concrete base in parallel in the longitudinal direction; the reinforced concrete base is arranged on the bridge deck cast-in-place layer; the bridge deck cast-in-place layer and the reinforced concrete base are connected into a whole through the connecting element. The embedded track structure has the benefits as follows: by adopting the embedded track structure, the vibration reduction and noise reduction effects are good; the structure is simple, the self weight is light, structural requirements of a city bridge are reduced, the construction cost is reduced and city quick construction requirements are met; the connecting element adopts a rigid connection mode, so that the whole stability of the track structure on the bridge is improved.

Owner:CHENGDU XINZHU ROAD & BRIDGE MASCH CO LTD

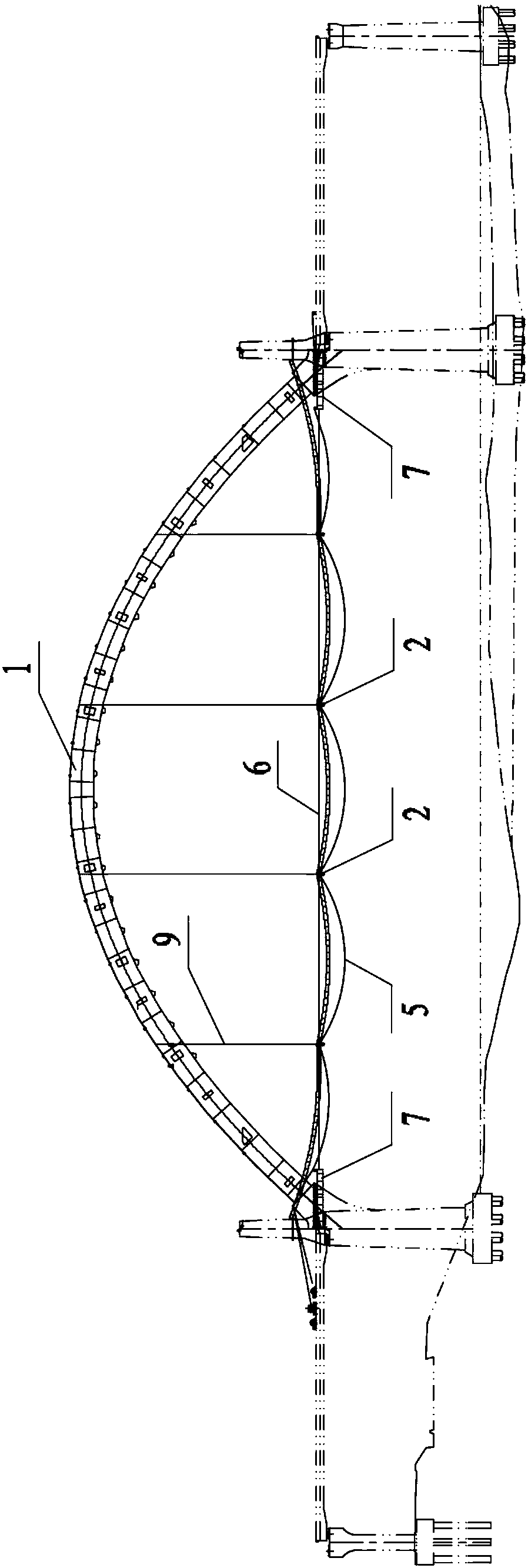

Method for mounting large-span arch bridge tie bars

InactiveCN108330833AReduce spanSatisfy rapid constructionBridge erection/assemblyArch-type bridgeEngineeringSpandrel

The invention discloses a method for mounting large-span arch bridge tie bars and relates to the field of bridge engineering construction. The method includes following steps: S1, hanging multiple supports on arch ribs at intervals, arranging at least one supporting frame on each support, arranging multiple spaces for storing the tie bars on the supporting frames, and mounting a winch and a traction rope at two ends of an arch bridge; S2, connecting the front end of one tie bar with the traction rope, and starting the winch to enable the tie bar to sequentially pass all supports from one sideof the arch bridge; S3, allowing the winch to continue working to enable the tie bar to penetrate a pipeline positioned on the other side of the arch bridge, and putting the tie bar on the supportingframes; S4, repeating the steps S2-S3 to put the rest tie bars onto the supporting frames; S5, penetrating two ends of all tie bars into a tensioning device, and utilizing the tensioning device to synchronously tension all tie bars to finish. The method is free of channel occupation, short in construction period and needless of a cable crane for aerial operation.

