18 m hydraulic pressure rise and fall retractable drill tower

A telescopic, drilling tower technology, used in drilling equipment, earthwork drilling, support devices, etc., can solve the problems of auxiliary work and auxiliary time increase, only 12.5 meters at most, and unable to meet market needs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

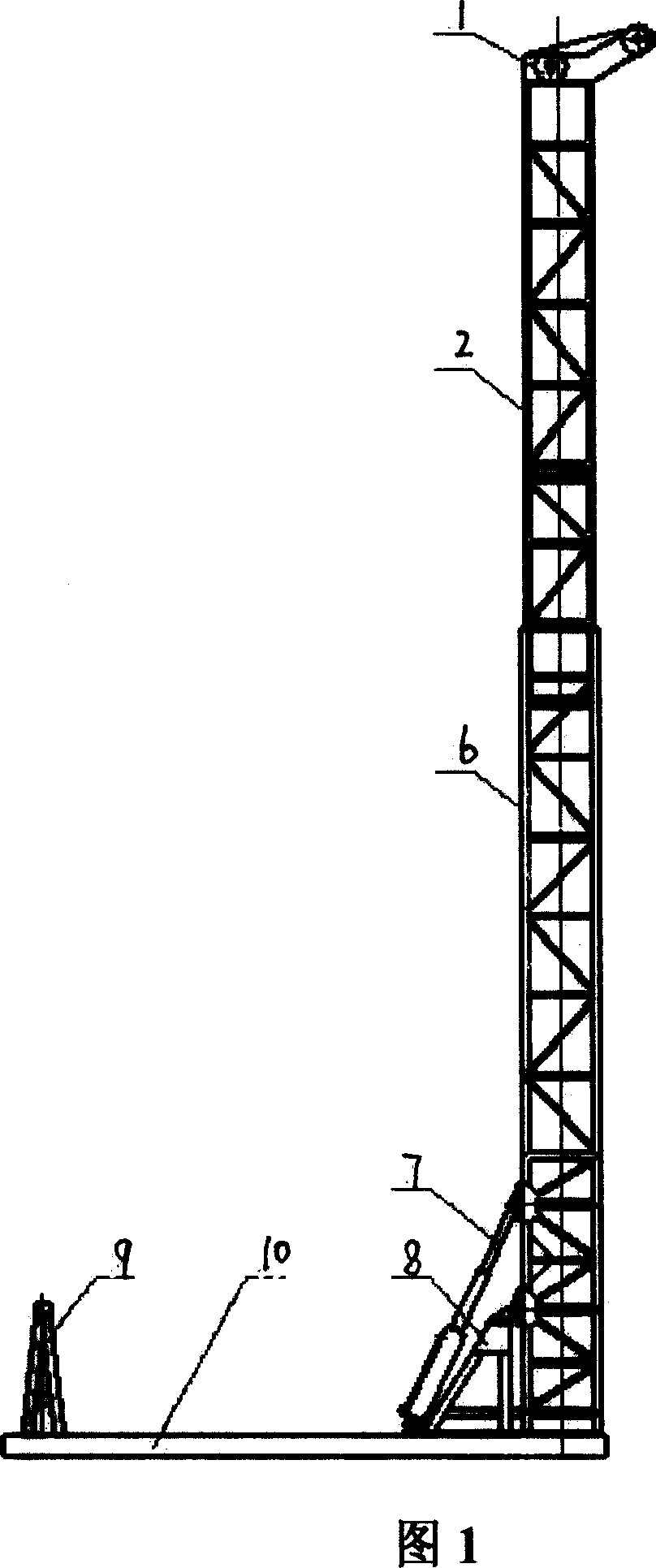

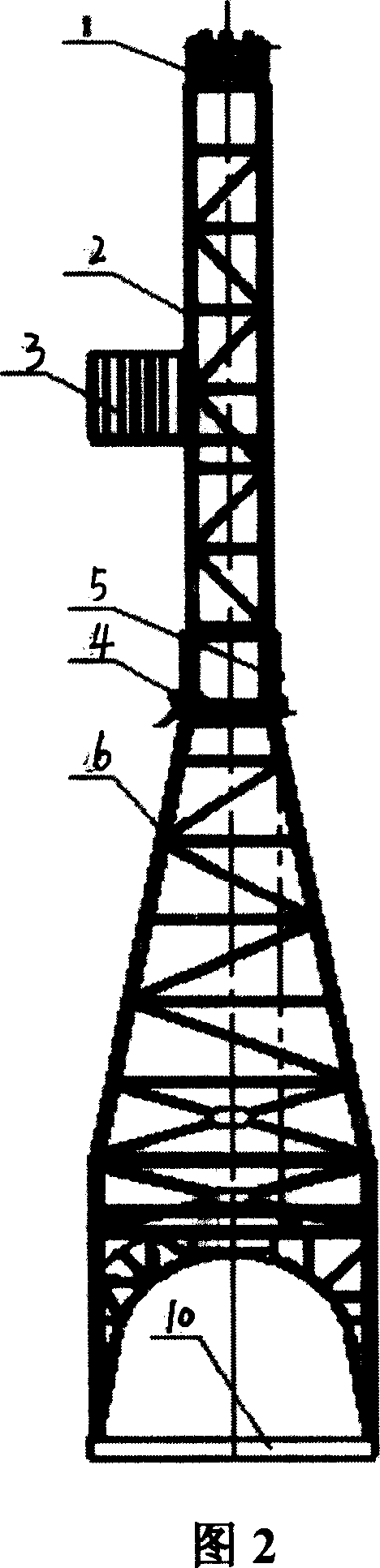

[0011] As shown in Figure 1 and Figure 2, the 18-meter hydraulic lifting and retractable drilling tower consists of a crown block 1, an upper tower body 2, a second-floor platform 3 (stand support), a limit locking device 4, a lifting mechanism 5, a lower The tower body 6, the vertical tower oil cylinder 7, the vertical tower support 8, the drop tower support 9 and the drilling tower chassis 10 constitute.

