Assembly type solar photovoltaic power generation road surface module and application thereof

A solar photovoltaic and prefabricated technology, applied in the direction of photovoltaic modules, photovoltaic power generation, photovoltaic module support structures, etc., can solve the problems of no design requirements and indicators, damage to the photovoltaic power generation layer, easy water permeability, etc., to improve construction efficiency, Potential-induced attenuation assurance, effect of avoiding troublesome processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Table 1 Fabricated solar photovoltaic power generation surface module structure

[0050] Translucent anti-skid wear layer 2 mm light-transmitting concrete The protective layer tempered glass Solar photovoltaic panel layer Monocrystalline silicon photovoltaic cells insulation sealing layer Ethylene-vinyl acetate copolymer EVA film (GB / T 29848)

[0051] In this embodiment, the assembled solar photovoltaic power generation surface module is a cuboid with a length of 1200 mm, a width of 540 mm, and a thickness of 25 mm. The light-transmitting anti-skid wear layer is made of the following raw materials: E-type epoxy resin (HJ2-741 -72) 2 parts by weight, tempered glass particles 97.4 parts by weight, curing agent (ethylenediamine) 0.6 parts by weight.

[0052] When in use, pave and bond materials with bonding properties on the existing road surface, such as epoxy resin, ethylene-vinyl acetate copolymer EVA resin, neutral silicone weather-r...

Embodiment 2

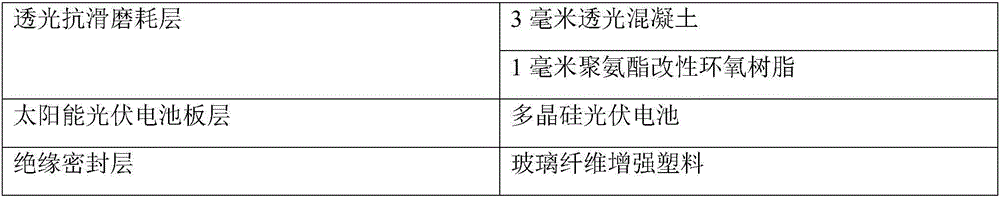

[0054] Table 2 Fabricated solar photovoltaic power generation surface module structure

[0055]

[0056] In this embodiment, the fabricated solar photovoltaic power generation surface module is a cuboid with a length of 1000 mm, a width of 670 mm, and a thickness of 5 mm. The light-transmitting anti-skid wear layer is made of light-transmitting concrete and light-transmitting epoxy resin, and the light-transmitting concrete is made of the following raw materials: 12 parts by weight of E-type epoxy resin (HJ2-741-72), 84 parts by weight of glass particles Part, 4 parts by weight of curing agent (benzophenone tetracarboxylic dianhydride);

[0057] When in use, the pavement is now paved with adhesive materials, such as epoxy resin, ethylene-vinyl acetate copolymer EVA resin, neutral silicone weather-resistant adhesive, asphalt or modified asphalt, and then the assembled solar photovoltaic power generation Pavement modules are laid on the pavement.

Embodiment 3

[0059] Table 3 Fabricated solar photovoltaic power generation surface module structure

[0060] Translucent anti-skid wear layer 12 mm thick light-transmitting concrete The protective layer tempered glass Solar photovoltaic panel layer Polycrystalline silicon photovoltaic cells insulation sealing layer tempered glass Adhesive layer Ethylene-vinyl acetate copolymer EVA resin

[0061] In this embodiment, the assembled solar photovoltaic power generation surface module is a cuboid with a length of 1956 mm, a width of 992 mm, and a thickness of 200 mm. The light-transmitting anti-skid wear layer is made of the following raw materials: 9 parts by weight of E-type epoxy resin (HJ2-741-72), 88 parts by weight of glass particles (tempered glass), 3 parts by weight of curing agent (alkanolamine) share.

[0062] In this embodiment, the tempered glass in the protective layer and the tempered glass in the insulating sealing layer encapsulate the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com