Owner:CHINA RAILWAY MAJOR BRIDGE ENG GRP CO LTD

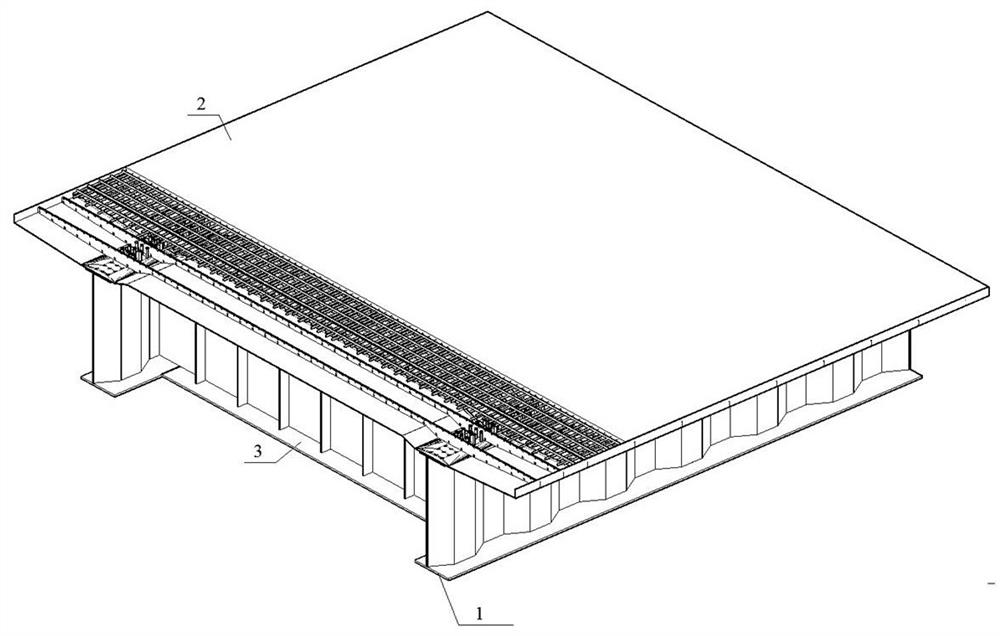

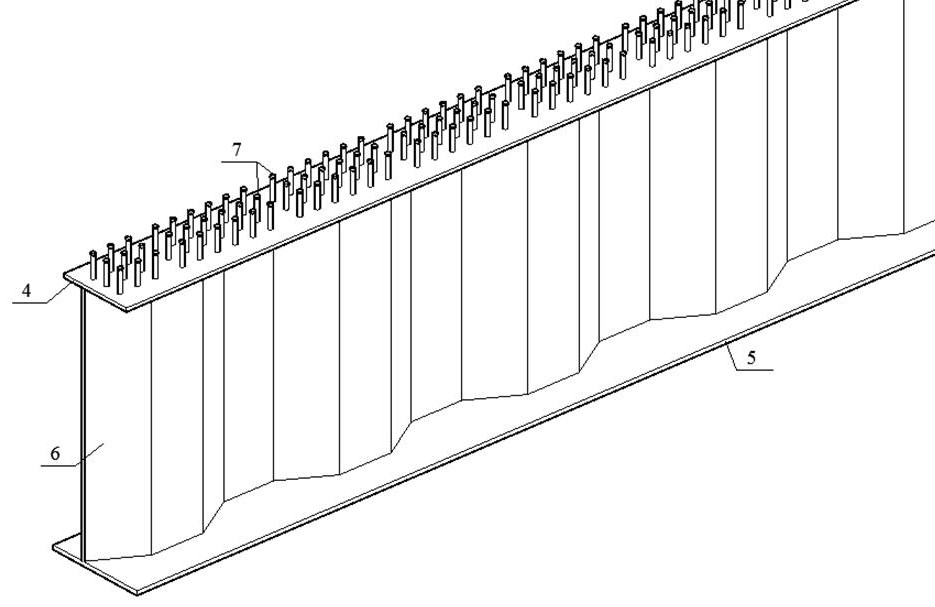

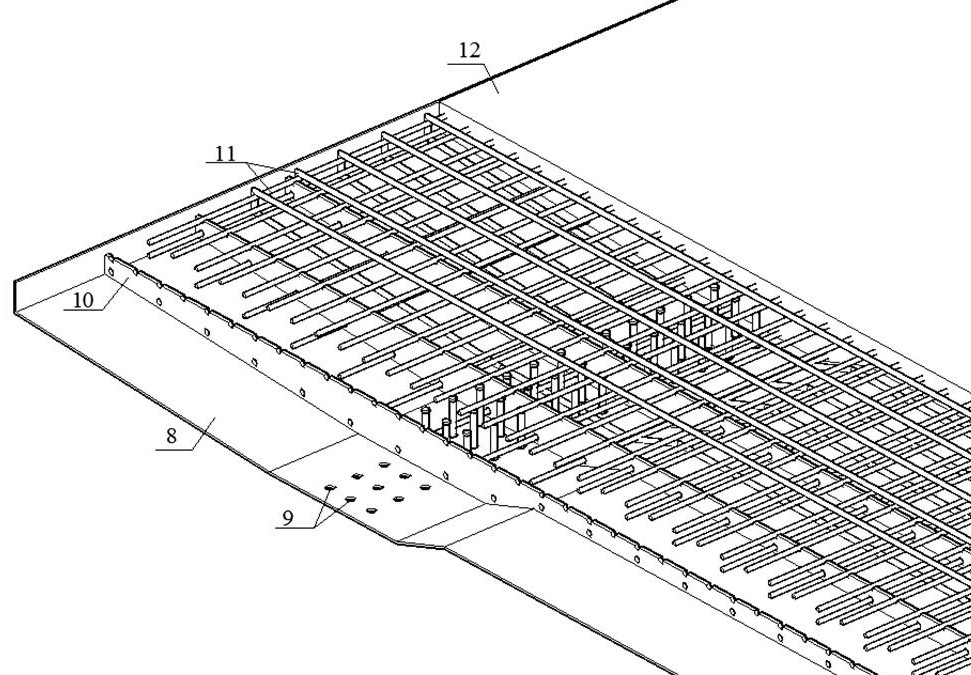

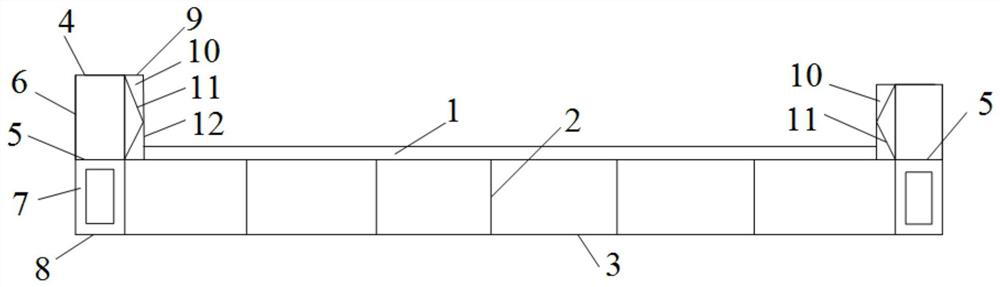

Corrugated steel web I-shaped composite beam for steel-concrete superposed bridge deck

PendingCN113186822AOptimizing Sectional DetailingSolve problems such as insufficient carrying capacityBridge structural detailsBridge materialsArchitectural engineeringBridge deck

The invention relates to a corrugated steel web I-shaped composite beam for a steel-concrete superposed bridge deck. The composite beam comprises a steel-concrete composite bridge deck slab, corrugated steel web I-shaped steel beams and transverse linkage beams; the corrugated steel web I-shaped steel beams are arranged in parallel in the longitudinal bridge direction; a plurality of transverse linkage beams are arranged between every two adjacent corrugated steel web I-shaped steel beams and arranged in parallel in the longitudinal bridge direction; and the steel-concrete composite bridge deck slab is located above the corrugated steel web I-shaped steel beams and the transverse linkage beams. The structural form of a steel-concrete combined system is enriched, the number of steel girders, the number of bridge deck slab steel bars and girder detail structures can be effectively optimized, meanwhile, work such as formwork erection in bridge deck slab construction can be omitted through application of the steel-concrete combined bridge deck slab, the construction procedure is greatly simplified, and the rapid construction requirement of the steel-concrete combined structure is met.

Owner:CCCC FIRST HIGHWAY CONSULTANTS +1

A prefabricated assembled narrow-web composite box girder structure and its construction method

ActiveCN111501518BLower beam heightSolve the situation where the beam height is limitedBridge erection/assemblyArchitectural engineeringBridge deck

The invention discloses a prefabricated and assembled narrow-web combined box girder structure, which comprises a box girder body and two side longitudinal beams respectively arranged at both ends of the box girder body, and a bridge deck is arranged on the top surface of the box girder body; An anti-collision zone is provided on the side of the upper part of each side stringer close to the bridge deck, and the crash zone includes a sealing plate, an anti-collision panel and an anti-collision zone fixedly connected with the side plate of the side stringer. Collision K brace, the anti-collision panel is located on the side of the anti-collision K brace away from the side longitudinal beam, the sealing plate is located above the anti-collision K brace, the anti-collision panel and the side longitudinal beam The beams are fixedly connected to the sealing plates respectively. The prefabricated and assembled narrow-web composite box girder structure and its construction method of the present invention have simple structure and convenient assembly, and can meet the requirements of rapid construction of urban bridges.

