Process for cleaning whole inner wall of long pipeline for high-purity gas

A high-purity gas, integrated process technology, applied in the direction of cleaning hollow objects, cleaning methods and utensils, drying solid materials, etc., can solve the problems of incomplete cleaning of impurities, discontinuous time schedule, and insufficient manual work, to avoid The effect of reverse running of the pig, improving construction quality and reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

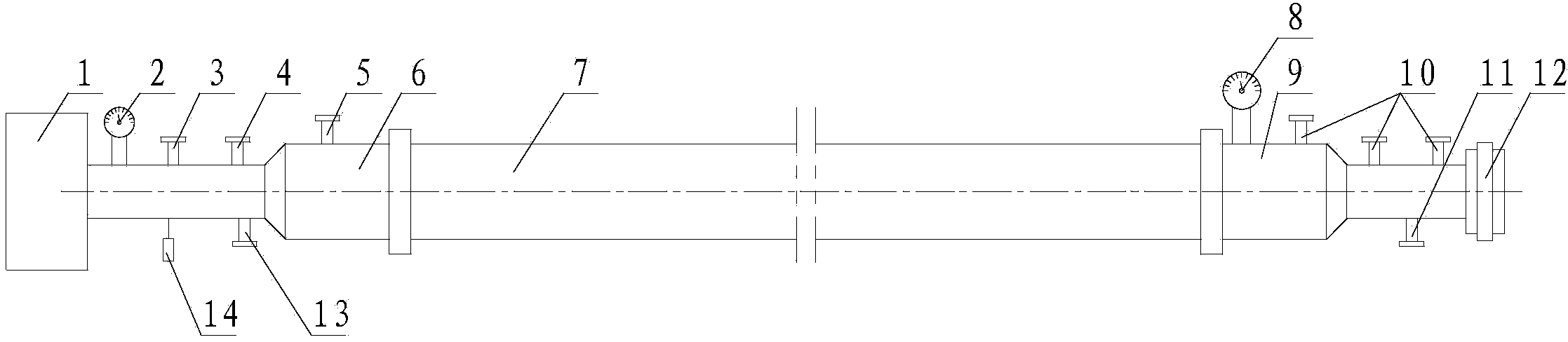

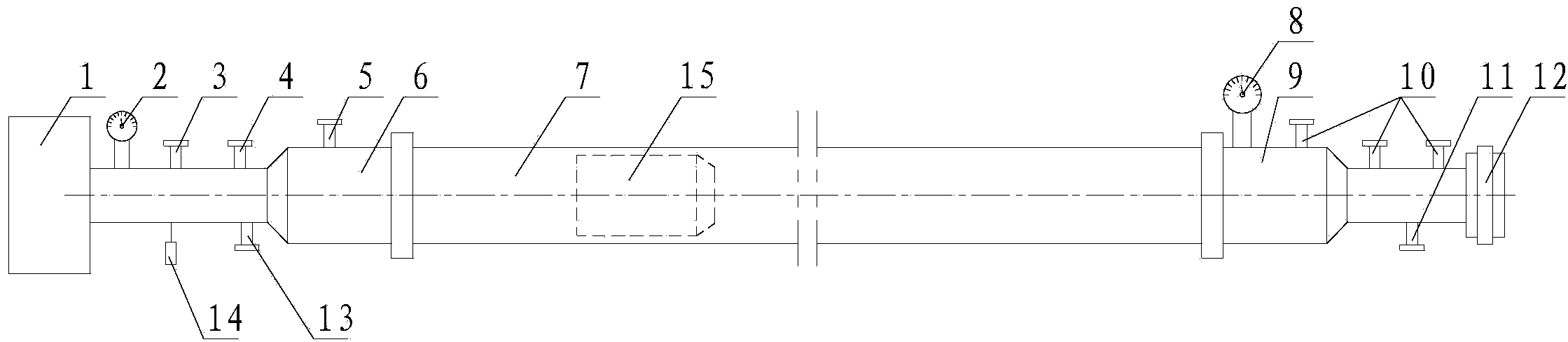

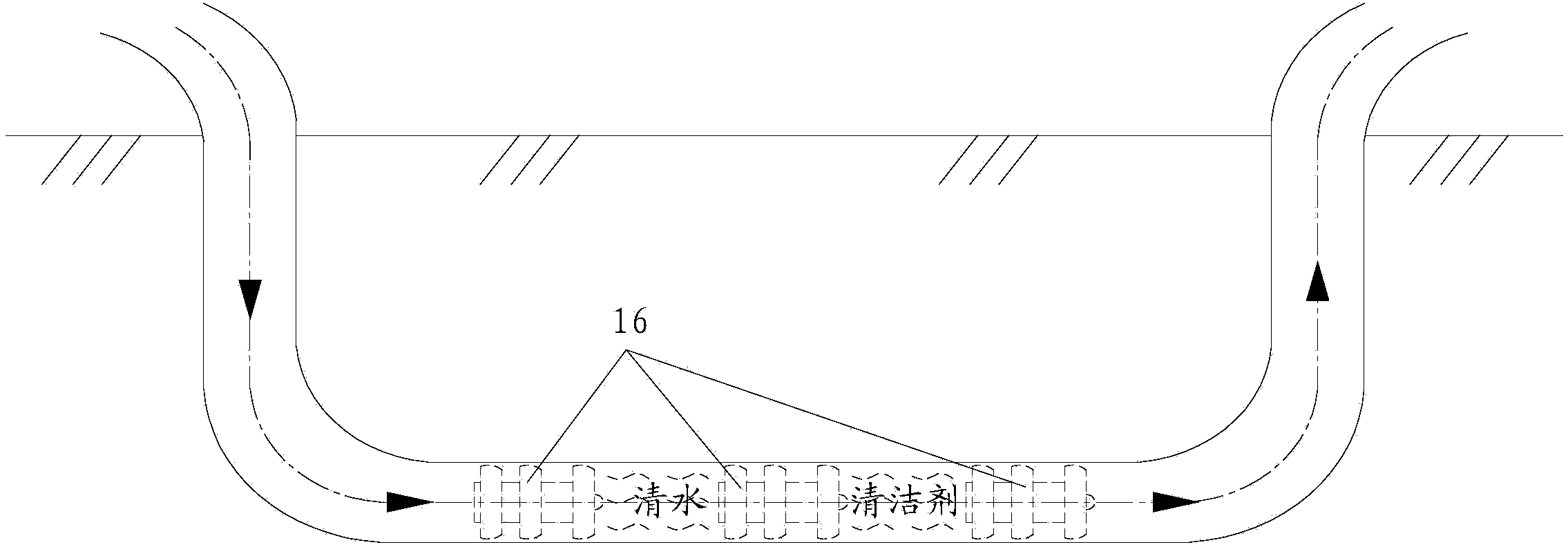

[0031] The embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings; it should be noted that the embodiments are illustrative, not restrictive, and cannot limit the protection scope of the present invention.

[0032] An integral process for cleaning the inner wall of a high-purity gas long pipeline, which includes the following steps:

[0033] ⑴. Pipeline status investigation and treatment.

[0034] The pipeline status investigation and treatment include the following items: understand the direction of the pipeline, the relationship between the position and other pipelines through the drawings; the pipelines that need to be cleaned must meet the following conditions: the inner diameter of the same pipeline should be the same or similar, and the difference between the inner diameters is ≤ 10mm ;Pipeline layout should be as straight as possible, and the general curvature radius of the elbow that must be used is R≥1.5D; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com