Patents

Literature

258results about How to "Improve construction work efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

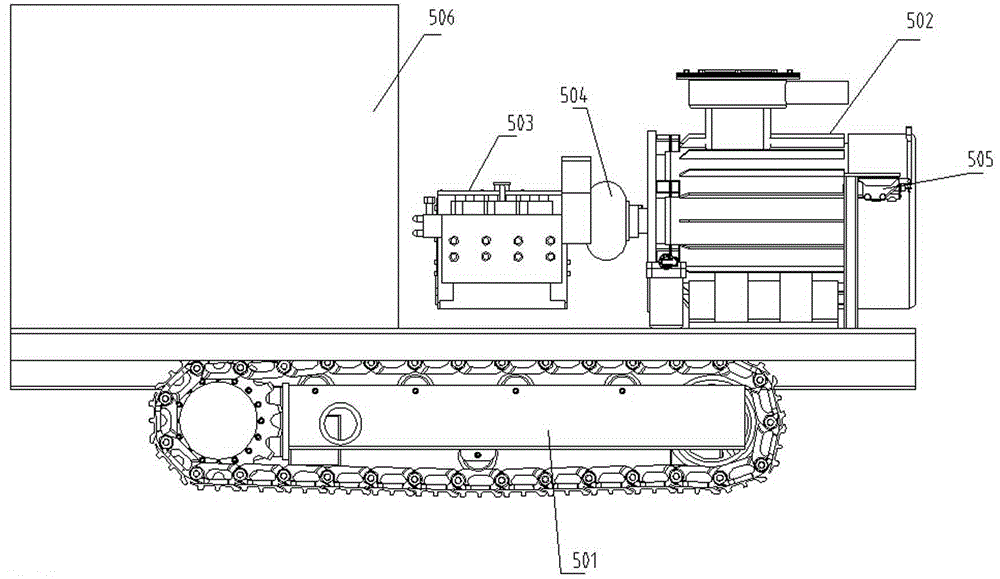

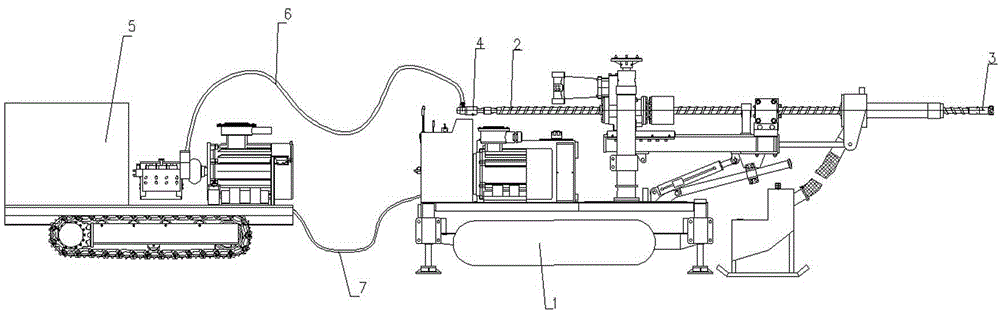

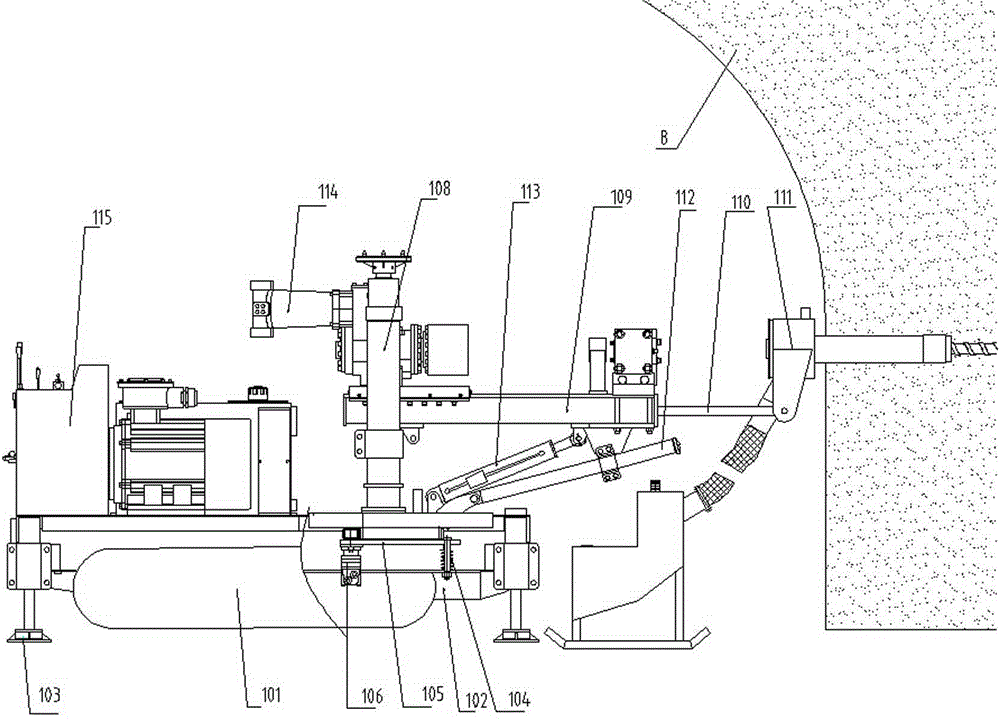

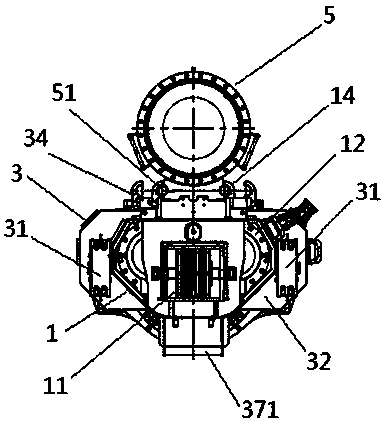

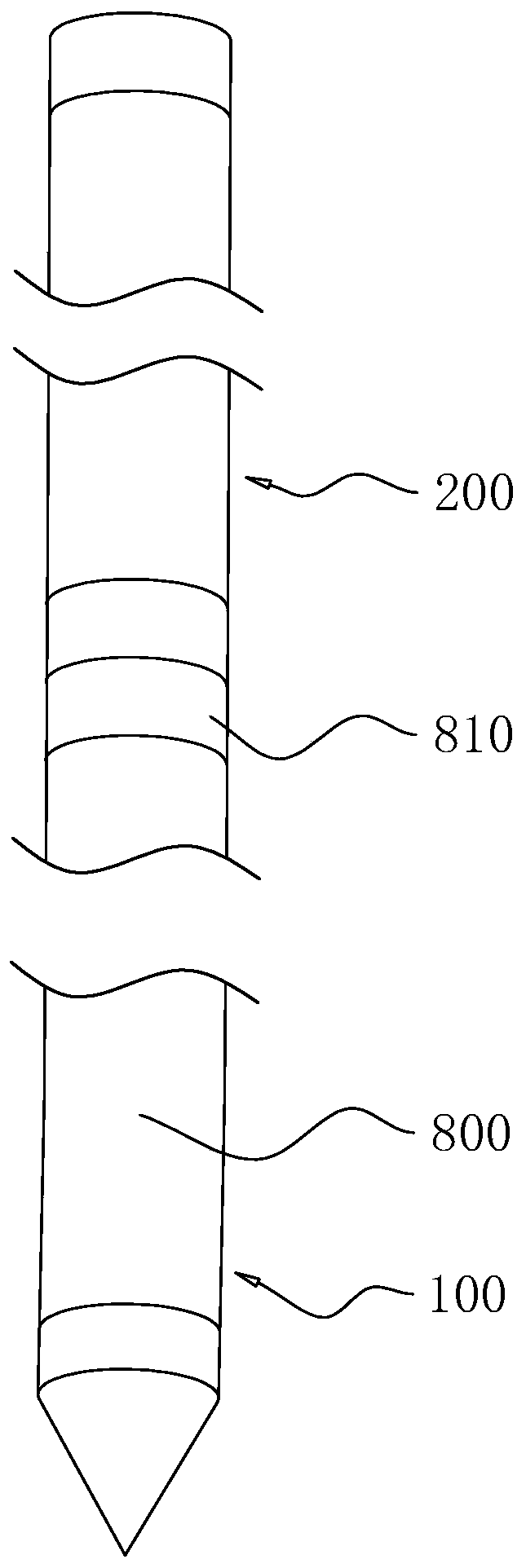

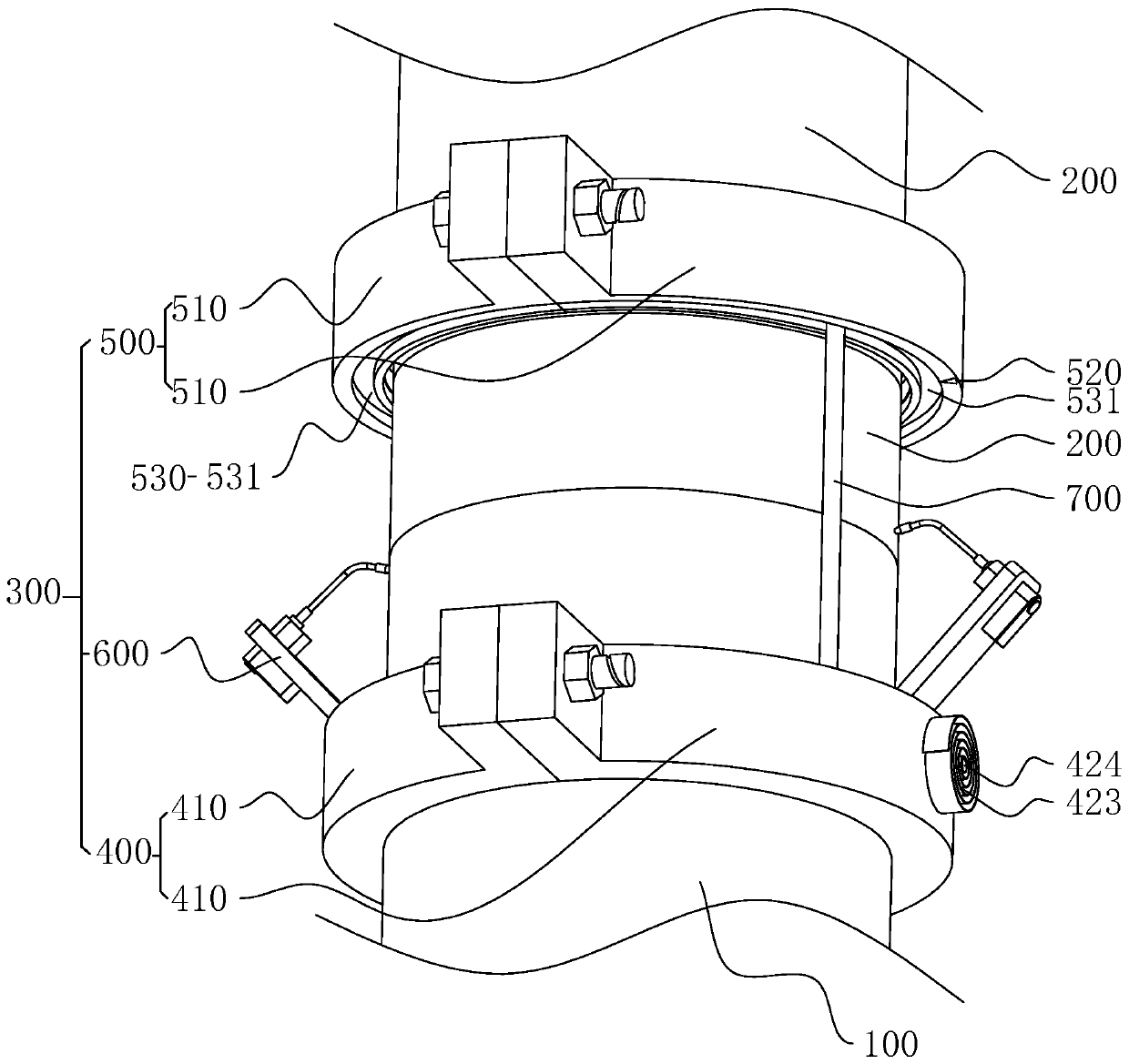

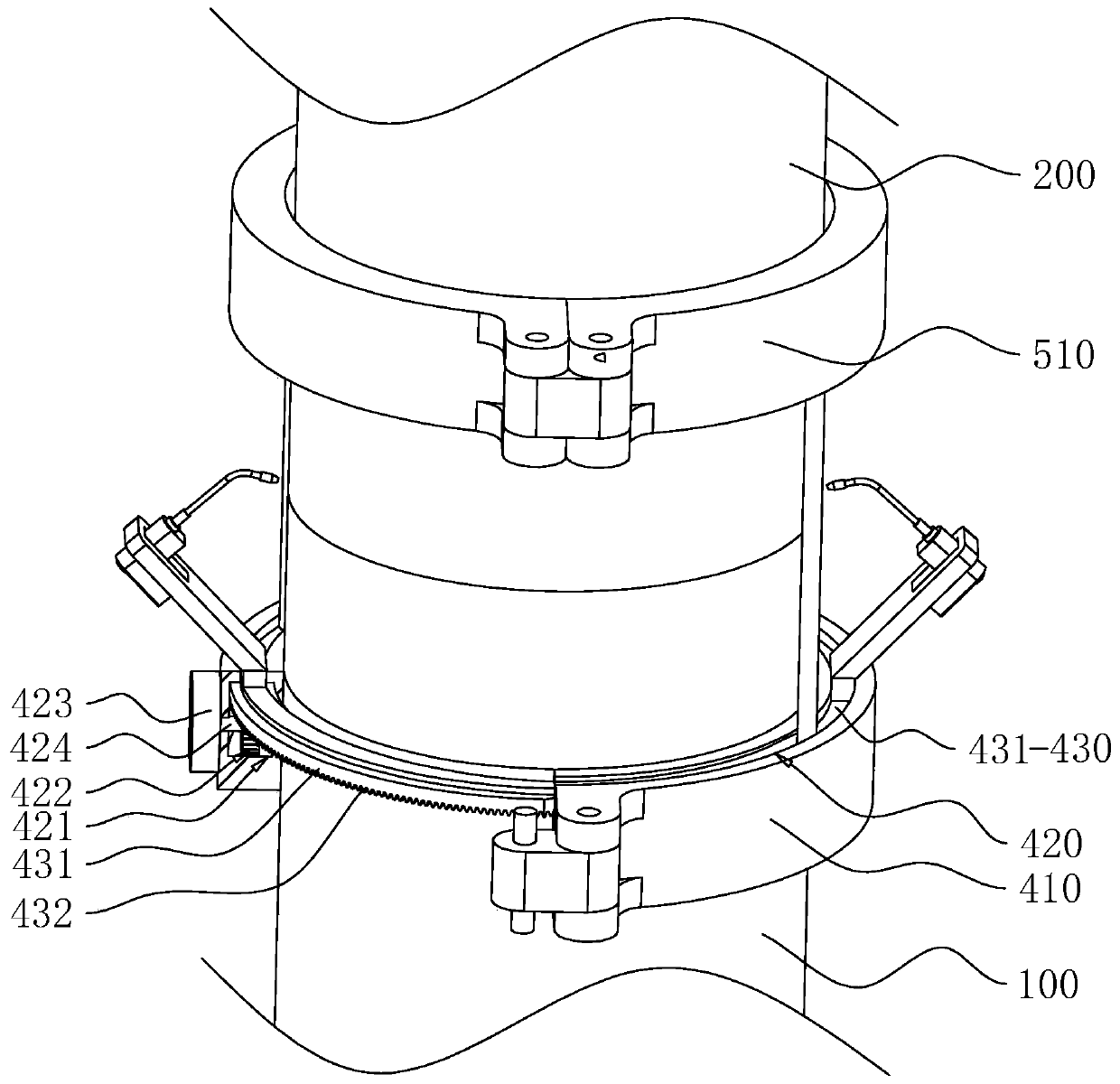

Coal mine downhole crawler type drilling and punching integrated equipment

ActiveCN104895484ASafe and efficient productionImprove extraction efficiencyConstructionsBorehole drivesPunchingDual purpose

Coal mine downhole crawler type drilling and punching integrated equipment comprises a crawler type hydraulic drilling machine, a high-pressure-resistant sealing drill stem, a drilling and punching dual-purpose drill bit, a high-pressure rotation connector and a high-pressure water pump station, wherein the body of the high-pressure-resistant sealing drill stem penetrates and is fixed in the power head inner hole of the crawler type hydraulic drilling machine, a power head provides rotation speed and torque to the body of the high-pressure-resistant sealing drill stem, one end of the high-pressure-resistant sealing drill stem is connected with the high-pressure water pump station through the high-pressure rotation connector, the high-pressure water pump station provides high-pressure water needed by punching, the other end of the high-pressure-resistant sealing drill stem is connected with the drilling and punching dual-purpose drill bit, and hydraulic operations can be performed after drilling without replacing the drill bit. The coal mine downhole crawler type drilling and punching integrated equipment has the advantages that streamlined operations of coal mine downhole gas pressure relief, drilling and punching can be completed by the equipment, safe and efficient production of outburst mines is guaranteed, coal seam coal and gas outburst danger is eliminated, a regional pre-drainage gas drilling construction period is shortened, coal seam drilling and punching and gas extraction efficiency are increased, and gas disaster prevention and control cost is reduced.

Owner:HENAN TIEFULAI EQUIP MFG CO LTD +1

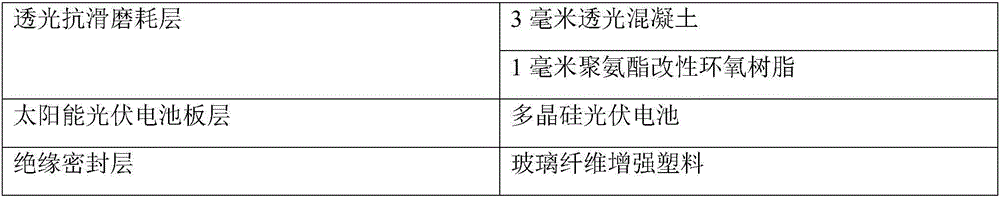

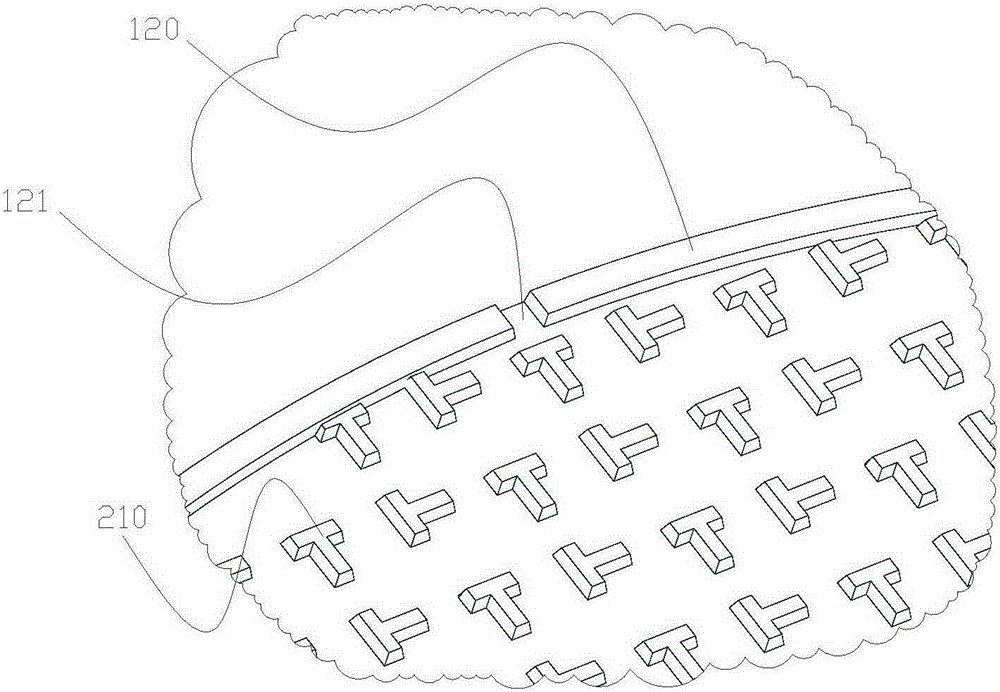

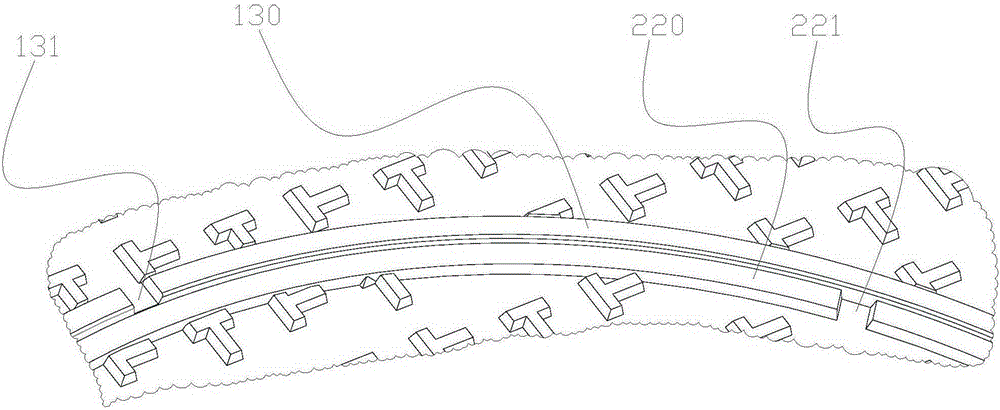

Assembly type solar photovoltaic power generation road surface module and application thereof

InactiveCN106549629AIncrease profitCapable of bearing pressurePhotovoltaic supportsPhotovoltaic energy generationComputer moduleRoad surface

The present invention provides an assembly type solar photovoltaic power generation road surface module and application thereof. The module comprises at least the following structures from bottom to top: an insulated sealing layer, a solar photovoltaic panel layer, and a transparent anti-slide wearing layer. The module is mainly used for solar photovoltaic power generation. The assembly type solar photovoltaic power generation road surface module can meet both the road bearing demand and the solar photovoltaic power generation demand, and has a broad market prospect.