Owner:SHENZHEN MUNICIPAL DESIGN & RES INST

Concrete prefabricated kerb demoulding auxiliary support frame

InactiveCN103112081AImprove appearance qualityEasy to demouldDischarging arrangementStructural engineeringMechanical engineering

Owner:济南市城建材料开发服务中心

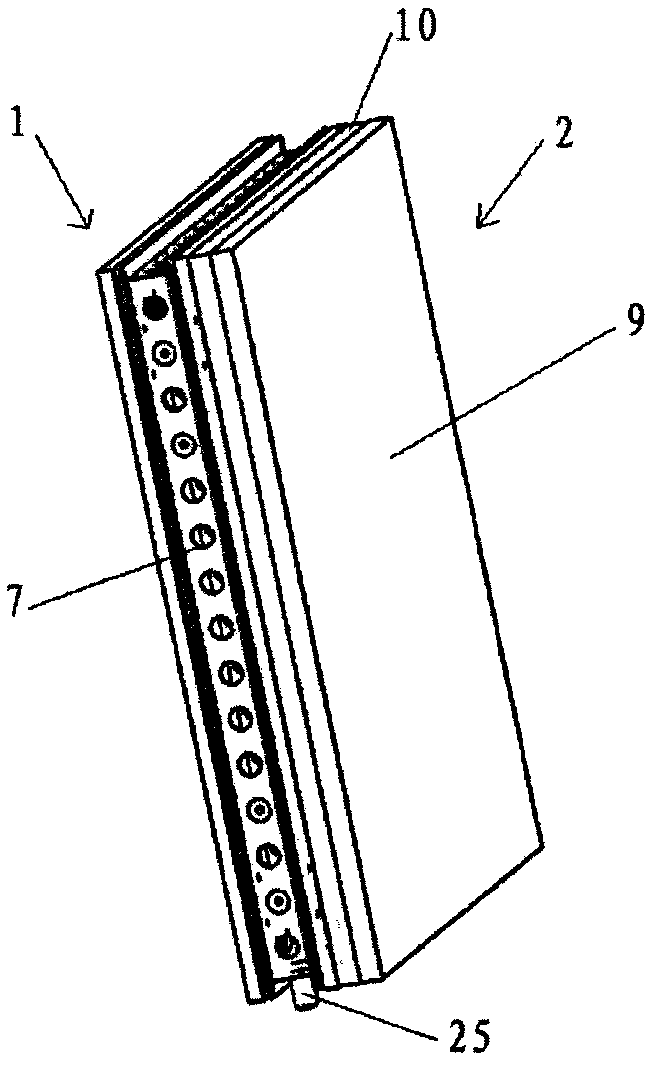

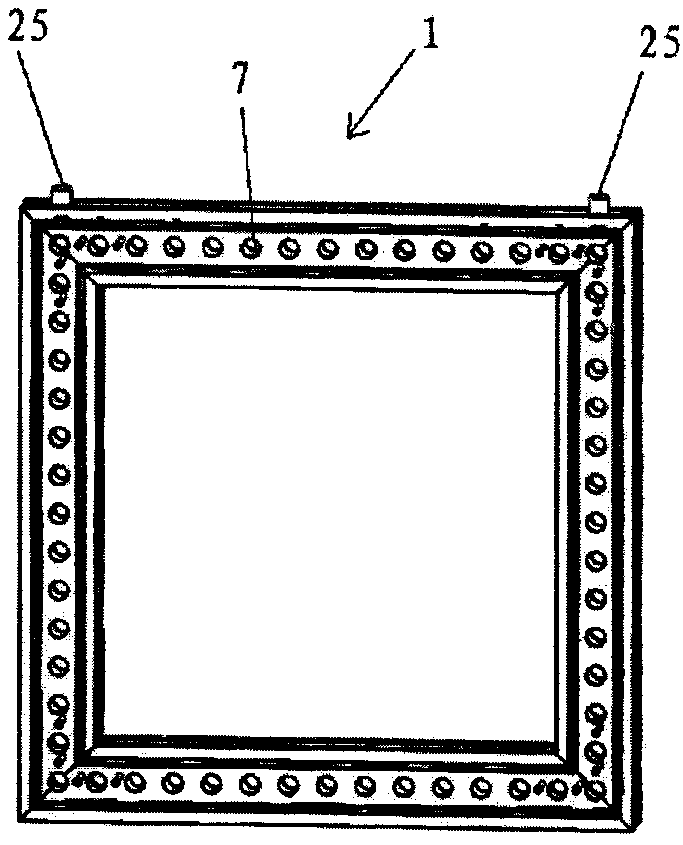

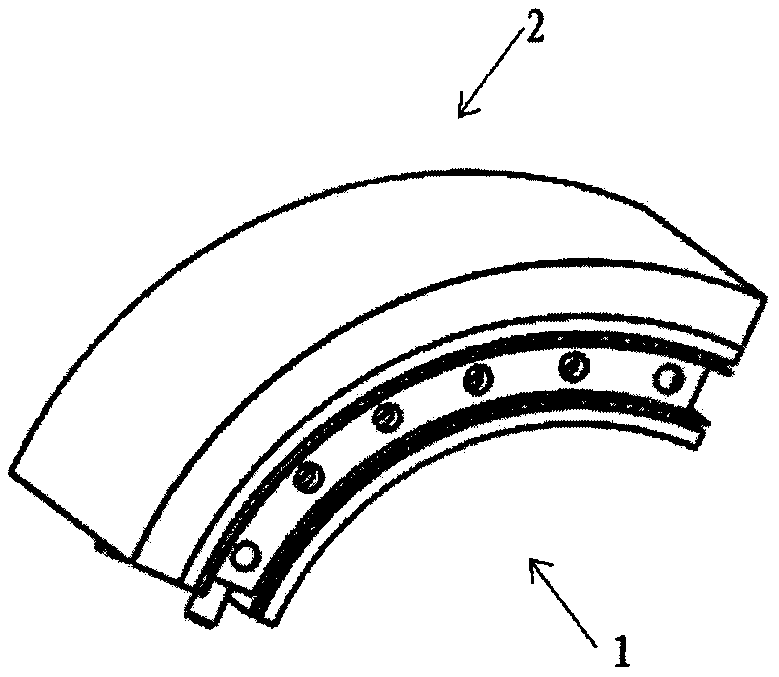

Building module and built structure

PendingCN108797802AAvoid wastingPromote environmental protectionBuilding constructionsUltimate tensile strengthCivil engineering

The invention discloses a building module and a built structure. The building module comprises a profile frame and a cover face material; and the profile frame is formed by splicing of a plurality ofprofiles, and the cover face material is connected to the profile frame through a connecting device. The built structure comprises the multiple building modules, and the building modules are connectedthrough second connecting pieces. The building module and the built structure have the advantages that repeat recycling can be achieved, environmental protection is good, building at will and free combination can be achieved, dismounting and mounting are convenient, modular production can be achieved, the mounting error is small, and the connecting strength between the profiles is high.