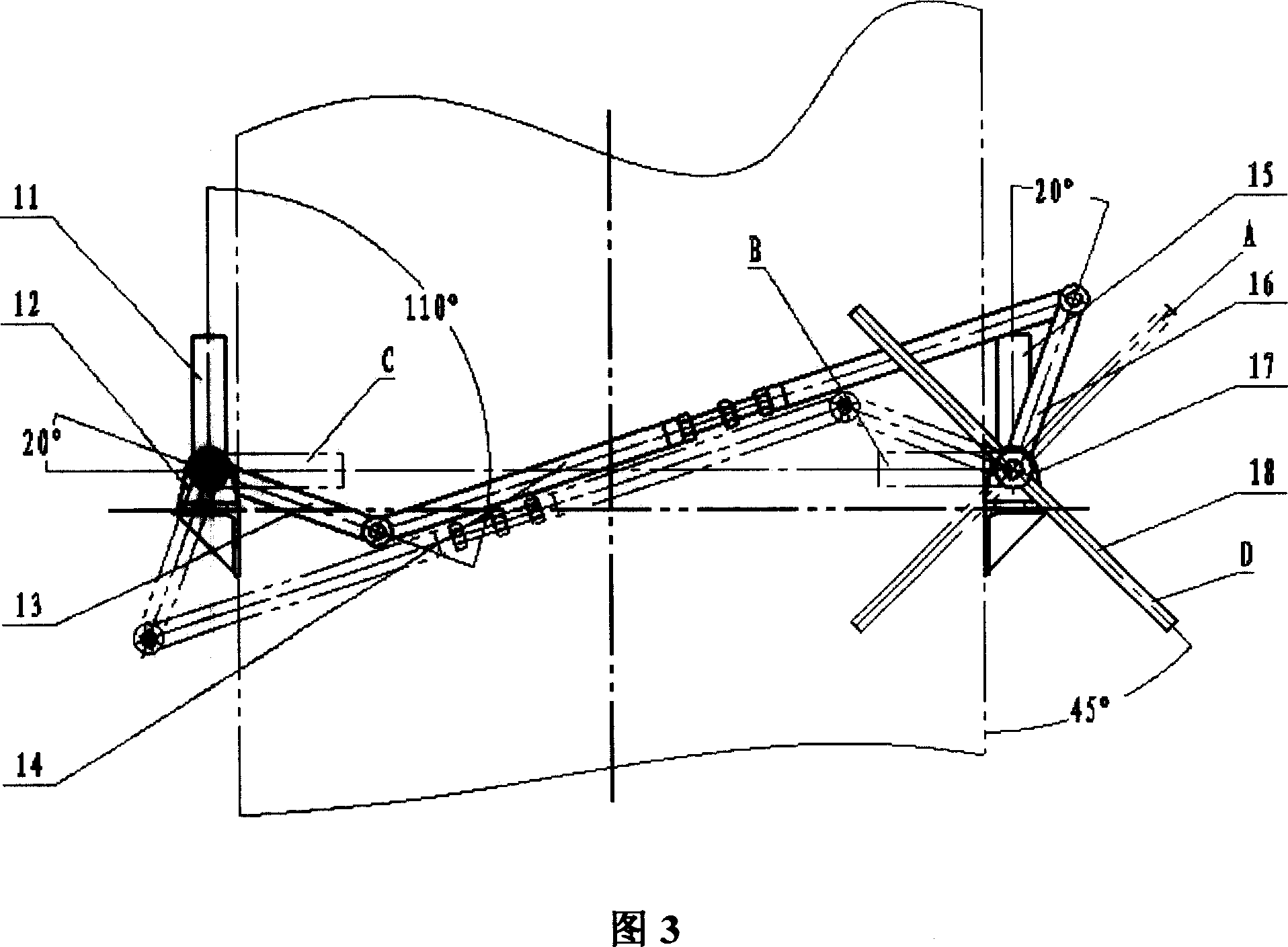

[0012] Drilling tower chassis 10 is an integral welded structure of section steel. Vertical tower support 8 is welded into an A-frame by rectangular square tubes, which are directly welded on drilling tower chassis 10. The lower tower body 6 and upper tower body 2 are welded with seamless steel pipes to form a truss structure. , the lower tower body 6 is connected with the vertical tower support 8 through the hinge support 20, the upper tower body 2 is set in the lower tower body 6, and the lifting mechanism 5 composed of a hydraulic winch can realize flexible extension and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com