Owner:张宏超 +1

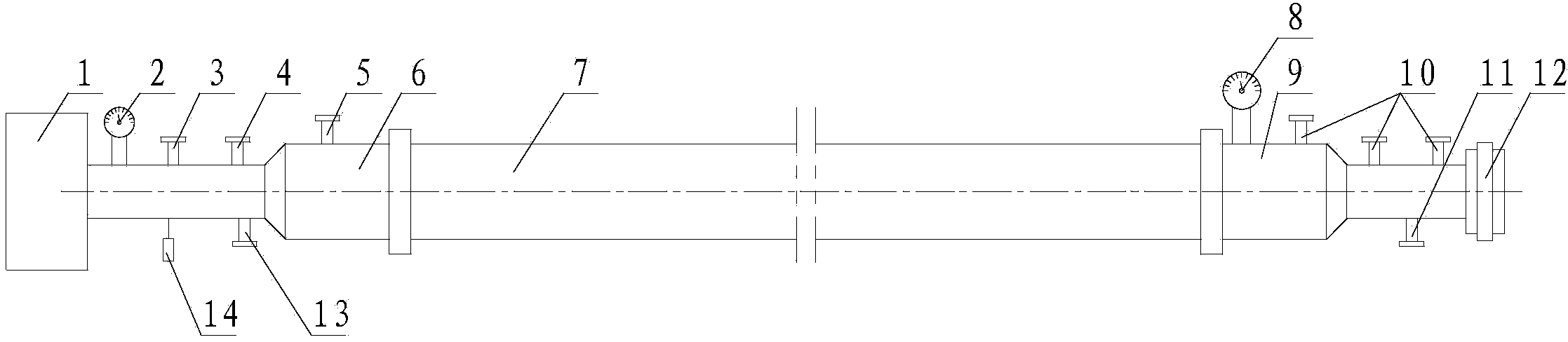

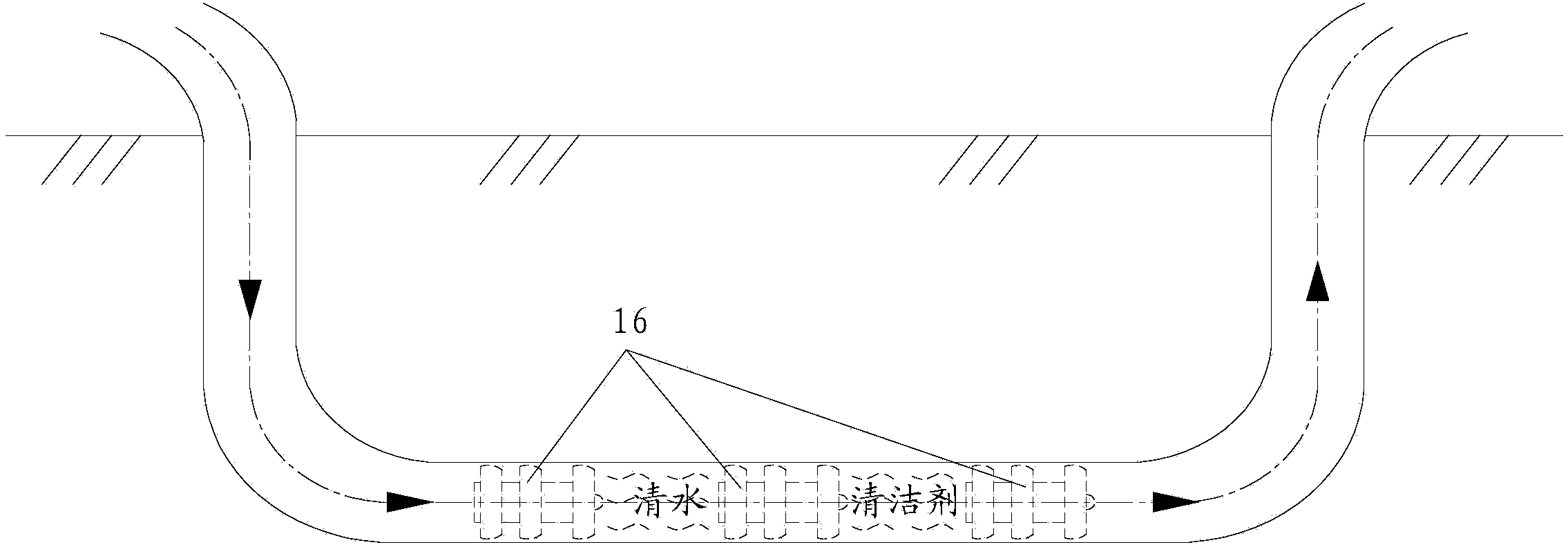

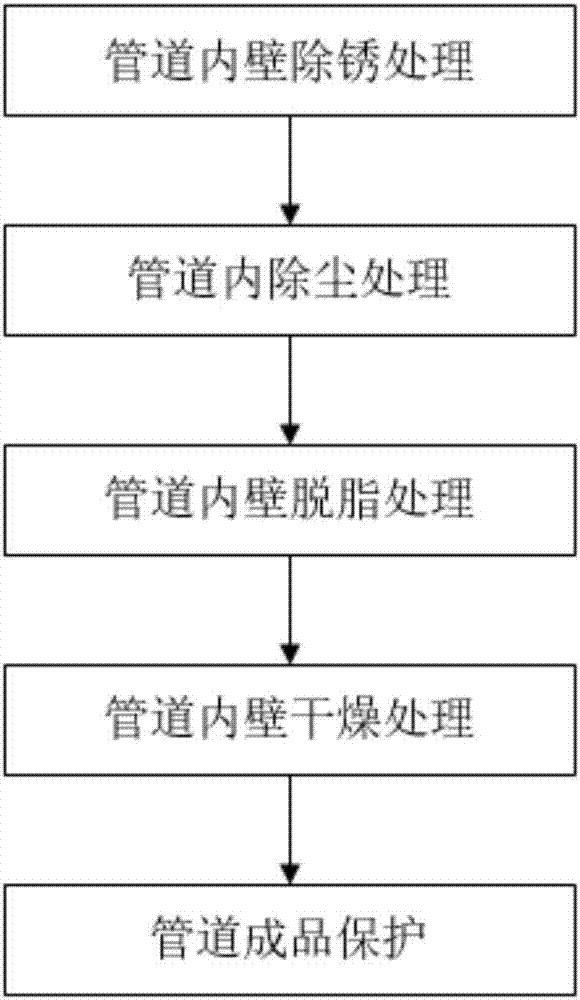

Process for cleaning whole inner wall of long pipeline for high-purity gas

ActiveCN104014562ASpeed upImprove cleanlinessDrying solid materials without heatHollow article cleaningImpurityRust

The invention relates to a process for cleaning the whole inner wall of a long pipeline for high-purity gas. The process includes the following steps that (1), present situation investigation and processing are carried out on the pipeline; (2), rust removal and dedusting cleaning processing is carried out on the inner wall of the pipeline, wherein a leather cup steel brush pipe cleaner and a foam pipe cleaner are pushed through oil-free compressed air to rapidly move in a laid long-distance pipeline in one direction so as to push quantities of residues and other impurities in the long-distance pipeline out of the pipeline; (3), drying processing is conducted on the inner wall of the pipeline, wherein a large-scale compressor and a gas storage tank accumulator are utilized to purge a pipeline system; (4) protection is conducted on a finished pipeline. The process for cleaning the whole inner wall of the long pipeline for high-purity gas is reasonable in design, easy and convenient to operate and especially applied to processing the inner wall of the pipeline for high-purity gas. By the adoption of the process, the construction progress can be quickened, construction quality can be improved, manual operation can be reduced, construction cost can be saved, and efficiency of construction operation is effectively improved.

Owner:TIANJIN PIPELINE ENG GROUP

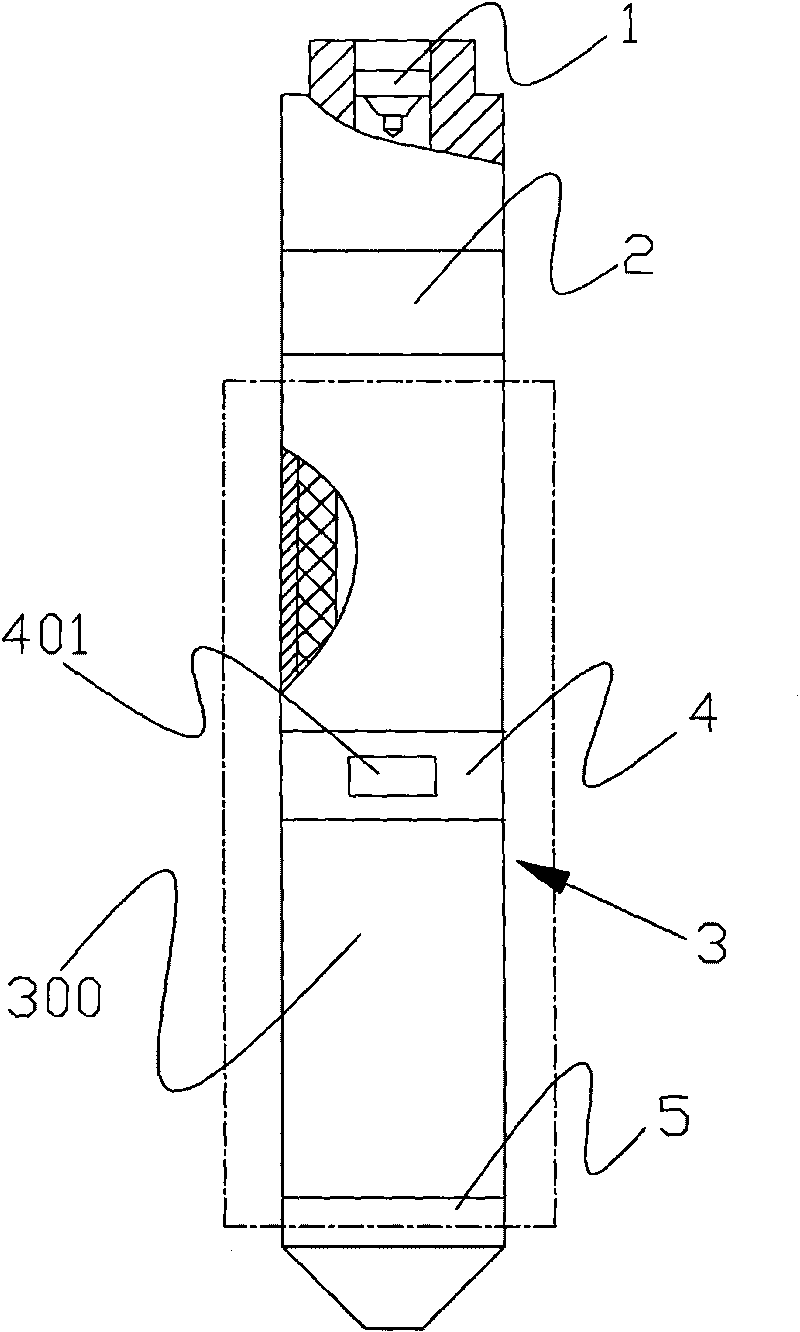

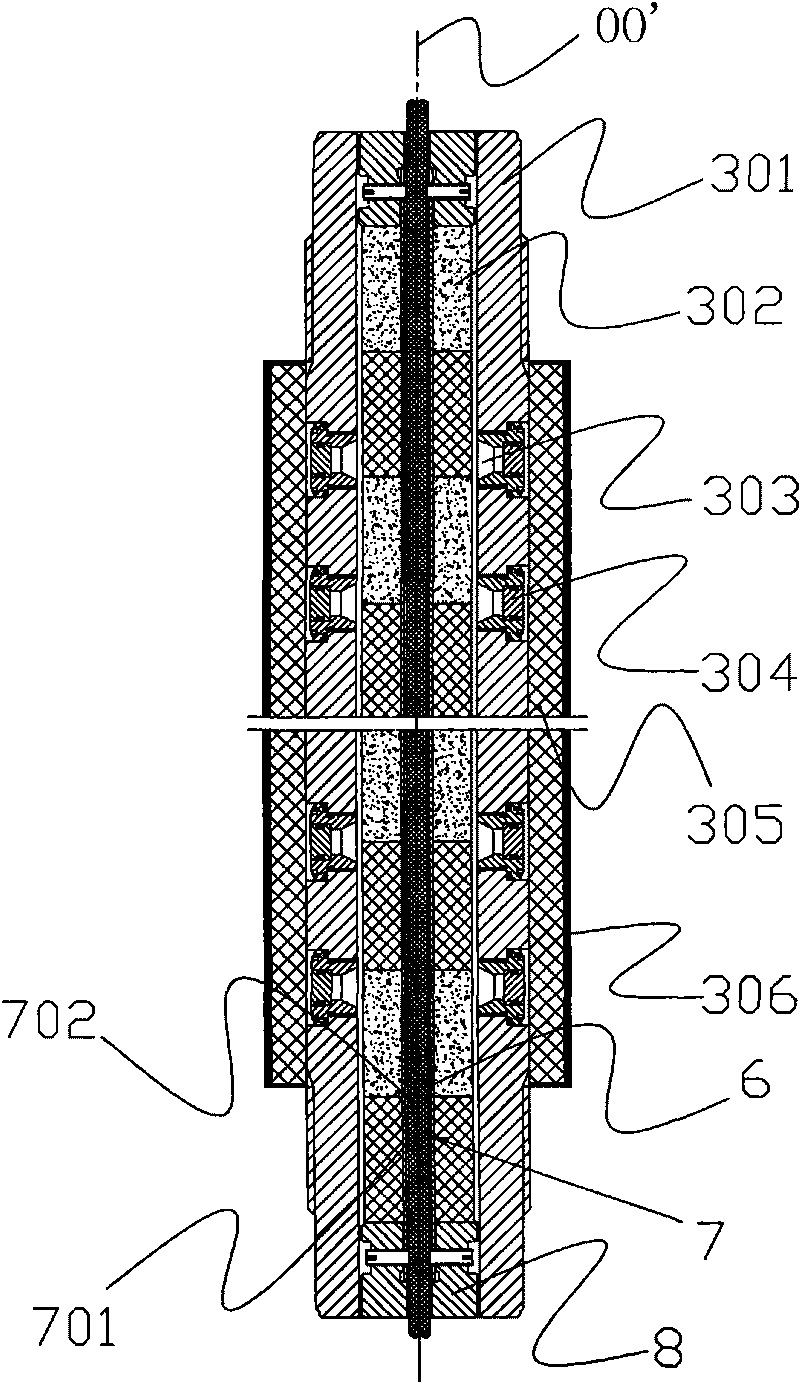

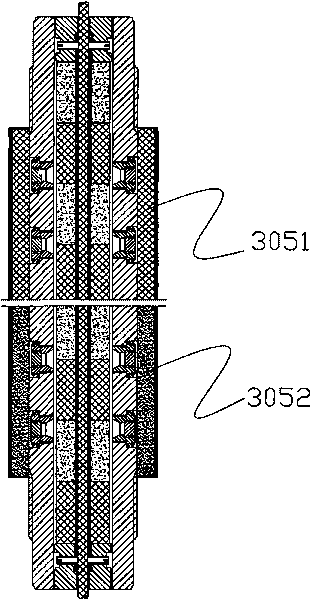

Controllable pulse gas energy pressure cracking device

ActiveCN101737026AGas pressure controllableGood fracturing effectFluid removalPressure risePeak pressure

The invention relates to a controllable pulse gas energy pressure cracking device used in mining of an oil and gas well, which comprises a gas energy pressure cracking device and igniters or exploders and tail plugs, wherein the igniters or exploders and the tail plugs are respectively arranged at two ends of the gas energy pressure cracking device, and the gas energy pressure cracking device comprises a gas energy pressure cracking assembly. The igniters or exploders and inner grains in the gas energy pressure cracking assembly are connected together through ignition channels. The gas energypressure cracking assembly comprises a center pipe, the inner grains filled into the center pipe and an outer cartridge arranged at the outer part of the center pipe. The pipe wall of the center pipeis provided with a pressure release fire transmission channel and a channel sealing cover. The invention solves the problem of low capacity caused by uncontrollability of the pressure cracking process and ineffective communication between stratum and a mineshaft in the prior art. The invention can form effectively outstretched communication between the net-shaped multi-crack construction and the mineshaft at the immediate vicinity of wellbore in the target bed through controlling the rate of pressure rise, peak pressure, pressure platform and total energy of the gas energy pressure cracking, thereby greatly improving the capacity of the oil and gas well.

Owner:XIAN NEW CHANNELING GASOLINEEUM TECH

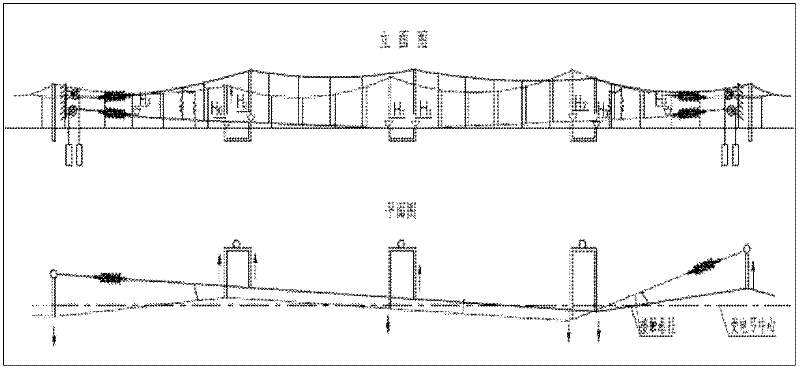

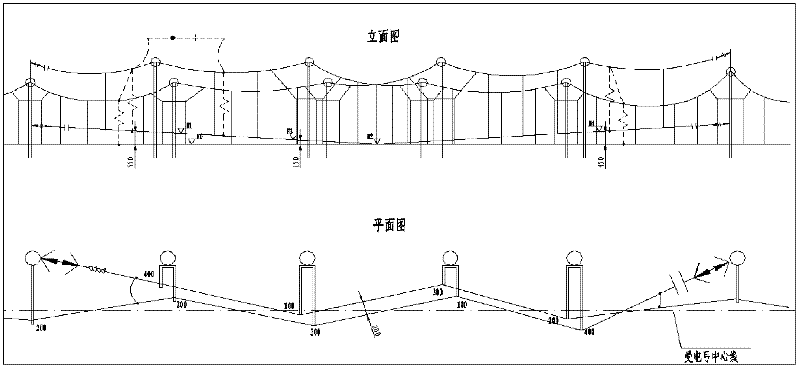

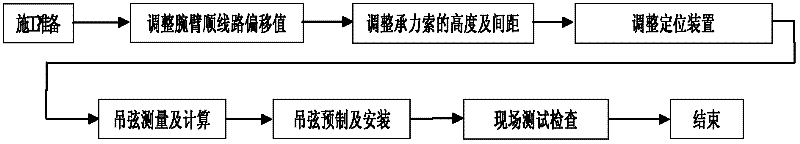

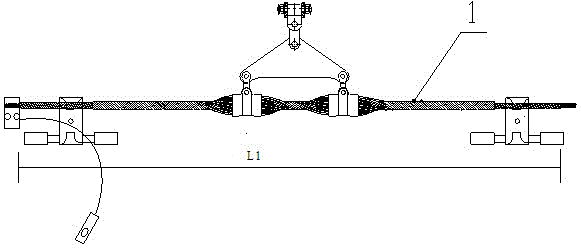

Installation construction method of electrified railway contact network anchored section joint hanger

The invention relates to a construction method of an electrified railway, in particular to an installation construction method of an electrified railway contact network anchored section joint hanger, which is characterized by comprising the specific steps of: preparing for construction, regulating an offset value of a cantilever along a line, regulating high conductivity and spacing between carrier cables, regulating a positioning position, measuring and calculating an anchored section joint hanger, prefabricating and installing the hanger, and testing and checking a site. The method providesa construction method for accurate installation of the electrified railway contact network anchored section joint hanger without secondary regulation, and the space structure and the stress state of the anchored section joint hanger can completely reach the design and construction standard requirement, thus the hanger in a contact network anchored section joint is installed once.

Owner:WUHAN RAILWAY ELECTRIFICATION BUREAU GRP CO LTD

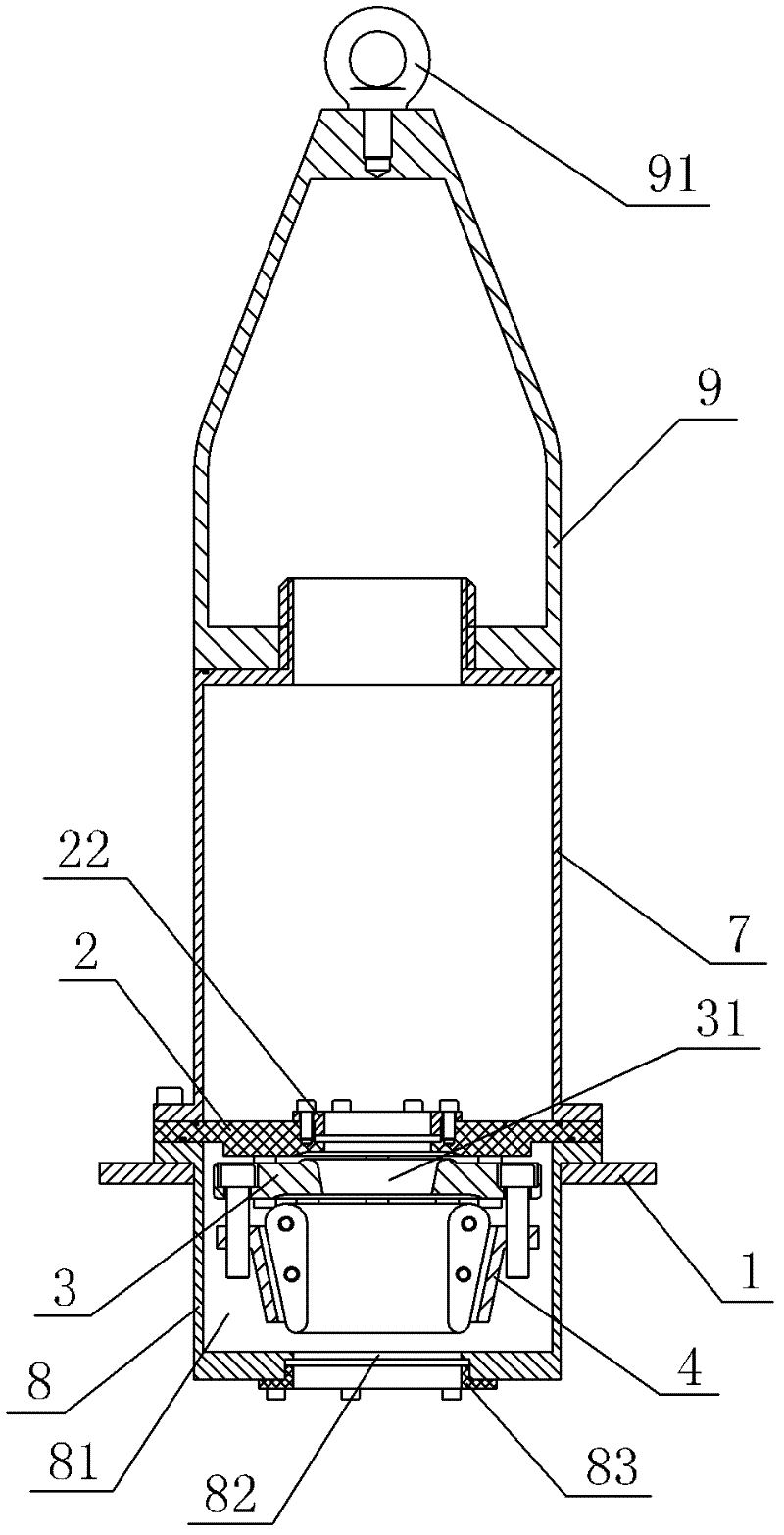

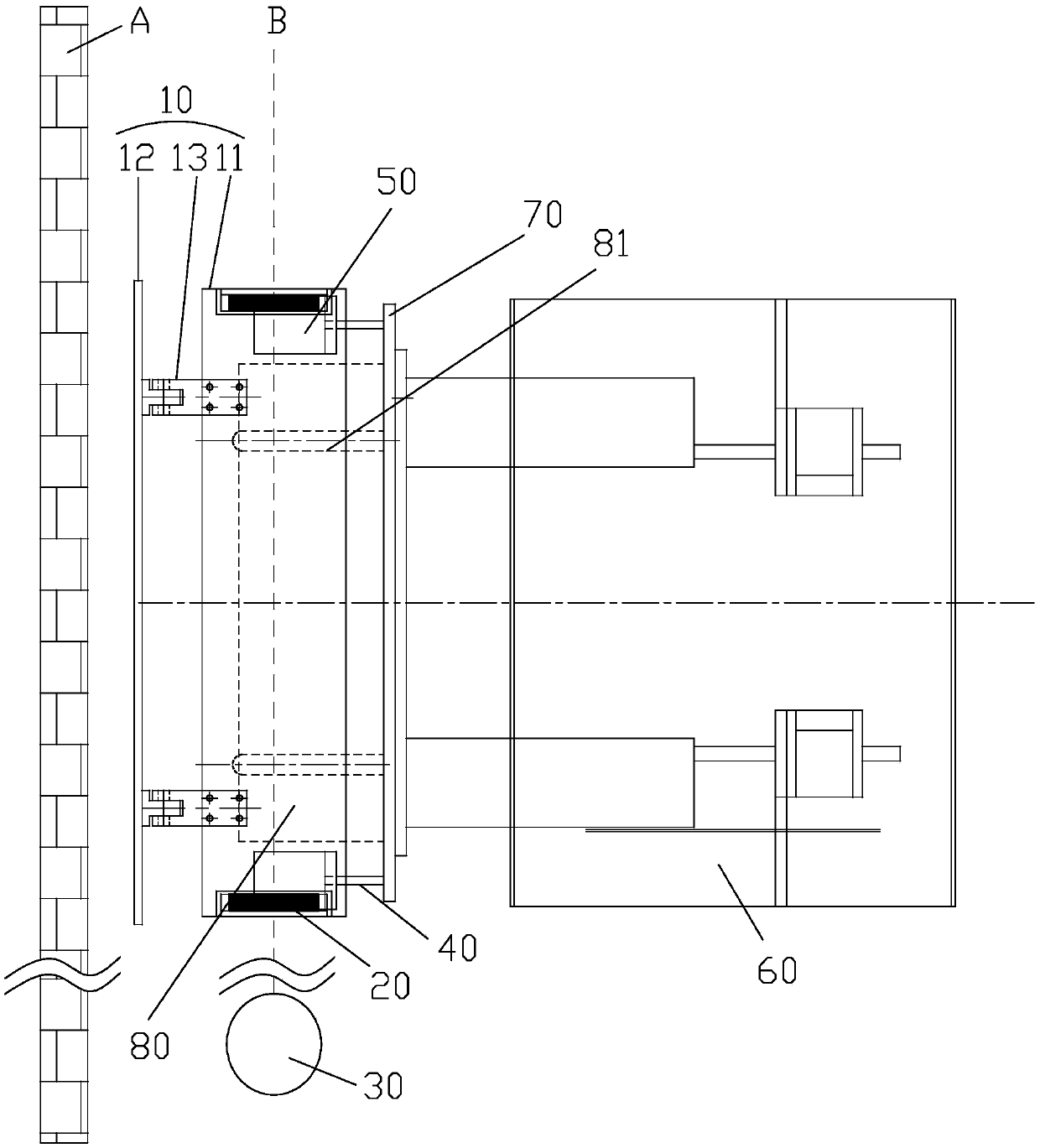

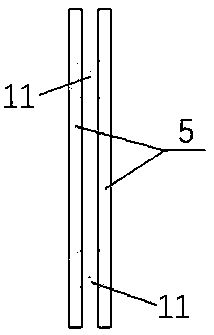

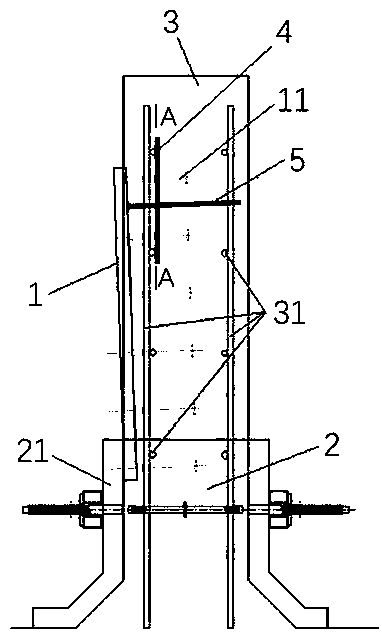

Device special for laying underwater cable

ActiveCN102361266AImprove construction work efficiencyPrevent water ingressApparatus for laying cablesMarine engineeringUltimate tensile strength

The invention discloses a device special for laying an underwater cable, comprising a dragging part and an anchoring part and is characterized in that the dragging part comprises an upper shell, a lower shell and a dragging head; the anchoring part comprises a base and an anchoring assembly for fixing the underwater cable; the upper shell and the lower shell are respectively fixedly connected with the anchoring assembly in a sealing way; the anchoring assembly is arranged in the lower shell; an inner cavity for filling waterproof sealant is arranged between the lower shell and the anchoring assembly; the base is sleeved on the lower shell; and the dragging head is fixedly connected to the upper shell in a sealing way and is in threaded connection with a hoisting screw. The device special for laying the underwater cable has the advantages that the underwater cable can be draught by only dismounting the base at the dragging stage of the underwater cable, the underwater cable can be fixed and installed through sleeving the base on the lower shell and then fixedly installing the base on a top flange of a J-shaped pipe or I-shaped pipe in an installing site when the underwater cable is needed to be installed and fixed after the dragging, thus, the construction operation efficiency of the underwater cable is increased, and meanwhile, the construction difficulty and strength are also reduced.