Owner:YEEDAA ENVIRONMENTAL TECH SHANGHAI CO LTD

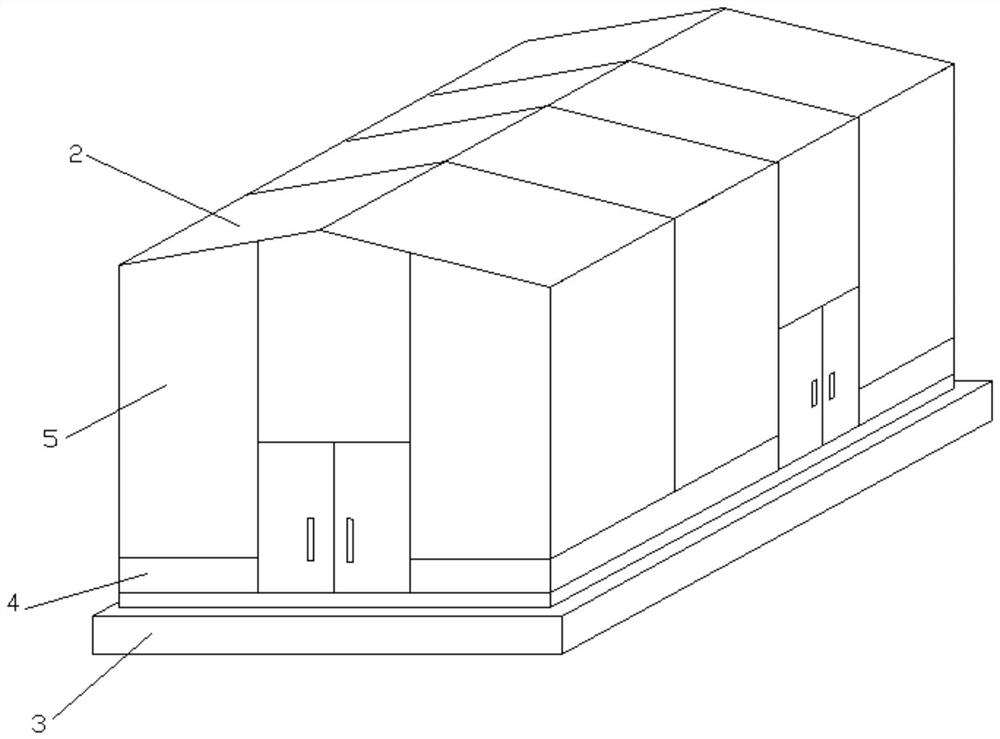

Structure and enclosure combined modular equipment room

PendingCN114396122AShorten the on-site construction periodMeet the requirements of rapid constructionBuilding roofsBuilding insulationsModularityComposite slab

The invention relates to the technical field of buildings, and discloses a structure and enclosure combined modular equipment room. The composite board comprises a frame chassis, a folding type house wall surface composite board, a lightweight concrete batten and a door and window composite board, the folding type house wall surface composite board and the door and window composite board are corrosion-resistant, fireproof, heat-insulating, decorative and structural integrated boards, and the bottom of the folding type house wall surface composite board is fixed to the frame chassis. The door and window composite boards are installed on the two sides of the folding type house wall face composite board, and an equipment room is built. The modular equipment room is an integrated system, design, production, transportation, installation and site are considered in an integrated mode, components and materials needed by the site are integrated in a frame chassis through the modular equipment room, expansion and combination work can be conducted on the site, and the site installation process and the site installation technology are simplified.

