Method and device for integral river entering of high narrow steel cofferdam and fully-enclosed supporting bracket

A fully enclosed, narrow steel technology, applied in construction, infrastructure engineering, caissons, etc., can solve the problems of time-consuming and labor-intensive, high water depth requirements, etc., to save the construction period and project cost, control the construction period and cost, and meet the requirements of rapid construction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

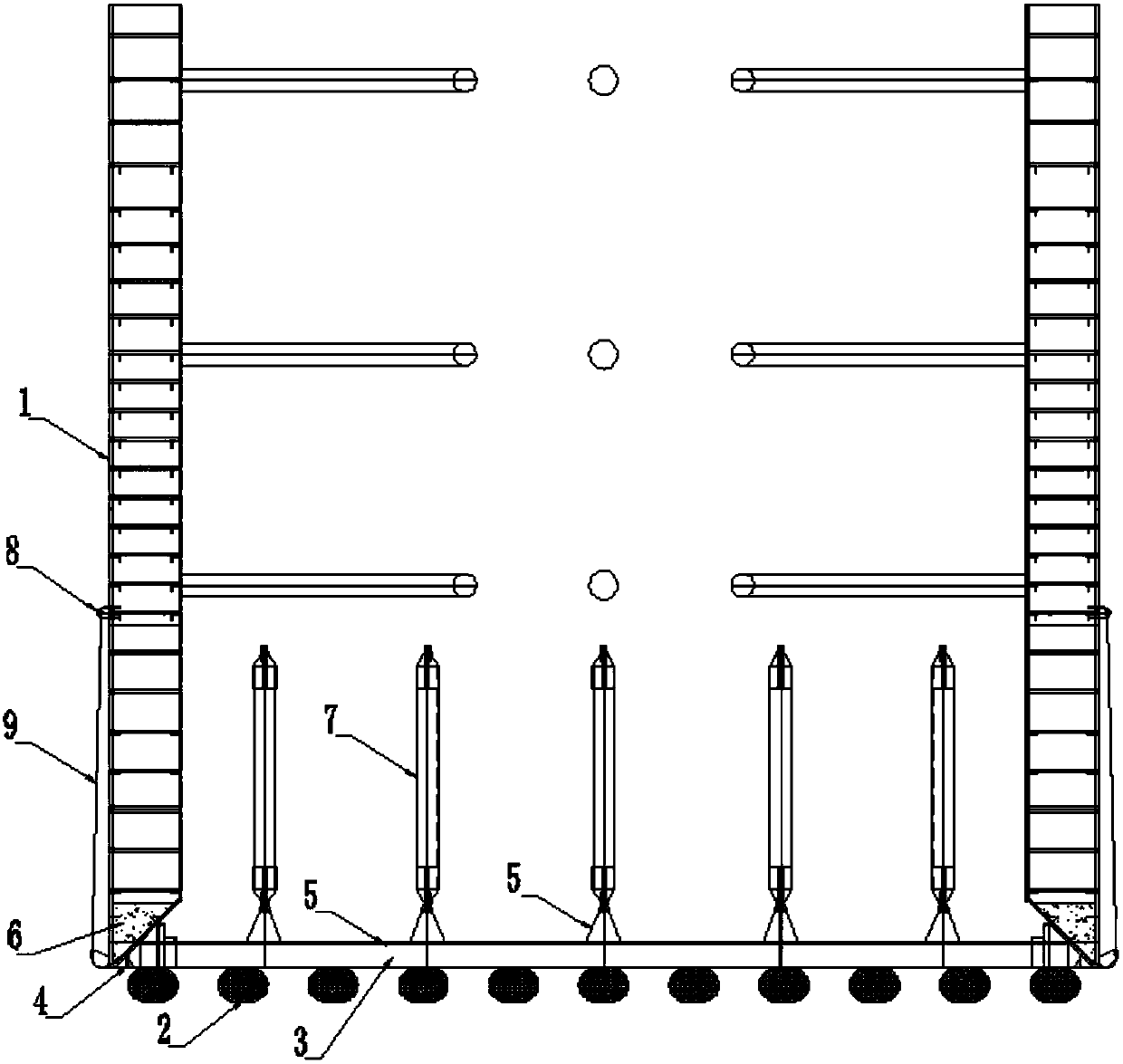

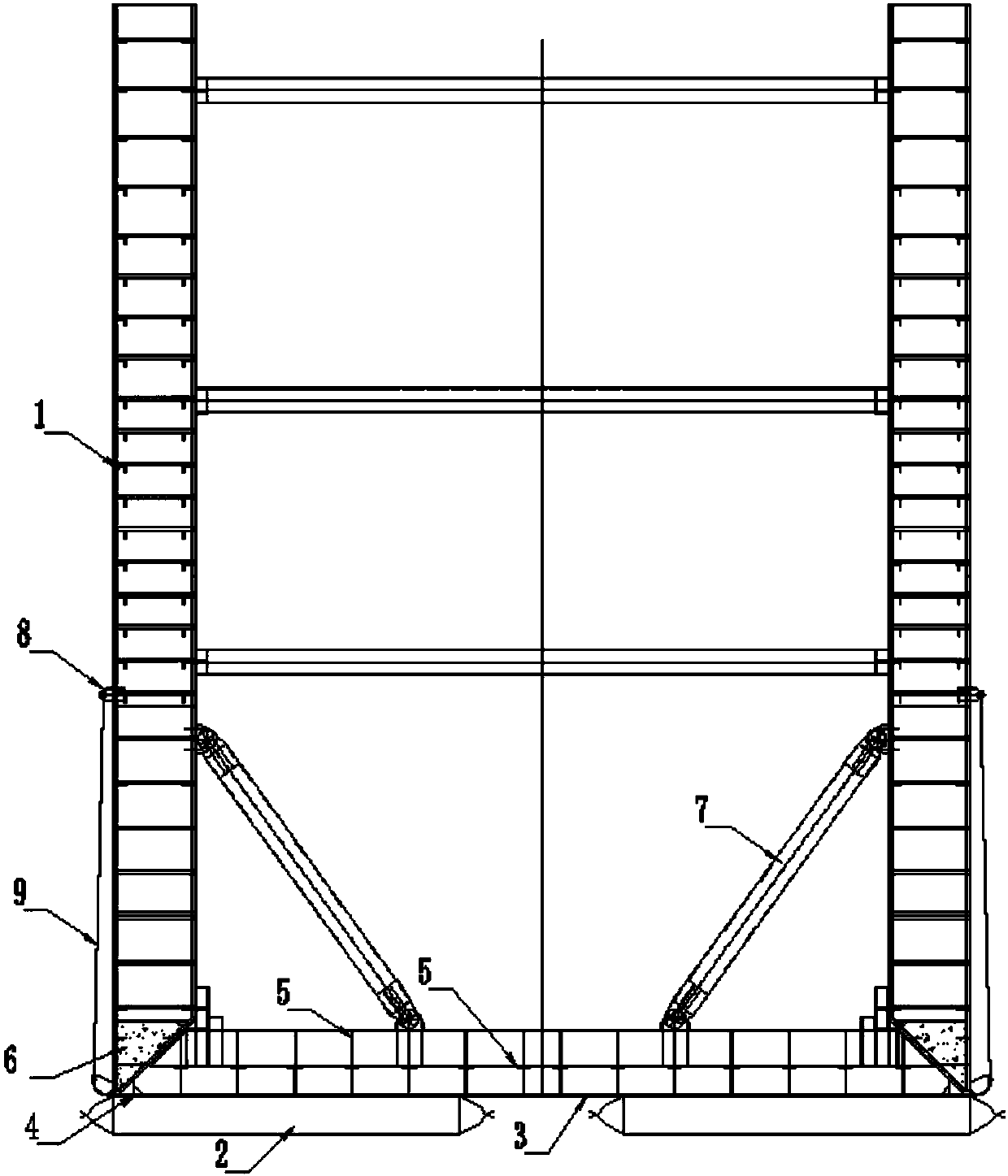

[0031] see figure 1 As shown, the embodiment of the present invention provides a fully enclosed bracket for a high-narrow steel cofferdam as a whole, including: a bottom support plate 3, an air bag 2 is arranged under the bottom support plate 3, the bottom support plate 3 and the high-narrow steel cofferdam The weir 1 is detachably connected, and the bottom support plate 3 is set in a state of closed cooperation with the bottom of the high and narrow steel cofferdam 1 to form a semi-closed space; The remaining gap between the bottom support plate 3 and the high-narrow steel cofferdam 1 is completed to ensure the integrity of the connection between the bottom support plate and the high-narrow steel cofferdam;