Owner:宁波东方电缆股份有限公司

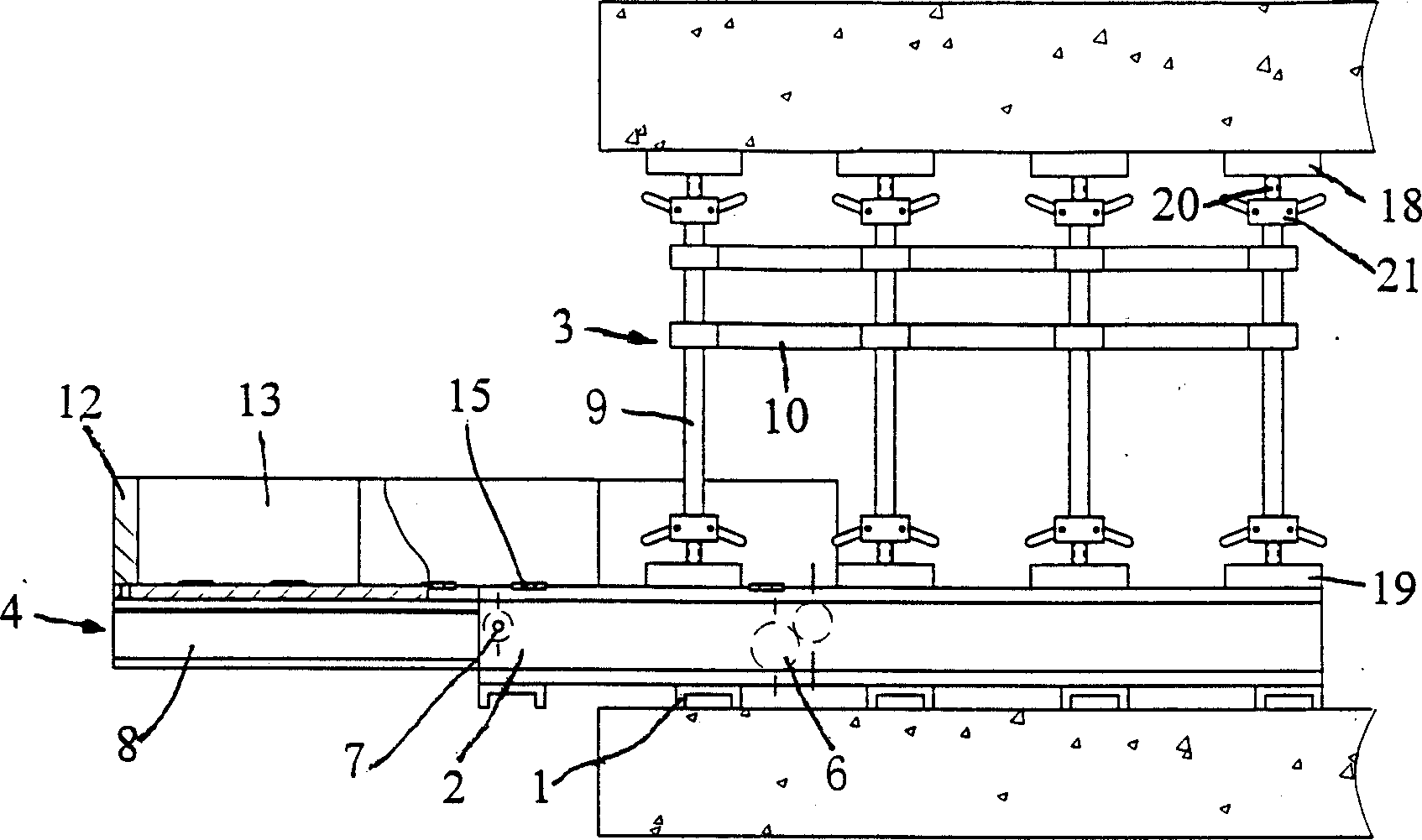

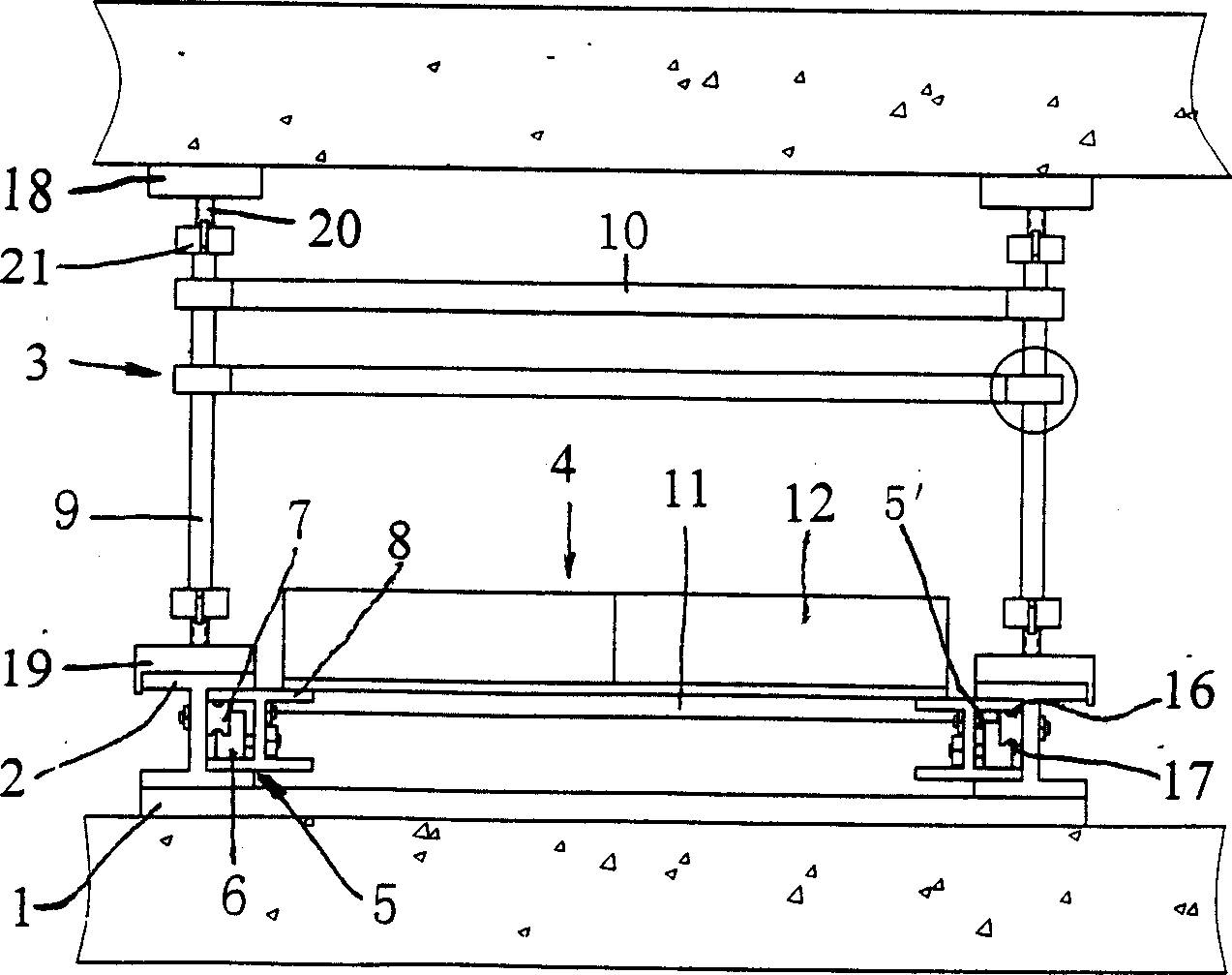

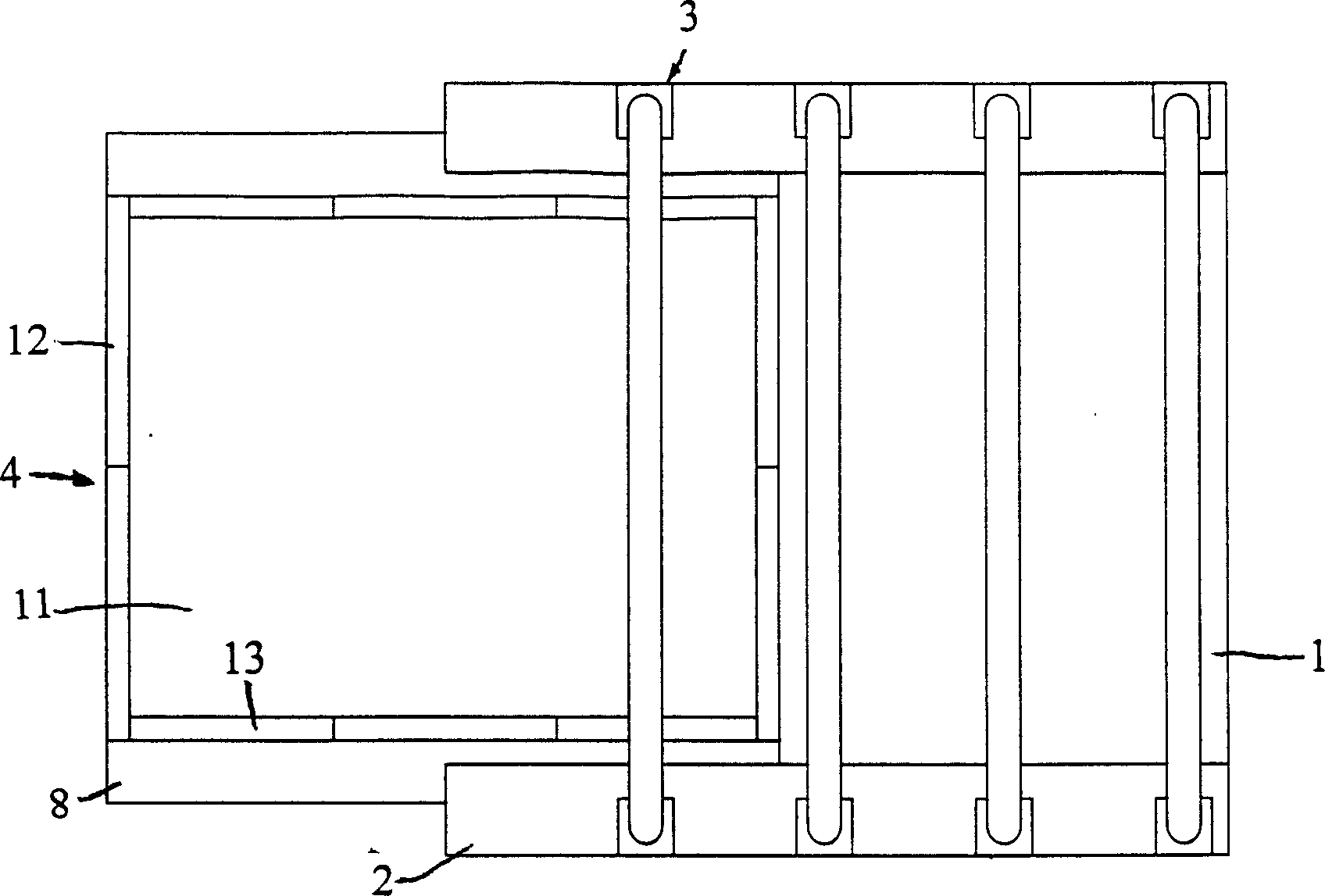

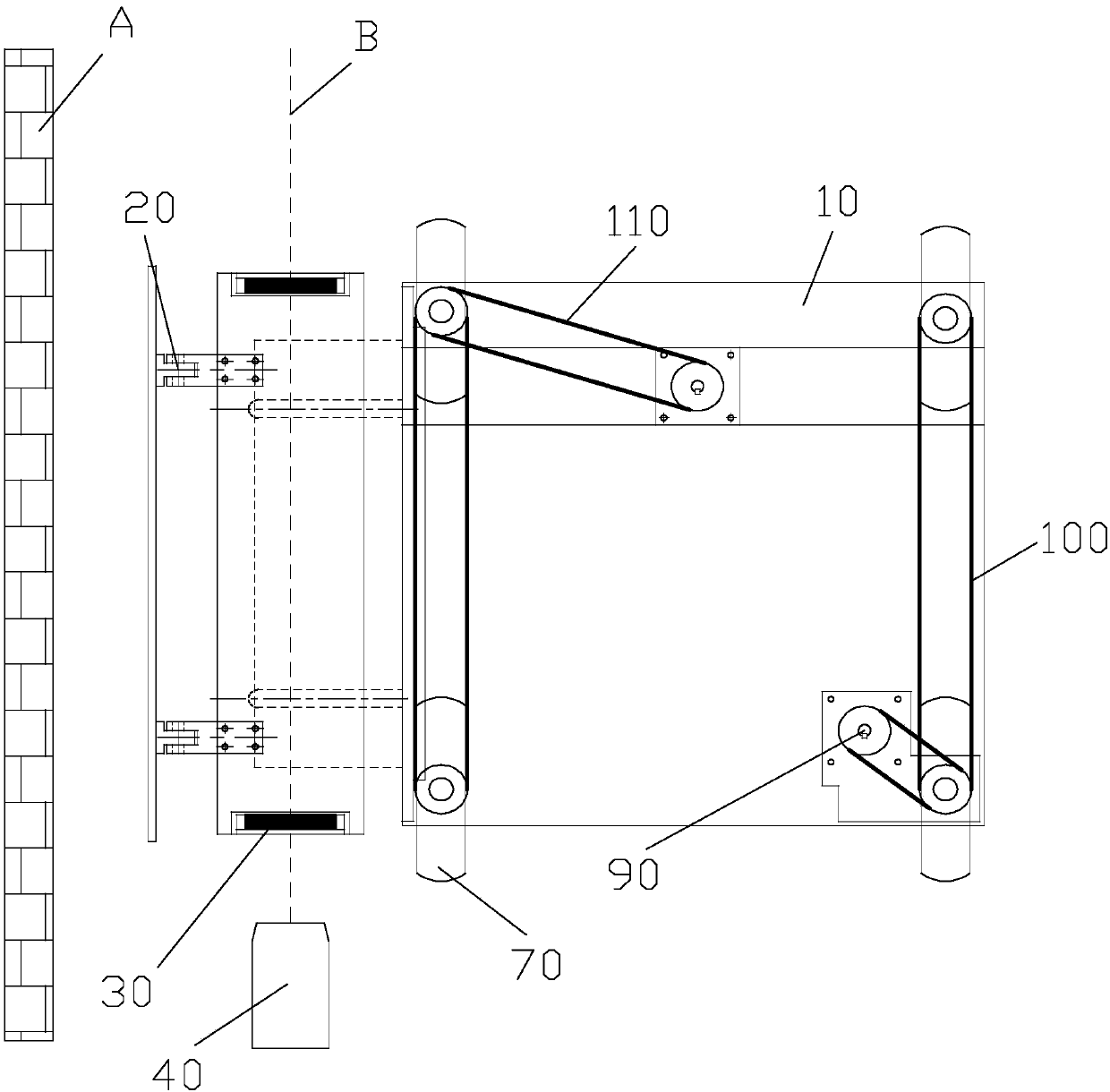

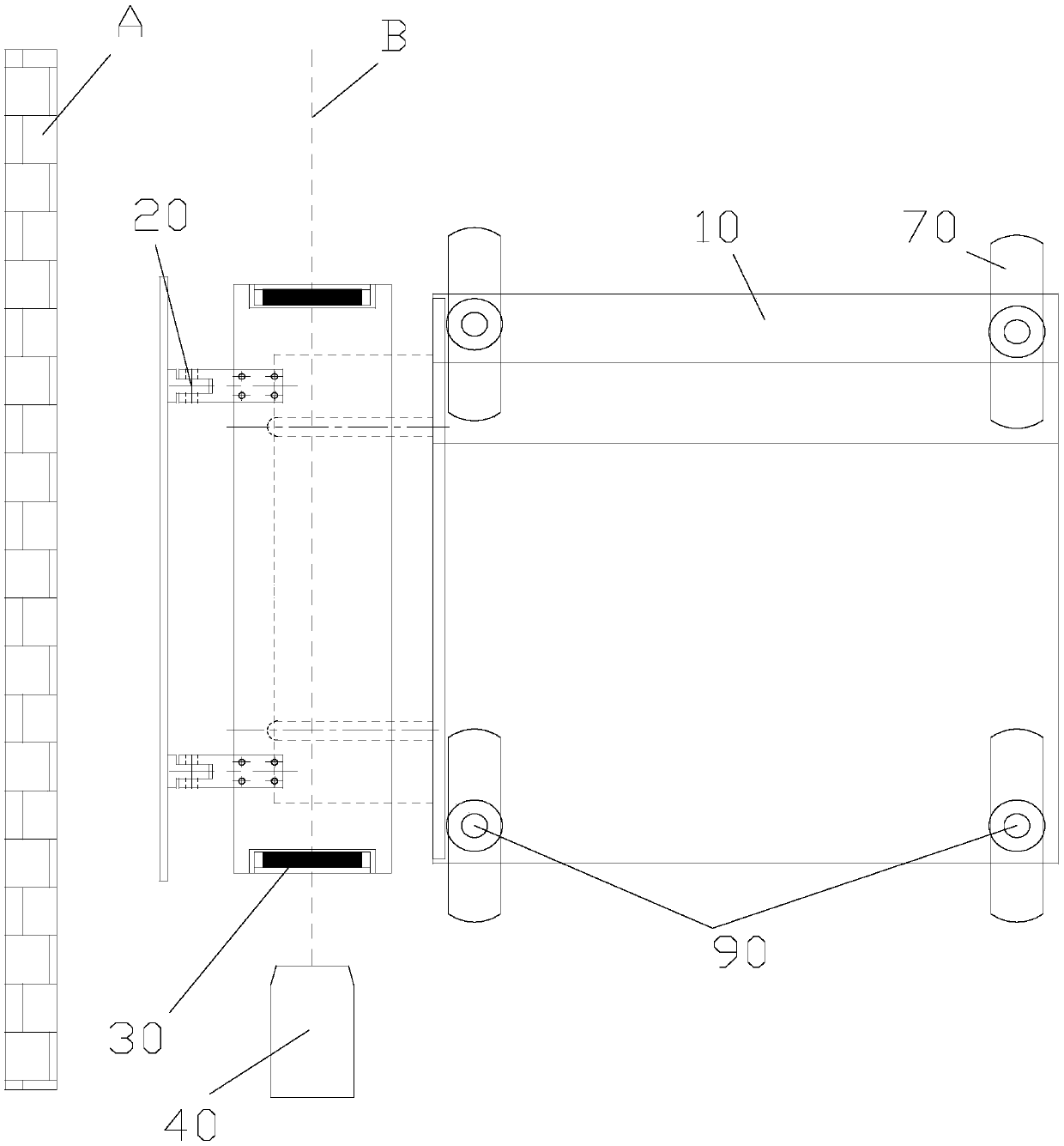

Telescoping construction platform

A telescopic building platform is composed of a base, two parallel guide tracks with two opposite slots (one for each), two lifting-fixing units (one for each guide track) for fixing the guide track between top slab and base, and a carriage whose wheels at both sides are matched with the slots on guide tracks for transporting building materials. It can increase the construction efficiency.

Owner:北京中瑞金祥国际贸易有限公司 +1

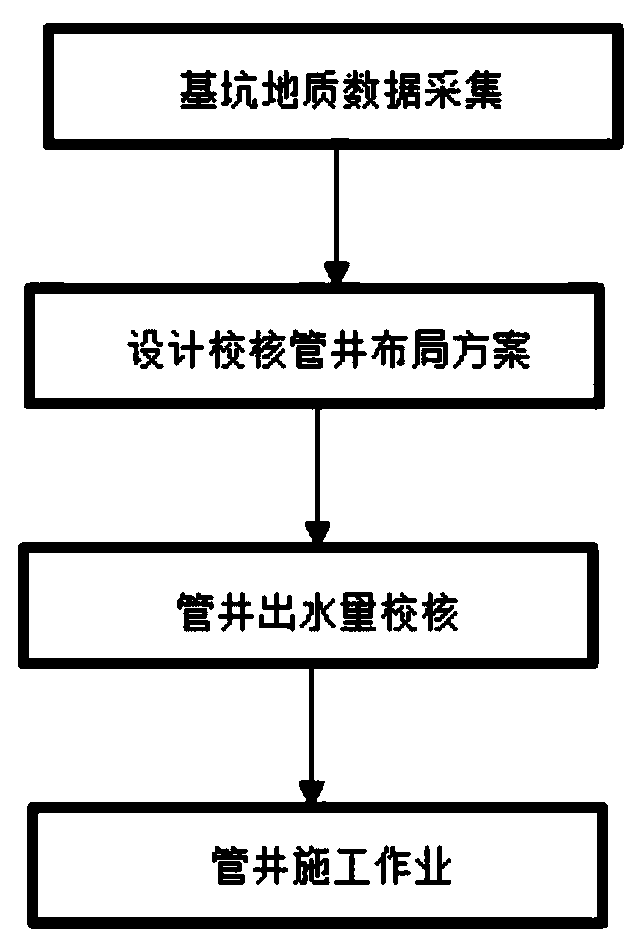

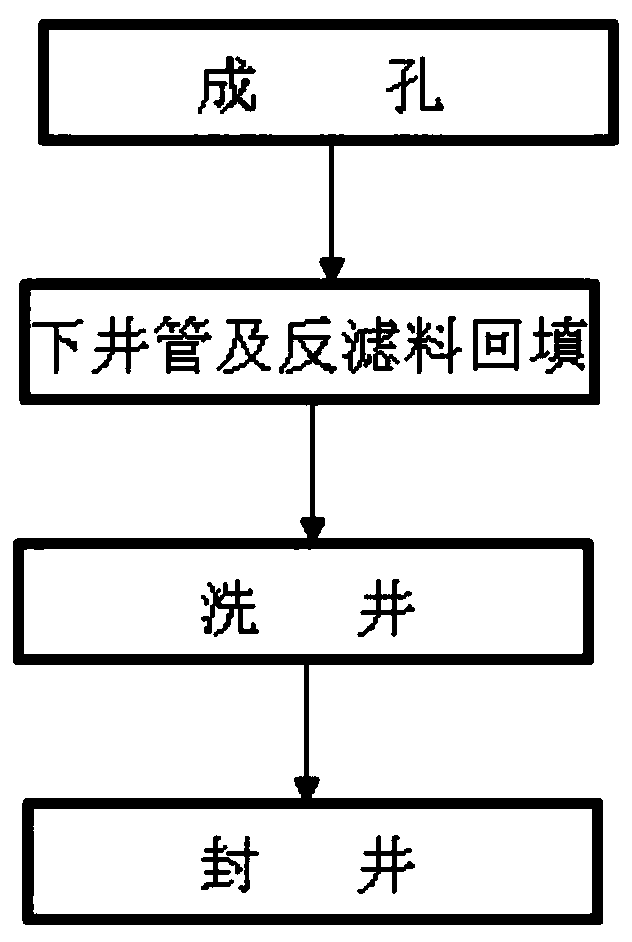

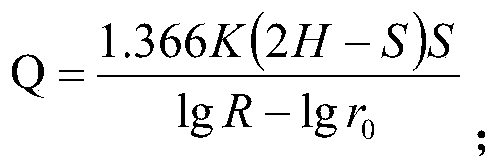

Water conservancy project foundation pit tube well combined light well point dewatering and drainage method

InactiveCN109736338ASimplify the amount of constructionImprove efficiencyFoundation engineeringArchitectural engineeringGeodat

The invention relates to a water conservancy project foundation pit tube well combined light well point dewatering and drainage method. The method comprises four steps of foundation pit geological data collection, tube well layout scheme design and check, tube well water yield check and tube well construction operation. Compared with a traditional drainage construction technology, on one hand, theconstruction amount of drainage construction operation is effectively simplified, the construction operation efficiency is improved, the operation cost of drainage construction and drainage operationis effectively reduced, on the other hand, the efficiency of foundation pit drainage operation is effectively improved, the influence of construction drainage on engineering construction is reduced,and the efficiency and quality of foundation pit construction operation are improved.