Owner:上海绿筑住宅系统科技有限公司 +1

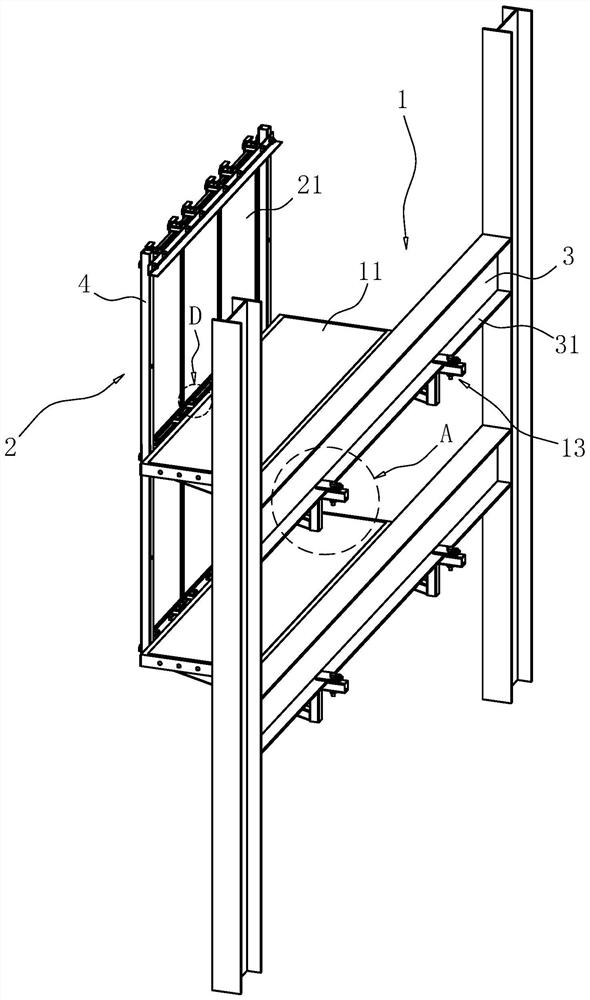

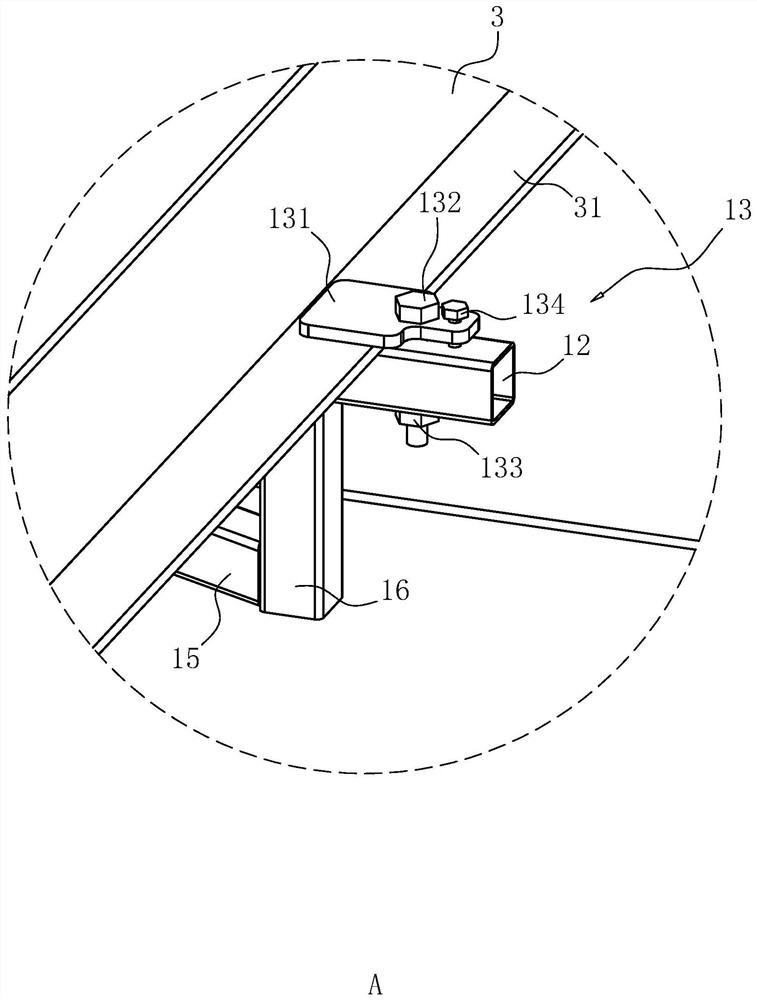

Edge working platform for building and construction method thereof

InactiveCN113585701AEasy to buildMeet the requirements of rapid constructionScaffold accessoriesBuilding support scaffoldsArchitectural engineeringMechanical engineering

The invention relates to the field of steel structure building construction, in particular to an edge working platform for building and a construction method thereof. The edge working platform for building is characterized by comprising a walkway device, the walkway device comprises a walkway plate and at least two supporting beams, and two clamping assemblies are arranged on each supporting beam; each clamping assembly comprises clamping plates, connecting bolts are arranged at the ends, away from each other, of the two clamping plates on each supporting beam, the planes where the clamping plates are located are parallel to the extending direction of the supporting beams, the connecting bolts penetrate through the clamping plates and the supporting beams at the same time, the clamping plates are in sliding connection with the connecting bolts, connecting nuts are screwed on the connecting bolts, the connecting nuts abut against the sides, away from the clamping plates, of the supporting beams, and the walkway plate is fixed on the supporting beams. The purpose of facilitating building construction of the edge working platform so as to meet the requirement for rapid construction of a steel structure building is achieved.

