Installation method of groove type embedded part in underground integrated pipe gallery

A technology of comprehensive pipe gallery and installation method, applied in underwater structures, water conservancy projects, artificial islands, etc., can solve the problems of waste, easy bending deformation, skew and deviation of trough embedded parts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

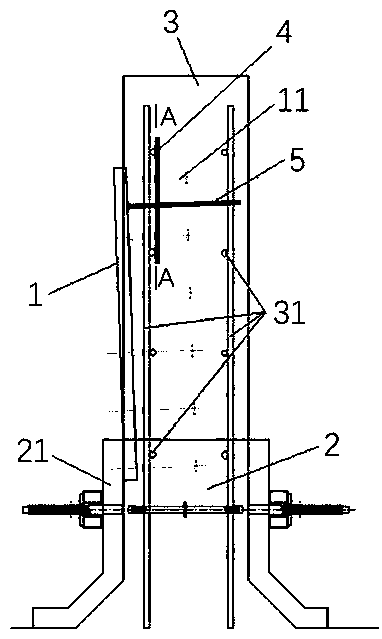

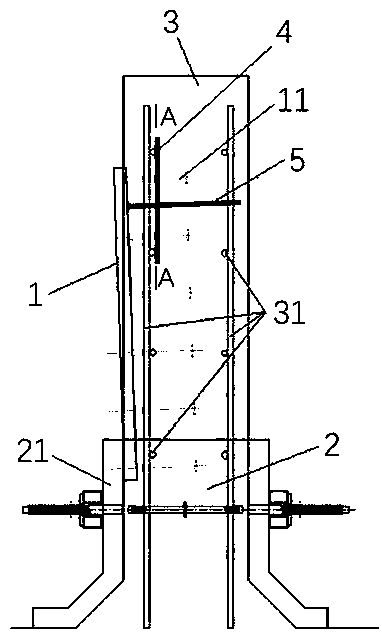

[0015] Example figure 1 As shown, the installation method of the trough-type embedded parts in the underground comprehensive pipe gallery of the present invention includes the following steps:

[0016] Step 1. According to the designed installation height of the trough-type embedded part 1, during the construction of the bottom plate of the underground comprehensive pipe gallery and the guide wall 2, the lower part of the trough-type embedded part 1 is closely attached to the inner side of the steel formwork 21 of the guide wall 2, and the groove The groove-type embedded parts 1 are arranged obliquely to the outside, and the lower part of the groove-type embedded parts 1 is welded to the steel formwork 21 of the guide wall 2;

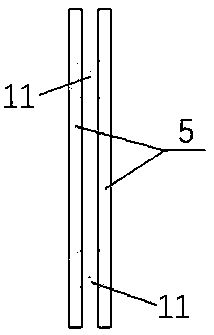

[0017] Step 2: After the concrete pouring of the guide wall 2 is completed, the lower part of the trough-type embedded part 1 is fixed in the concrete of the guide wall 2, and the anchor bolt 11 on the back of the trough-type embedded part 1 is located ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com