Owner:JIANGSU PROVINCE WATER ENG SCI TECH CONSULTING

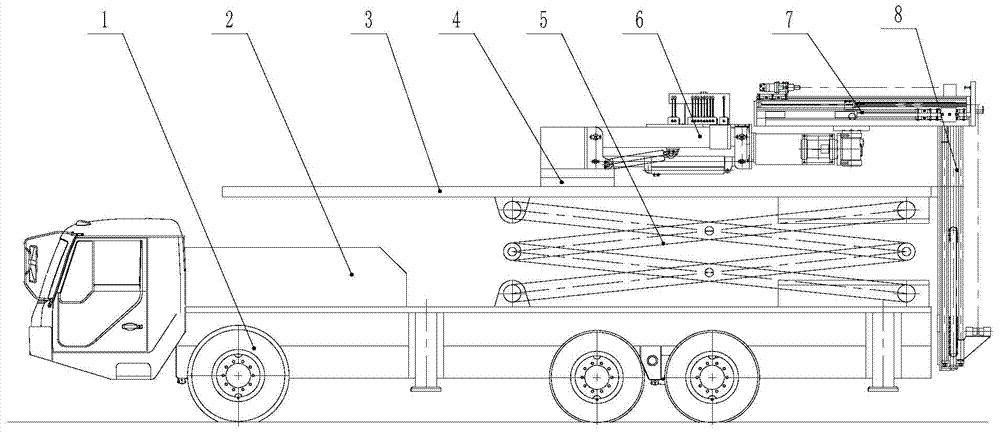

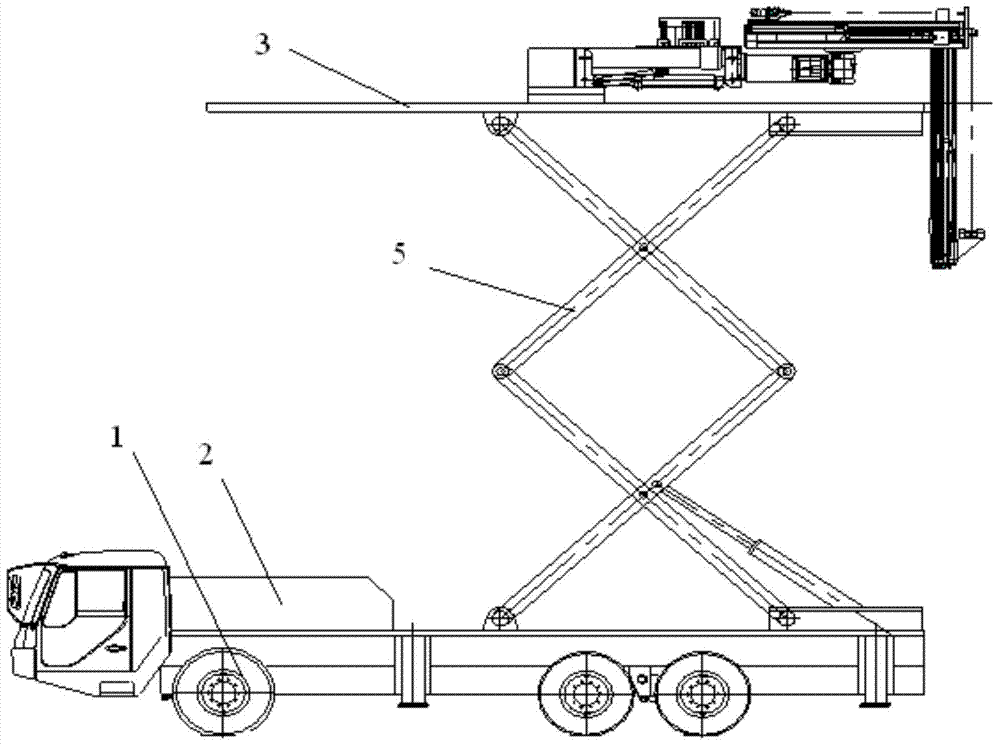

Tunnel construction trolley

ActiveCN104747078AMeet construction requirementsSolve construction difficultiesDerricks/mastsAnchoring boltsArchitectural engineeringDrill

The invention discloses a tunnel construction trolley. The tunnel construction trolley comprises a walking mechanism, a lifting platform, a drill arm mechanism, a lifting mechanism and a power and control device, wherein the walking mechanism is located on the bottom of a trolley body, and the power and control device is installed on the walking mechanism; the lifting platform is arranged above the walking mechanism in a liftable mode; the drill arm mechanism and the lifting mechanism are both installed on the lifting platform; the power and control device controls the lifting platform, the drill arm mechanism and the lifting mechanism to act. According to the tunnel construction trolley, anchor protection and lifting are integrated, not only can the construction requirement for the inland tunnel anchor bolt support be met, but also the mechanization and the automation of large section tunnel anchor bolt support work are achieved, the labor intensity is relieved, the efficiency is improved, and a better guarantee of the tunnel engineering quality is achieved.

Owner:蒲长晏

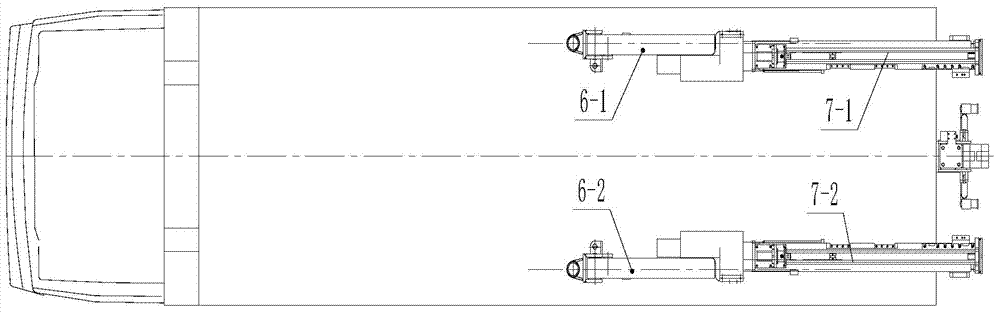

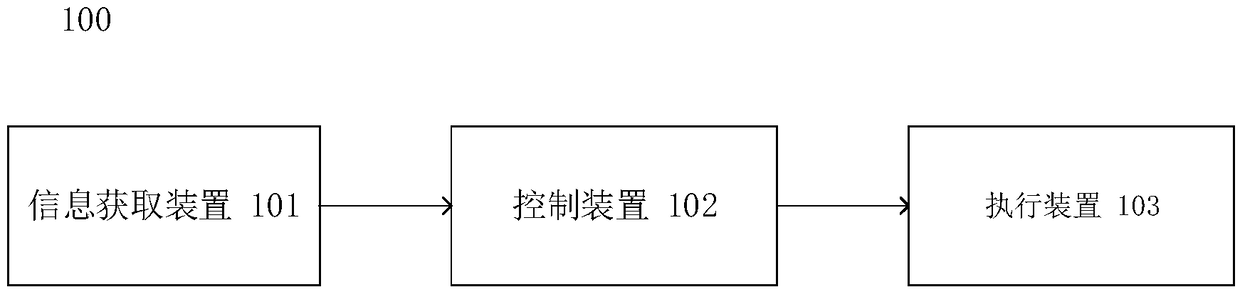

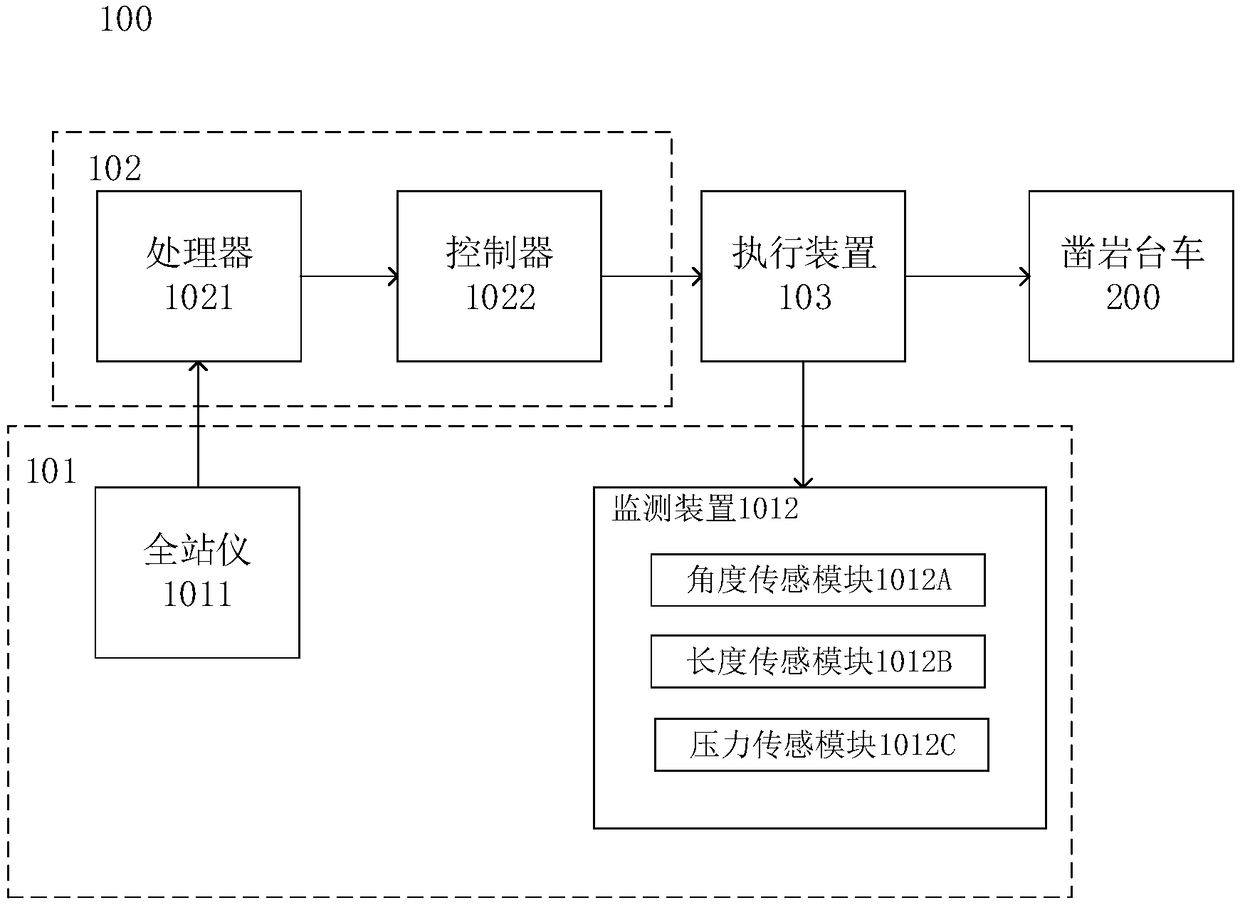

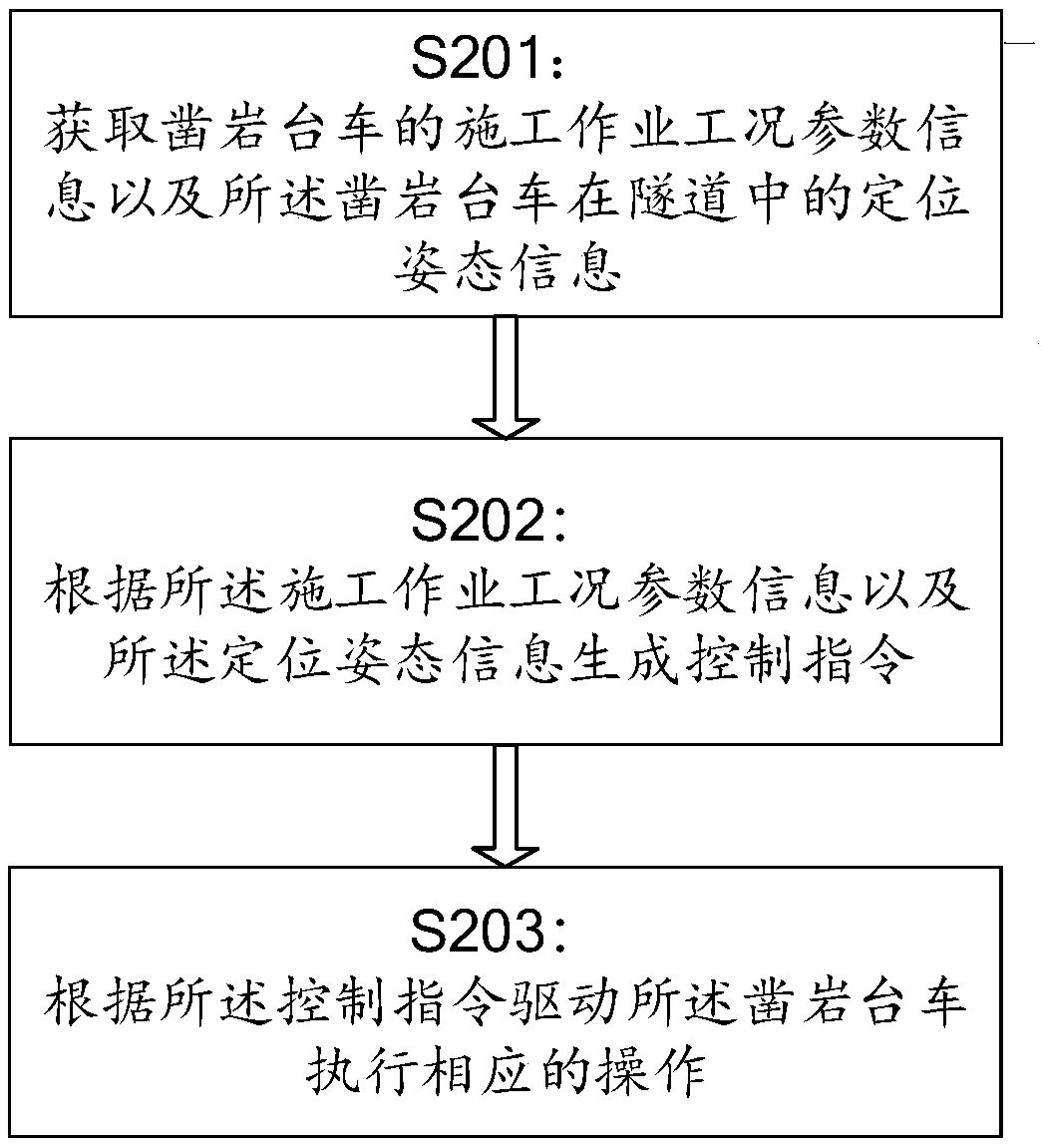

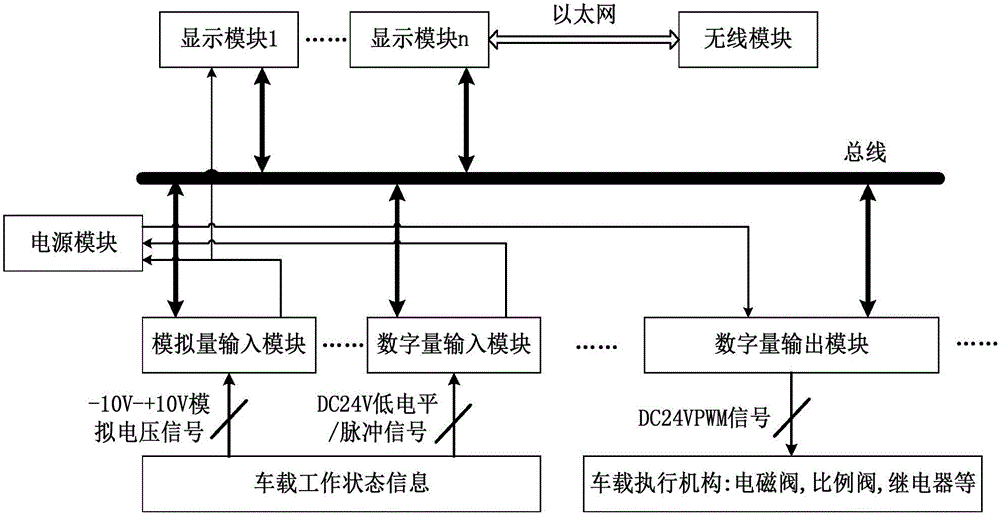

Control system and method used for drill jumbo

PendingCN109025815AReduce investmentReduce resource inputDrilling machines and methodsAutomatic control for drillingControl systemControl engineering

The invention provides a control system and method used for a drill jumbo. The control system includes an information acquirement device, a control device and an execution device. The information acquirement device is used for acquiring construction operation working condition parameter information of the drill jumbo and positioning posture information of the drill jumbo in a tunnel; the control device is used for receiving the construction operation working condition parameter information and the positioning posture information from the information acquirement device and generating control instructions according to the construction operation working condition parameter information and the positioning posture information; the execution device is used for receiving the control instructionsfrom the control device and driving the drill jumbo to carry out corresponding actions according to the control instructions.

Owner:北京路凯智行科技有限公司

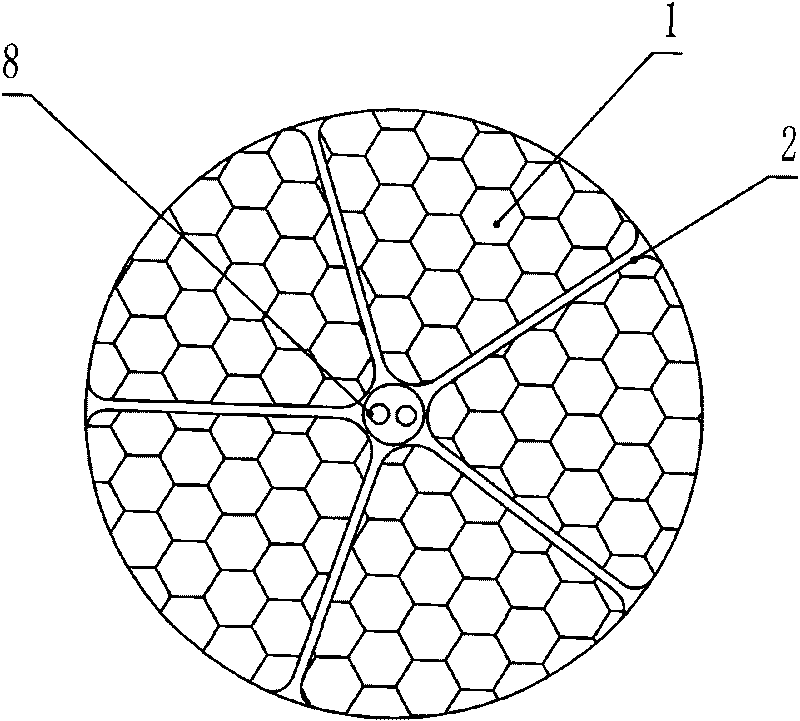

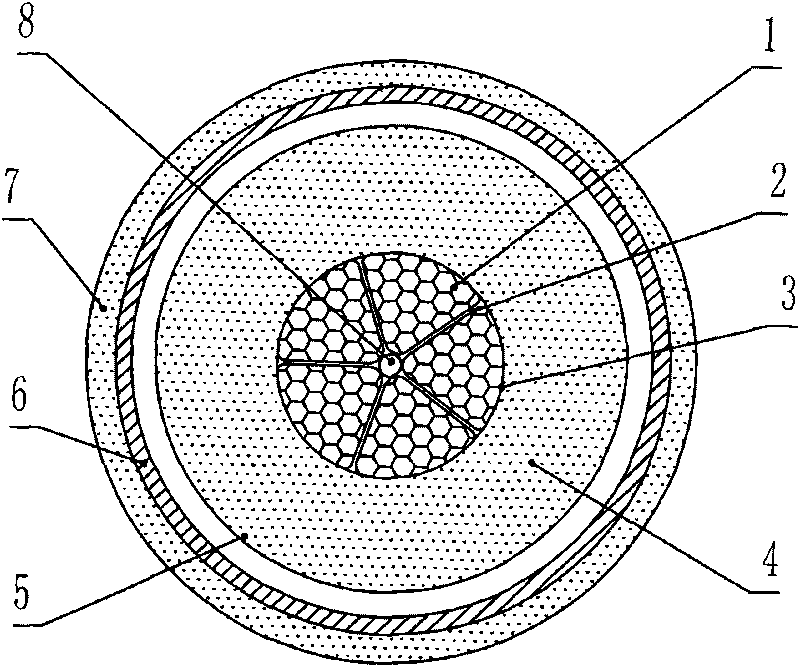

Method for twisting fibers in center of composite power cable conductor

InactiveCN101714433AReduce aging speedUse the transmission abilityCommunication cablesCable/conductor manufactureFiberElectrical conductor

The invention relates to a method for twisting fibers in the center of a composite power cable conductor, solving the lasting problem of arranging optical fiber in the center of the cable conductor, which is unsolved all along by technical staff in the field. The invention utilizes the conventional frame-type wire-twisting machine, twists compacted and molded fan-shaped conductor units into a round segment conductor by fan-shaped filming, and twists the optical fiber with a stainless steel sleeve into a space enclosed by the round segment conductor center at the same time, and sequentially arranges a semi-conductive shielding layer, a crosslinked polyethylene insulator, an insulated semi-conductive shielding layer, a metal sheath and a plastic sheath on the periphery of the round segment conductor to prepare a composite power cable. The invention has simple process flows and together successfully twists the optical fiber with the stainless steel sleeve in the conductor center of the cable core on a basis of unchanging the prior cable manufacture process flows so that the product reaches the aims of accurately realizing the online measurement of practical cable temperature rise, exerting the transmission capability of the cable to the maximum extent and ensuring the safe operation of a power cable line.

Owner:SHENYANG FURUKAWA CABLE

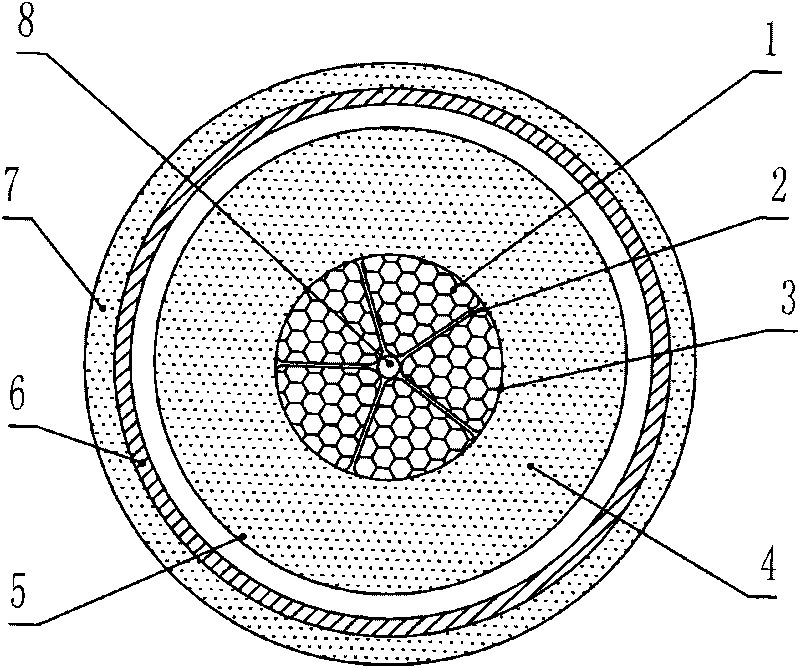

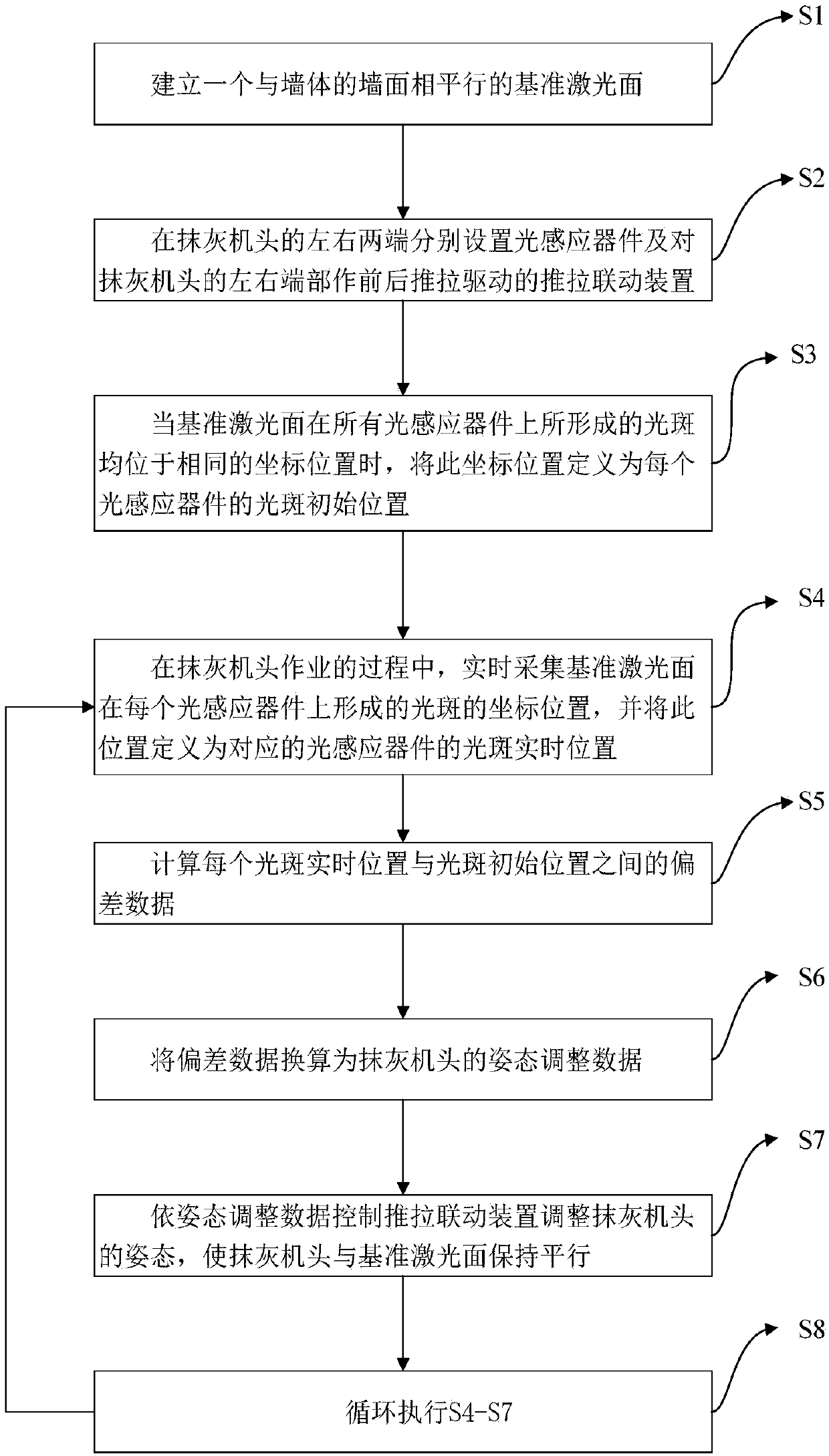

Method for automatically adjusting plastering thickness and plastering robot

ActiveCN109577614AReal-time dynamic adjustmentGuaranteed flatnessBuilding constructionsLight sensingPush pull

The invention discloses a method for automatically adjusting a plastering thicknessand a plastering robot. The method comprises the steps of S1, establishing a reference laser surface parallel to a wall surface of a wall; S2, respectively setting a light sensing device and a push-pull linkage device on the left and right ends of a plastering machine head; S3,defining a light spot initial positionof each light sensing device; S4, conducting real-time collection of the light spot real-time position of the light sensing device in the operation process of the plastering machine head; S5, calculating the deviation data between the real-time position of each light spot and the initial position of eachlight spot; S6, converting the deviation data into posture adjustment data of the plastering machine head; S7, according to the posture adjustment data, controlling the push-pull linkage device to adjust the posture of the plastering machine head, so that the plastering machine head and the reference laser surface are kept parallel; the method can achieve the plastering machine head real-time dynamic adjustment, do not need manual intervention, be capable of automatic calculation of the thickness, have short adjustment time and high precision, can greatly improve the efficiency of construction work, and effectively ensure the thickness of the plastering and the flatness of the working wall surface.