Owner:北京韬盛科技发展有限公司

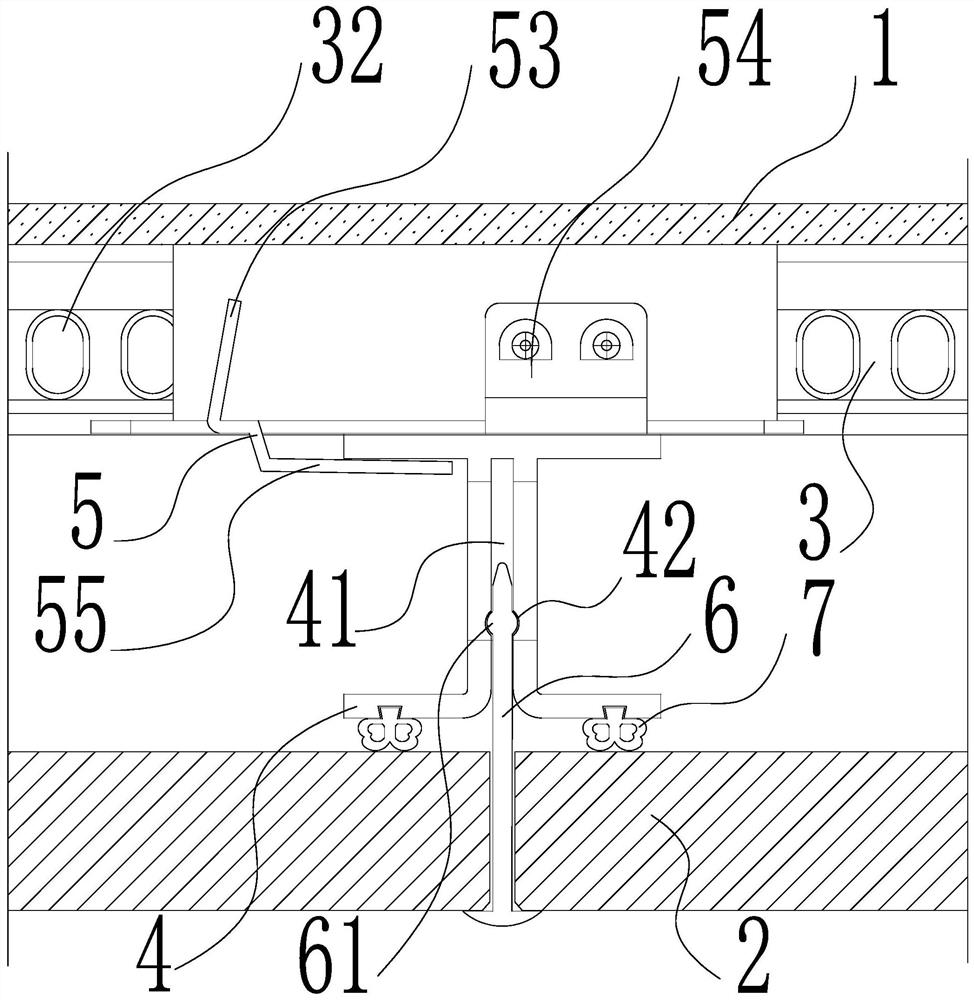

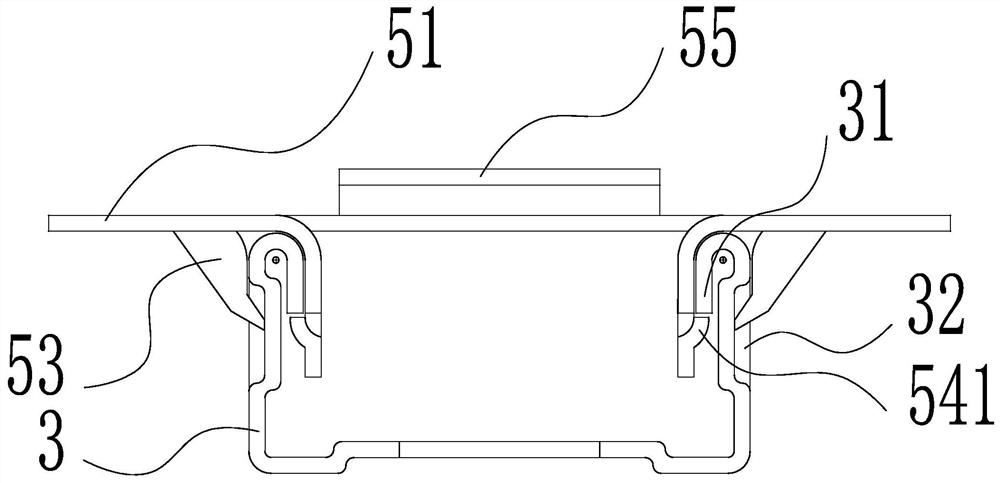

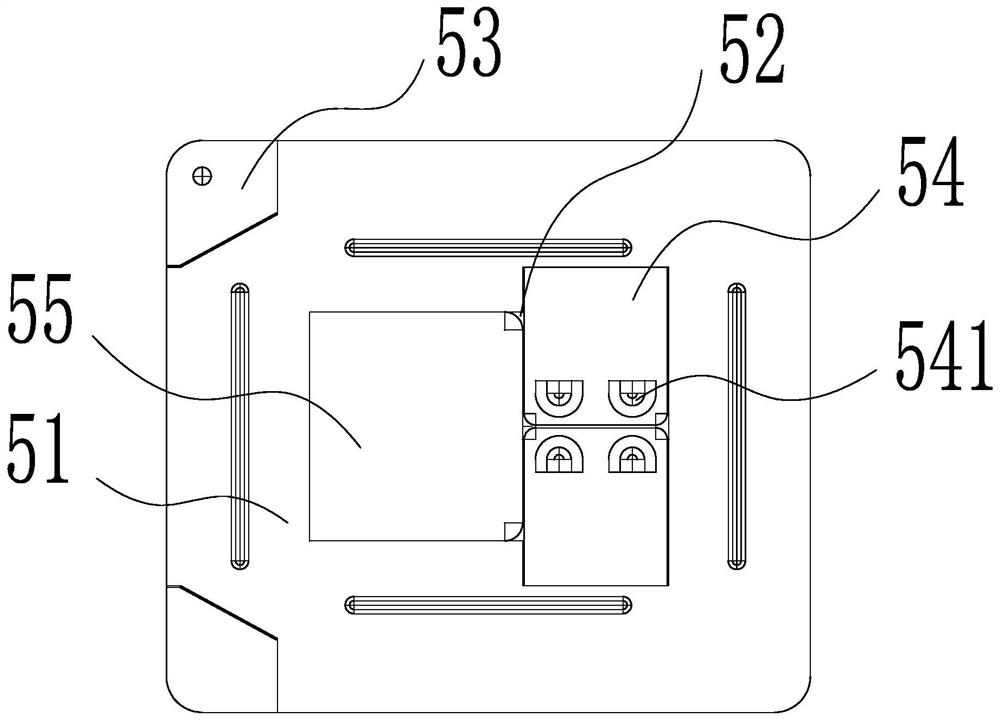

Installation structure and installation method of a wall panel

ActiveCN111576774BPaving saves time and effortEasy to installCovering/liningsMechanical engineeringIndustrial engineering

The invention relates to the field of architectural decoration, and provides a wall panel installation structure and installation method that are convenient and quick to install wall decorative panels, save time and effort, smooth decorative panels, and have good decoration quality. The wall decoration panel pavement construction period is long, the pavement process is time-consuming and laborious, the flatness is poor, and the decoration quality cannot be guaranteed. The panel, the horizontal bracing keel is fixed on the wall surface, and the vertical bracing keel is fixed on the back of the decorative panel. The horizontal bracing keel is a U-shaped structure with the opening end facing the decorative panel. There is a movable lock between the horizontal bracing keel and the vertical bracing keel. The two sides of the inner end of the movable lock are respectively elastically clamped on both sides of the opening end of the horizontal support keel, and the outer ends of the movable lock are hooked on the inner ends of the vertical support keel.

Owner:GREENTOWN DECORATION ENG GRP CO LTD

A focused bathymetric three-dimensional induced polarization advanced detection system and method carried by a TBM

ActiveCN108776354BDo not interfere with constructionMeet the requirements of rapid constructionElectric/magnetic detectionAcoustic wave reradiationEngineeringInstrument control

Owner:山东百廿慧通工程科技有限公司

Method and device for integral river entering of high narrow steel cofferdam and fully-enclosed supporting bracket

The invention discloses a method and device for integral river entering of a high narrow steel cofferdam and a fully-enclosed supporting bracket, and relates to the field of bridge construction. The fully-enclosed supporting bracket comprises a bottom supporting plate and a supporting frame, wherein an airbag is arranged below the bottom supporting plate, the bottom supporting plate is in detachable connection with the high narrow steel cofferdam, and the bottom supporting plate is arranged to be matched with the bottom of the high narrow steel cofferdam in a sealed mode; and the supporting frame is arranged on the bottom supporting plate and comprises a plurality of steel beams which are horizontally arranged and connected in a vertically staggered mode, the two ends of each steel beam are provided with blocking blocks, and each steel beam tightly abuts against the high narrow steel cofferdam through the corresponding blocking block. According to the method for integral river enteringof the high narrow steel cofferdam, the fully-enclosed supporting bracket and a cofferdam structure jointly form a floating body with high rigidity to resist impact overturning during river entering,so that the floating body integrally enters a river, there is no need to arrange a river entering sliding channel and a bottom partition bin structure to assist river entering and floating, and requirements of rapid construction are met.

