Quick construction method for over-crossing business line hangar tunnel T-shaped girder in narrow space

A narrow space and construction method technology, applied in construction, protective equipment and other directions, can solve the problems of T-beam hoisting operation obstruction, slow construction progress, increased rental costs, etc., to solve the problem of insufficient prefabricated sites, avoid safety risks, and avoid excessive The effect of the next request

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

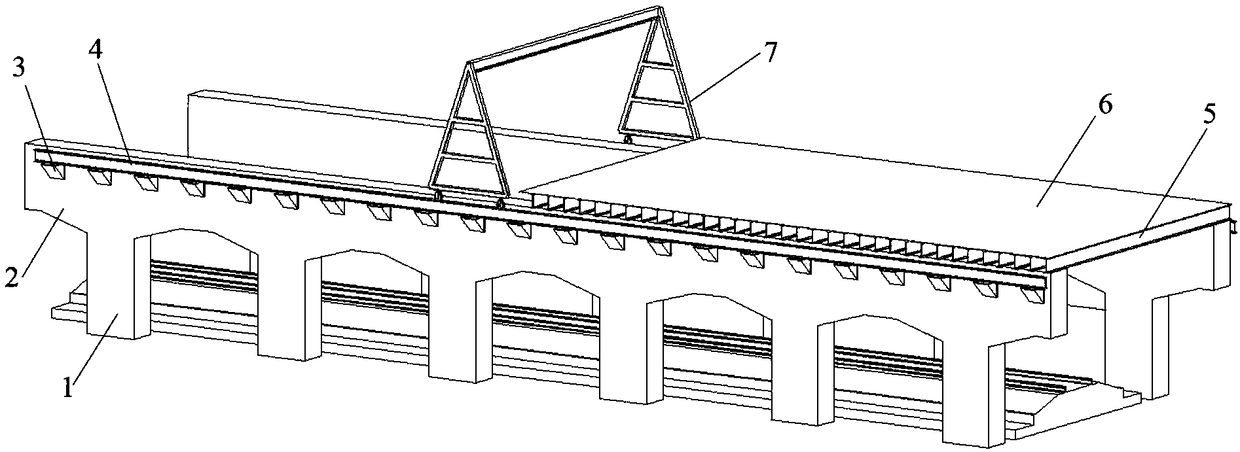

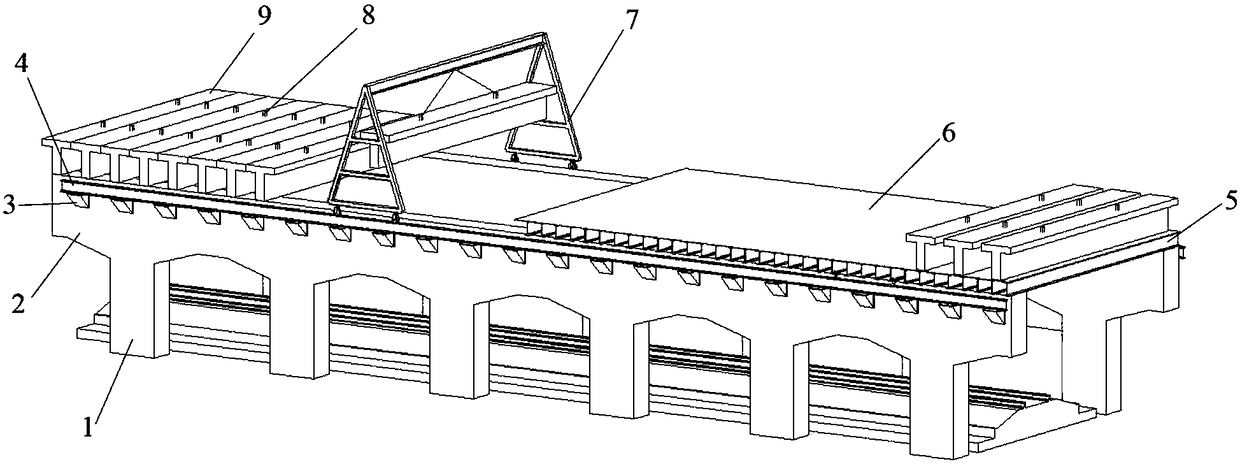

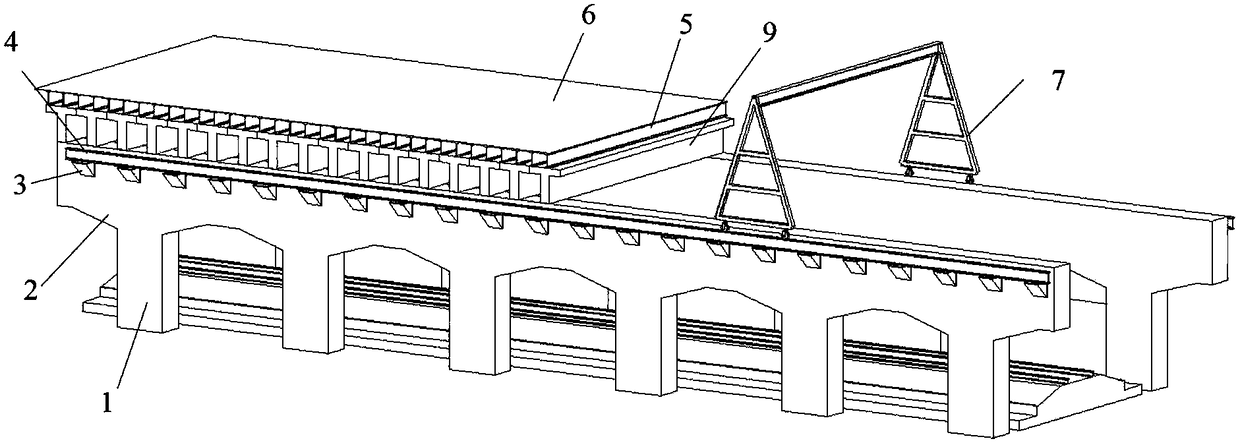

[0024] combine Figure 1 to Figure 4 Shown is a specific embodiment of the present invention's rapid construction method for a T-beam that spans a business line shed in a narrow space, mainly including the following steps:

[0025] Step 1): Excavate the foundation pit of the shed tunnel according to the design position, and construct the shed tunnel column 1 in the foundation pit of the shed tunnel, wherein the design position is a design point selected respectively on two parallel lines.

[0026] Step 2): Construct two parallel shed hole longitudinal beams 2 on the shed hole column 1, and pre-embed corbel brackets 3 on the two shed hole longitudinal beams 2, as figure 1 As shown, the corbels 3 are pre-buried equidistantly along the length direction of the corresponding shed tunnel longitudinal beams 2 on the sides of the shed tunnel longitudinal beams 2, and then on the corbel brackets 3 of the two shed tunnel longitudinal beams 2 Set up the gantry crane walking track 4 resp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com