Owner:深圳市森博机器人有限公司

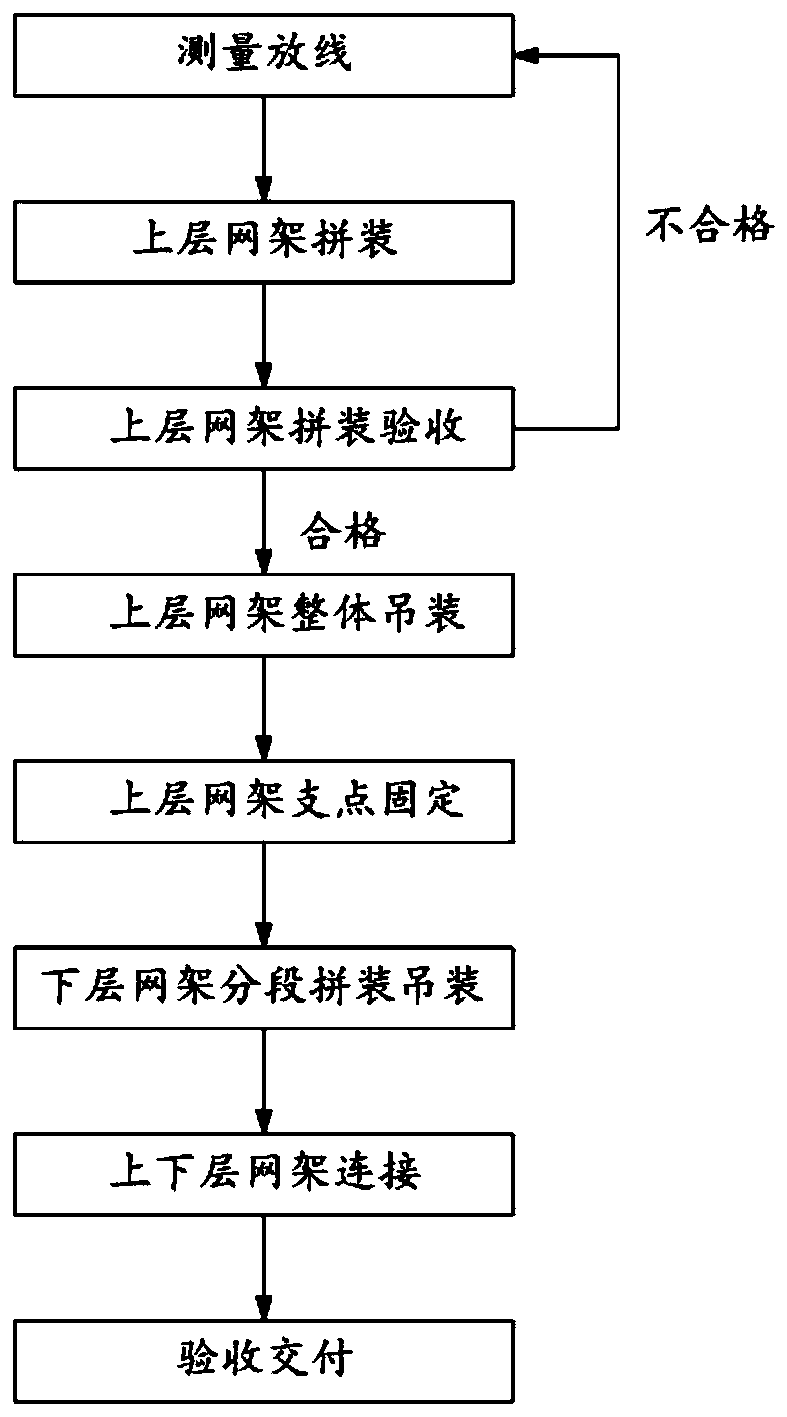

Large-span spherical net frame integral lifting method

The invention discloses a large-span spherical net frame integral lifting method. The large-span spherical net frame integral lifting method lifts large-span spherical net frames by adopting a mode ofcombining integral lifting with segmented lifting; upper chords and lower chords of upper layers of the net frames are integrally lofted through a total station for integral assembly; a reserved value of a springing height is set in the assembly process; multiple lifting equipment is used for integrally lifting and mounting the upper layers of the net frames; upper part structures integrally lifted are used for forming an operation platform; and lower part structures are assembled, lifted and connected in a segmented mode to form a whole, so that the aerial bulking of components is reduced, the scaffold use level is reduced, the aerial workload is reduced, the construction is safe and reliable, the construction risk is reduced, the construction efficiency is improved, and the control of the quality of the net frames and the control of the production safety are facilitated.

Owner:CHENGDU NO 1 CONSTR

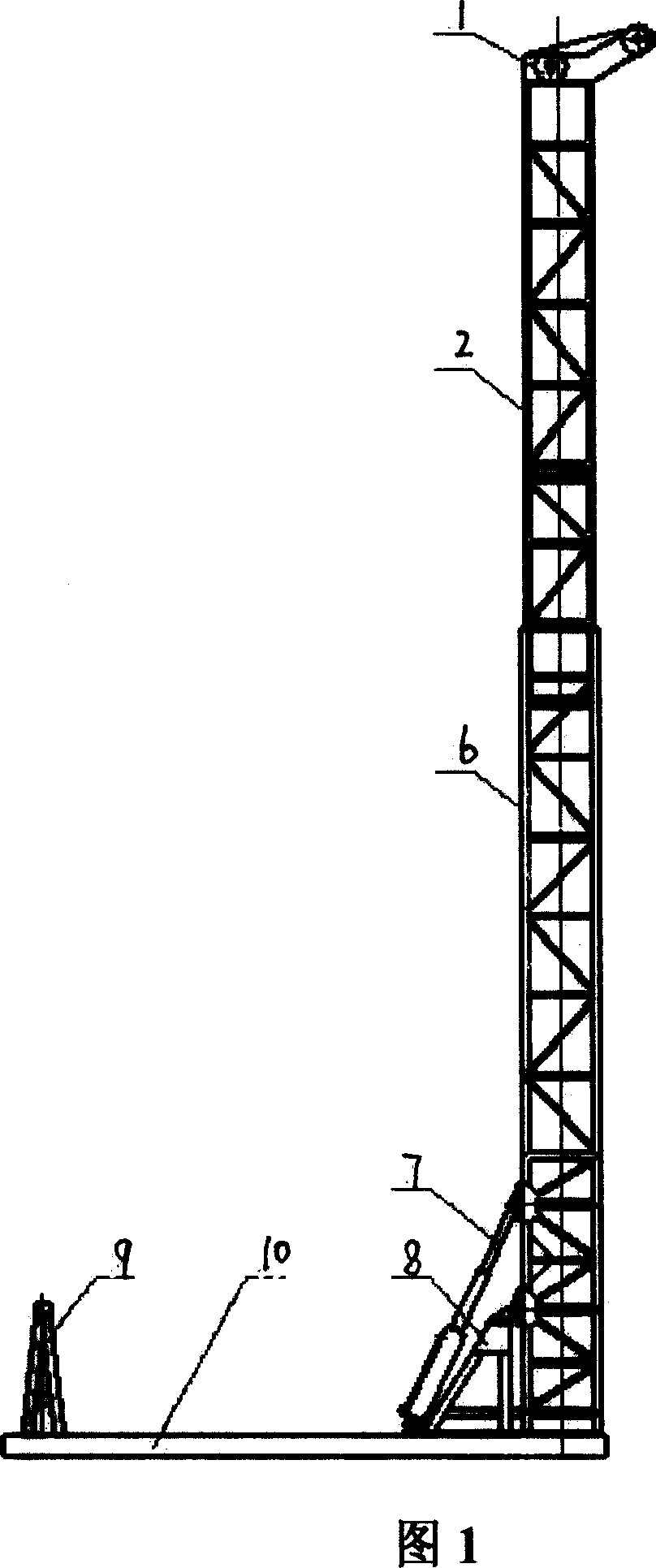

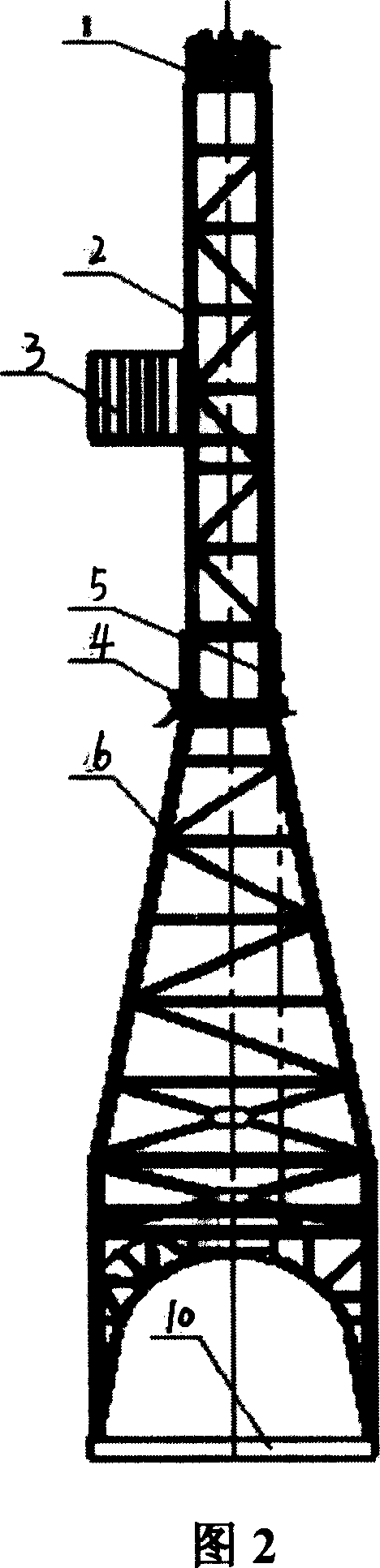

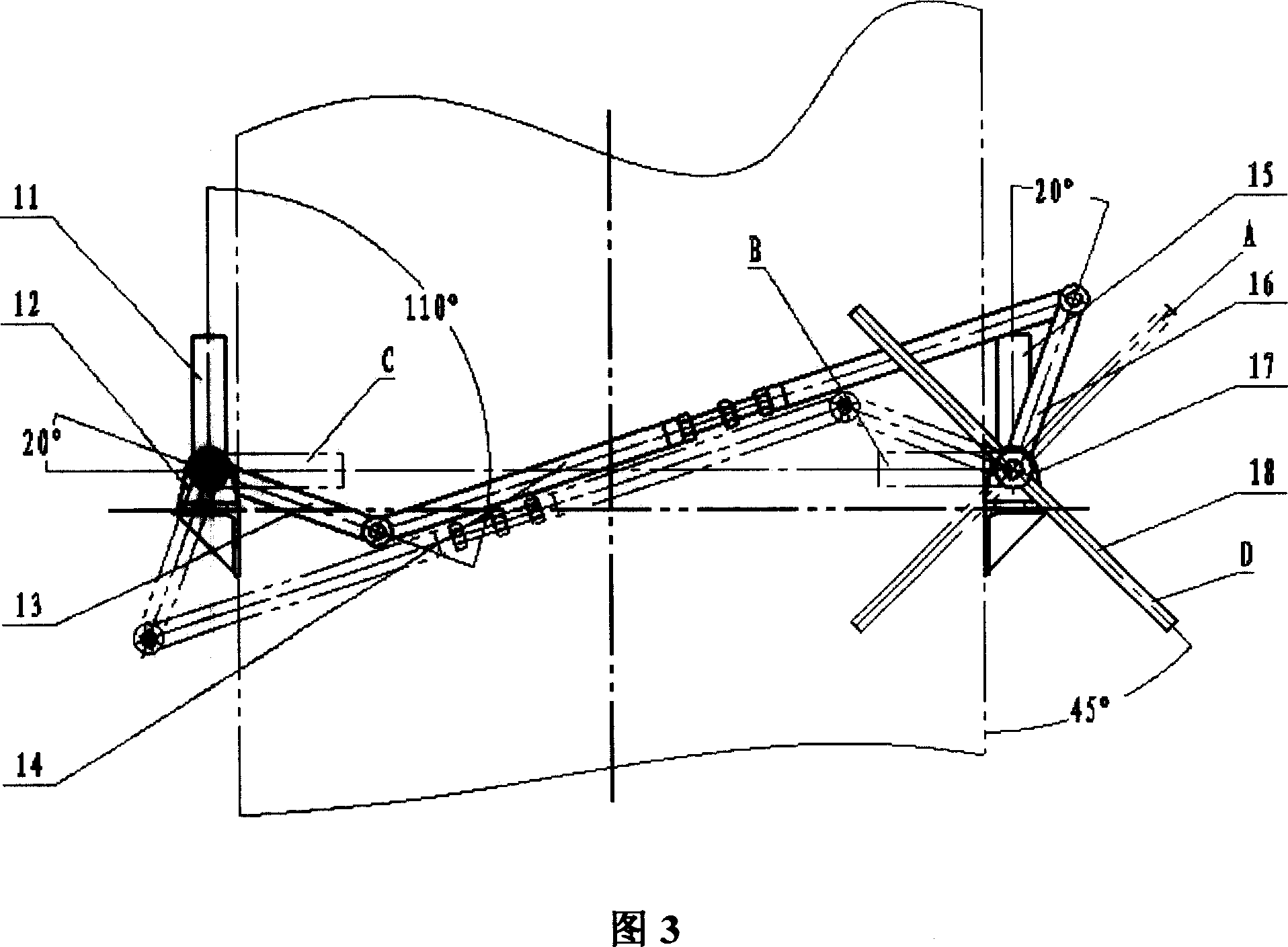

18 m hydraulic pressure rise and fall retractable drill tower

InactiveCN101016827AEasy to transportImprove carrying capacityDerricks/mastsSteel tubeTelescopic cylinder

A 18m hydraulic lifting flexible drilling tower is formed by a crown block, an upper tower, a two-layer table, a limit locking device, a lifter, a lower tower, an upright tower cylinder, an upright tower support, a fall tower support and a drilling tower chassis. The crown block is formed by three front and two back block groups, to be connected on the top of the upper tower via bolts, the drilling tower chassis is integral steel, the upright tower support is welded into A-shaped support via welding rectangle square tube to be welded on the drilling tower chassis, the lower and upper towers are welded via seamless steel tube into truss structure, the lower tower and the upright tower support are connected via a hinge base, the upper tower is sheathed in the lower tower, the upright tower cylinder is formed by two-stage flexible cylinder, the two-layer table is welded from steel tubes to be connected at 12.5-8.2m of the drilling tower via flanges, and the fall tower support is welded from section steel. The invention can drill 18m deep, with improved bearing ability, high efficiency and reduced cost.

Owner:陕西省核工业地质局工程机械研究所

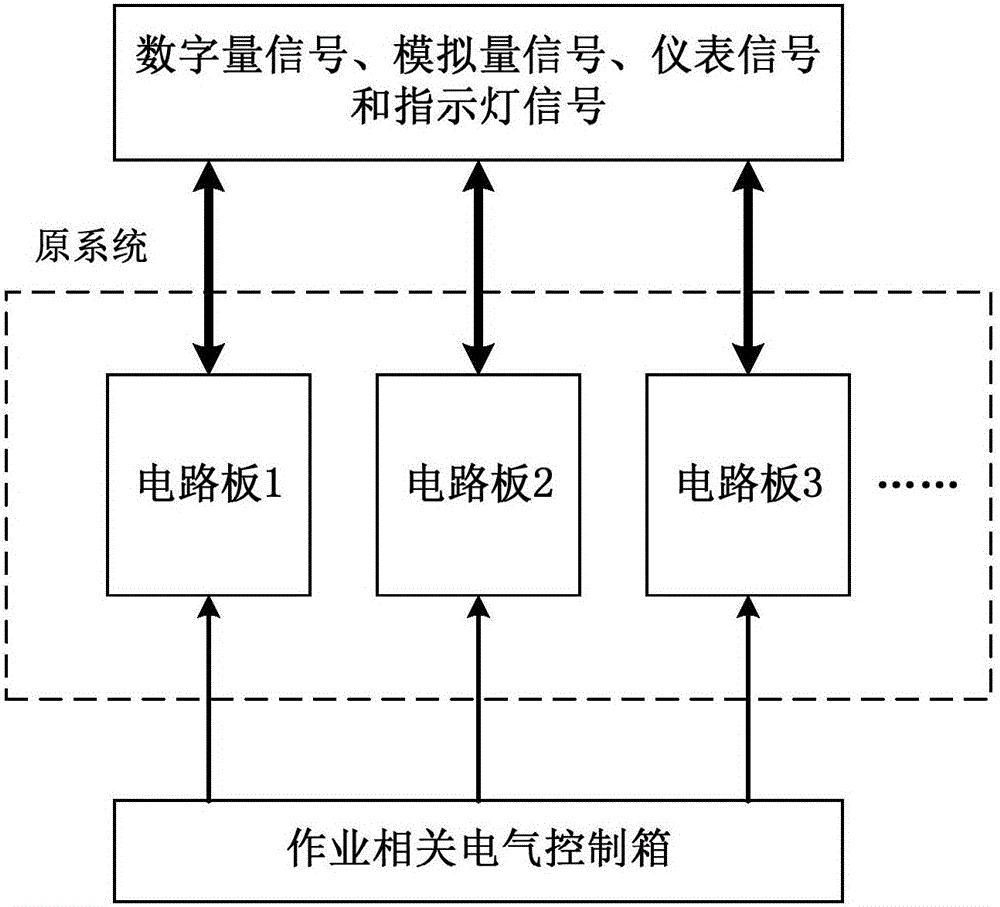

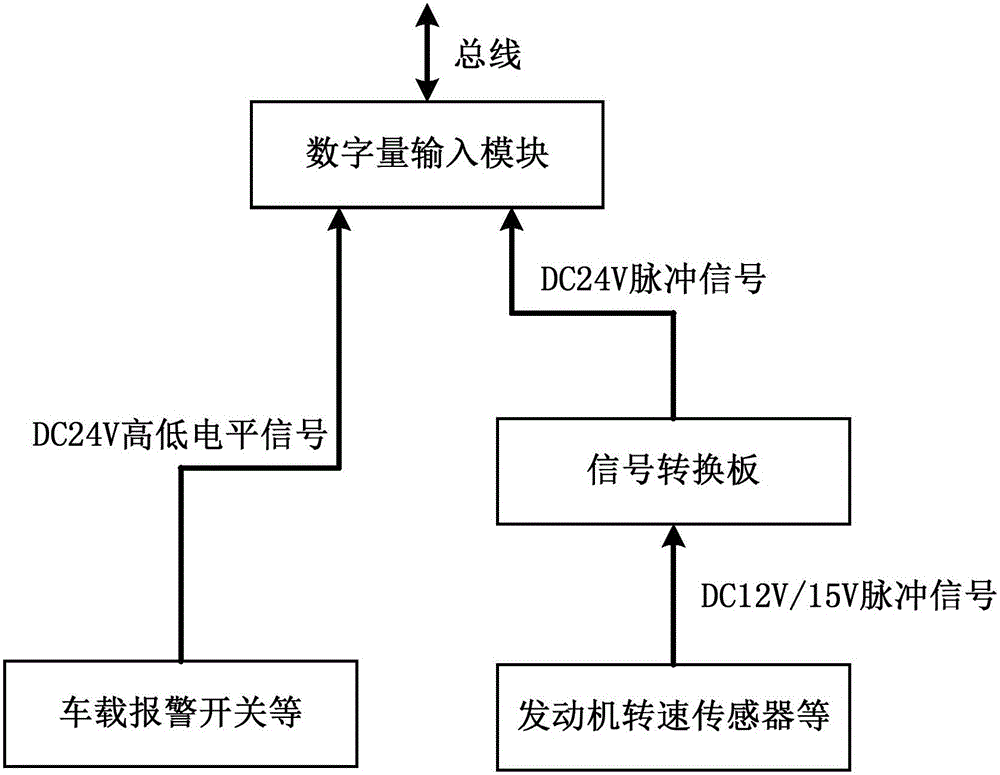

Remote diagnosis system for existing track engineering machinery

ActiveCN105700516AReduce in quantityReduce the amount of wiringElectric testing/monitoringAgricultural engineeringVehicle driving

The invention discloses a remote diagnosis system for existing track engineering machinery. The remote diagnosis system comprises a vehicle-mounted host machine, a switch device, a front end analog quantity acquisition board, a multipath analog quantity acquisition board, a program control motherboard, at least two vehicle driving monitoring digital quantity acquisition modules and at least two vehicle driving monitoring analog quantity acquisition modules. Data interaction is conducted between the vehicle-mounted host machine and a third party device via the switch device; the front end analog quantity acquisition board, the multipath analog quantity acquisition board and the program control motherboard transmit collected operating condition data of the track engineering machinery to the vehicle-mounted host machine via an on-site bus. The vehicle driving monitoring digital quantity acquisition modules and the vehicle driving monitoring analog quantity acquisition modules transmit collected vehicle driving safety monitoring data of the track engineering machinery to the vehicle-mounted host machine. The remote diagnosis system can solve technical problems of difficult existing track engineering machinery information acquisition monitoring, low trouble-shooting efficiency, difficult on-site management, and difficult vehicle-mounted equipment installation and wire arrangement.

Owner:ZHUZHOU TIMES ELECTRONICS TECH CO LTD +1

Coal-ash dry-mixed plastering mortar and preparation method thereof

The invention discloses coal-ash dry-mixed plastering mortar and a preparation method thereof. The coal-ash dry-mixed plastering mortar is characterized by comprising the following raw materials in percentage by mass: 10-15% of coal ash, 10-15% of cememt, 60-70% of machine-made sand, 5-10% of dust, 0.5-1.5% of re-dispersible latex powder and 0.1-0.5% of a water-retaining agent, wherein the total mass ratio of the above raw materials reaches 100%. The preparation method comprises the following step: sequentially adding the above raw materials into a mixing machine for sufficient stirring and uniform mixing, so as to obtain the coal-ash dry-mixed plastering mortar. The prepared coal-ash dry-mixed plastering mortar has the strong adhesive force with a wall substrate; being dry powder, the coal-ash dry-mixed plastering mortar can be stored for a long time, is convenient to transport, and is applicable to machine spraying construction; and accordingly, the construction work efficiency can be improved, a new way is opened up for the utilization of solid waste, and the manufacturing cost of dry-mixed mortar can be reduced.