Owner:CHINA RAILWAY MAJOR BRIDGE ENG GRP CO LTD

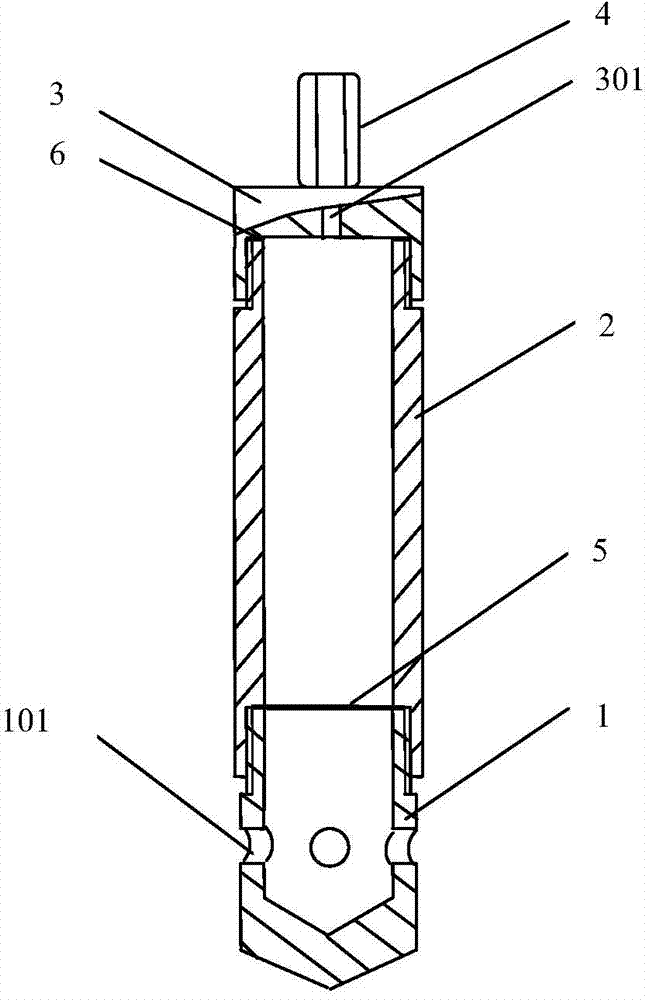

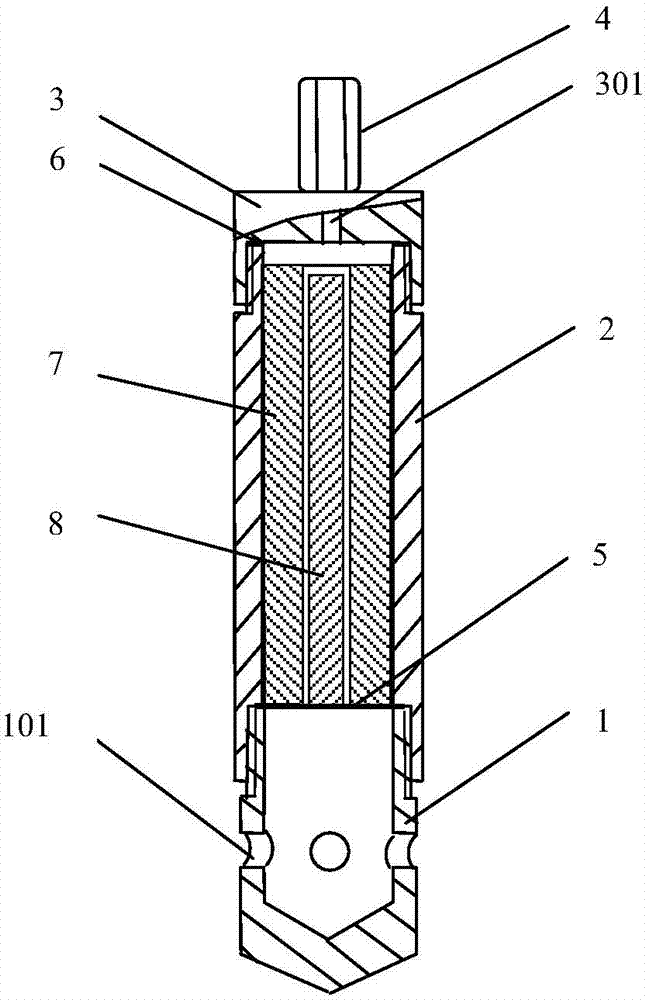

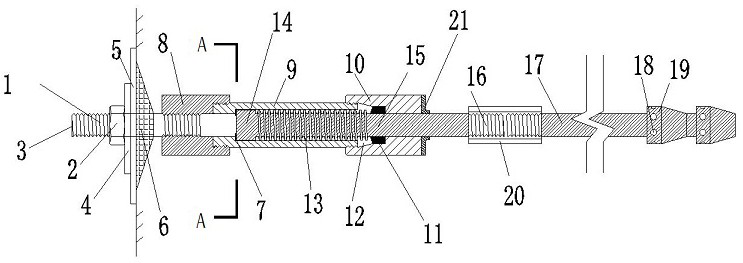

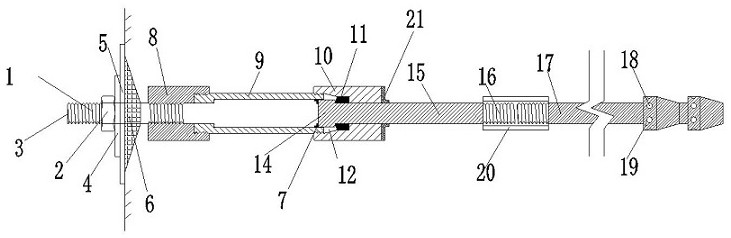

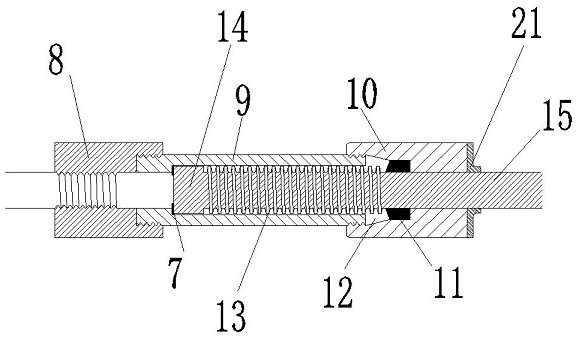

Cutting type constant-resistance large-deformation anchor rod

PendingCN113775365AImprove work performanceExtended service lifeAnchoring boltsAnnular cutterLarge deformation

The invention relates to a cutting type constant-resistance large-deformation anchor rod, and belongs to the field of anchoring support. The cutting type constant-resistance large-deformation anchor rod comprises an anchoring section, a free section and a constant-resistance component, wherein the constant-resistance component is formed by combining a threaded rod, a sleeve and an annular cutter, the tail of the threaded rod is provided with threads and is connected with a rod body of the free section through the sleeve, the tail end of the rod body of the free section is an anchor head with an enlarged diameter, a circle of slurry discharging holes are formed in the outer diameter of the anchor head, the anchor rod body is of a hollow structure and can conduct pressurized grouting, and slurry flows out from the slurry discharge holes at the anchor head. The constant-resistance component cuts the threads on the end of the threaded rod through the annular cutter, continuous constant resistance is provided, and additionally, the rod body moves forwards so as to provide the required large deformation. The cutting type constant-resistance large-deformation anchor rod has the advantages of the simple structure and convenience in construction, joints are in threaded connection, continuous constant resistance can be provided, the required resistance can be controlled by adjusting the shape and distance of the threads, materials of the threads and other conditions, the structure is stable and reliable, and the requirement for on-site rapid construction is met.

