Installation construction method of electrified railway contact network anchored section joint hanger

A technology for electrified railways and construction methods, applied in overhead lines and other directions, can solve the problems of not being able to reflect the force of the suspension string, difficult to control the force of the suspension string, and uneven force of the suspension string.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

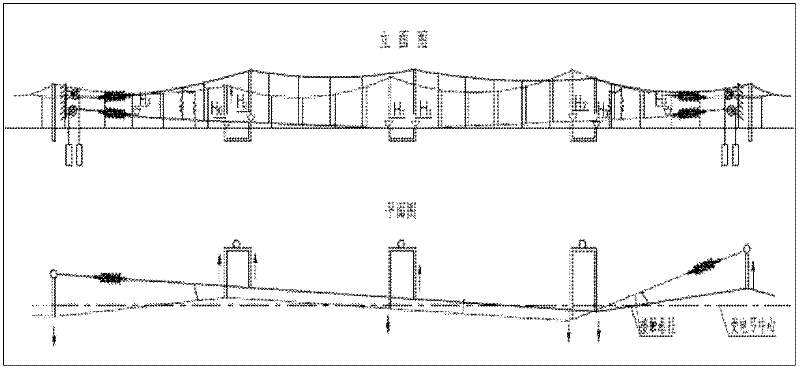

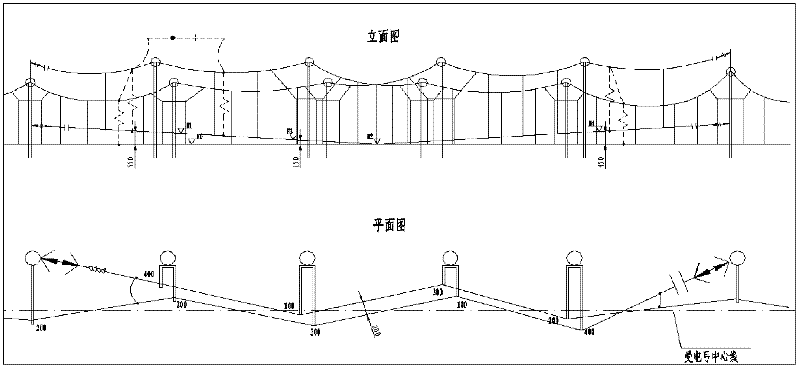

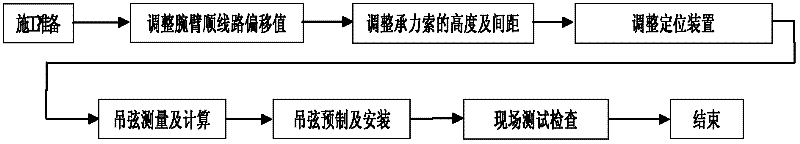

[0149] Embodiment 1: Installation and construction method of hanging strings for anchor section joints of electrified railway catenary - four-span anchor joints:

[0150] According to the steps of the present invention, each work before calculation is done item by item.

[0151] The preparation of the calculation data, the following are the example parameters of the four-span anchor section joints of a certain section of the Beijing-Shanghai high-speed railway:

[0152] Pillar number: 893#, 895#, 897#

[0153] Uniform load of catenary cables: 10.437N

[0154] Uniform load of contact wires: 13.23N

[0155] Hanging string single weight: 3.234N

[0156] Catenary horizontal tension: 20000N

[0157] Contact wire horizontal tension: 40000N

[0158] The heights of catenary cables are: 6.879m, 7.079m, 7.170m

[0159] The height of the contact wire is: 5.300m, 5.340m, 5.800m

[0160] The spans are: 49.460m, 48.700m

[0161] Hanging string distribution spacing: 5.000m, 7.892m, 7...

Embodiment 2

[0166] Embodiment 2: Installation and construction method of hanging strings for anchor section joints of electrified railway catenary - five-span anchor joints:

[0167] According to the steps of the present invention, each work before calculation is done item by item.

[0168] The preparation of calculation data is the example parameters of the five-span anchor section joint of a certain section of high-speed railway:

[0169] Pillar number: 1117#, 1119#, 1121#

[0170]Uniform load of catenary cables: 10.437N

[0171] Uniform load of contact wires: 13.23N

[0172] Hanging string single weight: 3.234N

[0173] Catenary horizontal tension: 21000N

[0174] Horizontal tension of contact wire: 30000N

[0175] The catenary heights are: 7.570m, 7.500m, 6.960m

[0176] The height of the contact wire is: 5.900m, 5.450m, 5.300m

[0177] The spans are: 48.720m, 49.370m

[0178] Hanging string distribution spacing: 6.000m, 7.344m, 7.344m, 7.344m, 7.344m, 7.344m, 6.000m;

[0179...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com