Owner:上海漕源新型建材有限公司 +1

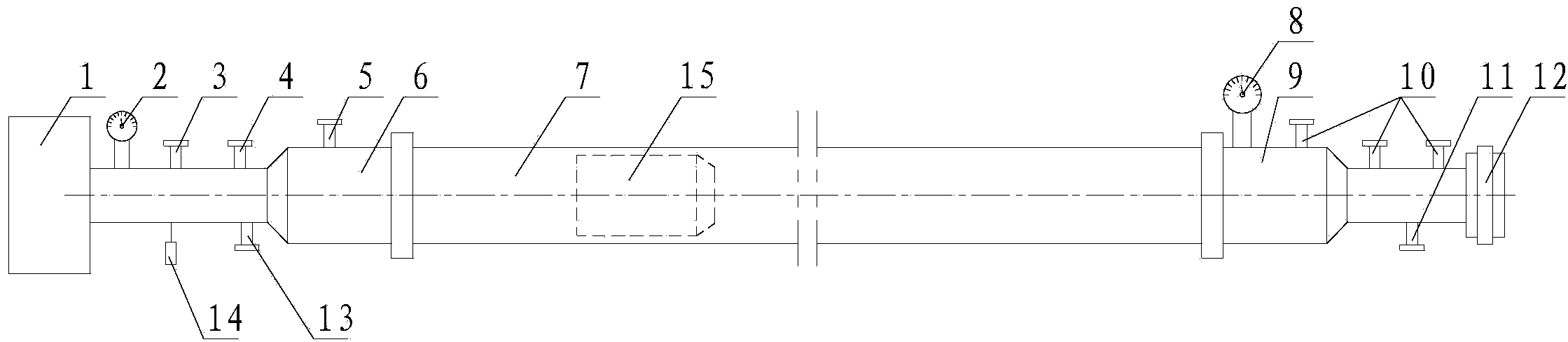

Degreasing cleaning method and degreasing cleaning device for pipeline

InactiveCN107983737AImprove cleanlinessReduce value-added linksHollow article cleaningRubber ringArchitectural engineering

The invention discloses a degreasing cleaning method and a degreasing cleaning device for a pipeline. The degreasing cleaning method for the pipeline comprises the following steps that a, the inner wall of the pipeline is subjected to rust removal treatment, oil-free compressed air is used for pushing a leather cup steel brush pipe cleaner to move in a one-way manner in the pipeline, wherein one end of the leather cup steel brush pipe cleaner is provided with a sealed rubber ring, the rubber ring abuts against the inner wall of the pipeline, a rotatable cylindrical magnetic body is arranged onthe rubber ring, the axis of the cylindrical magnetic body coincides with the axis of the pipeline, and a steel brush is arranged on the surface of the cylindrical magnetic body to clean the inner wall of the pipeline; b, dust removal treatment is carried out in the pipeline; c, degreasing treatment is carried out on the inner wall of the pipeline; d, drying treatment is carried out on the innerwall of the pipeline; and e, a finished product of the pipeline is protected. According to the degreasing cleaning method and the degreasing cleaning device, the construction progress can be accelerated, the construction quality can be improved, manual operation can be compressed, construction cost is saved, and the efficiency of construction operation can be effectively improved.

Owner:THE SIXTH CONSTR CO LTD OF CHINA NAT CHEM ENG

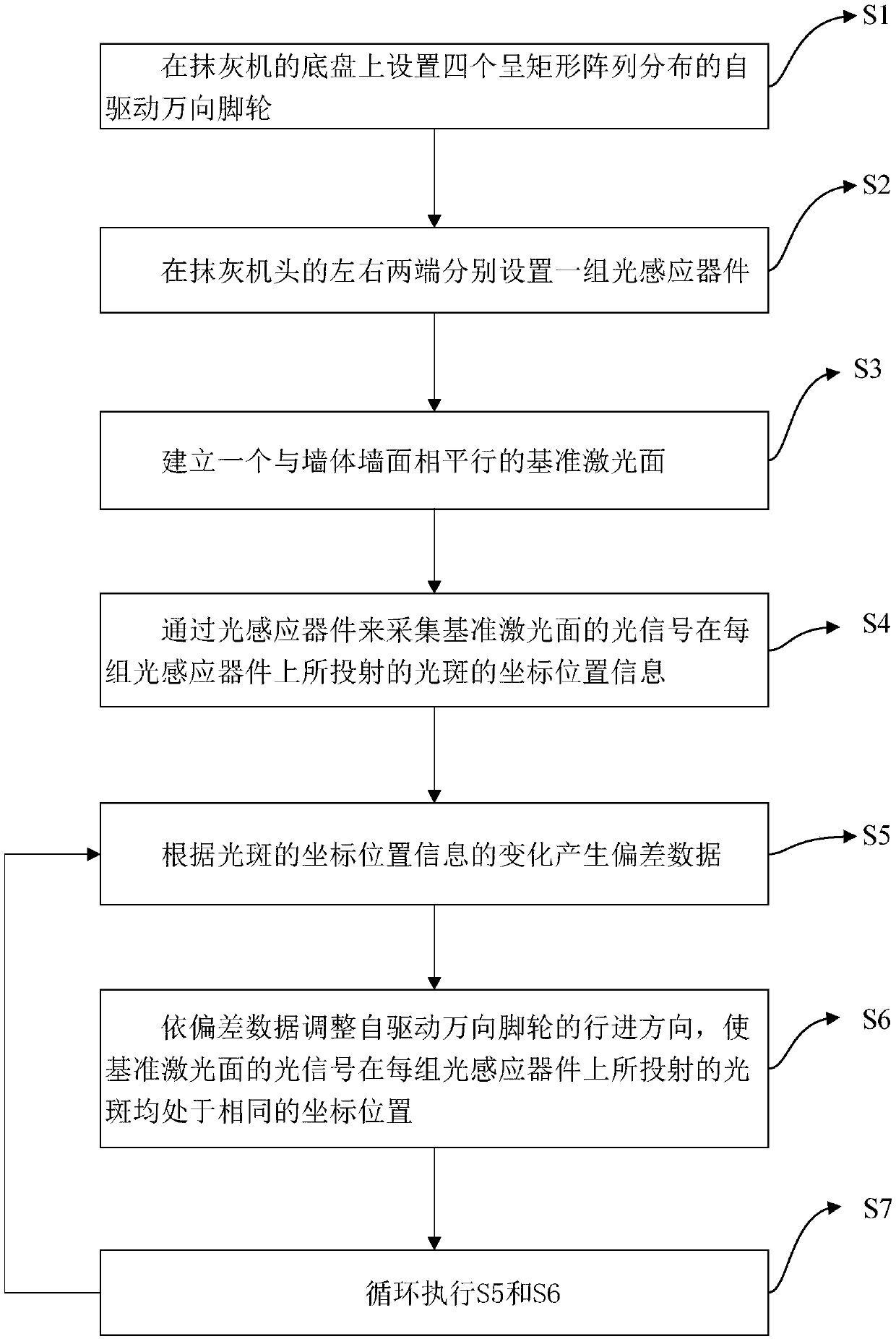

Plastering machine automatic horizontal moving and walking control method and plastering robot

ActiveCN109577616ANo human intervention requiredImprove construction work efficiencyBuilding constructionsLight sensingLight spot

The invention discloses a plastering machine automatic horizontal moving and walking control method and a plastering robot. The method comprises the steps that S1, four self-driven universal trundlesdistributed in a rectangular array are arranged on a chassis of a plastering machine; S2, the left end and the right end of a plastering machine head are both provided with a group of light sensing devices; S3, a reference laser surface parallel to the wall surface of a wall body is established; S4, coordinate position information of light spots projected by light signals of the reference laser surface on each group of the light sensing devices is collected through the light sensing devices; S5, deviation data is generated according to the change of the coordinate position information of the light spot; S6, the advancing direction of the self-driven universal trundles is adjusted according to the deviation data, so that the light spots projected by the light signals of the reference lasersurface on each group of the light sensing devices are located at the same coordinate positions. The effect of dynamically correcting the advancing path of the plastering machine can be achieved, it is guaranteed that the plastering machine is always parallel to the wall surface of the wall body in the process that the plastering machine moves left and right, and the construction operation efficiency can be greatly improved.

Owner:深圳市森博机器人有限公司

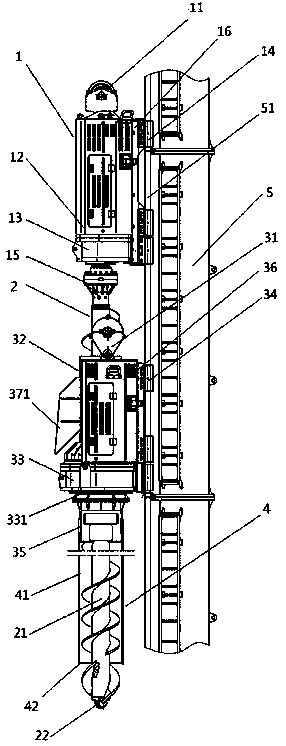

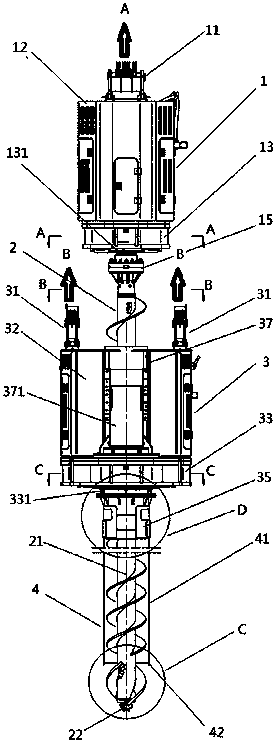

Double-drive drilling machine

ActiveCN108194022AImprove construction work efficiencyMeet construction requirementsDrill bitsDrilling rodsClockwiseBreaking capacity

Provided is a double-drive drilling machine. The double-drive drilling machine comprises a drilling tool driving head comprising a first reduction box, an inner drilling tool comprising a spiral drilling rod and a drill bit, a connecting flange with a second reduction box, a rectangular hole and a lower ring of a straight groove communicated with the connecting flange, a sleeve driving head of a fixing sleeve with a soil outlet opening, a pipe body with a sleeve, a positioning block, an outer sleeve with cutter body on the end portion , and a pile frame; a spiral drill rod is fixedly installedon the lower end of a hollow drill rod shaft of the first reduction box; a connecting flange is fixedly installed on the lower end of the hollow output sleeve, and the soil outlet opening is positioned on the front face of the sleeve driving head; while the inner drilling tool rotates clockwise inside the outer sleeve to drill, stir and discharge the soil, the outer sleeve rotates anticlockwise to cut and protect the wall. According to the double-drive drilling machine, double combined drilling and digging of the inner drilling tool and the outer sleeve is realized, strong drilling on variouscomplicated strata is carried out, and the soil is continuously discharged by the outer sleeve wall protection and the inner drilling tool. The double-drive drilling machine has the characteristics of strong overall rigidity, large rock drilling and breaking capacity, uniform mixing, high construction accuracy, monitoring of construction parameters, high operation efficiency and the like.

Owner:上海工程机械厂有限公司

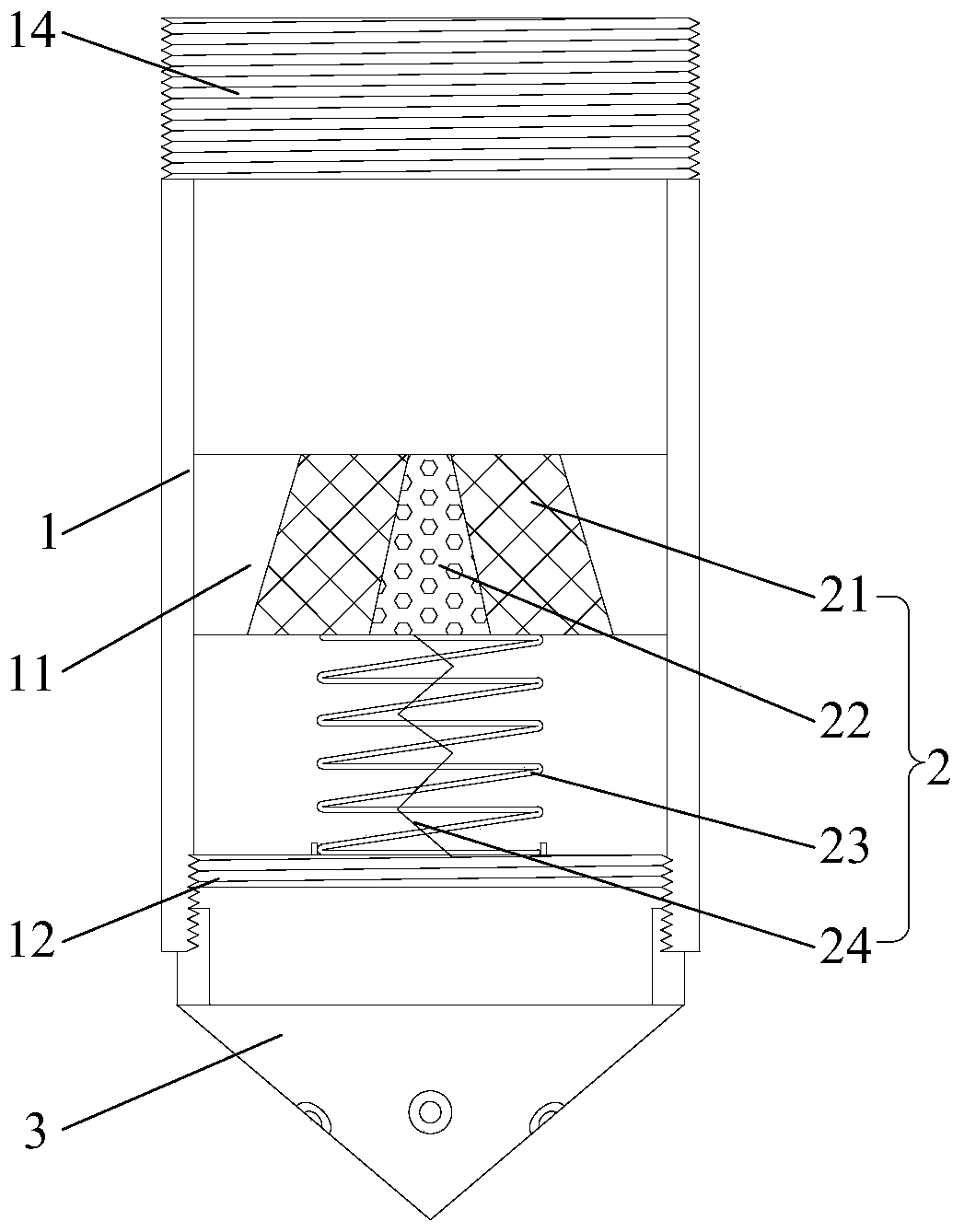

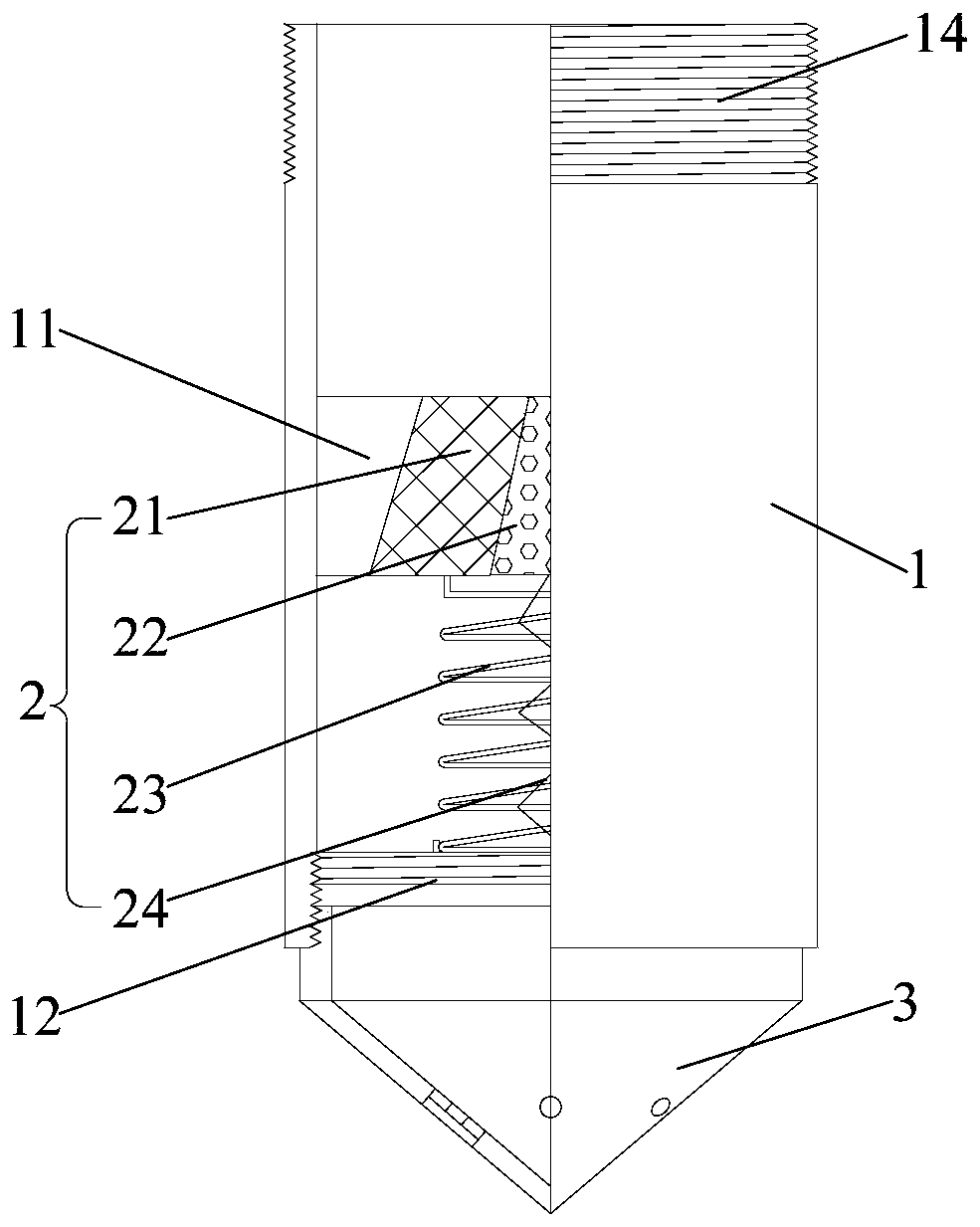

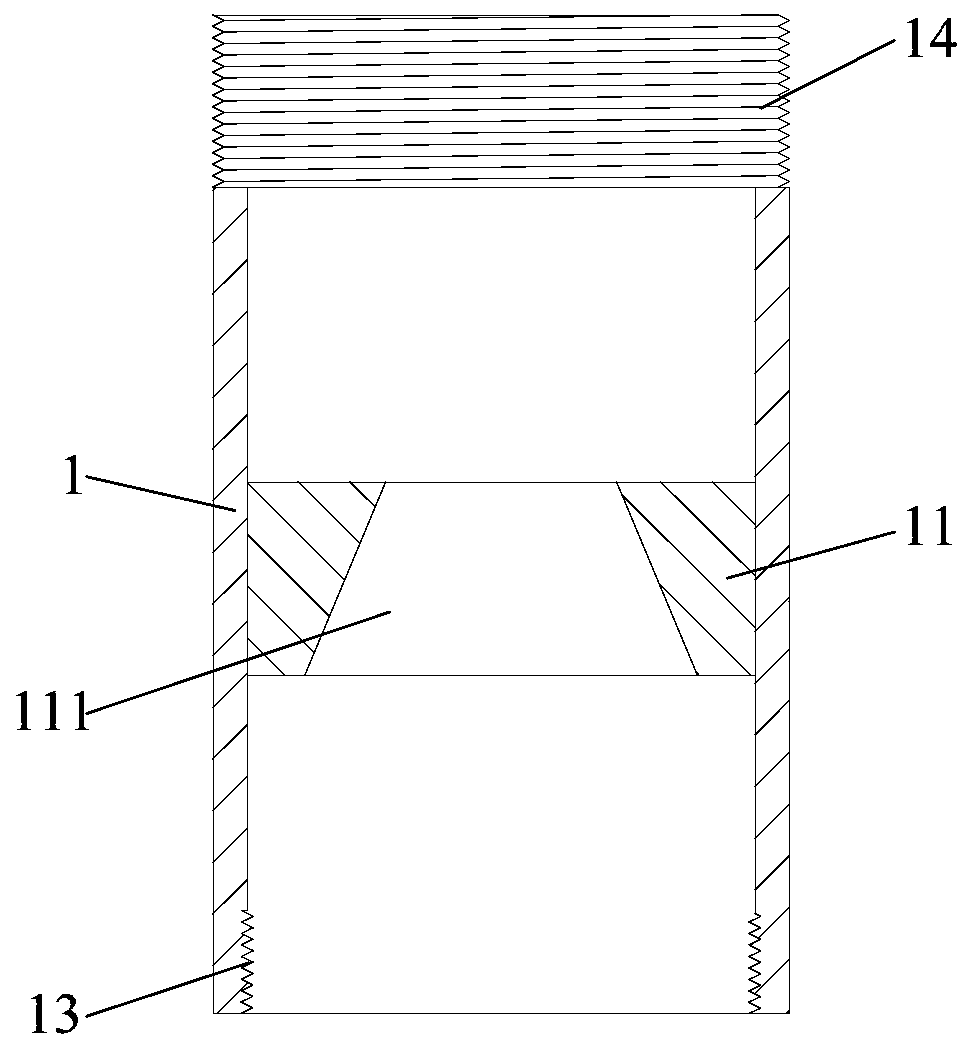

Pile end grouting spray head

PendingCN110499765AConstruction safetyEfficient constructionFoundation engineeringArchitectural engineeringPiston

The invention provides a pile end grouting spray head. The pile end grouting spray head comprises a grouting pipe, an adjusting assembly and a grouting head, wherein a baffle and a base are connectedin the grouting pipe in the grouting direction in a spaced mode; the baffle is provided with a first grout outlet hole, and the base is provided with grout passing holes; the adjusting assembly can bemovably arranged in the first grout outlet hole; the adjusting assembly comprises at least two pistons arranged in a sleeving mode from inside to outside in sequence; the pistons are connected with the base through corresponding elastic parts, and the elastic force of the elastic parts connected with the corresponding pistons increases progressively in sequence from inside to outside; the grouting head is connected to the grout outlet end of the grouting pipe and is provided with grouting holes. Through the pile end grouting spray head provided by the invention, under the condition that grouting pressure meets the using requirement, the first grout outlet hole can be opened smoothly to complete grouting operation. The pile end grouting spray head can adjusting the grout flow according tothe grouting pressure to ensure that the grout flow meets the using requirement.