Owner:沈阳促晋科技有限公司

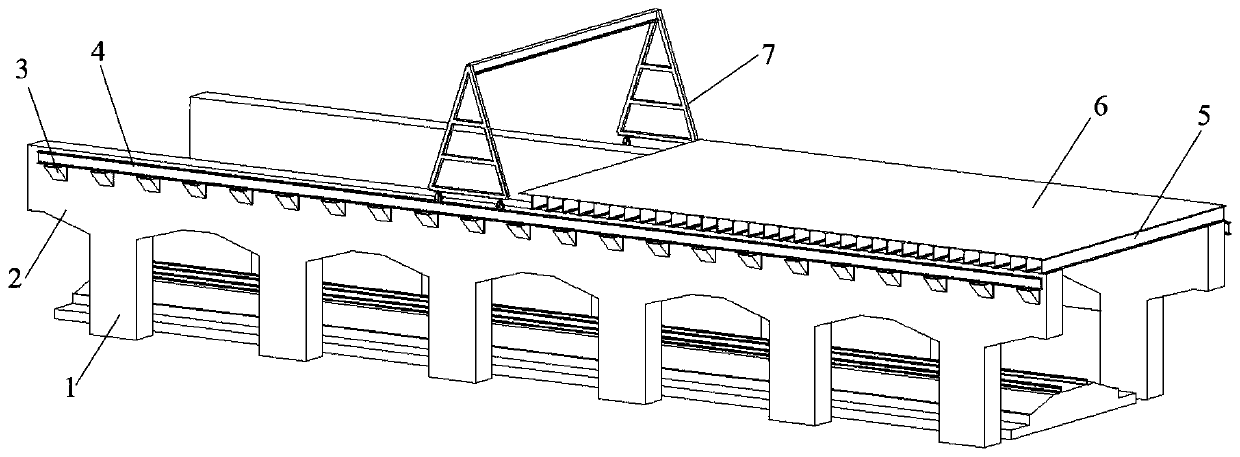

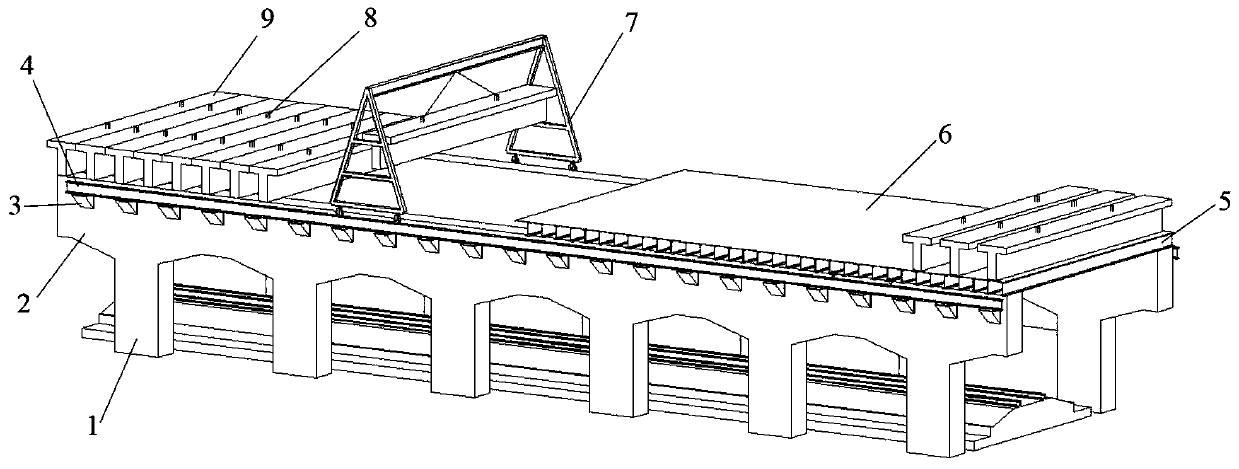

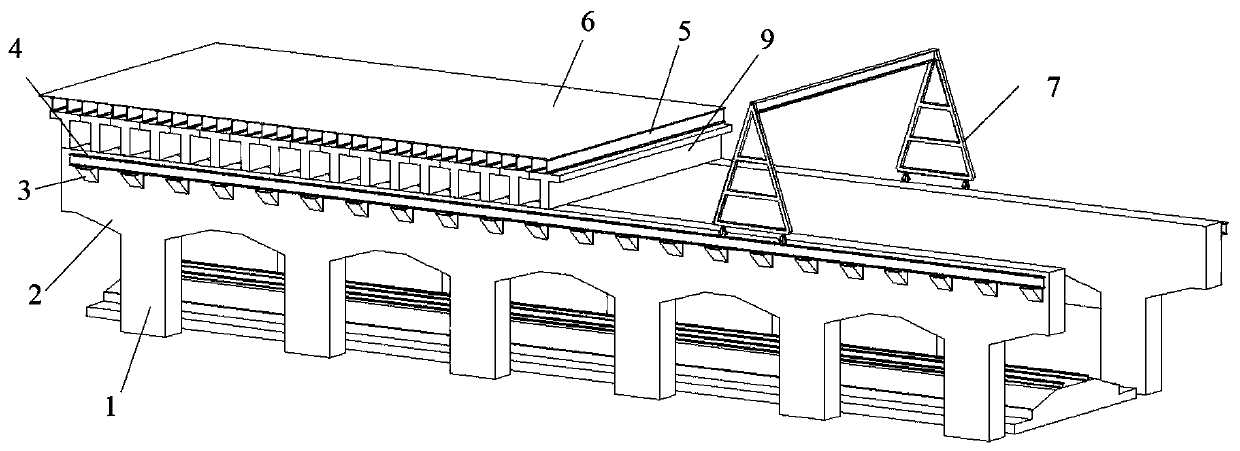

A rapid construction method of T-beams in the shed opening of the upper-span business line in a narrow space

ActiveCN108589568BQuick erectionSolve problemsProtective constructionArchitectural engineeringStringer

The invention discloses a quick construction method for an over-crossing business line hangar tunnel T-shaped girder in narrow space. The quick construction method includes the following steps that ahangar tunnel foundation pit is dug according to a designed location and a hangar tunnel stand column is constructed; a hangar tunnel vertical girder is constructed, a bracket support is pre-buried and a gantry crane walking railway is set up on the bracket support; a distributive girder and a form board are laid on the top of the hangar tunnel vertical girder to be used as a T-shaped girder primary prefabricating platform, and a gantry crane is arranged on the gantry crane walking railway; a T-shaped girder is poured on the T-shaped girder primary prefabricating platform and hoisted to a vacant zone; if the vacant zone can not be laid fully, then the step is conducted repeatedly; the T-shaped girder primary prefabricating platform is demolished, and the form board is laid on the T-shapedgirder to be used as a T-shaped girder secondary prefabricating platform; a T-shaped girder is poured on the T-shaped girder secondary prefabricating platform and hoisted to a vacant zone and erectingof the T-shaped girder is completed; the T-shaped girder secondary prefabricating platform is demolished and auxiliary facilities are exerted; and other unnecessary facilities are demolished. The problem of insufficient prefabricating places can be solved and the risk of the hoisting operation near the business line is avoided.

Owner:THE SECOND CONSTR OF CTCE GROUP +1

Process method for reinforcing and grouting of high-pressure water-rich solution cavity of tunnel

ActiveCN102278130BControl deformationAvoid deformationUnderground chambersTunnel liningGlass fiberGeomorphology

The invention relates to the technical fields of tunnel and underground engineering, providing a process method for reinforcing and grouting of a high-pressure water-rich solution cavity of a tunnel. The process method comprises the following steps of: carrying out drilling, grouting and reinforcing within a range required to be reinforced in front of a tunnel work face by adopting an advanced segmented grouting mode; after the grouting is ended, carrying out drilling and flushing on a anchor rod hole at the original grouting hole site by using a geological drilling rig; and feeding a glass fiber anchor rod into the anchor rod hole and carrying out grouting construction. According to the process method disclosed by the invention, the glass fiber anchor rod is additionally arranged in a grouting solidified body to form a space meshy structure body with soil (sand) body, thus the action of the glass fiber anchor rod for resisting shearing, cutting and tensioning in the system is fully exerted. In addition, according to the process method disclosed by the invention, the deformability of digging a hole body is effectively controlled while water from karst can be blocked and the soft ground stratum is reinforced; and the capability of resisting high water pressure can be born and the construction requirement for quick digging and coupling of the karst hole body is met.

Owner:CHINA RAILWAY TUNNEL GROUP CO LTD

Explosion-proof iron runner castable

Owner:HENAN HUAXI FURNACE REFRACTORY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com