Building module and built structure

A profile and cover technology, applied in the field of structures, can solve the problems of low connection strength of connectors, too simple profile section, waste of manpower, material and financial resources, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0073] The present invention will be further described below in conjunction with the drawings and specific embodiments:

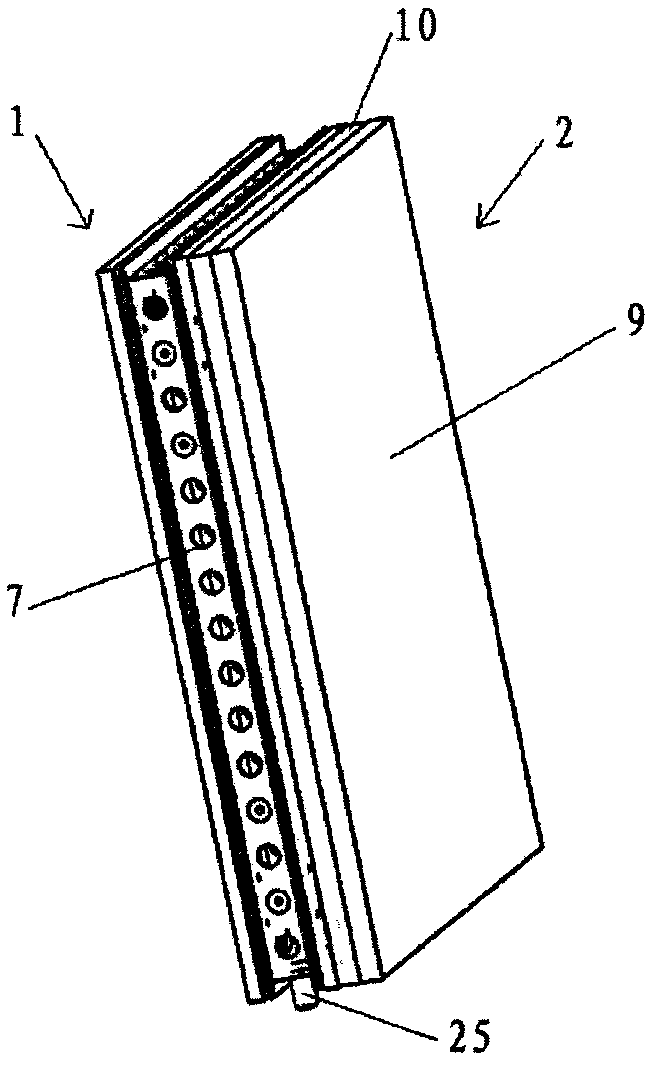

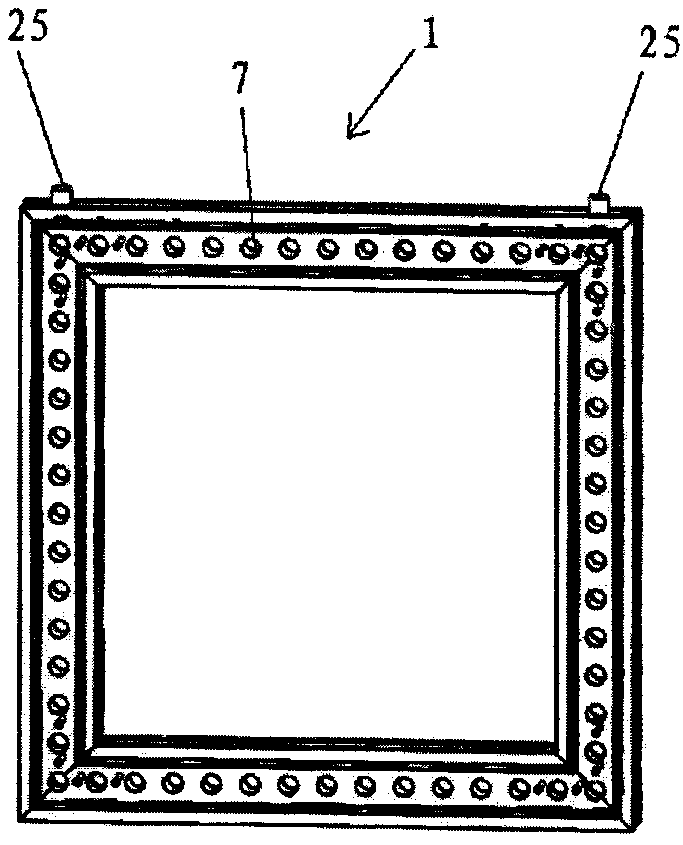

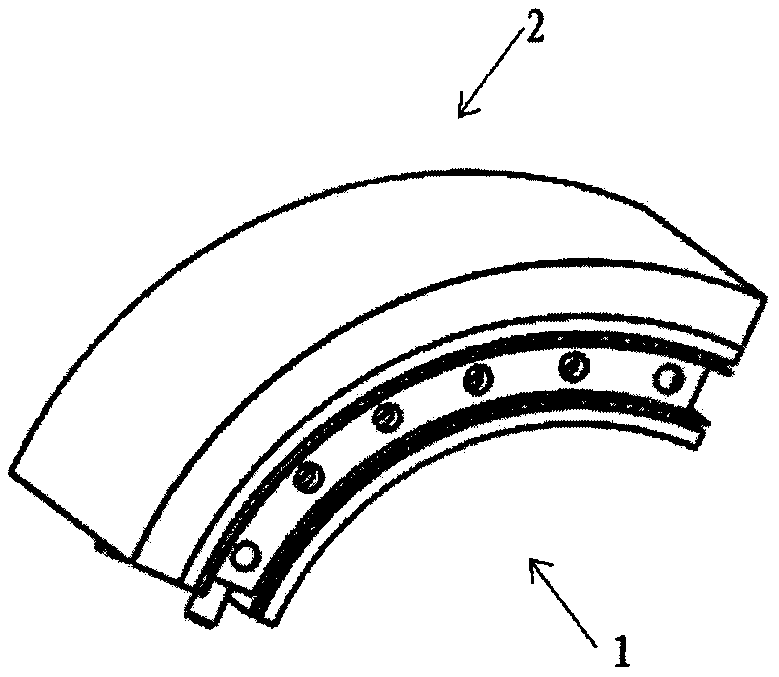

[0074] Reference Figure 1-22 As shown, a building module includes: a profile frame 1 and a cover surface material 2. The profile frame is formed by splicing a plurality of profiles 3, and the cover surface material is connected to the profile frame through a first connector on. The profile is composed of the same four sides, and each of the four sides has the same structure. Each side includes a first groove 5 and a second groove 6 extending along the longitudinal direction of the profile, and the first groove is located in each In the middle of one surface, the second groove is located on one or both sides of the first groove, and the groove bottom of the first groove is spaced apart along the longitudinal direction of the profile with a plurality of first through holes 7 adjacent to each other. The distance between the centers of the first through holes is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com