Owner:MCC CAPITAL ENGINEERING & RESEARCH

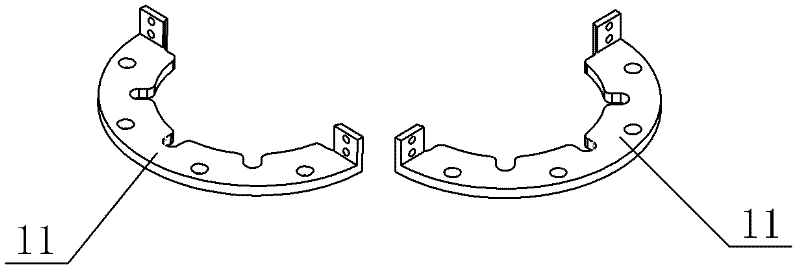

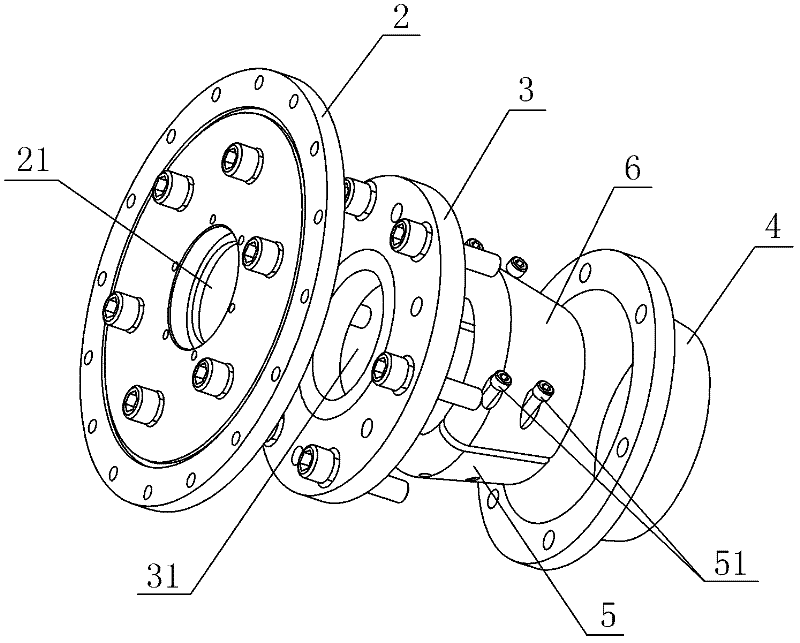

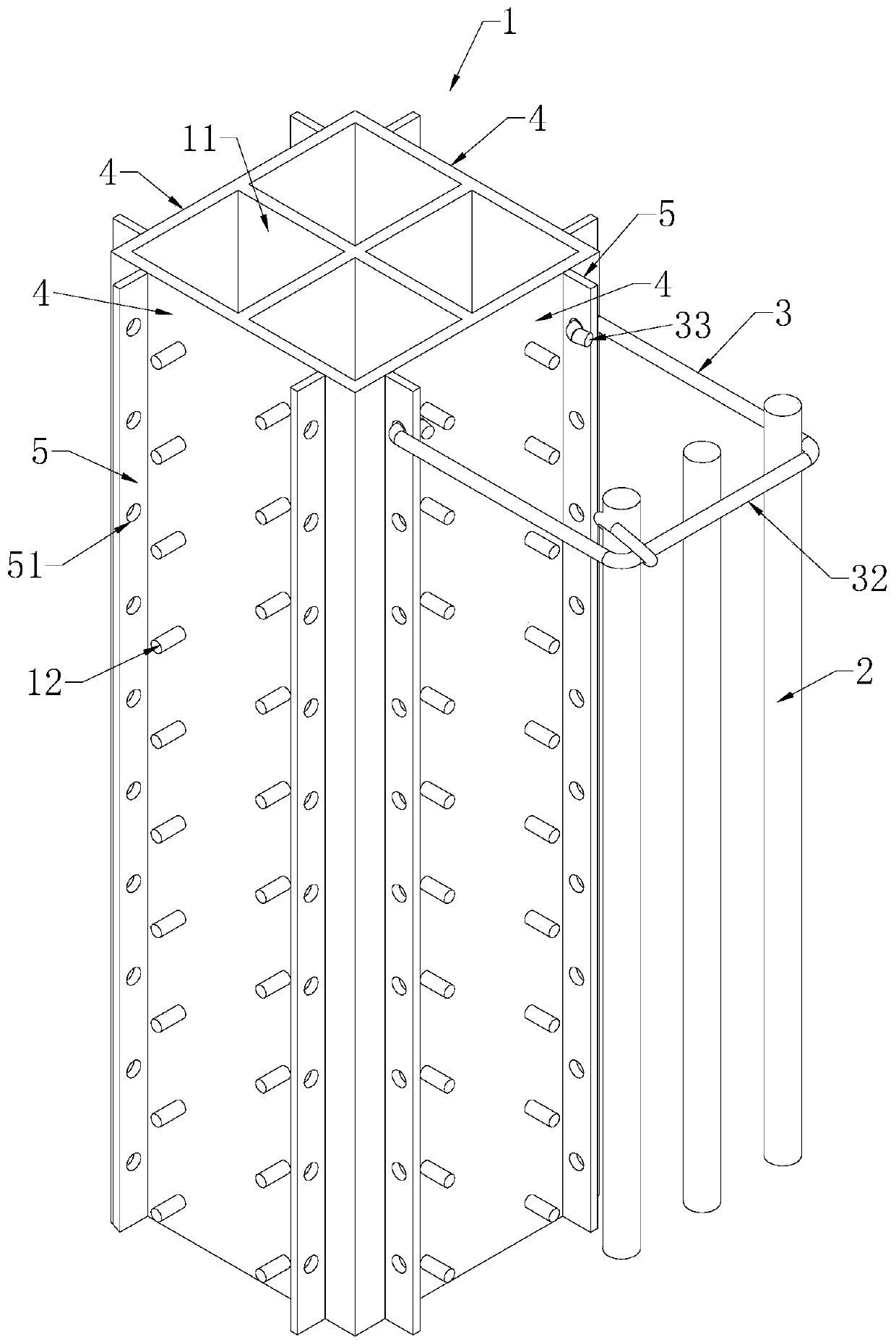

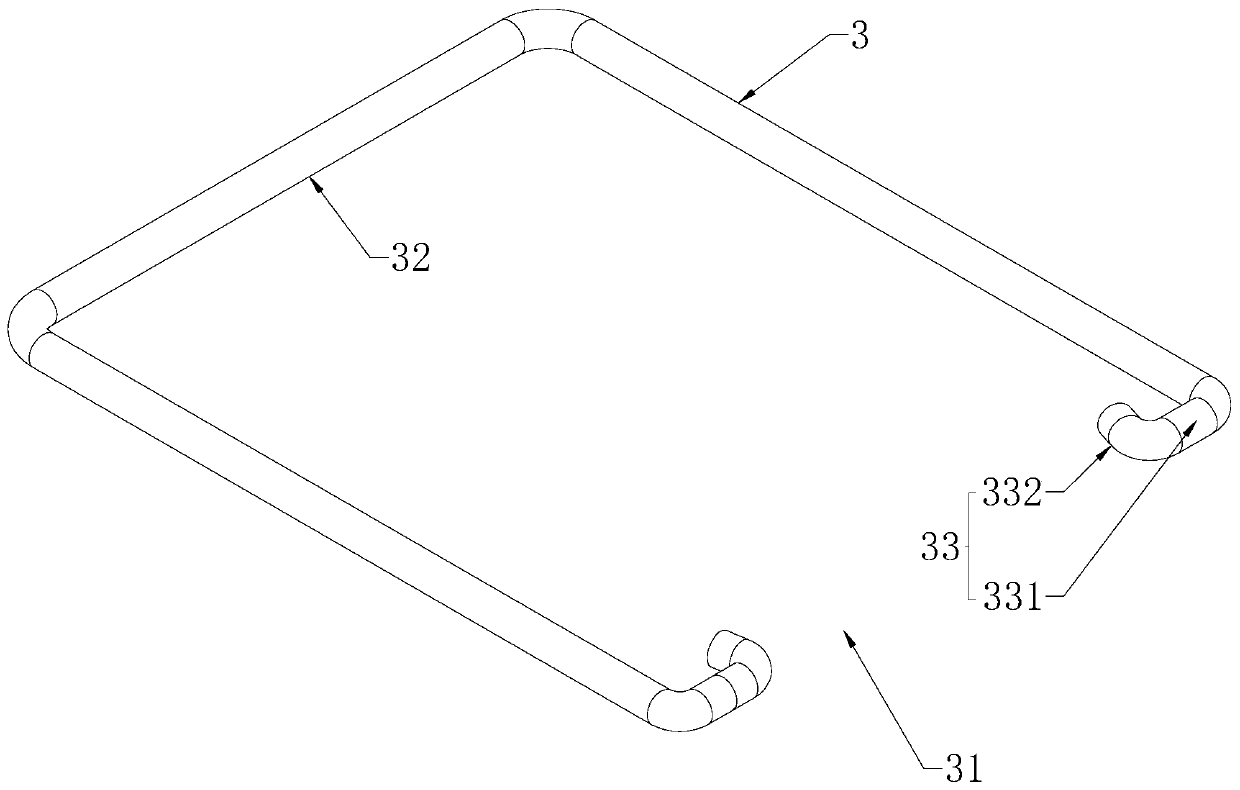

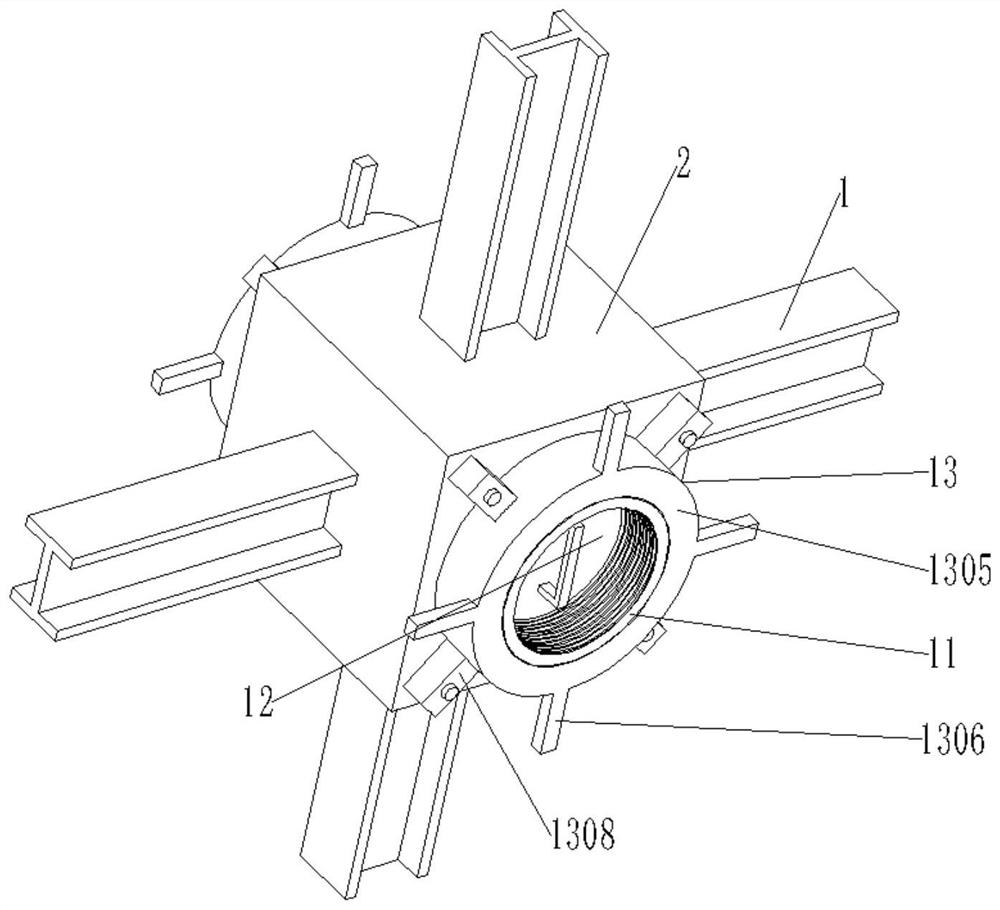

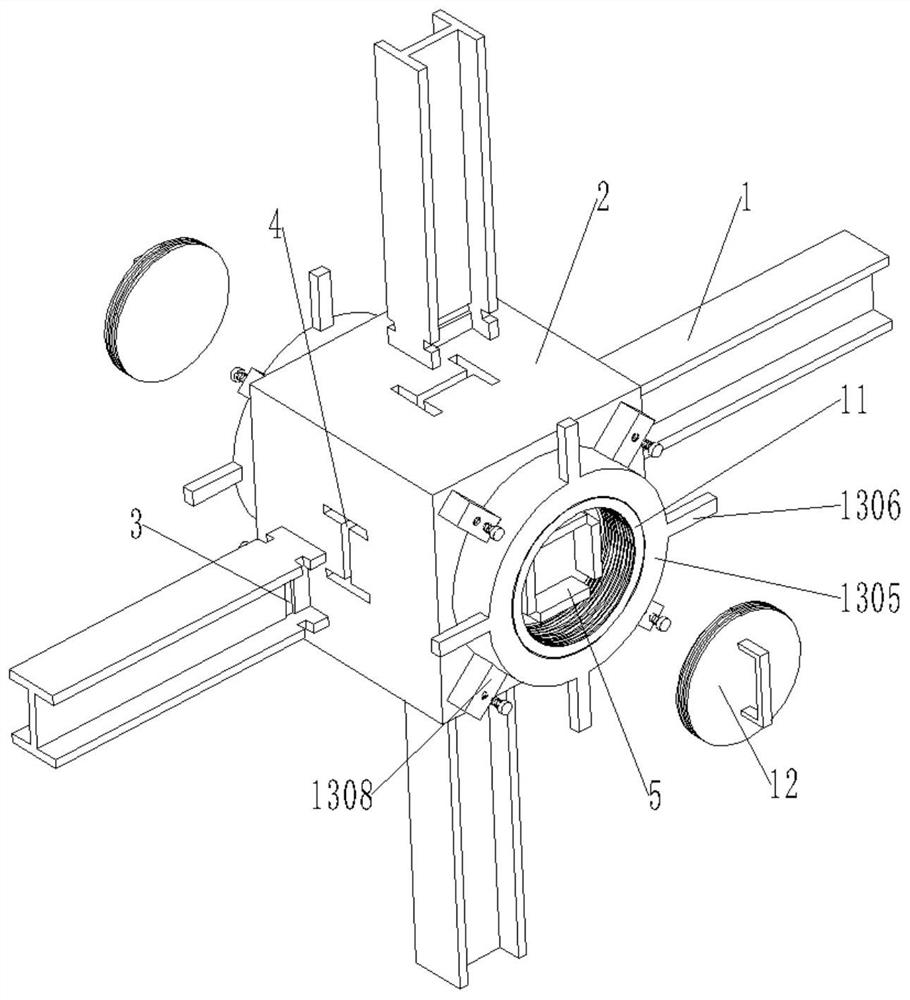

Construction method of prestressed pipe pile and locating hoop

ActiveCN111519609AEasy to placeEasy to rotate at the same timeBulkheads/pilesWelding accessoriesPre stressArchitectural engineering

The invention relates to a construction method of a prestressed pipe pile and a locating hoop. The locating hoop for the prestressed pipe pile comprises a locating ring, a limiting ring and two limiting bases, wherein the locating ring is arranged on the outer side of an upper section pile in a sleeving manner, the limiting ring is arranged on the outer side of a lower section pile in a sleeving manner, and the two limiting bases are used for carrying electrode holders. The locating ring is divided into two locating plates in a semi-ring shape. The ends of the two locating plates are connectedin a rotating manner, and the other ends of the two locating plates are detachably connected. The two limiting bases are connected with the locating ring in a sliding manner in the peripheral direction of the locating ring. The limiting ring is divided into two limiting plates in a semi-ring shape. The ends of the two limiting plates are connected in a rotating manner, and the other ends of the two limiting plates are detachably connected. The locating ring and the limiting ring are connected through a limiting rod. The two ends of the limiting rod are connected with the locating ring and thelimiting ring in a sliding manner in the periphery direction of the locating ring. By arranging the locating ring and the limiting ring, the purpose of improving construction work efficiency is achieved. According to the construction method of the prestressed pipe pile, by the adoption of the locating hoop, time for pile connecting of construction personnel is shortened, and the purpose of improving the construction work efficiency is achieved.

Owner:SHANDONG LUQIAO GROUP CO LTD

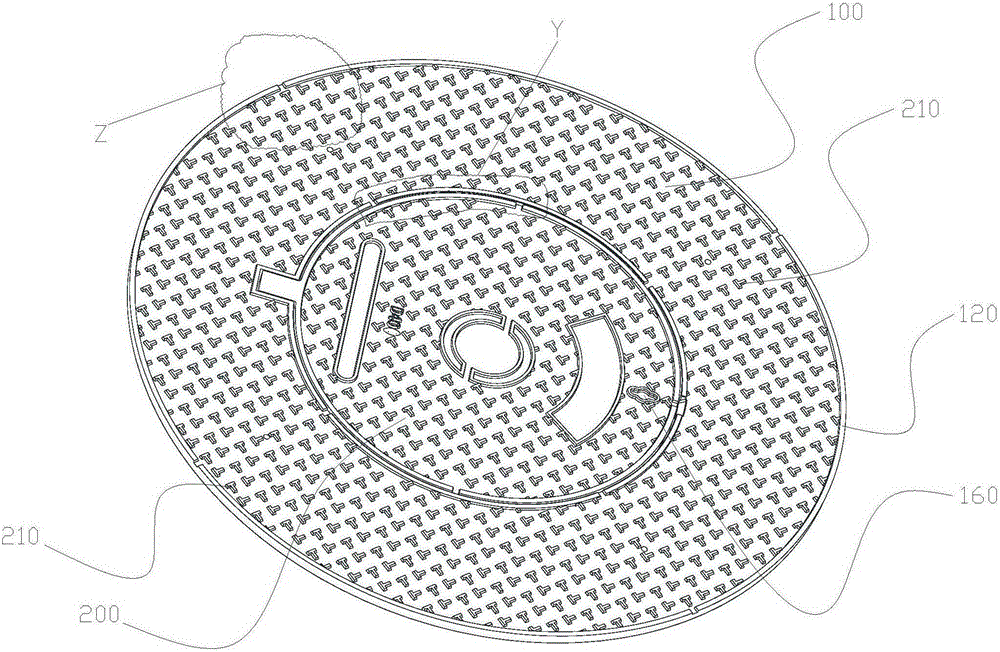

Pressure-resistant well lid for repair and method for mounting pressure-resistant well lid

ActiveCN105275018AHigh strengthDoes not cause unevennessArtificial islandsUnderwater structuresRepair materialRoad surface

The invention discloses a pressure-resistant well lid for repair and a method for mounting the pressure-resistant well lid. The outer sidewall of a ring body is provided with a first covered edge, and the inner sidewall of the ring body is provided with a second covered edge. The outer sidewall of a lid body is provided with a third covered edge. The width of the ring body is at least 16 cm. The method for mounting the pressure-resistant well lid sequentially comprises the following steps that firstly, a pit with the same shape as the outer edge of the ring body is cut in the road surface through a special device; secondly, the edge of the pit is evenly expanded outwards by a hoisting width, and the hoisting width is less than 6 cm; and thirdly, the lid body is hoisted onto the ring body and arranged on a through hole of the ring body in a covering mode. The pressure-resistant well lid for repair and the method for mounting the pressure-resistant well lid have the beneficial effects that the construction efficiency is improved; no repair mark and no obvious joint exist between the ring body and the road surface; the area of the ring body and the area of the lid body are expanded, and the well lid is high in strength and resistant to pressure; the surface of a well ring covers repair materials between the edge of the well lid and the edge of the cut pit, the appearance is attractive, the well ring protects the repair materials, and the well lid is not prone to secondary damage after being crushed by vehicles; the well lid is provided with anti-falling hooks and an anti-falling net, thereby being safer in use.

Owner:WUXI AILU CONSTR CO LTD

Positioning method for pre-embedded steel bars in assembled sleeves of building element

InactiveCN109208921AQuality improvementMake sure it's in placeBuilding material handlingSheet steelSteel bar

The invention discloses a positioning method for pre-embedded steel bars in assembled sleeves of a building element. According to the method, firstly a steel bar positioning tool is made, a steel plate is provided with through holes matched with the pre-embedded steel bars and vibrating holes, and the sleeves are welded on the through holes respectively; preliminary positioning is performed on thepre-embedded steel bars to determine the planar positioning dimensions of the pre-embedded steel bars; the sleeves are enabled to sleeve the pre-embedded steel bars, and the steel plate is fixed; concrete pouring is carried out on the cast-in-situ structure, the position and perpendicularity of the pre-embedded steel bars are re-checked after the pouring and before the initial setting of the concrete so as to complete the positioning for the pre-embedded steel bars. The positioning method realizes accurate positioning for the pre-embedded steel bars through the self-made tool, ensures the element to be hoisted in place for one time, and improves the construction efficiency and the installation quality of the element.

Owner:SHANGHAI BAOYE GRP CORP

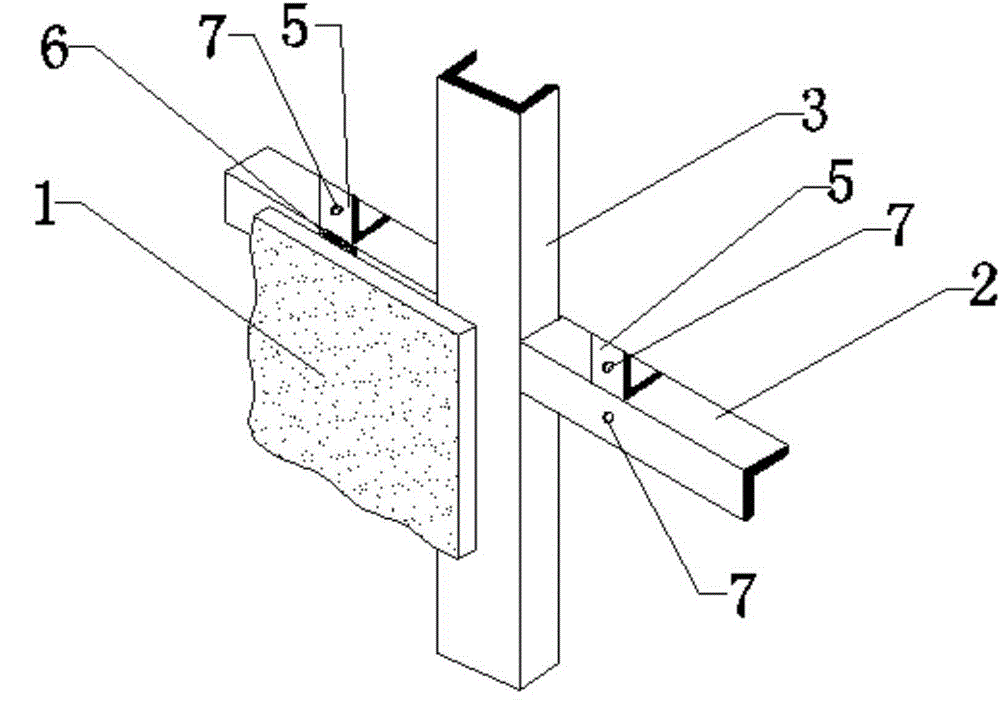

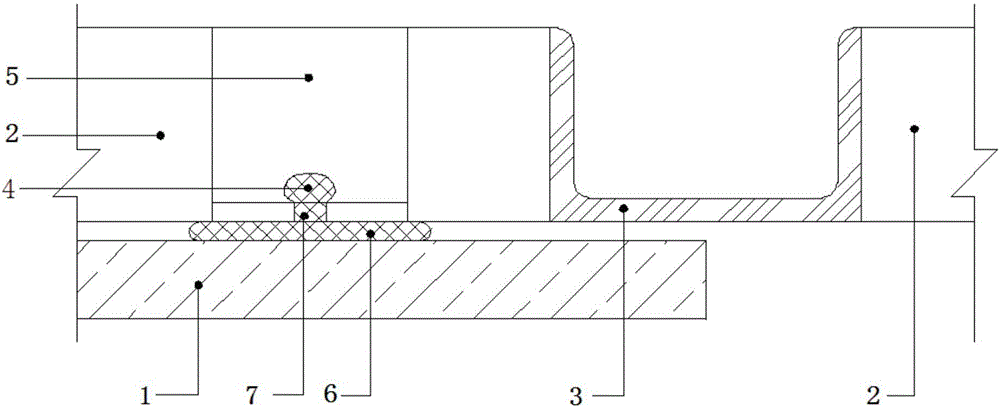

Stone dry bonding mounting structure unit and mounting method thereof

The invention discloses a stone dry bonding mounting structure unit and a mounting method thereof. The stone dry bonding mounting structure unit comprises stone, a transverse keel, a vertical keel, four glue penetration holes and two corner connectors, wherein the vertical keel is connected to a wall surface; the transverse keel is connected to the vertical keel; the upper end of the stone is connected to the transverse keel; the two corner connectors are fixed on the transverse keel and are symmetrically distributed on two sides of the vertical keel; the lower end of the stone is connected with the two corner connectors; two of the four glue penetration holes are respectively distributed in surfaces, which are in contact with the stone, of the two corner connectors; the other two glue penetration holes are uniformly distributed on a surface, which is in contact with the stone, of the transverse keel; epoxy resin structure glue layers coat portions, which correspond to the four glue penetration holes, of the stone; and the stone, the transverse keel and the corner connectors are connected to one another through the coated epoxy resin structure glue layers. Glue nails have a reinforcing effect, the problem that a dry hanging method is unsafe when the thickness of a dry hanging stone plate is insufficient can be solved, and construction efficiency is improved.

Owner:GOLD MANTIS CONSTR DECORATION

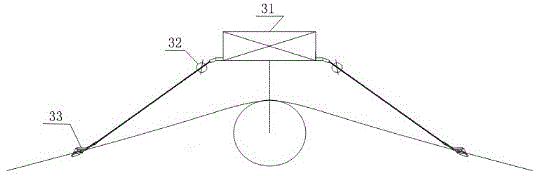

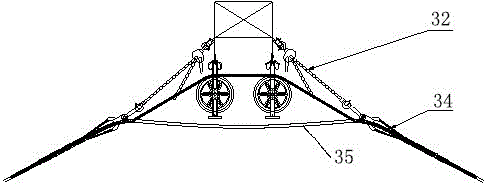

Mounting method for optical cable tackle suspension and accessories thereof based on two single-wheel tackles

ActiveCN103560437ASimple structureEasy to liftApparatus for overhead lines/cablesTowerConstruction design

The invention discloses a mounting method for optical cable tackle suspension and accessories thereof based on two single-wheel tackles. The method comprises the following operating steps that related parameters of an optical cable and related parameters of accessories of the optical fiber are determined; the parameters of the optical cable and the parameters of the accessories used by the optical cable are determined according to construction design requirements, and optical cable paying-off tackles and related construction devices and tools are selected referring to the parameters, wherein the parameters comprise the model number of the optical cable, the structure of cable clips and the length of structure strengthening bars. According to the method, the two tackles are connected through a supporting rod of a certain length, and are suspended below vertical construction holes near optical cable suspending points of a bridge tower by using steel slings, and mounting of the structure strengthening bars and mounting of the cable clips can be directly carried out between the two tackles after cable is tightened.