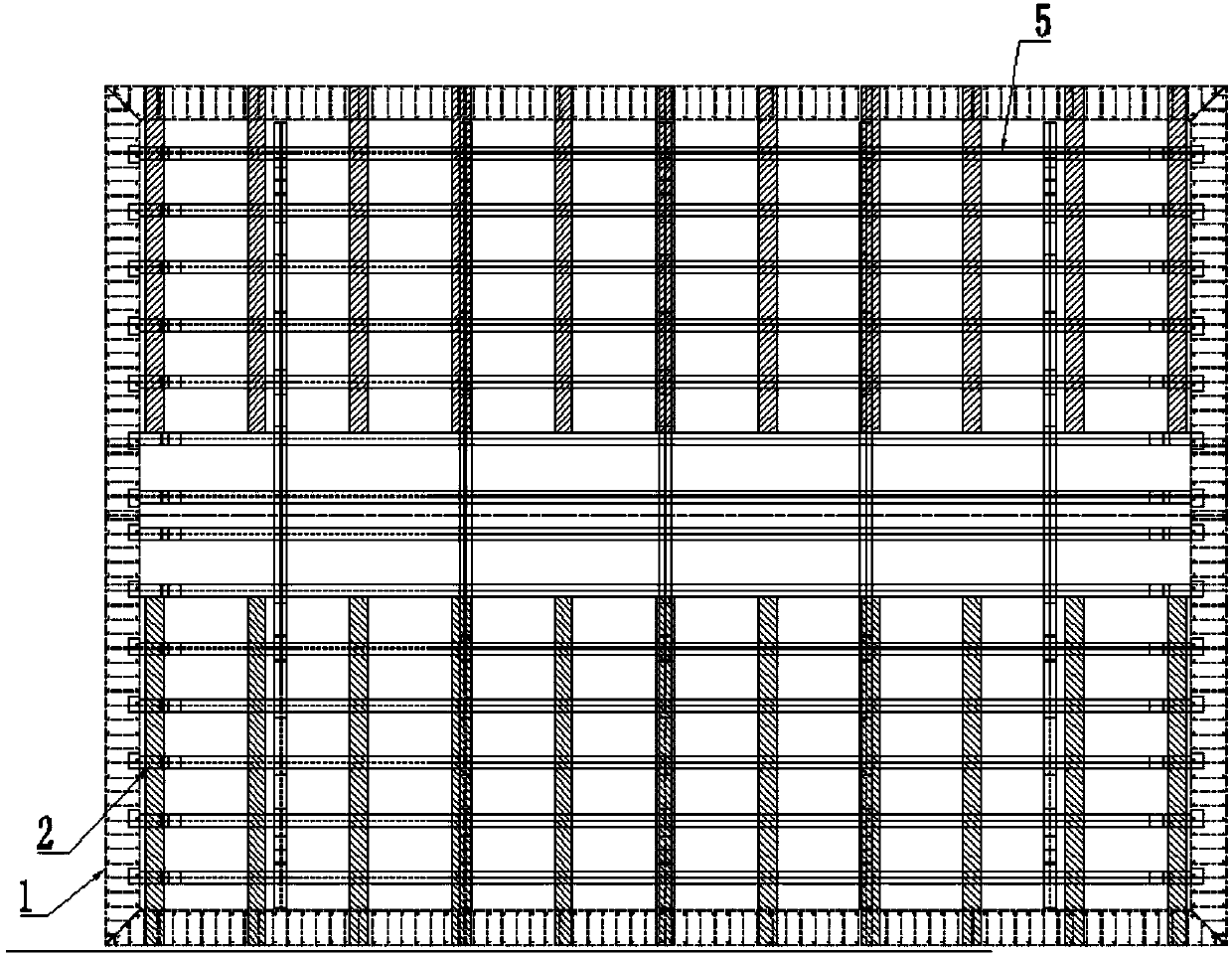

[0032] The bracket arranged on the bottom support plate 3, the bracket includes a plurality of steel beams 5 that are arranged horizon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com