Owner:STATE GRID CORP OF CHINA +1

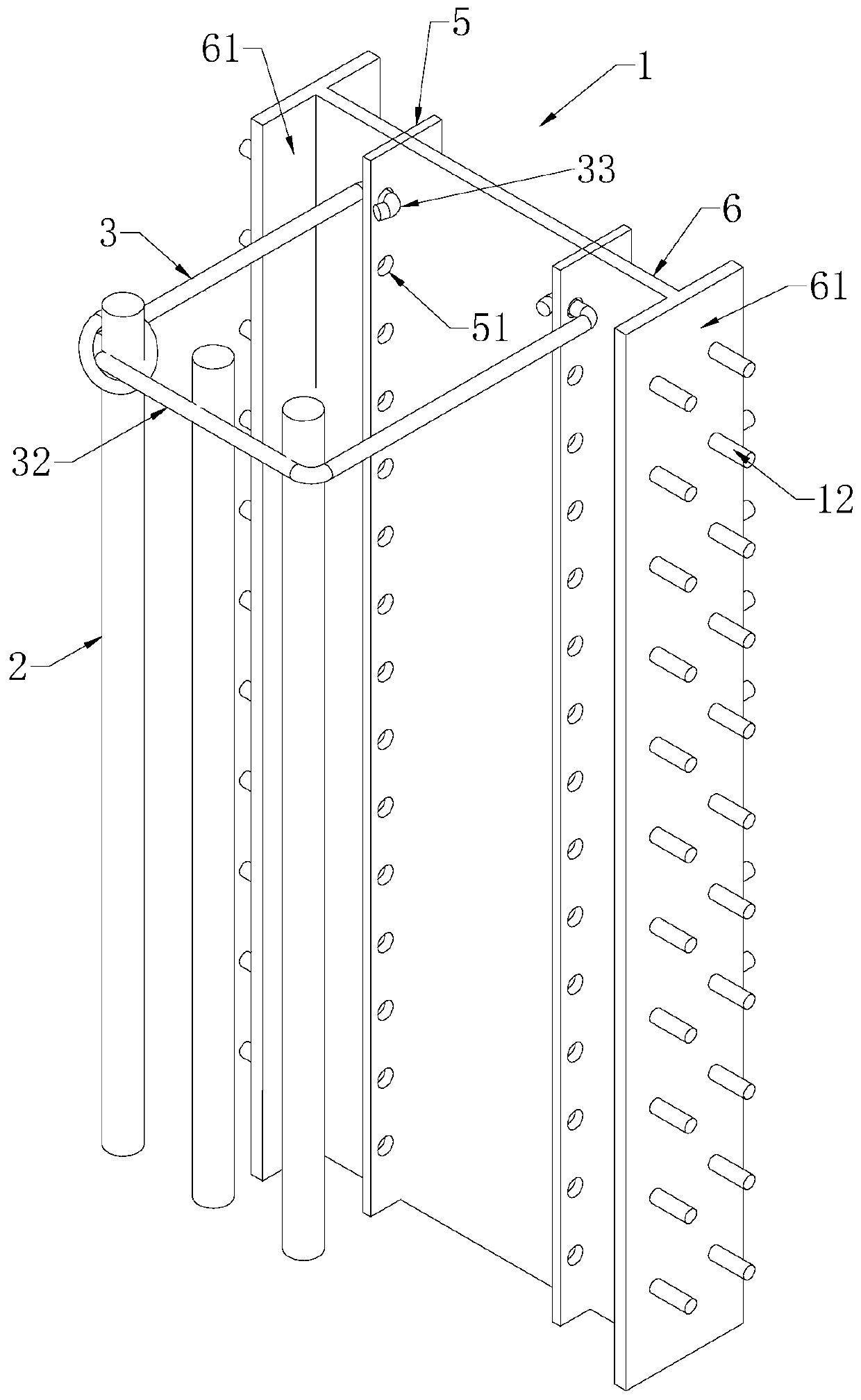

Connecting structure and construction method of steel ribs and hoops of steel rib concrete structure column

InactiveCN111139972AFast constructionReduce construction costsStrutsBuilding reinforcementsRebarSteel columns

The invention discloses a connecting structure and construction method of steel ribs and hoops of a steel rib concrete structure column and relates to the technical field of steel rib concrete structure column construction. The BIM technology is used for establishing data models of profile steel rib columns, longitudinal reinforcing steel bars and the hoops, and meanwhile, the size and the positions of hoop connecting boards and the hole diameter and the forming positions of run-through holes are determined; and binding, buckling and fixing operation of the hoops, the profile steel rib columnsand the longitudinal reinforcing steel bars is finished on the site. In the hoop connection construction process of the profile steel concrete structure column, the longitudinal hoop connecting boards are welded to profile steel column webs, the hoops are buckled to the hoop connecting boards, web perforation and hoop welding construction are not needed, construction operation efficiency can be improved, the profile steel web section loss ratio can be reduced, hoop connection reliability can be guaranteed, the profile steel stress performance is improved, meanwhile, cost can be saved, a construction period can be shortened, and construction operation difficulty and construction personnel labor intensity are reduced.

Owner:THE FIRST CONSTR CO LTD OF CHINA CONSTR FIRST GRP +1

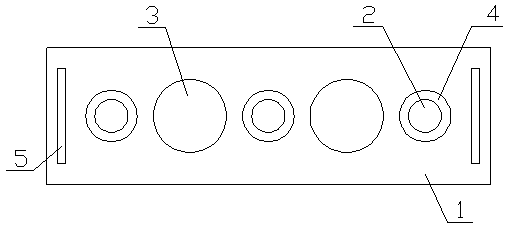

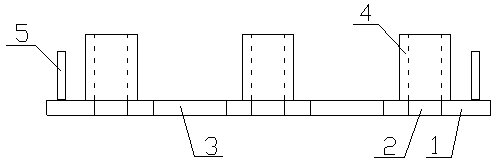

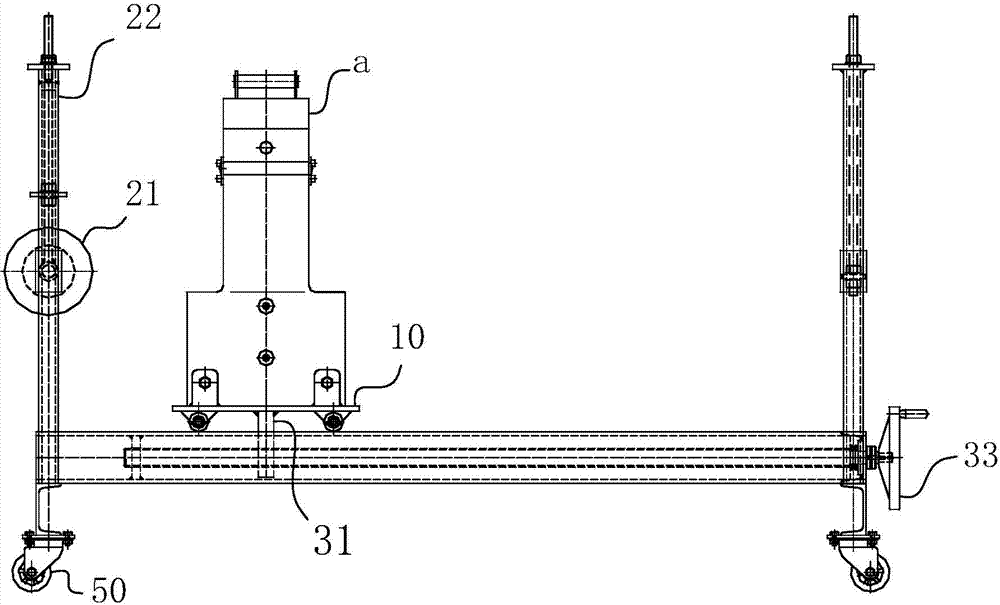

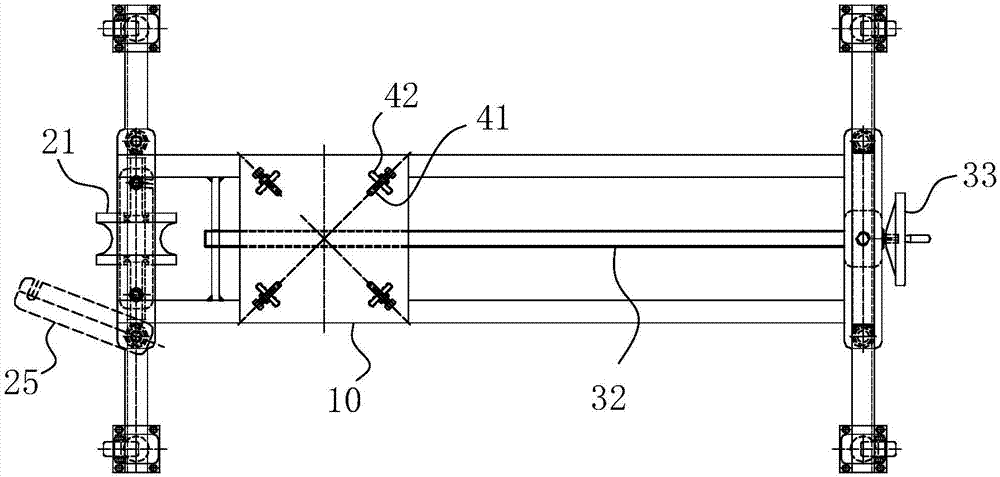

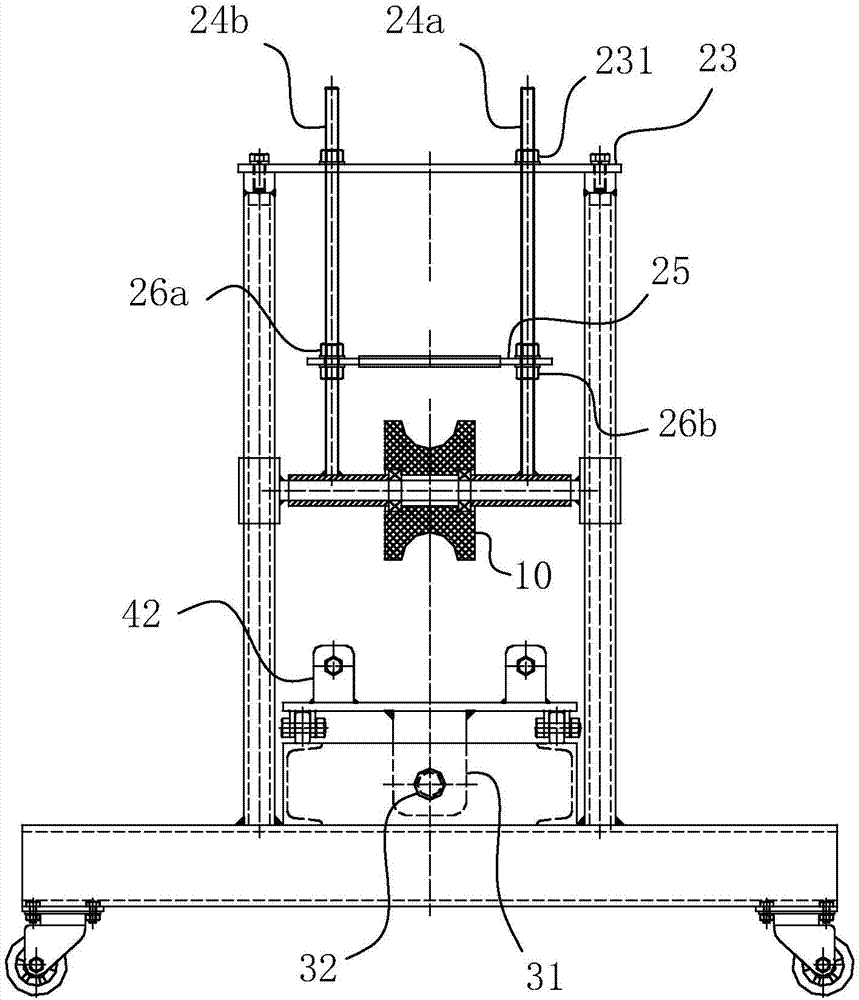

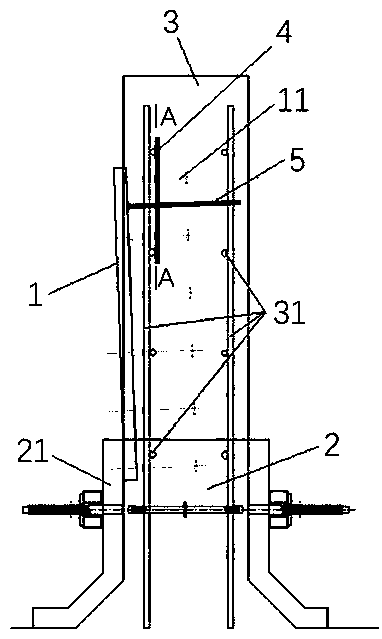

Wire compression jointing work platform

ActiveCN103594903AAvoid centeringAvoid errorsLine/current collector detailsProcess qualityFixed frame

The invention belongs to the field of electric power construction project large-section wire compression jointing manufacturing, and particularly relates to a wire compression jointing work platform used for large-section wire compression jointing. The wire compression jointing work platform comprises a fixing frame serving as a base body, a platform part fixedly connected with a compression jointing top is arranged on the fixing frame, a supporting unit used for supporting and limiting the spatial position of a wire to be in compression jointing is further arranged on the side, next to the platform part, of the fixing frame, and a supporting path of the supporting unit and a wire penetrating path of the compression jointing top are located in the same straight line. The wire compression jointing work platform is overall easy and convenient to operate, meanwhile, staff organizations are simplified, the compression jointing time is saved, and the wire compression jointing work platform has the advantages that the compression jointing process is improved, compression jointing workers are reduced, and the compression jointing time is shortened; the process quality is improved, and meanwhile the construction work efficiency is greatly improved.

Owner:STATE GRID CORP OF CHINA +1

Installation method of groove type embedded part in underground integrated pipe gallery

ActiveCN109706959AGuaranteed aestheticsAvoid skewArtificial islandsUnderwater structuresArchitectural engineeringRebar

The invention discloses an installation method of a groove type embedded part in an underground integrated pipe gallery. According to the installation method of the groove type embedded part in the underground integrated pipe gallery, during construction of a pipe gallery bottom plate and a guide wall, the lower part of the groove type embedded part is adhered to the inner side of a steel formworkof the guide wall, the groove type embedded part is arranged inclined to the outside, and the lower part of the groove type embedded part is connected with the steel formwork of the guide wall in a welded mode; after guide wall concrete is poured, the lower part of the groove type embedded part is fixed into the guide wall concrete, an anchor bolt on the back surface of the groove type embedded part is located in a wall body of the pipe gallery, the verticality of the groove type embedded part is checked by a levelling instrument, and after completion, locating steel bars fixedly connected with a steel mesh in the wall body of the pipe gallery are welded to the upper part of the back surface of the groove type embedded part; and a supporting steel bar is welded to the back surface of thegroove type embedded part and is connected with the steel mesh in the wall body of the pipe gallery, and installation of the groove type embedded part in the pipe gallery is completed. According to the installation method of the groove type embedded part in the underground integrated pipe gallery, it is ensured that the groove type embedded part is attached to a formwork surface, so that the groove type embedded part is levelled with the concrete surface after concrete pouring, the groove type embedded part is prevented from being inclined, the construction work efficiency is improved, the cost is reduced, and the overall aesthetic performance of the pipe gallery is ensured.

Owner:CHINA MCC20 GRP CORP

Connecting and mounting structure for steel frame building

ActiveCN111910779AEasy to buildFast constructionBuilding constructionsArchitectural engineeringSteel frame

The invention discloses a connecting and mounting structure for steel frame building. Locking clamping grooves formed in H-shaped steel plates are fixedly connected with a convex movable clamping plate arranged in a connecting square body in a clamped mode, the connecting square body is used for connecting and fixing, building construction of a steel structure is quite convenient and rapid, and the construction work efficiency is improved; connection strengthening and locking structures symmetrically arranged in the connection square body have a good strengthening auxiliary effect on connection and fixation of the H-shaped steel plates and the connection square body, then the firmness in steel framework connection construction is improved, the connection strength is improved, and the construction quality is guaranteed; and further, the connection strengthening and locking structures have a more stable connection strengthening function on the H-shaped steel plates and the connection square body, the stability of steel structure connection is guaranteed, and the construction quality is guaranteed.

Owner:FANGYUAN CONSTR GRP REAL ESTATE DEVT CO LTD

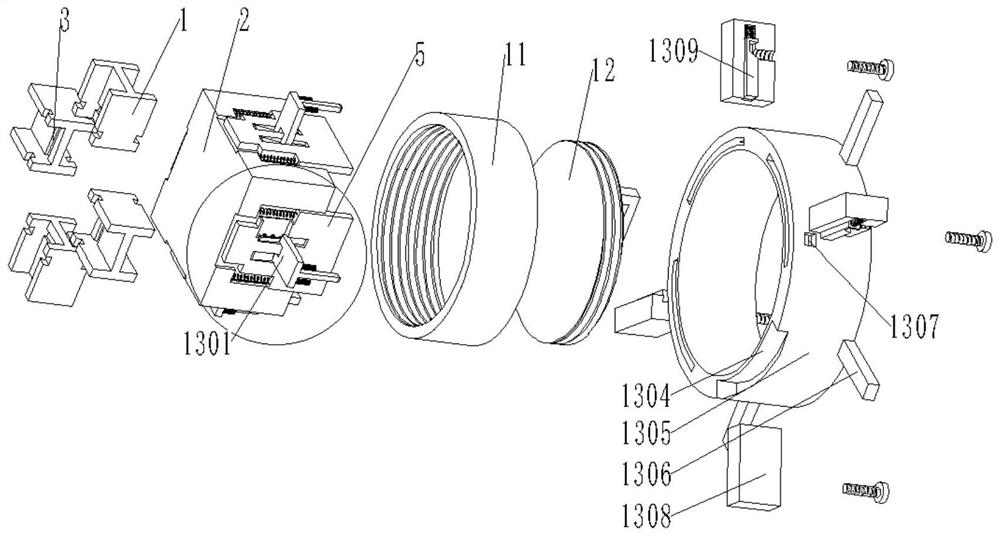

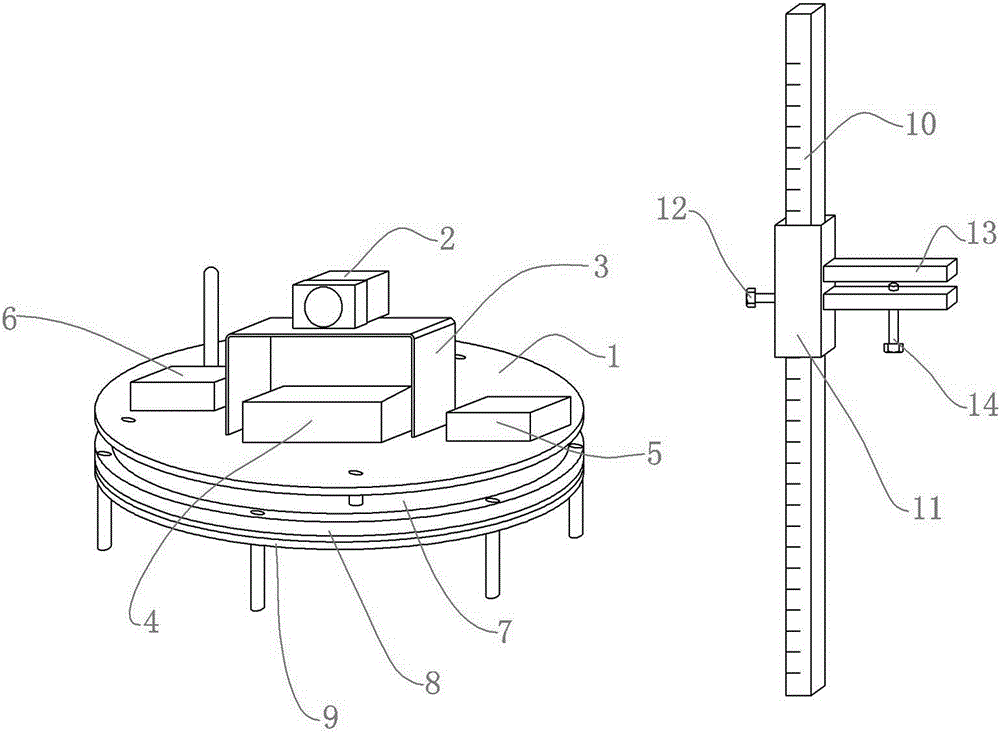

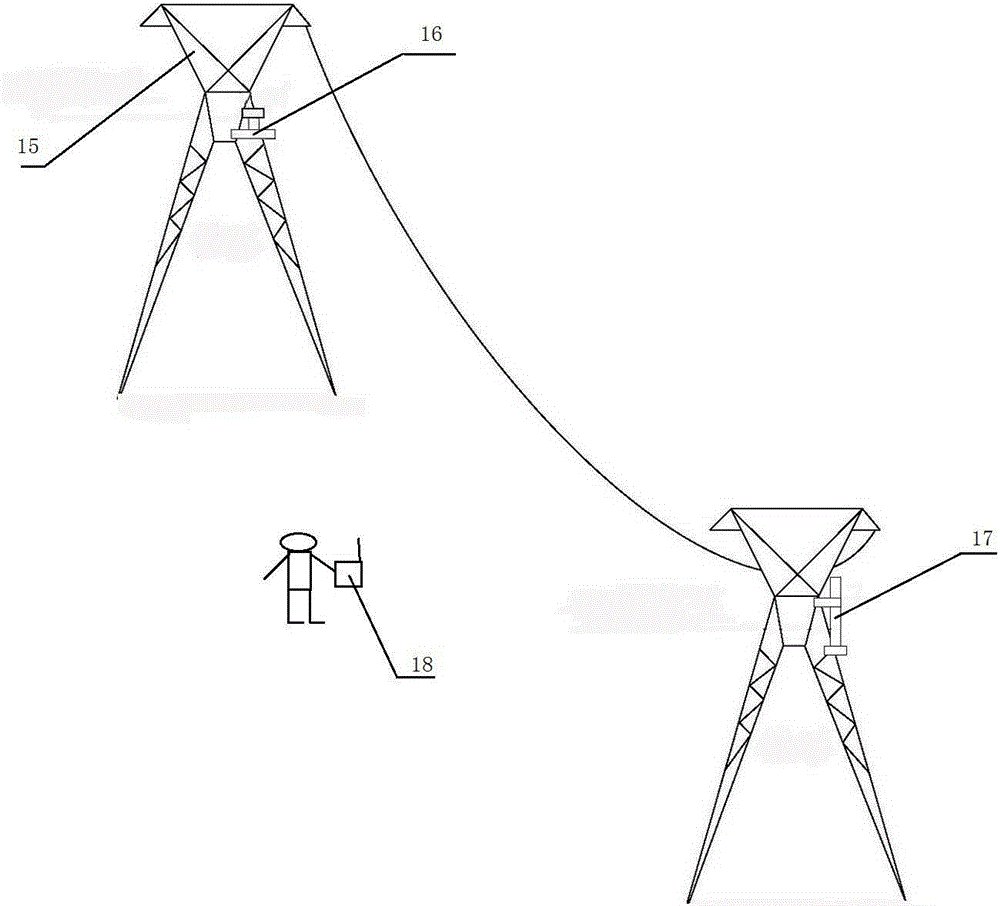

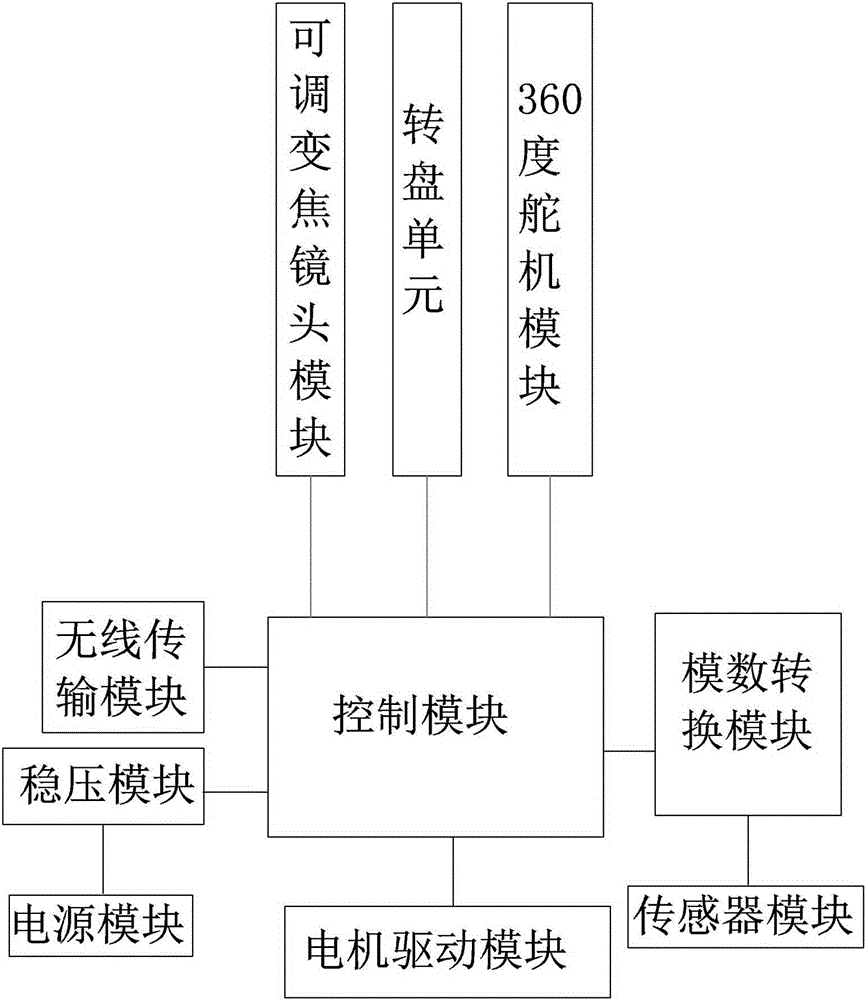

Intermediate support overhead line sag measurement device

ActiveCN105222716AReduce consumptionImprove measurement efficiencyUsing optical meansVoltage regulator moduleWireless transmission

The invention relates to an intermediate support overhead line sag measurement device comprising an image acquisition module, a wireless transmission module, and a hand-held control end. The image acquisition module comprises an adjustable zoom lens module, a measuring scale module, a turntable unit, a sensor module, a power module, an analog-to-digital conversion module, a motor drive module, a voltage regulator module, and a control module. The control module is connected with a 360-degree steering engine module. The adjustable zoom lens module is fixed to the 360-degree steering engine module through a U-shaped rotary bracket. The U-shaped rotary bracket is rotationally connected with the control module through the motor drive module. According to the invention, remote control is carried out through the control module and the handheld control end, observation and measurement are convenient, and the sag of a strain section needing measurement can be measured by a single person. The human cost is reduced, and operation is easy. The efficiency and precision of overhead line sag measurement can be improved effectively, and the installation efficiency and measurement precision of the sag measurement device are improved.

Owner:GONGYI CITY POWER SUPPLY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com